Low-cost deep flue gas purification device and purifying, dewatering and white-smoke-eliminating process thereof

A deep flue gas purification, low-cost technology, applied in gas treatment, climate sustainability, greenhouse gas reduction, etc., can solve the problems of corrosive heat exchangers, short service life of heat exchangers, blockage of heat exchangers, etc. Achieve the effect of saving energy and cost, reducing heat exchange energy consumption, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

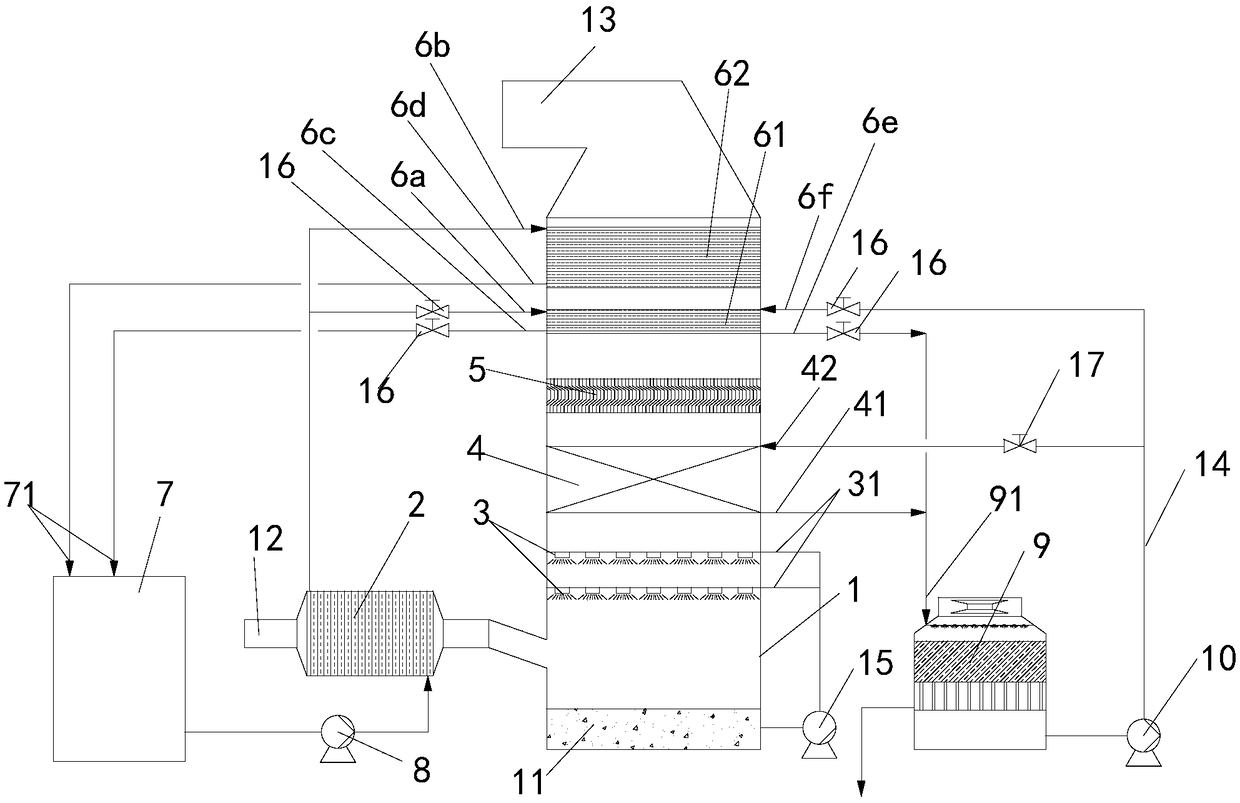

[0020] Embodiment 1: refer to figure 1 . A low-cost flue gas deep purification device, including a desulfurization tower 1, the bottom space of the desulfurization tower 1 is used as a desulfurization pulp pool 11, and a smoke inlet channel 12 is provided on the tower wall of the desulfurization tower 1 above the desulfurization pulp pool 11, and the upper end There is a smoke outlet 13 on one side, and the desulfurization tower 1 is sequentially provided with a desulfurization spray unit 3, a cooling condenser 4, a demisting and dehydrating layer 5, a first outlet heat exchanger 61, and a second outlet heat exchanger. 62. The flue inlet channel 12 is connected to the flue inlet heat exchanger 2, and the desulfurization tower 1 is equipped with a heat exchange fluid buffer tank 7, a heat exchange fluid circulation pump 8, a circulation fluid cooling tower 9, and a coolant circulation pump 10. The bottom side of the circulating liquid cooling tower 9 is respectively connected ...

Embodiment 2

[0022] Embodiment 2: refer to figure 1 . A low-cost flue gas deep purification process of collecting water and eliminating white smoke, including the following process steps: the coal-fired flue gas enters the desulfurization tower 1 after heat exchange and cooling through the inlet flue heat exchanger 2, and the cooled flue gas is mixed with the desulfurization spray The circulating slurry in the shower unit 2 forms high-humidity flue gas after wet desulfurization is completed; the high-humidity flue gas that has completed desulfurization passes through the cooling condenser 4, demisting and dehydrating layer 5, the first outlet heat exchanger 61, and the second outlet heat exchange The device 62 completes flue gas condensation, water collection and drying, and temperature rise to eliminate white smoke, that is: after desulfurization, the saturated flue gas enters the cooling condenser 4 upwards to conduct reverse contact and heat exchange with the cooling spray liquid, and t...

Embodiment 3

[0030] Example 3: A thermal power unit, a 410t / h coal-fired boiler flue gas desulfurization renovation project adopts this process, SO in the inlet flue gas 2 The concentration is 2513mg / m 3 , the dust concentration in the inlet flue gas is 42mg / m 3 , the liquid-to-gas ratio of the circulating liquid in the cooling and condensing section is 2.8L / Nm 3 , the spray layer coverage rate is 300%, the flue gas cooling range is 16°C; the outlet heat exchanger layer spacing is 0.6m, the heat exchange area ratio of the upper and lower layers is 2:1, and when the bottom of the outlet heat exchanger passes the heat medium, The flue gas temperature rises to 5°C, and when the refrigerant is used, the flue gas temperature drops to 3°C, and the upper layer of the outlet heat exchanger raises the temperature of the flue gas to 17°C; the thickness of the mist eliminator blades is 0.4mm, and the distance between the mist eliminator blades is 15mm. The layer height is 300mm. The concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com