Patents

Literature

61results about "Sulfur-halogen-hydrogen-oxygen compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

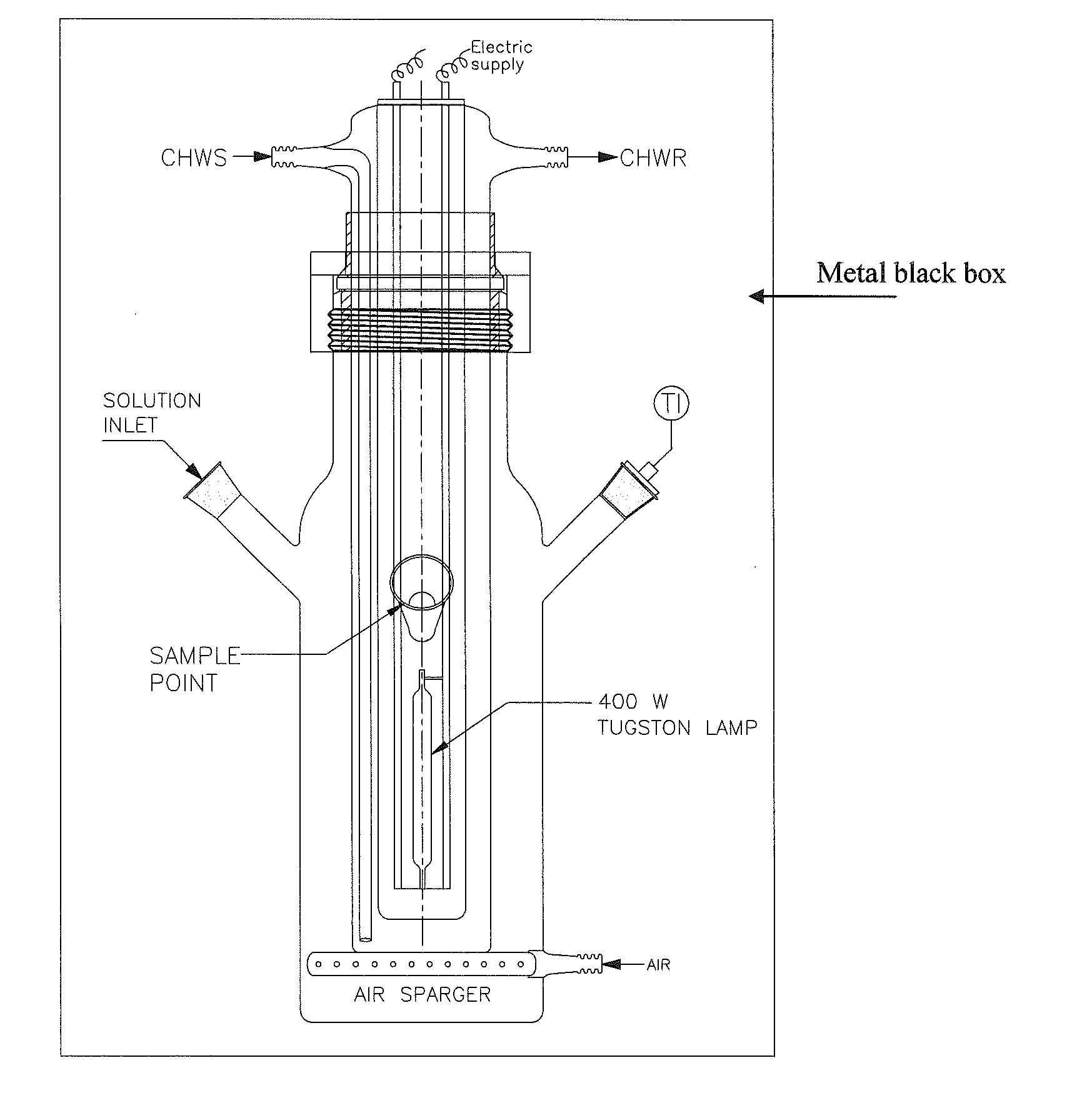

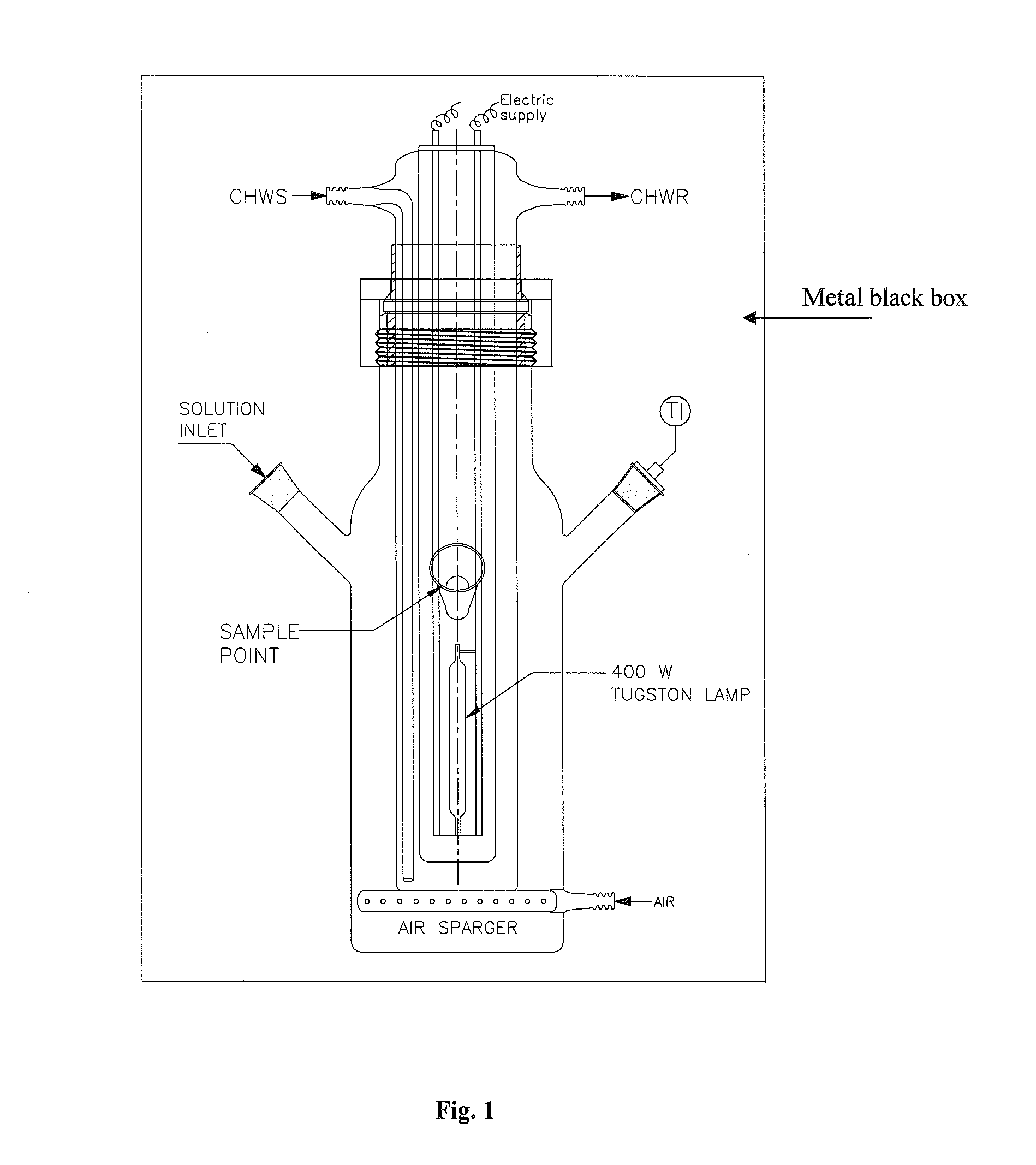

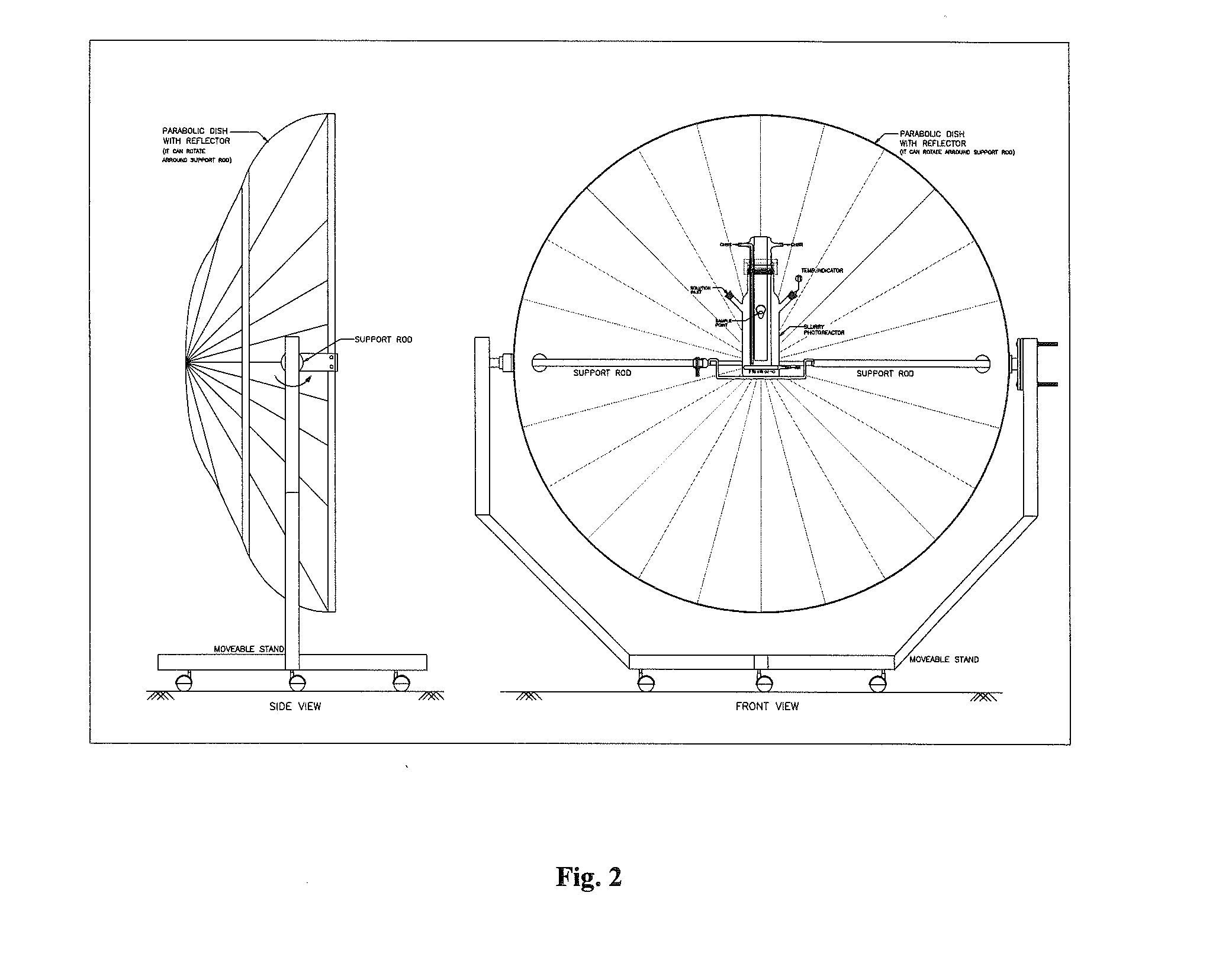

Photocatalytic degradation of pharmaceutical drugs and dyes using visible active biox photocatalyst

ActiveUS20160185615A1PhosphatesSulfate/bisulfate preparationPharmaceutical drugPhotocatalytic degradation

Provided is a visible active photocatalyst of formula BiOX wherein X=P or S and process of preparation and use thereof. Use of the catalyst is demonstrated in the photocatalytic degradation of pharmaceutical drug pollutants and pollutant dyes using solar radiation or artificial radiation.

