Continuous preparation system and preparation method of single-walled carbon nanotube

A technology for single-walled carbon nanotubes and preparation systems, applied in the direction of single-walled carbon nanotubes, carbon nanotubes, nano-carbons, etc., can solve the problems of clogging of filter devices and inability to operate continuously, and achieve the problems of avoiding clogging, continuous preparation and collection, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

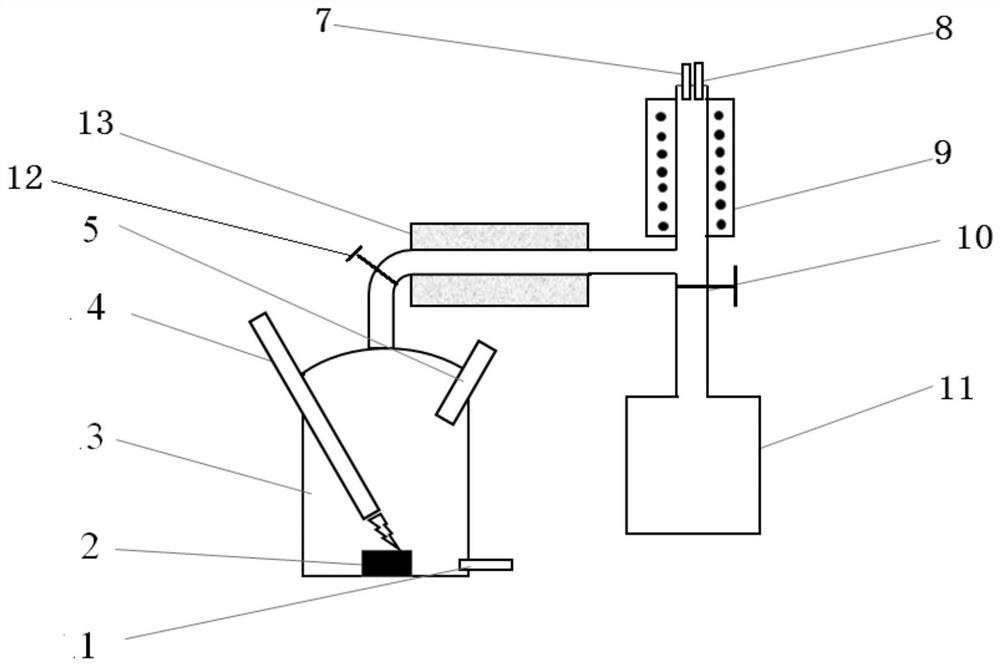

[0097] Schematic diagram of the continuous preparation system of single-walled carbon nanotubes using a single collection system. figure 1 As shown, it consists of a high-temperature reaction chamber 3, a cooling chamber 6 and a gas-solid separator 9 connected in series, with valve control, and auxiliary systems including vacuum, gas circuit, control, cooling and feeding systems. The outer layer of the high-temperature reaction chamber is composed of a double-layer water-cooled stainless steel shell lined with a graphite high-temperature insulation layer, and the inner wall is made of corundum. A bottom electrode 2 is provided at the bottom of the high-temperature reaction chamber, and a crucible is used to contain the catalyst, and the material is graphite; the arc gun inserted obliquely into the high-temperature reaction chamber is directly facing the bottom electrode 4; the side wall of the high-temperature reaction chamber is provided with organic carbon The source mixed g...

