Coal-fired power plant ammonia spraying control method based on big data analysis, and denitrating system

A control method and technology of coal-fired power stations, applied in general control systems, control/regulation systems, separation methods, etc., can solve problems such as inability to effectively filter large particles, intelligent control of ammonia injection, and damage to interception nets, so as to improve ash cleaning The effect of distance and cleaning efficiency, reducing dust accumulation and reducing resistance

Active Publication Date: 2019-03-12

GUODIAN SCI & TECH RES INST +1

View PDF9 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

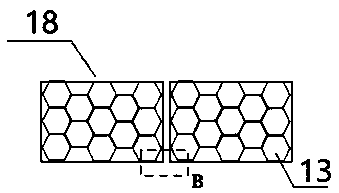

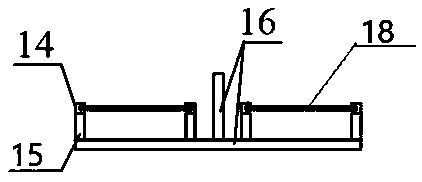

For example, setting the interception net on different slopes can effectively reduce the impact of large particles of ash on the screen, but the interception net is covered on the frame, and the relationship between wear and flue gas flow rate is positive cubic, and local blockage will lead to local The flow velocity increases several times, causing damage to the interception net and shortening its life

Or in order to reduce the wear and tear of the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

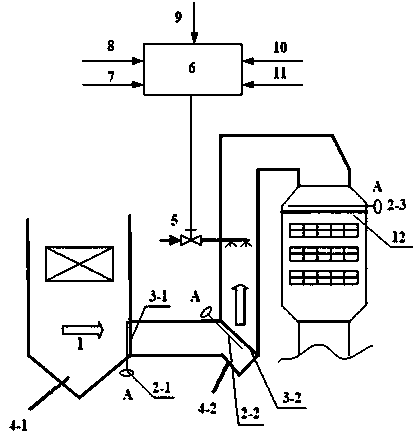

The invention discloses a coal-fired power plant intelligent ammonia spraying control method based on big data analysis. According to the method, by real-timely monitoring the fuel quality, the powdering working condition, the boiler air distribution working condition, the unit load and the CEMS operating working condition, the coal quality coefficient K1, the differential output yield value k ofthe actual coal firing amount, the correction factor K2 of the boiler air distribution working condition to the ammonia spraying amount, the correction factor alpha of the unit load to the ammonia spraying amount, and the correction factor K3 of CEMS to the ammonia spraying amount are fed back, and an ammonia spraying system is comprehensively analyzed and controlled. Based on big data analysis ofa boiler combustion system, through big data statistics and analysis of fuel quality judgment, combustion air distribution monitoring, working condition prejudgment caused by increasing, decreasing or switching of coal mills, unit load monitoring and CEMS operating working condition monitoring, prejudgment is conducted in advance, fine configuration and intelligent control over the ammonia spraying system are achieved, and the situation that over-spray of a reductant, namely ammonia occurs, and thus air preheater and catalyst blocking is caused is avoided.

Description

technical field [0001] The invention relates to a method for intelligently controlling ammonia injection in a coal-fired power station based on big data analysis, which belongs to the electric power industry. Background technique [0002] With the comprehensive promotion of ultra-low emission requirements for coal-fired power plants and the implementation of the pollutant discharge permit system, denitrification facilities have become one of the key facilities to achieve ultra-low emission of flue gas pollutants. In recent years, my country's coal-fired units are facing new situations such as deep peak shaving and complex and changeable coal quality. Through the evaluation of the operation status of denitrification facilities in coal-fired power plants, it is found that there are some common problems in the ultra-low emission transformation and operation of denitrification facilities. First, in order to meet the ultra-low emission requirements, the amount of ammonia injectio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D53/86B01D53/56G05B19/418

CPCB01D53/8631G05B19/4183G05B19/41845B01D2251/2062Y02C20/10

Inventor 柏源刘星辰薛建明唐仲恺

Owner GUODIAN SCI & TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com