Owner:COUNCIL OF SCI & IND RES

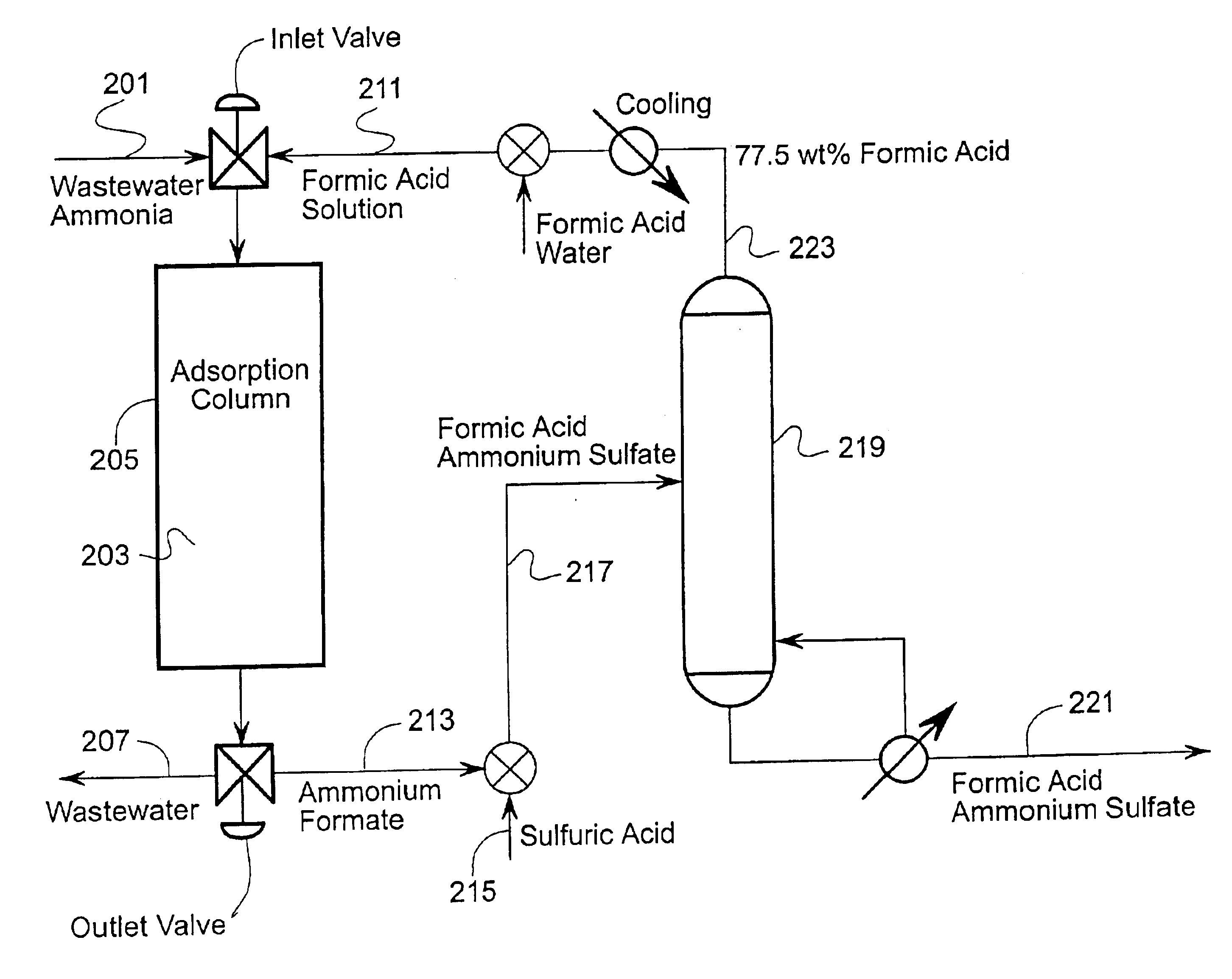

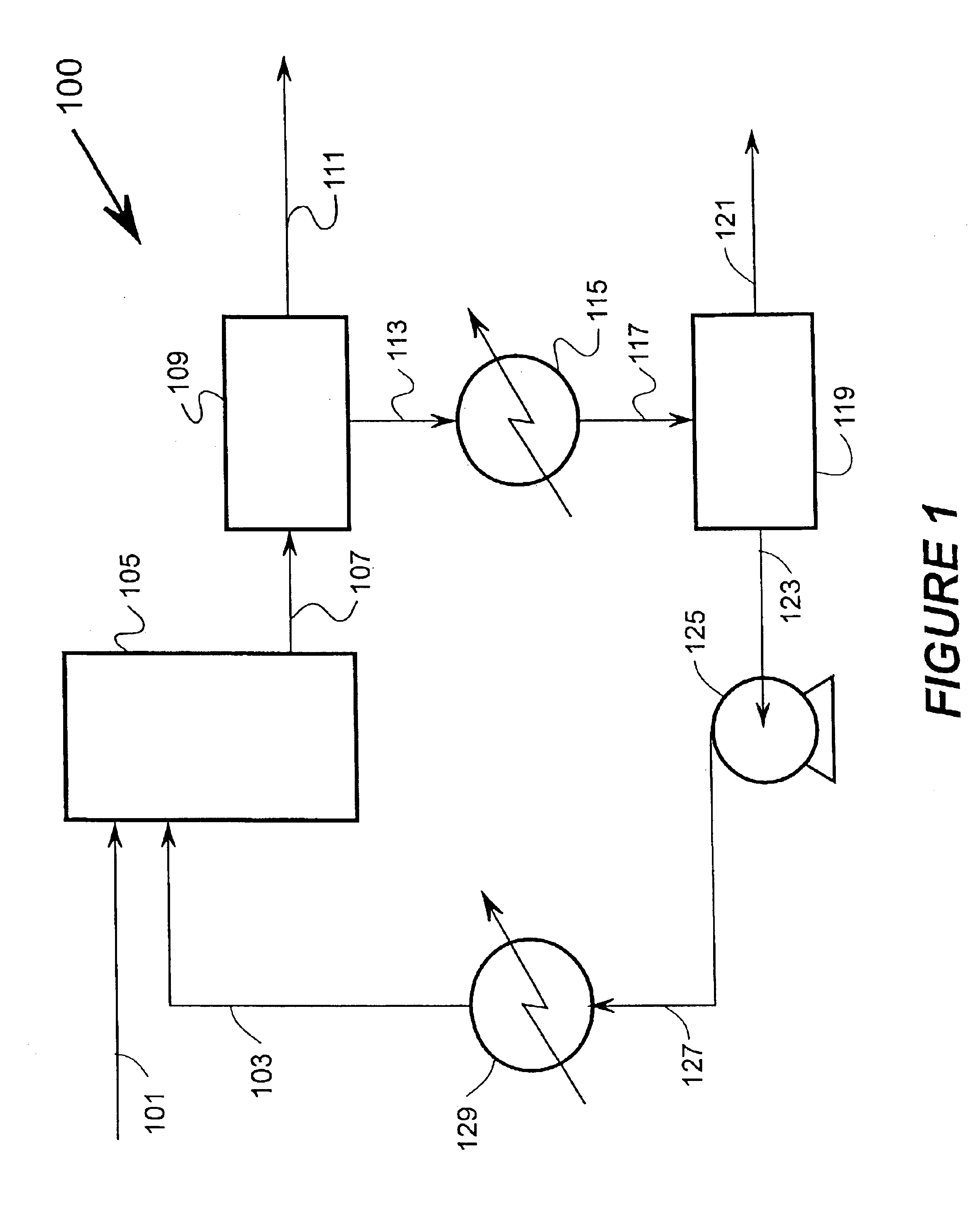

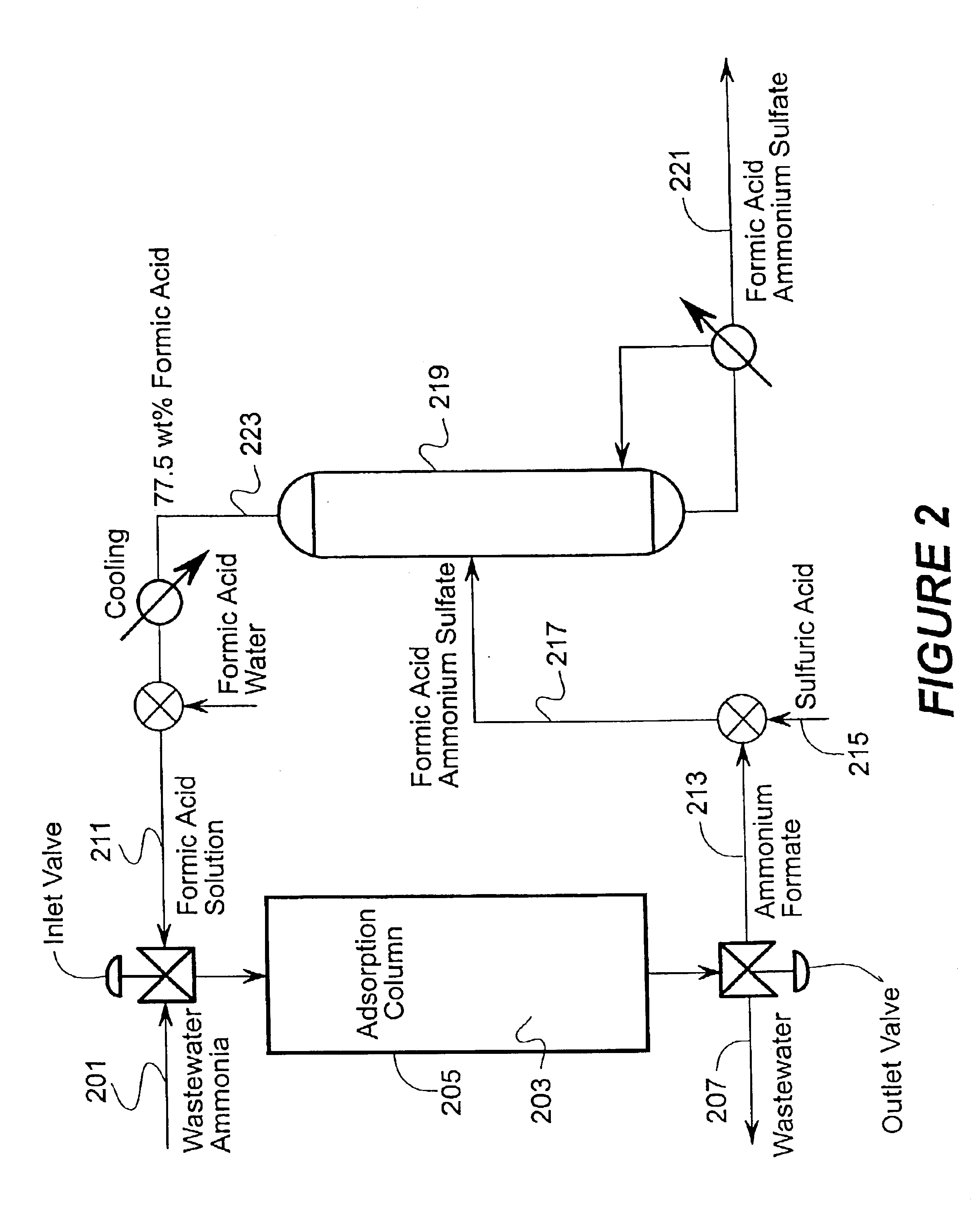

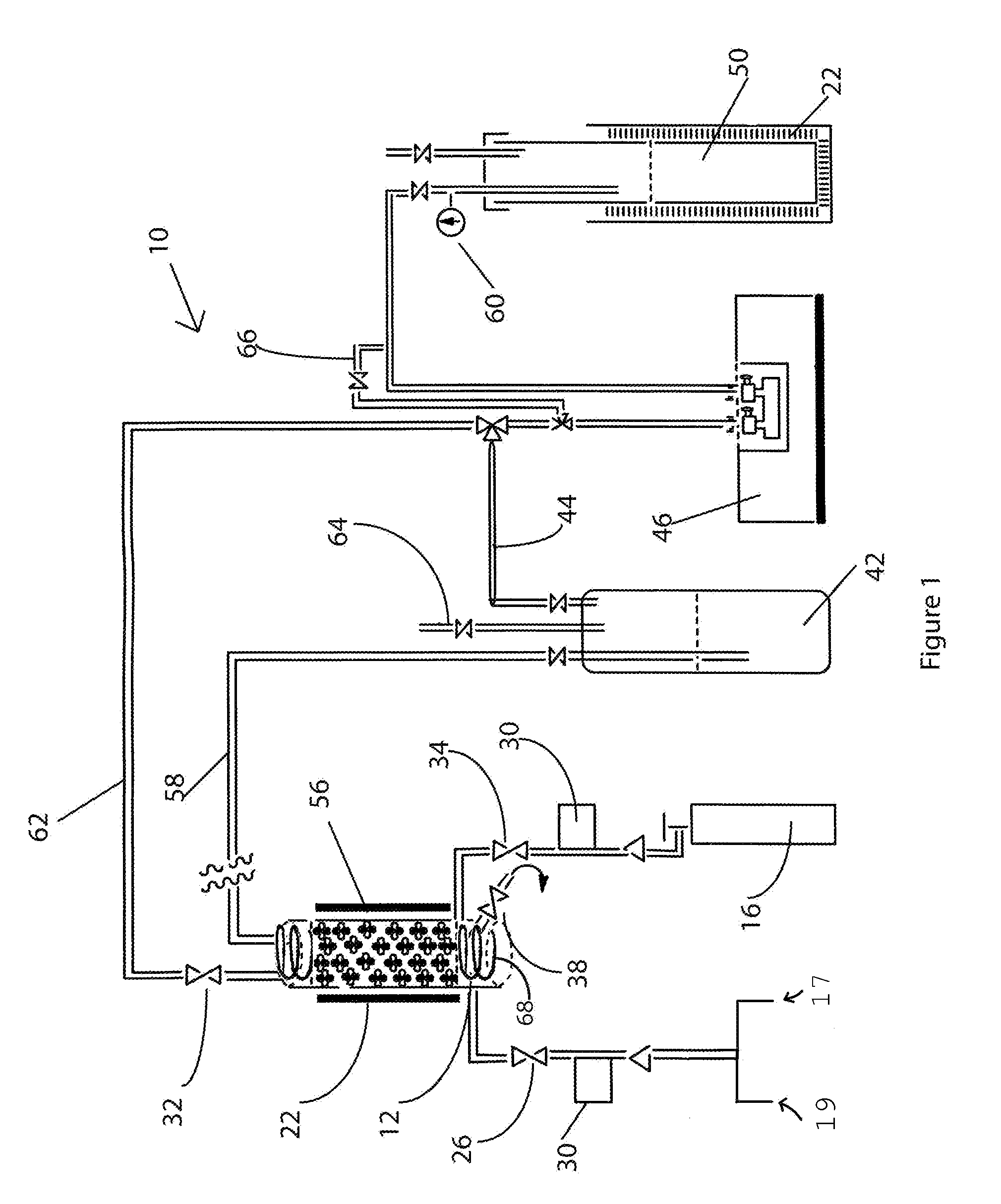

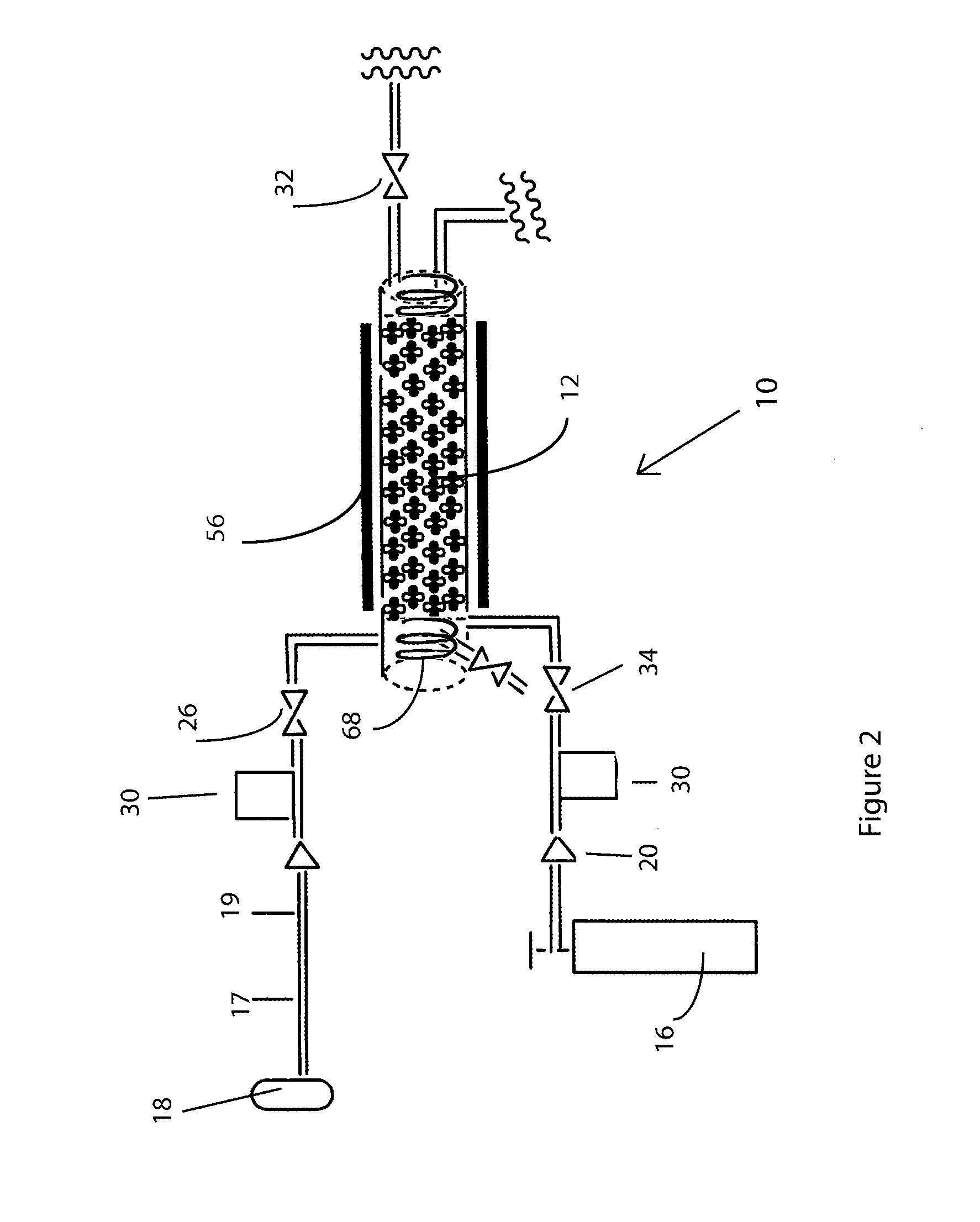

Apparatus and method for ammonia removal from waste streams

InactiveUS6838069B2Process economyCyanogen compoundsIon-exchanger regenerationZinc hydroxideDecomposition

Apparatus, materials, and methods for removing ammonia from fluid using metal hydroxides (e.g. zinc hydroxide) and metal cation loaded media (e.g. zinc loaded ion exchange resins); the metal hydroxides and metal cation loaded media may be regenerated with a weak acid (pKa between 3 and 7). Alternatively, ammonia is removed from fluids by using H2SO4 and ZnSO4 and metal cation loaded media; the metal cation loaded media may be regenerated with H2SO4 and ZnSO4; the ammonia containing H2SO4 and H2SO4 may be concentrated as necessary to form (NH4)2SO4.ZnSO4.6H2O (ammonium zinc sulfate hexahydrate) crystals. These crystals are removed from the mother liquor and heated to temperatures exceeding 200° C. releasing NH3 and H2O vapor upon the decomposition of the crystals.