Embodiment 2

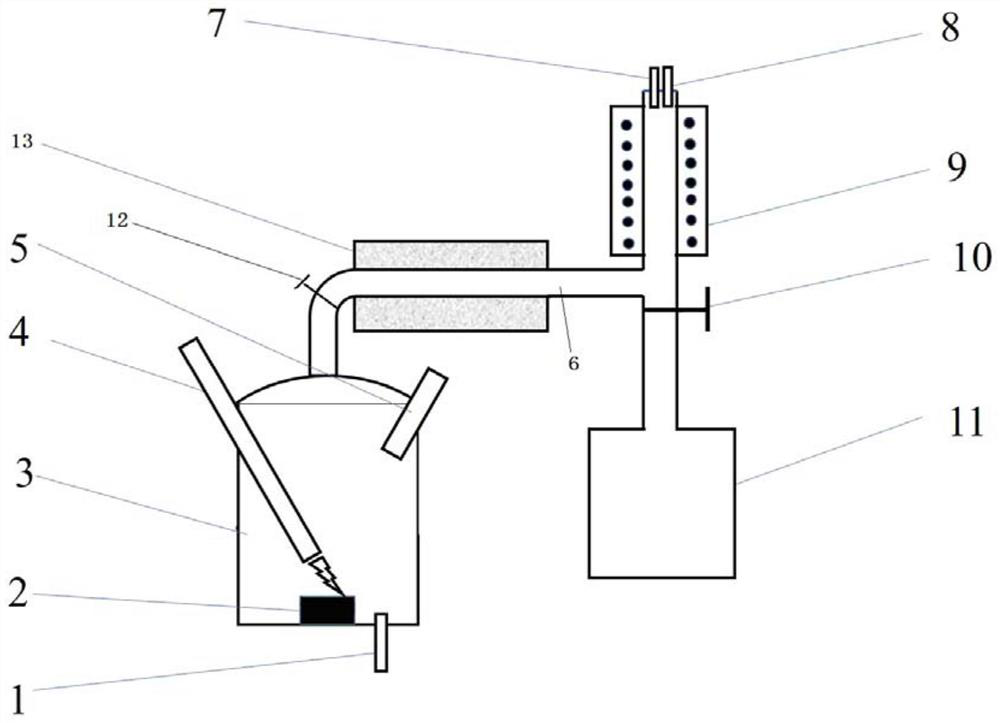

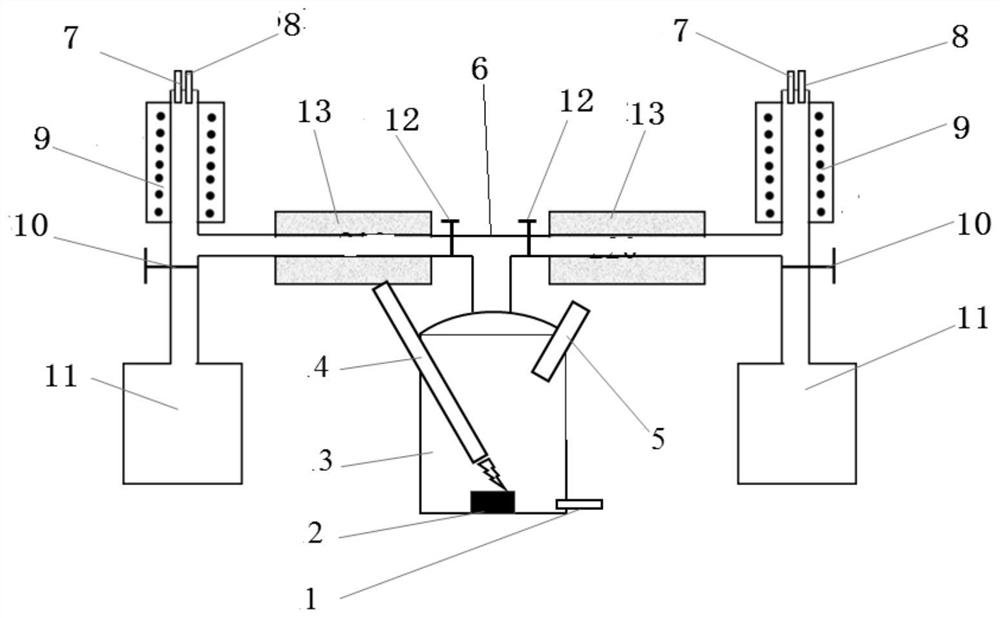

[0101] The schematic diagram of the continuous preparation system of single-walled carbon nanotubes using a double collection system is shown in figure 2 As shown, it consists of a high-temperature reaction chamber 3 and a collection device connected in series, and is controlled by a high-temperature valve 12, and auxiliary systems include vacuum, gas circuit, control, cooling and feeding systems, etc. The outer layer of the high-temperature reaction chamber 3 is composed of a double-layer water-cooled stainless steel shell lined with a graphite high-temperature insulation layer, and the inner wall is made of mullite. The bottom of the high temperature reaction chamber is provided with a bottom electrode 12, and a crucible is used to hold the catalyst, and the material is graphite; the arc gun inserted obliquely into the high temperature reaction chamber is facing the bottom electrode and the crucible 2; the bottom of the high temperature reaction chamber 3 is provided with or...

Embodiment 3

[0105] Schematic diagram of the continuous preparation system of single-walled carbon nanotubes using a single collection system. figure 1 As shown, it consists of a high-temperature reaction chamber 3 and a gas-solid separator 9 connected in series, with valve control, and auxiliary systems including vacuum, gas circuit, control, cooling and feeding systems. The outer layer of the high-temperature reaction chamber is composed of a double-layer water-cooled stainless steel shell lined with a graphite high-temperature insulation layer, and the inner wall is made of corundum. A bottom electrode 2 is provided at the bottom of the high-temperature reaction chamber, and a crucible is used to contain the catalyst, and the material is graphite; the arc gun inserted obliquely into the high-temperature reaction chamber is facing the bottom electrode 4; the bottom of the high-temperature reaction chamber is provided with an organic carbon source mixed gas Interface 1 ensures that the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com