High-temperature gas washing and cooling device

A cooling device and high-temperature gas technology, which is applied in the direction of gas dust removal, water shower cooler, and the manufacture of combustible gas. The effect of service life, avoiding safety accidents, and improving heat and mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the examples.

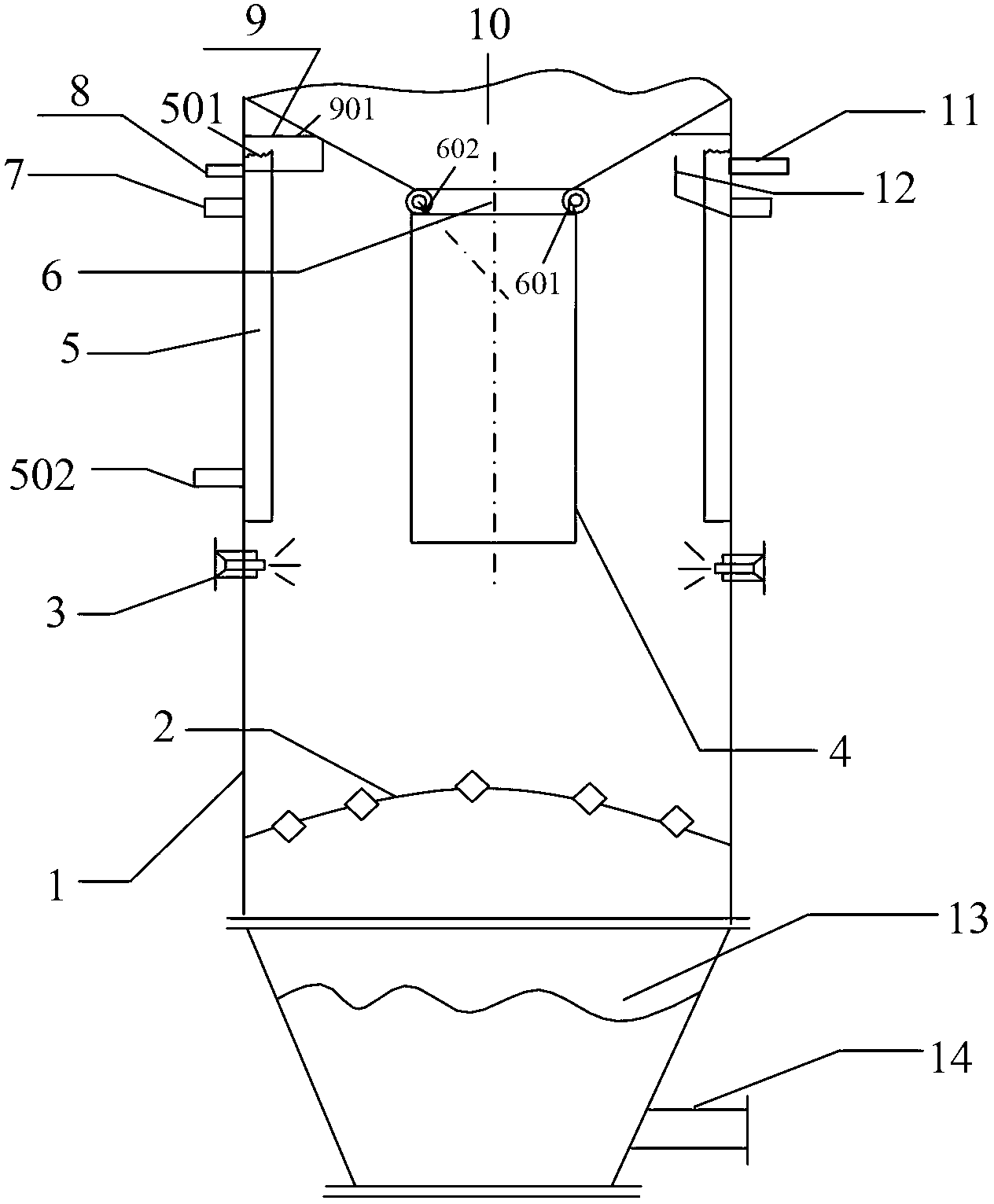

[0030] like figure 1 As shown, the high-temperature gas scrubbing and cooling device in this embodiment includes a housing 1, and the top of the housing 1 is provided with an opening 10 for receiving the cooling gas to be scrubbed, and a vertically extending downwards is provided in the housing 1. The air guide pipe 4, the inlet above the air guide pipe 4 is docked with the opening 10, and a washing cooling water distribution ring 6 is provided at the docking position, and a static slag breaker 2 is provided at the lower part of the housing 1. A gas outlet 11 is also provided above the housing 1, and a baffle baffle 12 is provided on the side of the gas outlet 11, so that the gas at the gas outlet side leaves the housing in a deflected manner, flows through the deflected flow, and the outlet is roughly synthesized. Part of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com