Owner:BATTELLE MEMORIAL INST

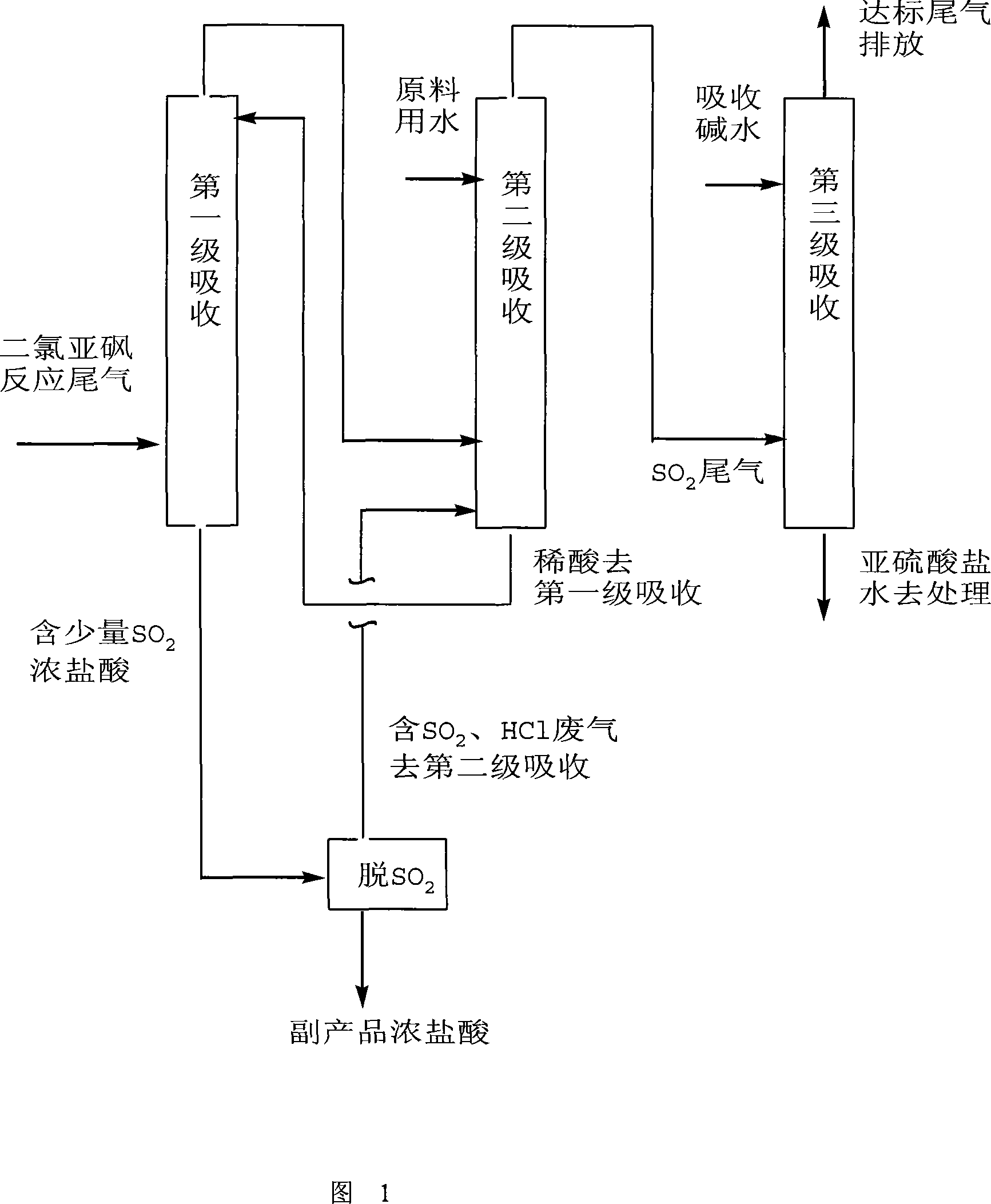

Method for treating tail gas of thionyl chloride chlorination

InactiveCN101121094AFully absorbedReduce dosageChlorine/hydrogen-chlorideSulfur-halogen-hydrogen-oxygen compoundsSulfite saltWastewater

The invention discloses a method for treating tail gas generated in chlorination reaction by using thionyl chloride. The existing traditional tail gas treatment method is costly due to a large amount of alkali consumption, and the pressure on environmental protection is high due to the final generation of a large amount of waste water containing heteroions. In the present invention, by controlling the amount of water, the hydrogen chloride in the tail gas is subjected to two-stage absorption with water, and the concentrated hydrochloric acid with a hydrogen chloride content close to saturation and a small amount of sulfur dioxide is obtained through the first-stage absorption; the second-stage absorption: after the first-stage absorption, the The exhaust gas is subjected to the second-stage absorption, and the added water is not discharged to obtain dilute hydrochloric acid containing a small amount of hydrogen chloride and a small amount of sulfur dioxide. The dilute hydrochloric acid is used as the raw material water for the first-stage absorption; after the above-mentioned secondary absorption treatment, it is then treated with alkali or alkali The third level of water absorption is used to absorb sulfur dioxide in the tail gas to obtain a relatively pure aqueous solution of sodium sulfite. The invention has high treatment efficiency, complete tail gas absorption, and reduces the pressure on environmental protection.

Owner:GAOYOU CITY ORGANIC CHEM FACOTRY

Bromine-facilitated synthesis of fluoro-sulfur compounds

Described herein are methods for the bromine-facilitated synthesis of fluoro-sulfur compounds, that include SF4, SF5Cl, SF5Br and SF6. The methods described herein generally require lower temperature and pressure, produce higher yields, require less time, do not use corrosive or costly reactants and solvents that are commonly used in the synthesis of the fluoro-sulfur compounds, and do not produce deleterious waste products when compared to previously-used methods.

