Anti-adhesion paint

An anti-blocking and coating technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of poor wear resistance, poor corrosion resistance, low coating hardness, etc., to prolong the service life, quickly release the mold, and solve the problem of blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

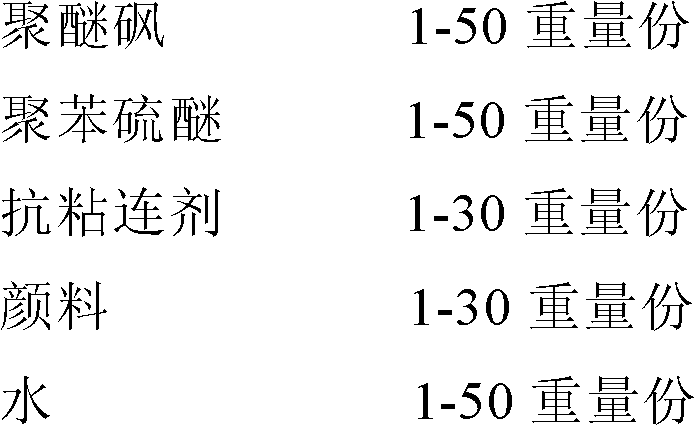

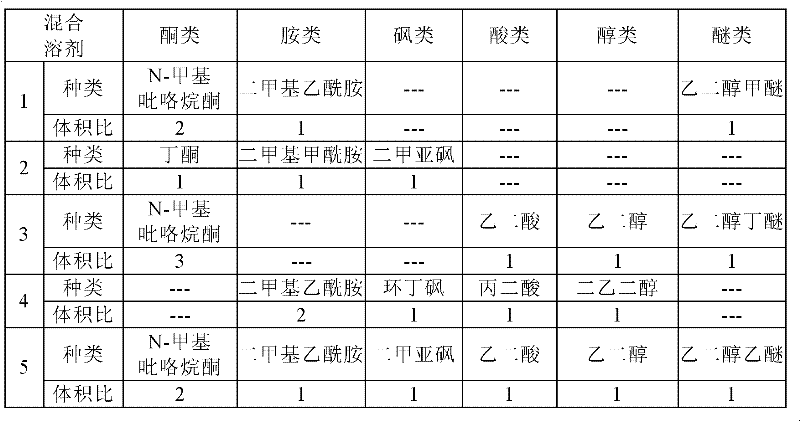

[0046] Adopt the following production process to prepare the anti-blocking coating of the present invention that is used for monolayer: polyethersulfone (PES) micropowder (purchased from Caihong High-tech Materials (Laiyang) Co., Ltd.), polyphenylene sulfide (PPS) resin of following weight portion (purchased from DAINIPPON Ink and chemicals, Inc, Tokyo, Japan), titanium dioxide (Shanghai Jiangfu White Pigment Products Co., Ltd., Japan R930#), deionized water, ketone alcohol ether amine mixed solvent (in volume ratio, N -Methylpyrrolidone: ethylene glycol: ether: dimethylacetamide (1:1:1:1) is put into the container according to the above ratio, and after dispersing with a high-speed disperser (800-960 rpm) for 30 minutes, Filter through a 200-400 mesh filter, then add polytetrafluoroethylene resin (Solvay (Shanghai) Co., Ltd., 538#) according to the following ratio, and stir at a low speed (60-100 rpm) for about 20 minutes to obtain this product. The anti-blocking coating descri...

Embodiment 2

[0049] Using the same method as in Preparation Example 1, the anti-blocking coating of the present invention used for coating the intermediate layer was prepared according to the following parts by weight. Wherein, the pigment is titanium blue pigment (HOLIDAY, UK, 5008#), the water is pure water, and the rest of the raw materials are the same as in Preparation Example 1.

[0050]

Embodiment 3

[0052] Using the same method as in Preparation Example 1, the anti-blocking coating of the present invention used for the surface layer of the coating was prepared according to the following parts by weight. Wherein, the pigment is titanium blue pigment (HOLIDAY, UK, 5008#), the water is pure water, and the rest of the raw materials are the same as in Preparation Example 1.

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com