Owner:AVANTBIO CORP

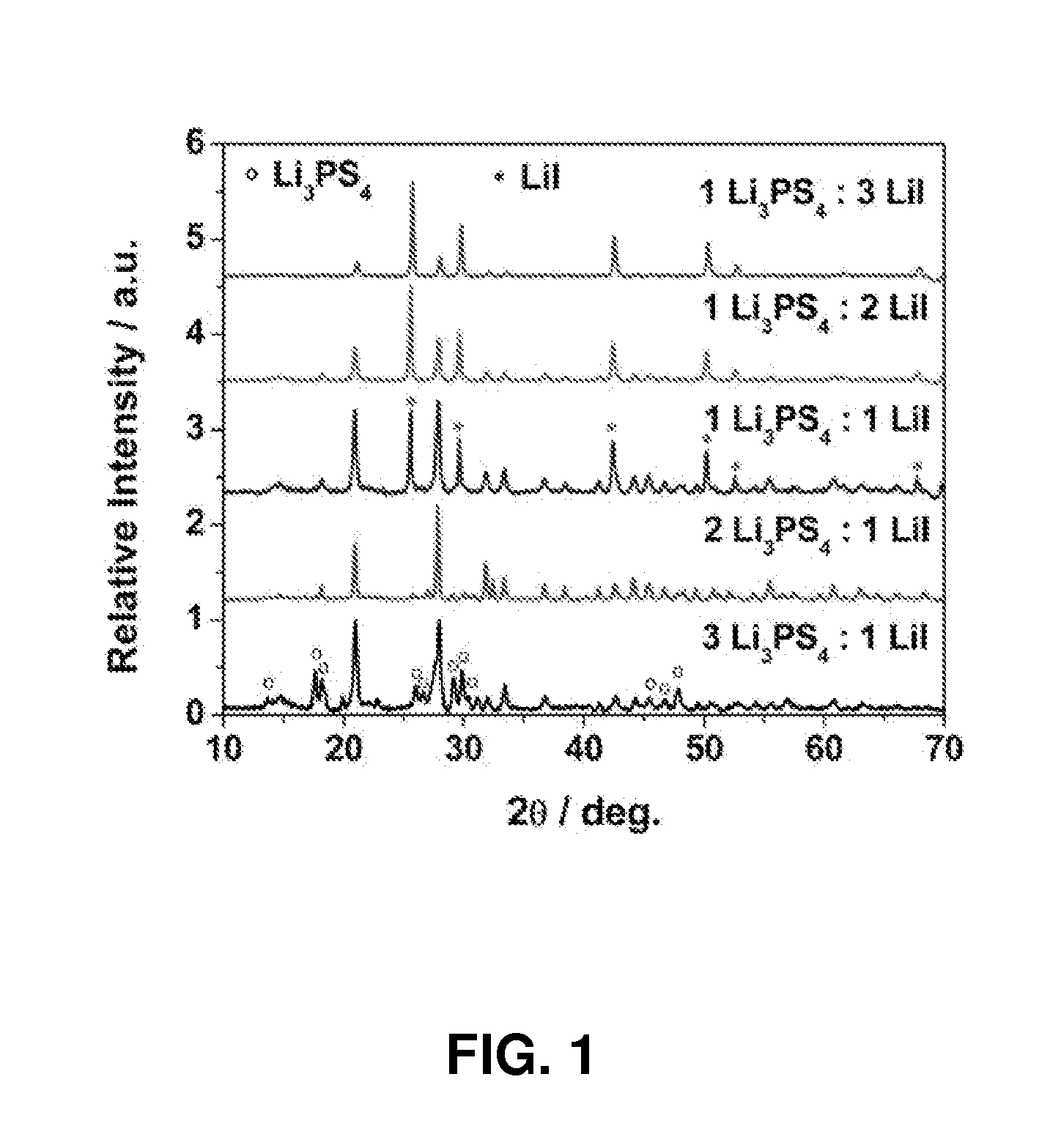

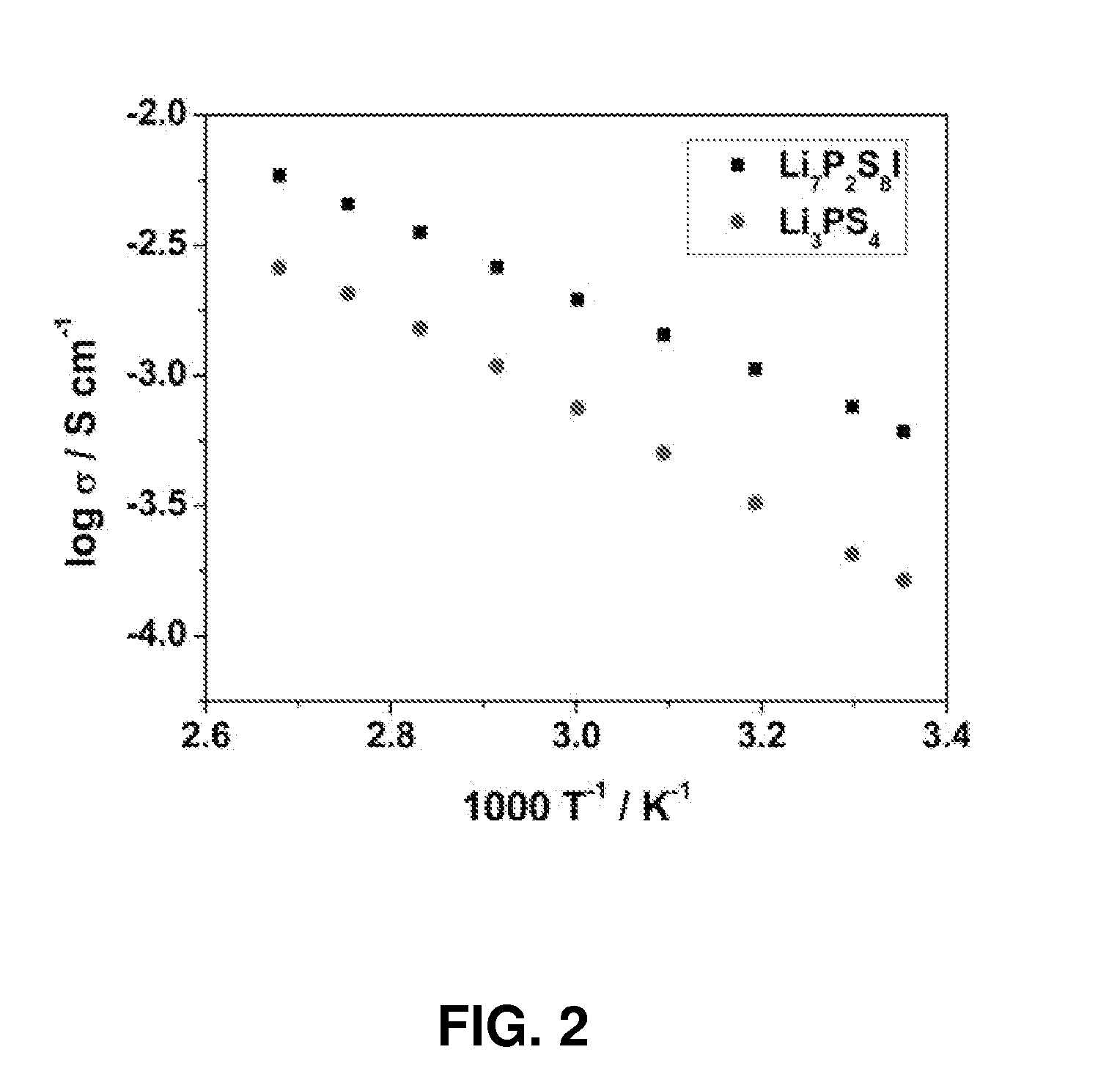

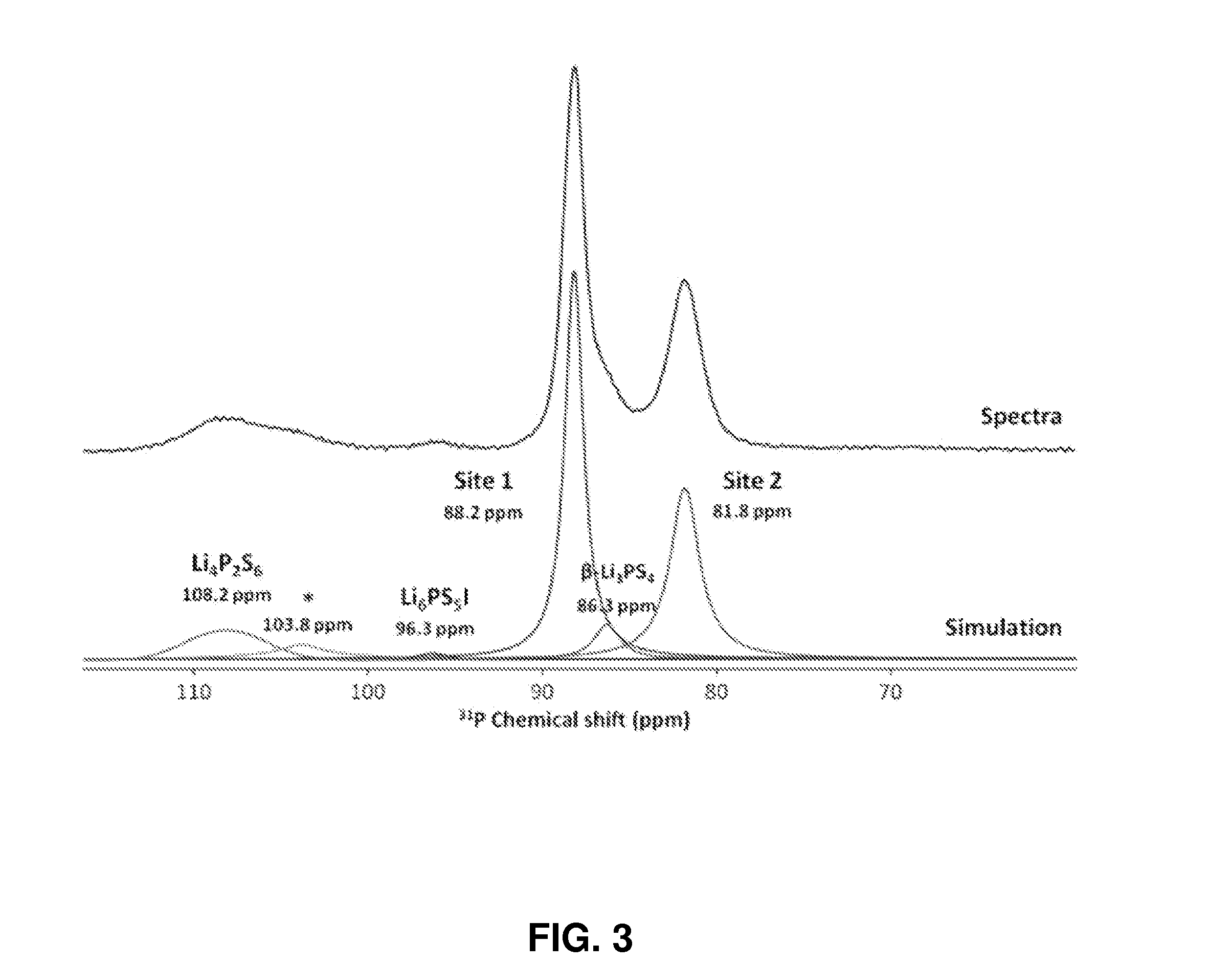

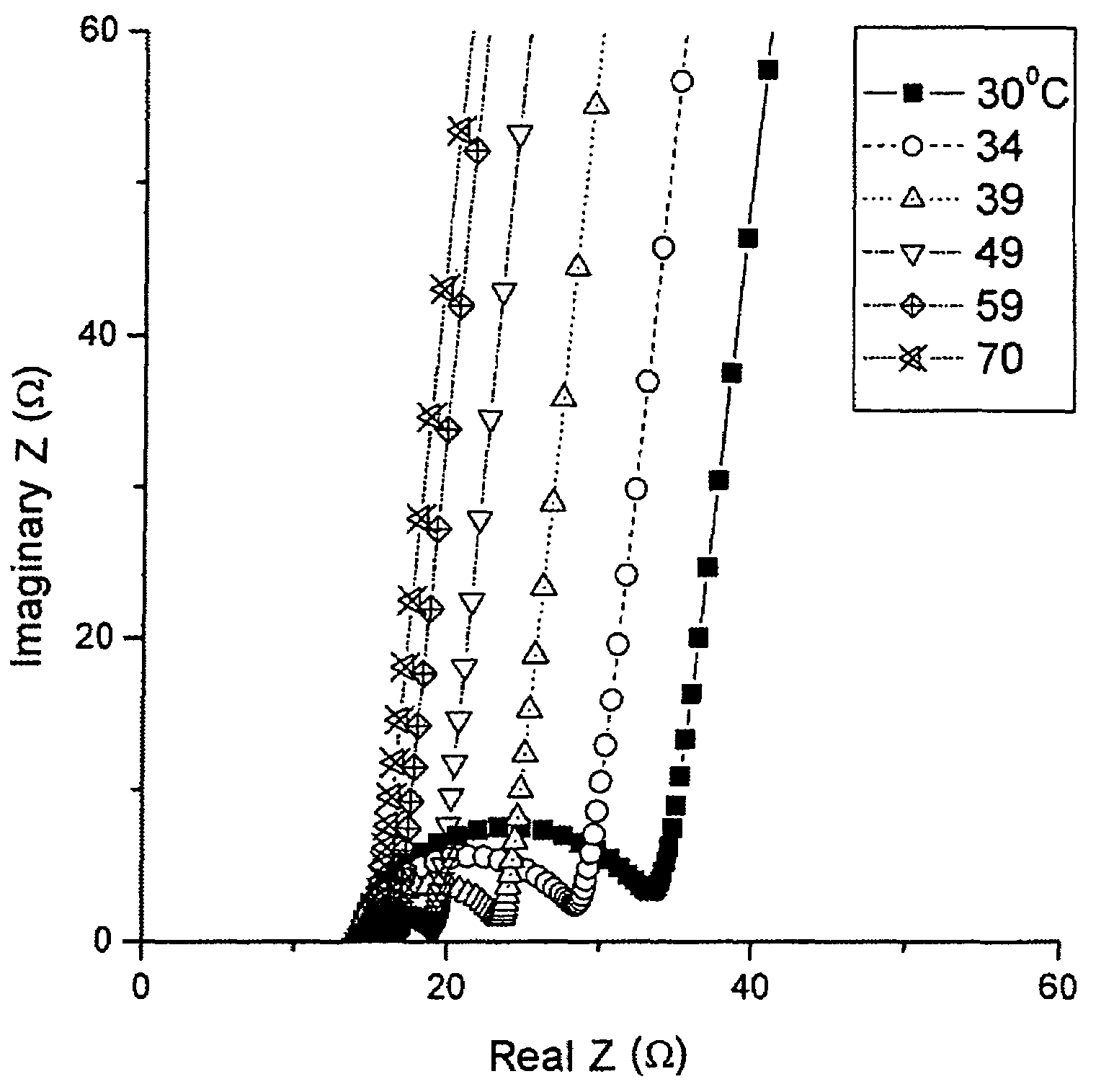

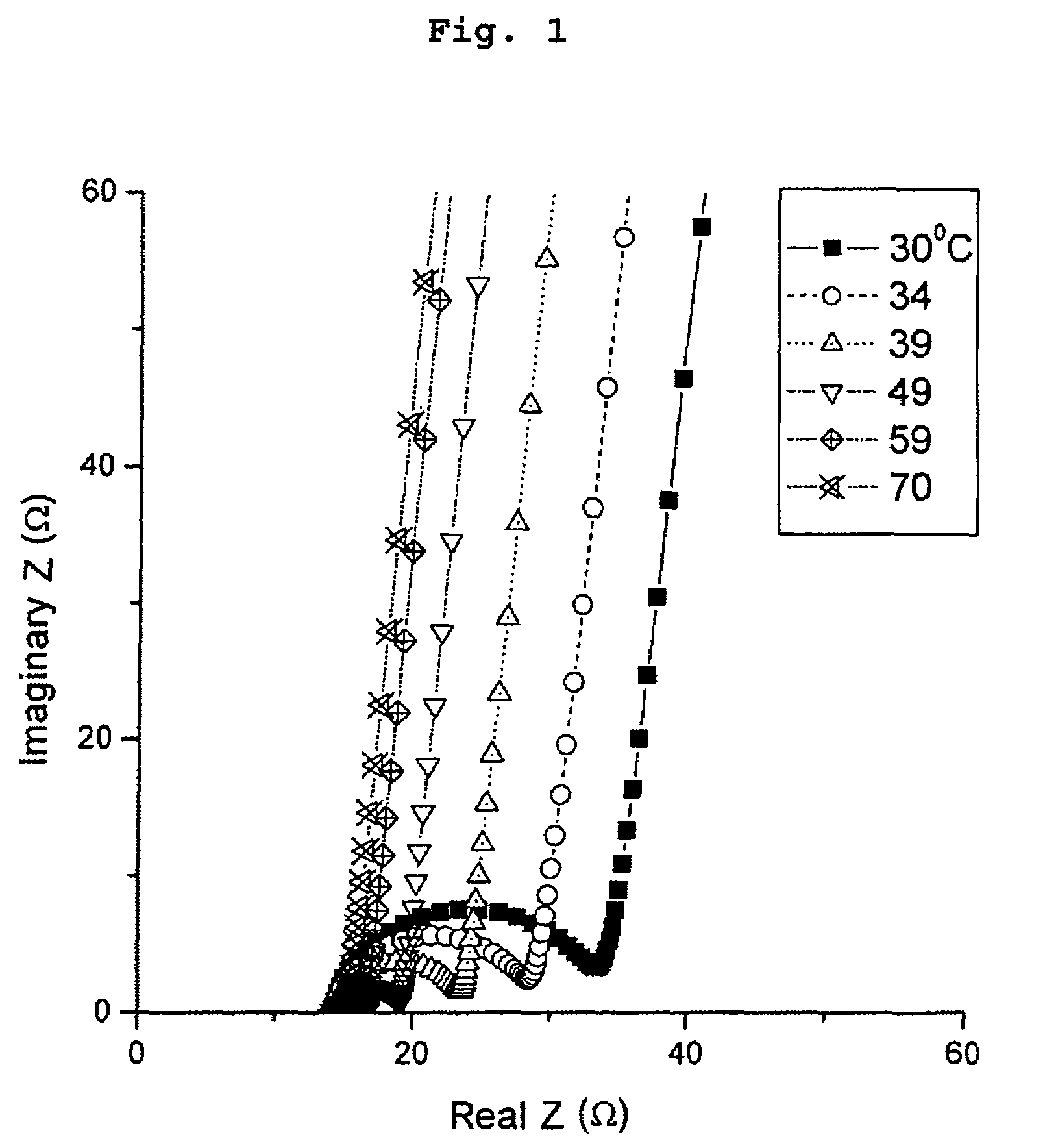

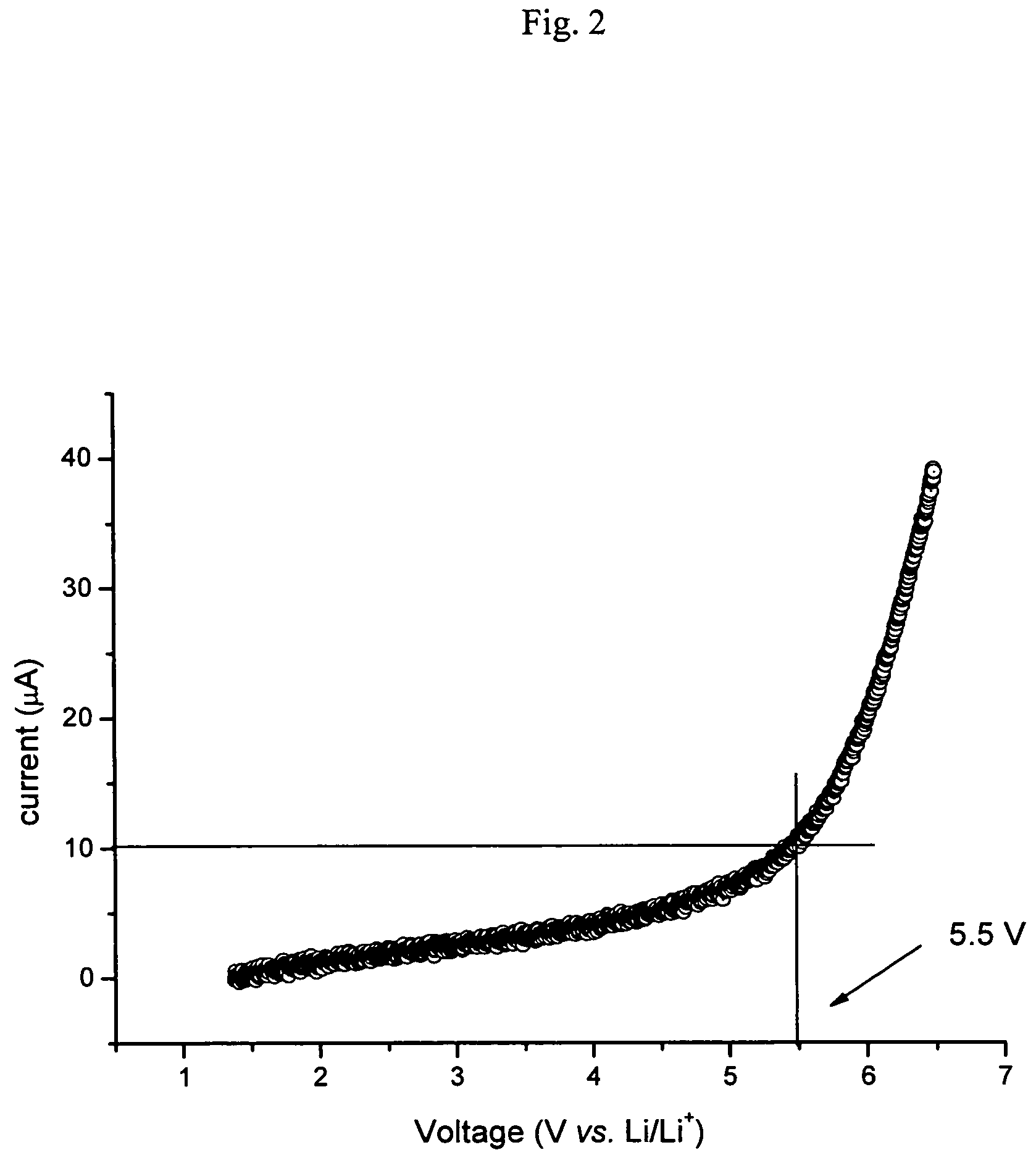

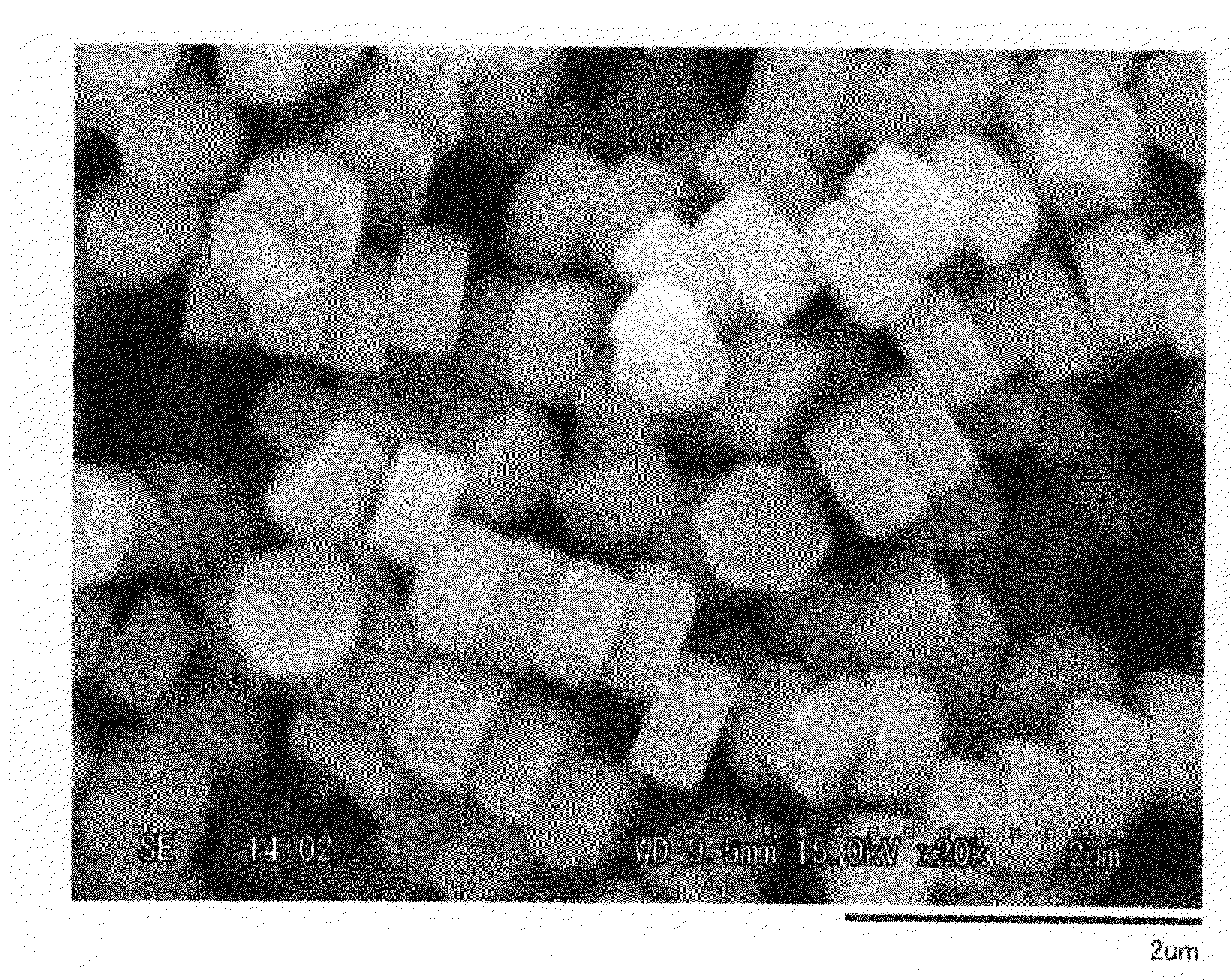

Electrochemically stable li7p2s8i superionic conductor

InactiveUS20160028104A1Solid electrolytesSulfur-halogen-hydrogen-oxygen compoundsPhysical chemistryElectrolyte

A Li7P2S8I electrolyte for a battery is disclosed. The electrolyte can be a single phase of Li7P2S8I. A battery having a Li7P2S8I electrolyte is disclosed. A method of making a battery including a Li7P2S8I electrolyte is also disclosed.

Owner:UT BATTELLE LLC

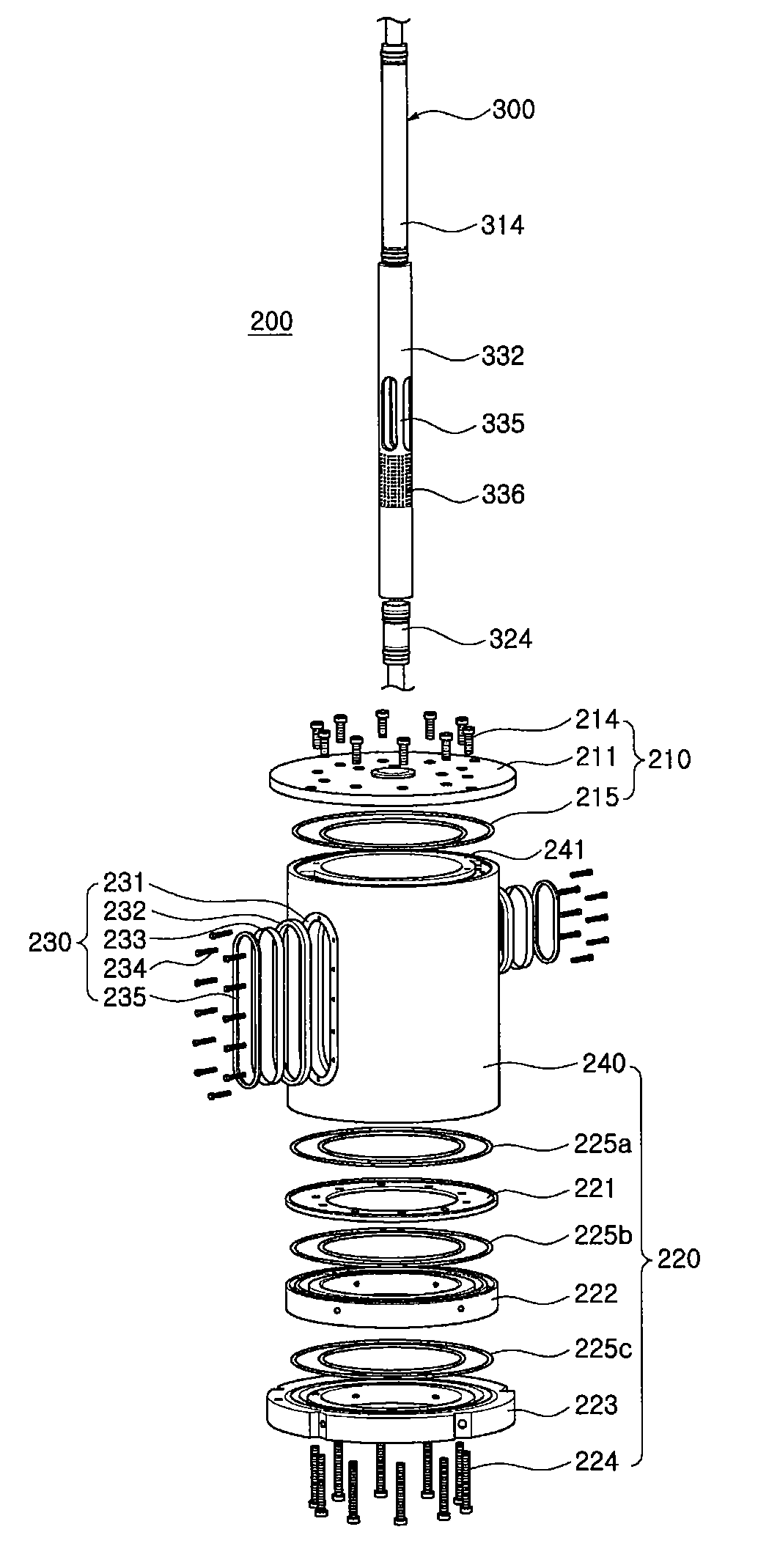

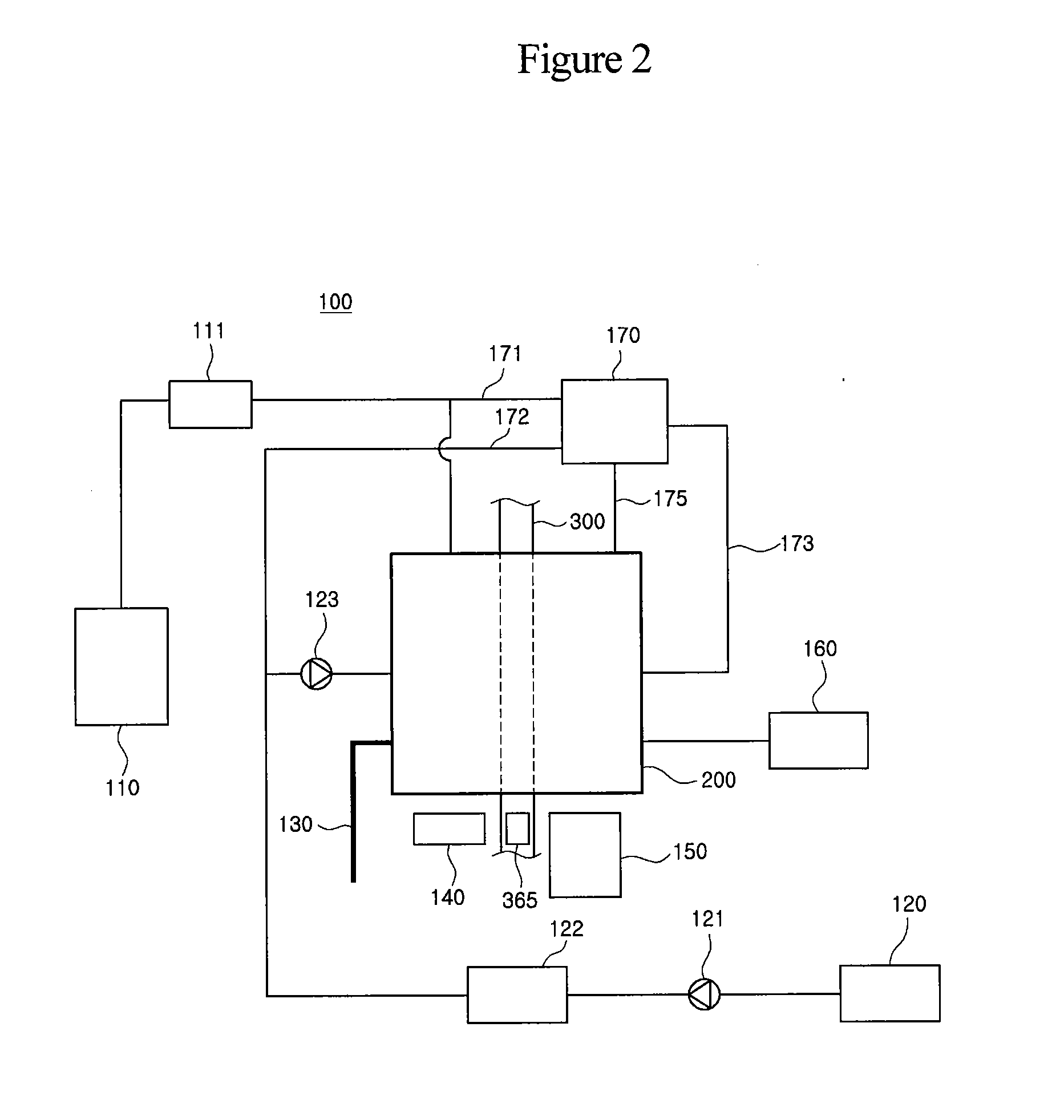

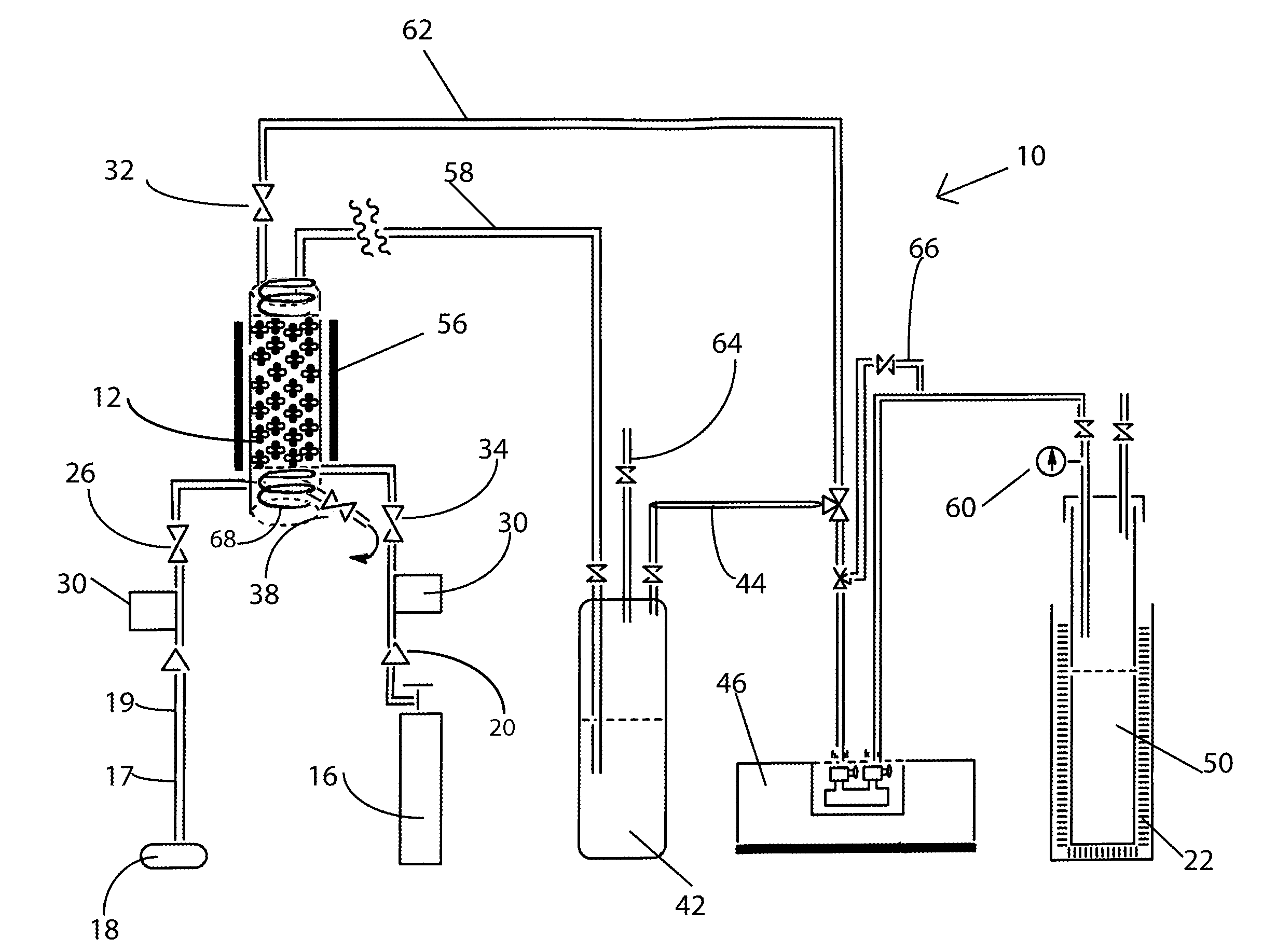

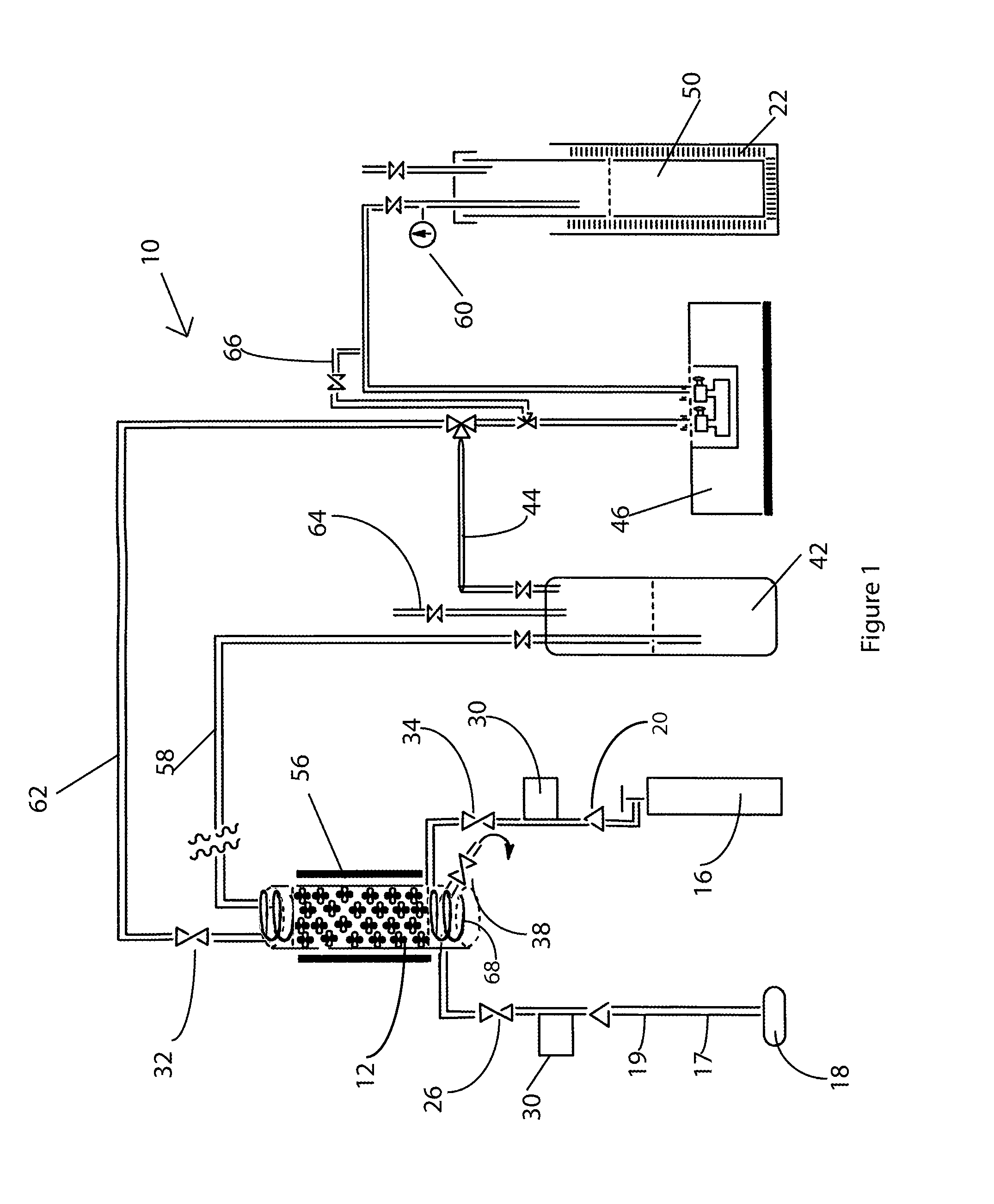

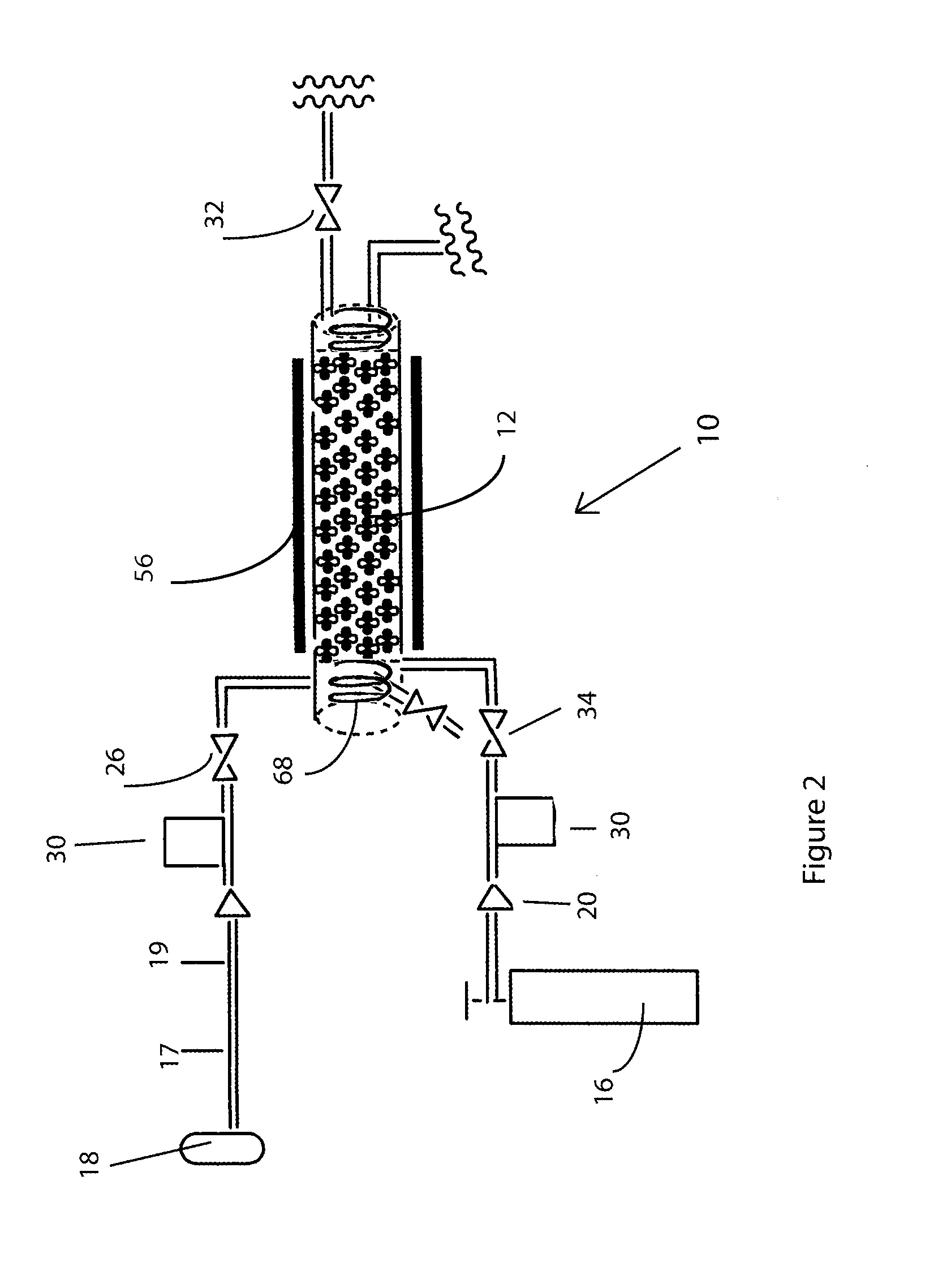

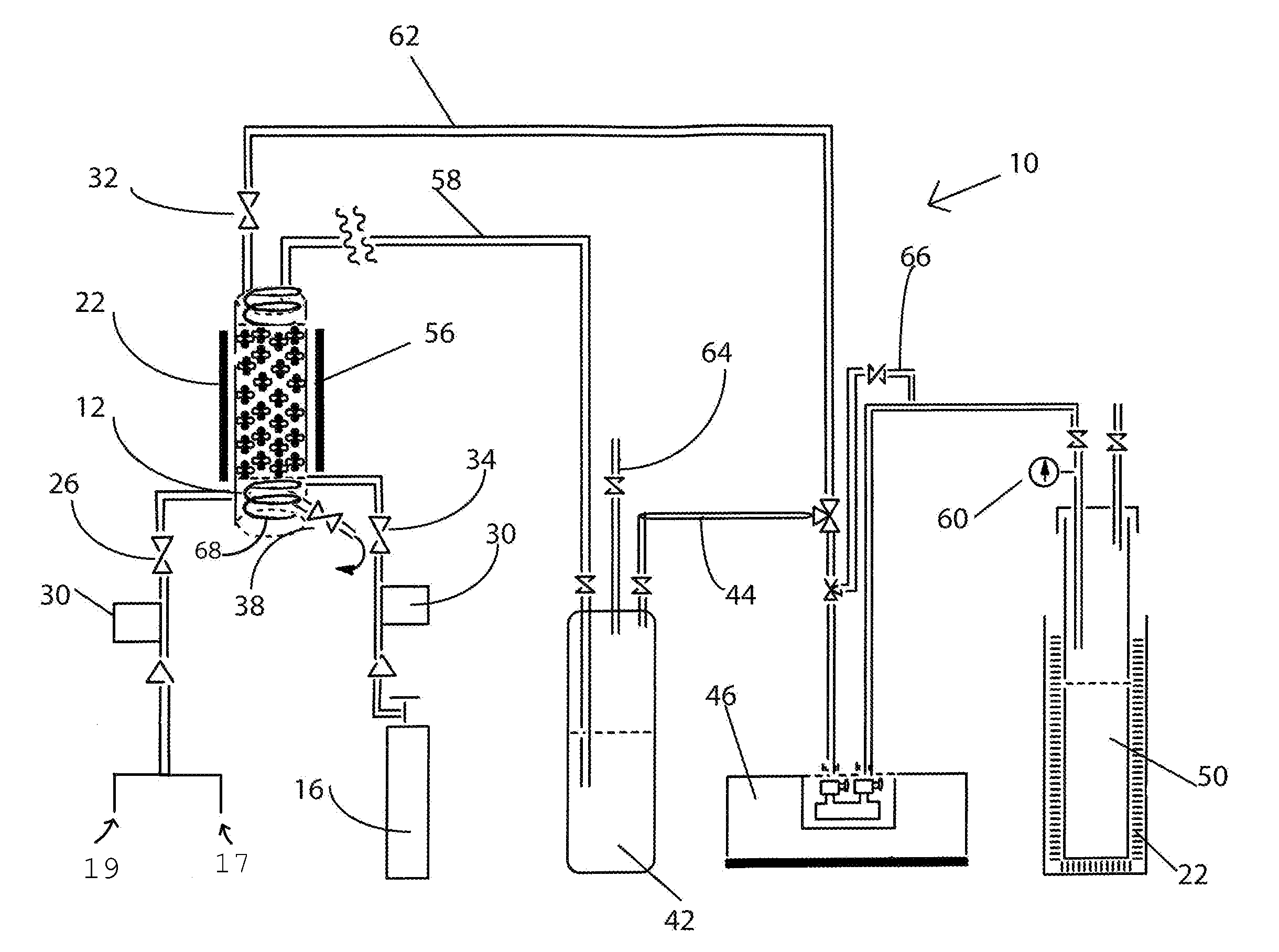

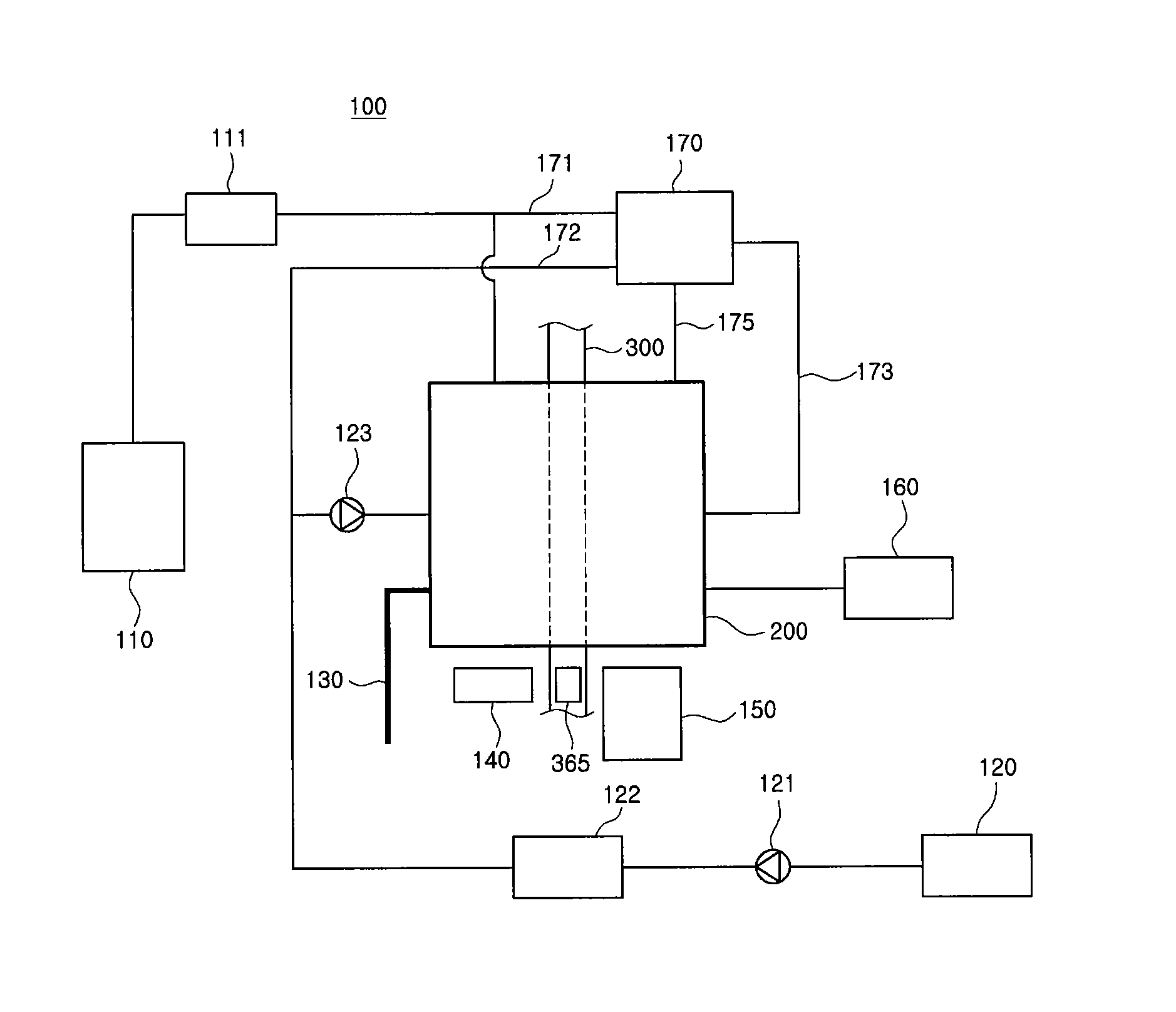

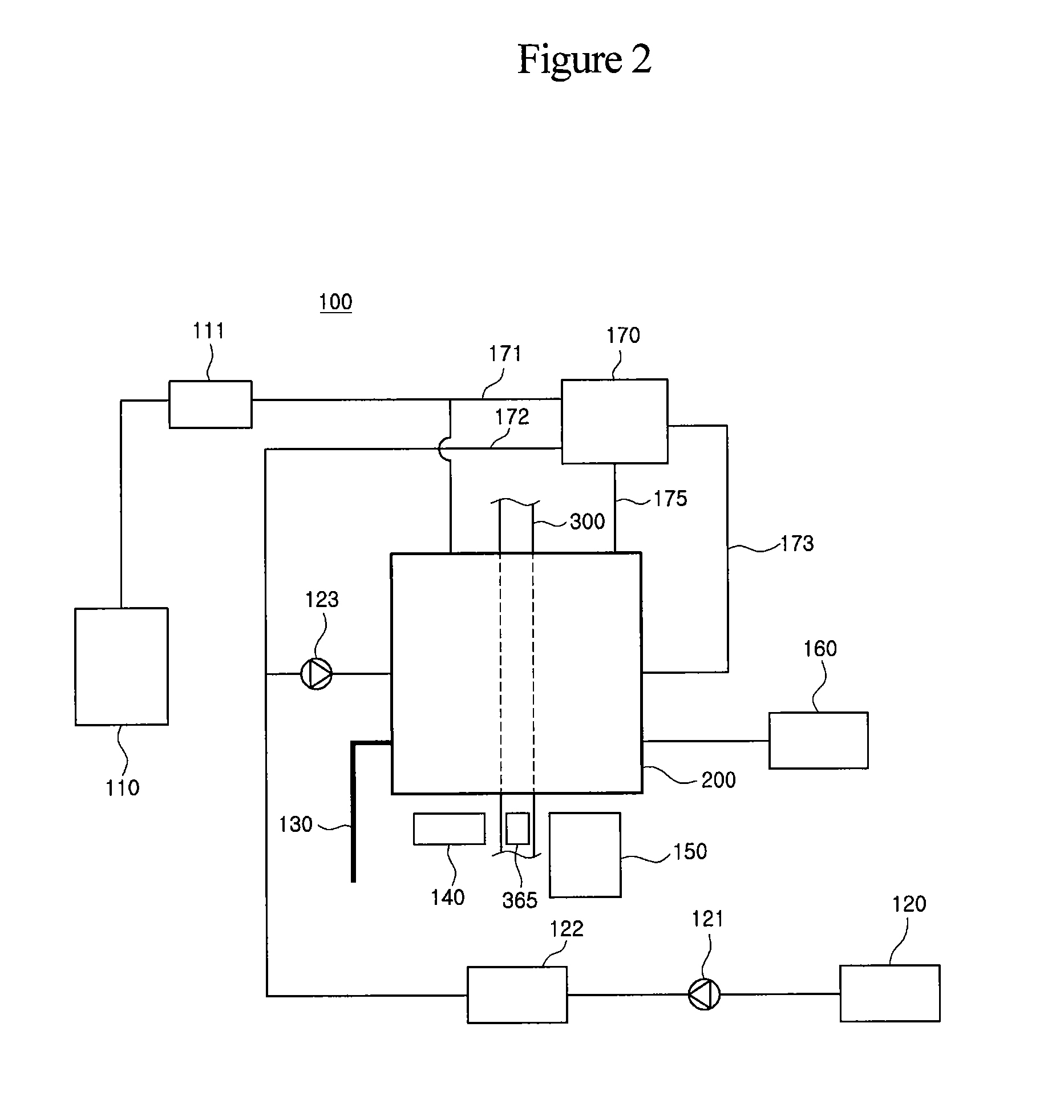

Apparatus and method for continuously producing and pelletizing gas hydrates using dual cylinder

Disclosed herein is an apparatus for continuously producing and pelletizing gas hydrates. The apparatus includes a gas supply unit, a water supply unit and a reactor. Gas and water are respectively supplied from the gas supply unit and the water supply unit into the reactor. The gas and water react with each other in the reactor. The reactor includes a dual cylinder unit which forms a gas hydrate in such a way as to squeeze a slurry of reaction water formed by the reaction between the gas and water. The dual cylinder unit includes an upper cylinder, a lower cylinder and a connection pipe which connects the upper cylinder to the lower cylinder. The connection pipe has passing holes through which the reaction water in the reactor flows into and out of the connection pipe.

Owner:KOREA INST OF IND TECH +2

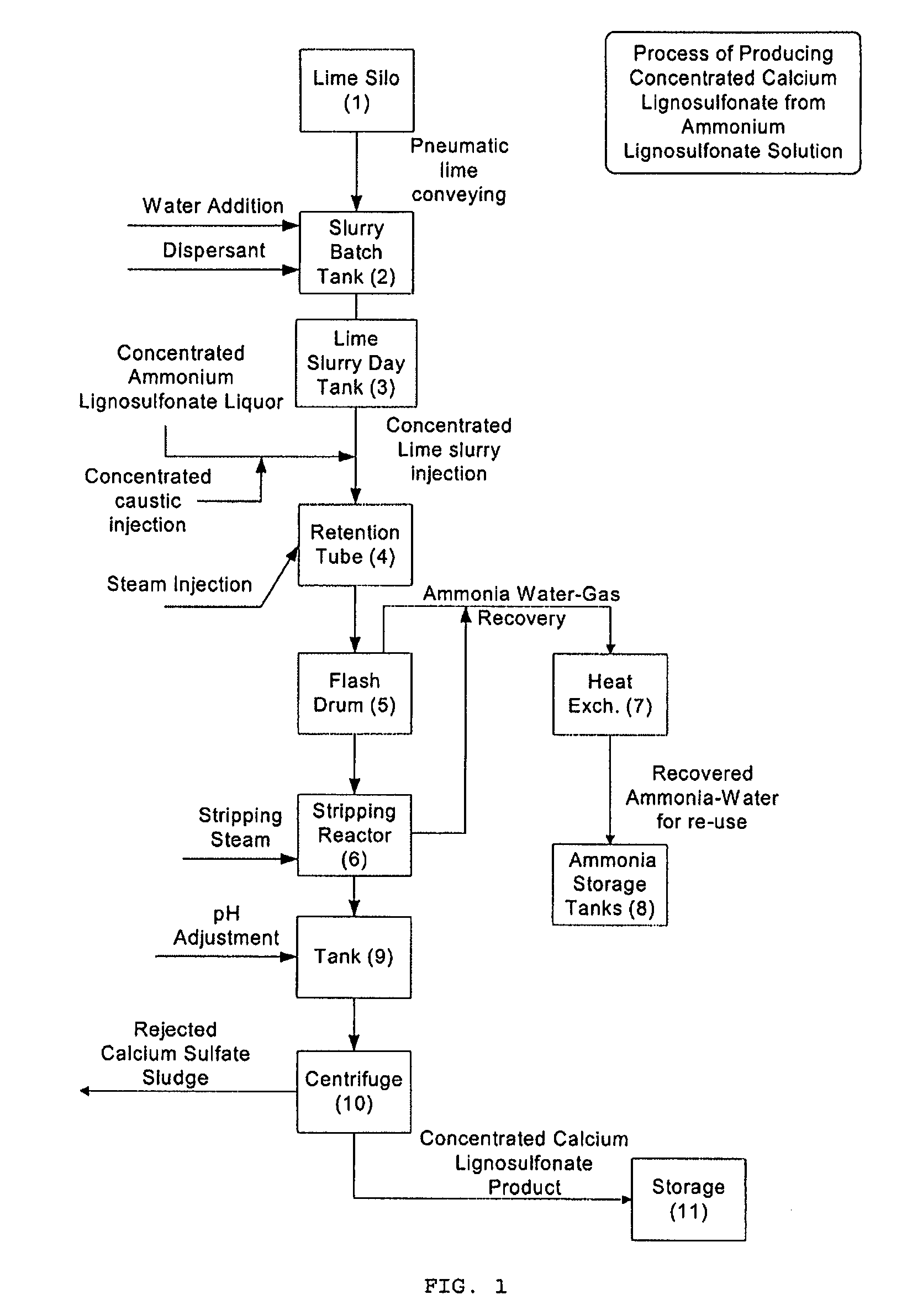

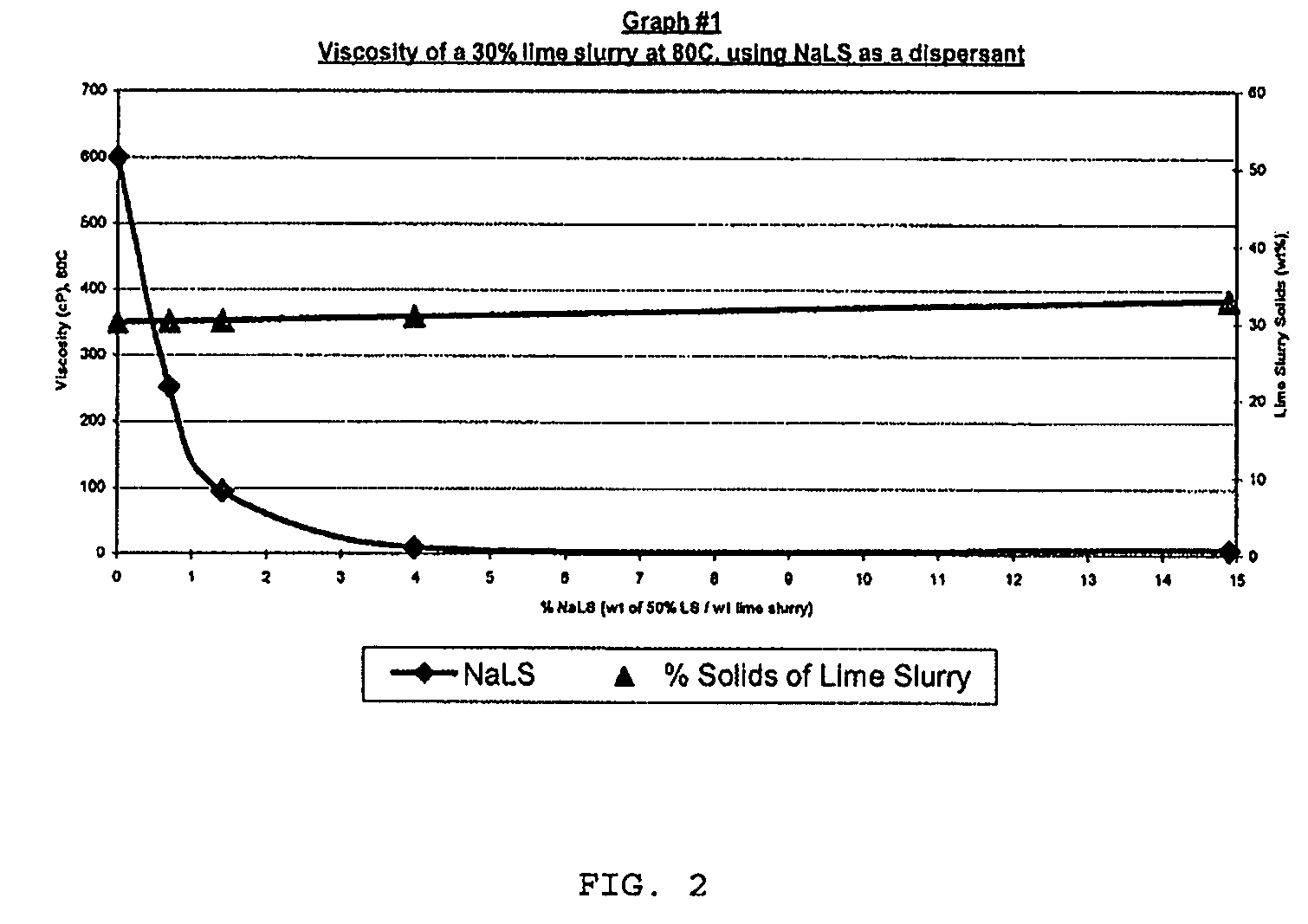

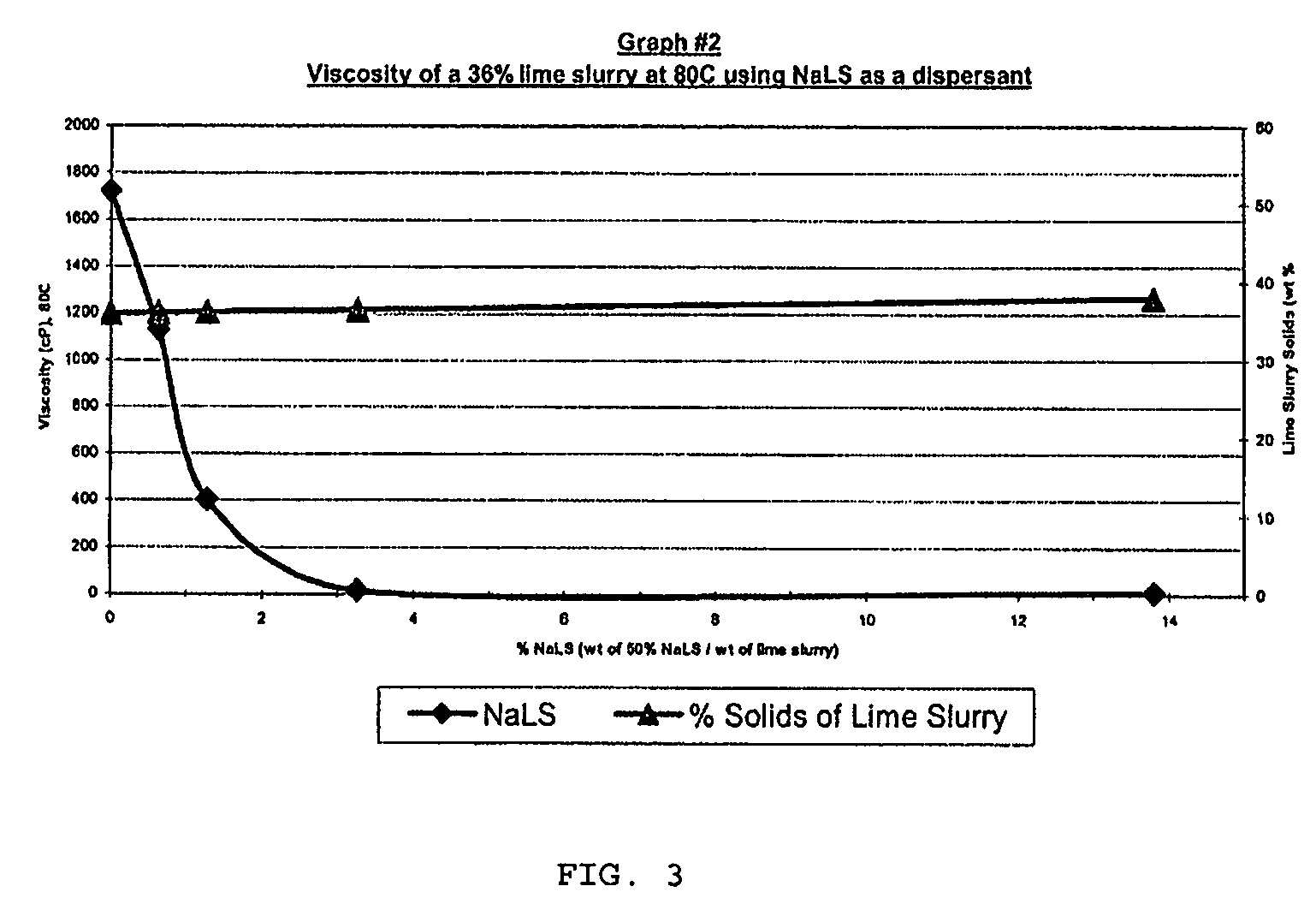

Higher than 30% concentration lime slurries, preparation and uses thereof

InactiveUS20080206126A1Reduced final product viscosityEliminate processingNon-fibrous pulp additionNatural cellulose pulp/paperCalcium hydroxideSulfate

The present invention relates to a composition comprising water, more than 30% w / w of calcium hydroxide, and >0.2% w / w dispersant. A process for preparing such a composition is also disclosed. The composition which can be in the form of a 45-55% concentration lime slurry is particularly useful for converting concentrated ammonium lignosulfonate into calcium lignosulfonate, for converting ammonium lignosulfonate into low sulfate calcium, potassium, sodium, or magnesium lignosulfonate and mixtures thereof, for removing soluble sulfate from concentrated sodium, potassium, ammonium or magnesium lignosulfonate or for treating a weak liquor obtained from the pulp and paper industry.

Owner:TEMBEC INC

Alkali/Transition Metal Halo-And Hydroxy-Phosphates And Related Electrode Active Materials

InactiveUS20100276632A1Increase capacityImprove cycle performancePhosphatesFluoride preparationHalogenPhosphate

The invention provides a novel polyanion-based electrode active material for use in a secondary or rechargeable electrochemical cell, wherein the electrode active material is represented by the general formula AaMb(SO4)2Zd.

Owner:VALENCE TECH INC

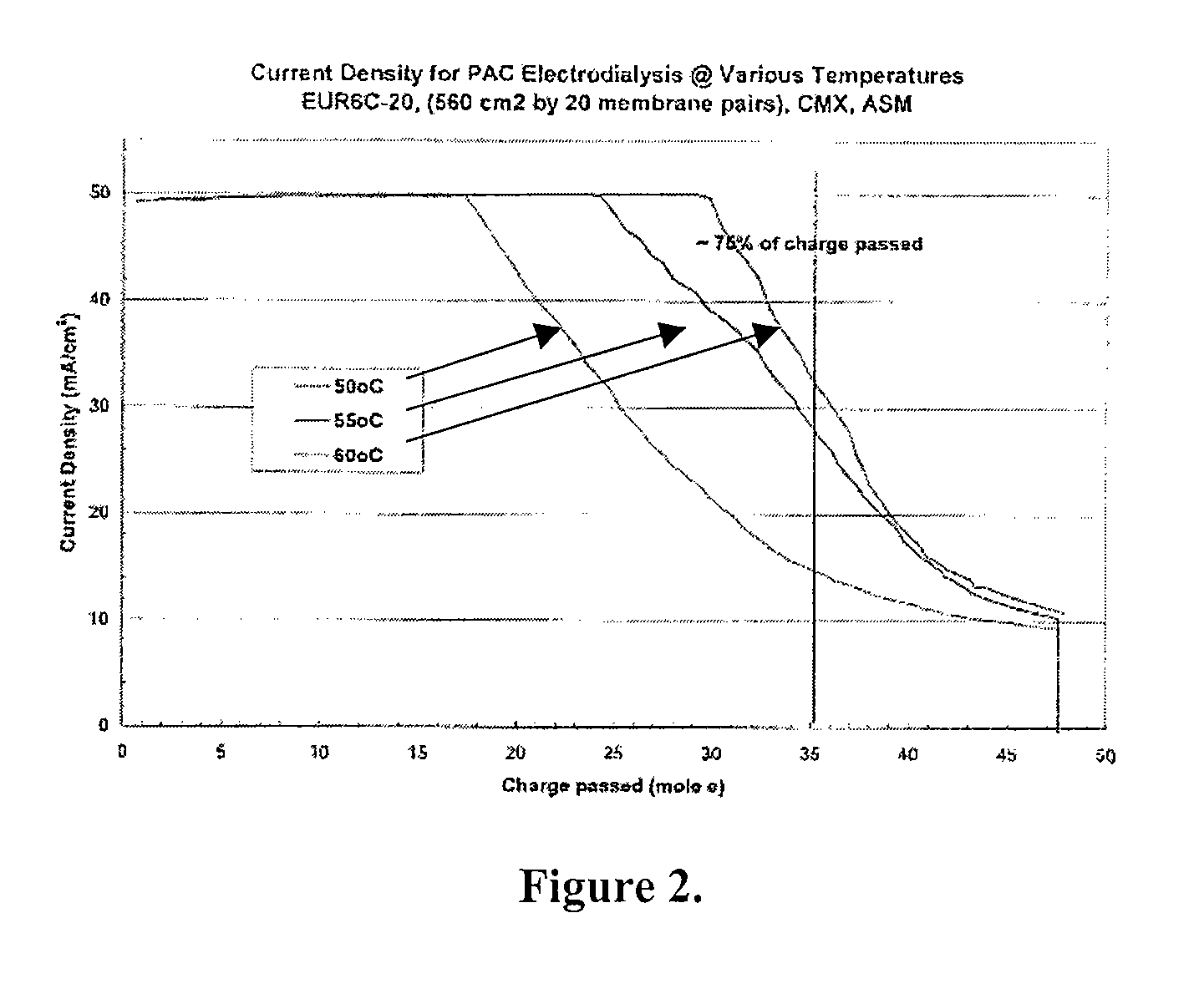

Process for producing stable polyaluminum hydroxychloride and polyaluminum hydroxychlorosulfate aqueous solutions

InactiveUS20070092433A1Aluminium compoundsSulfur-halogen-hydrogen-oxygen compoundsChemistryAqueous solution

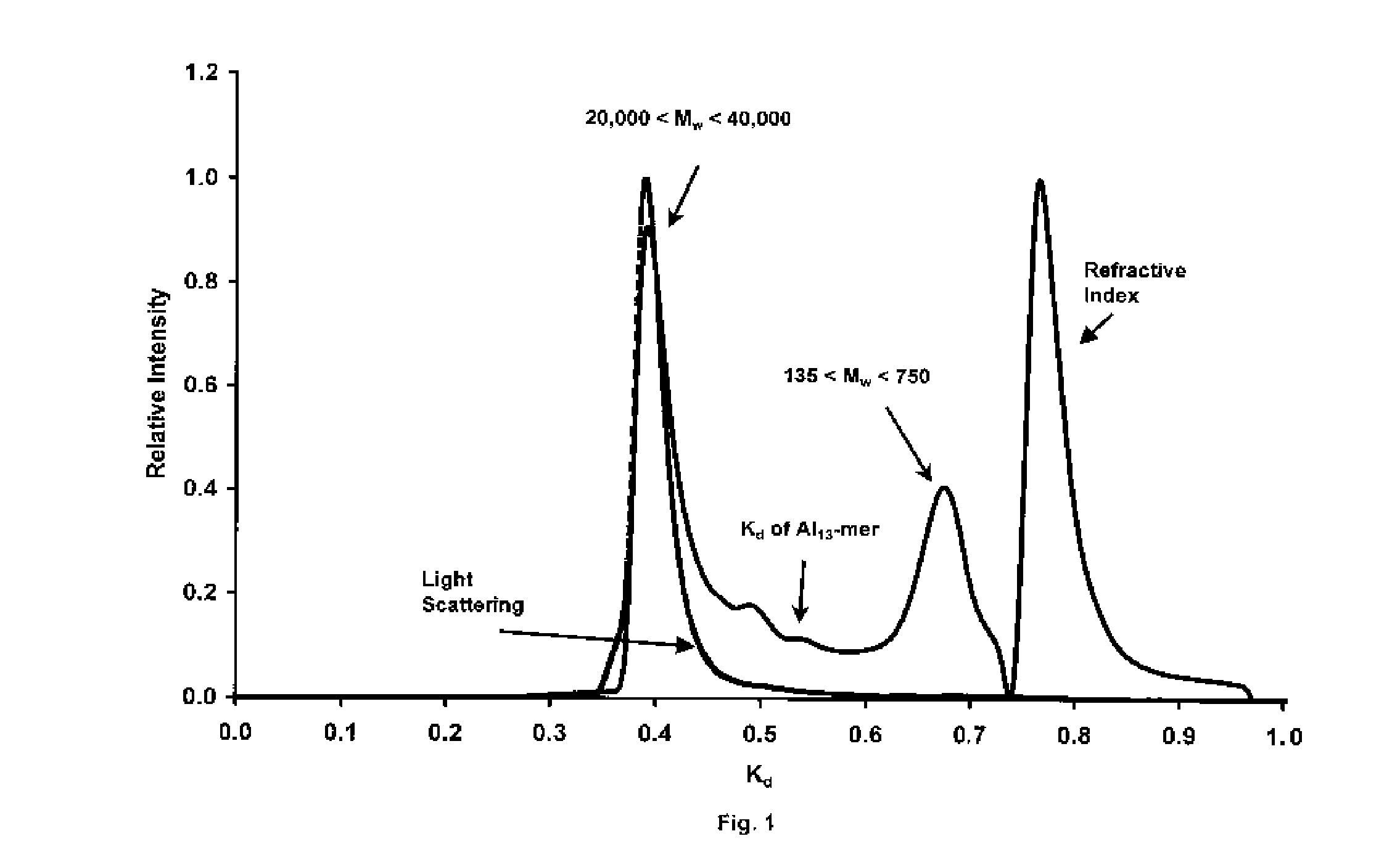

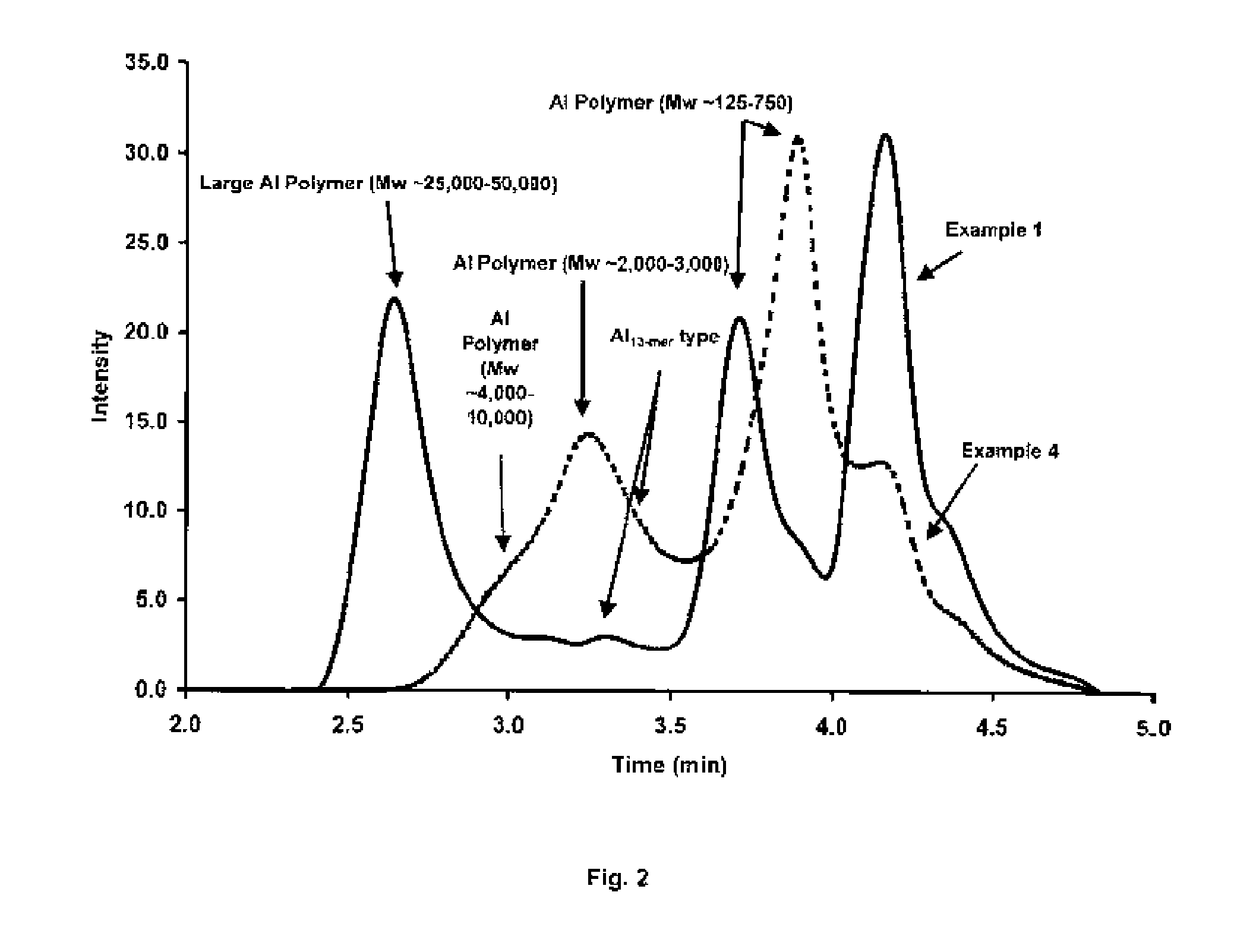

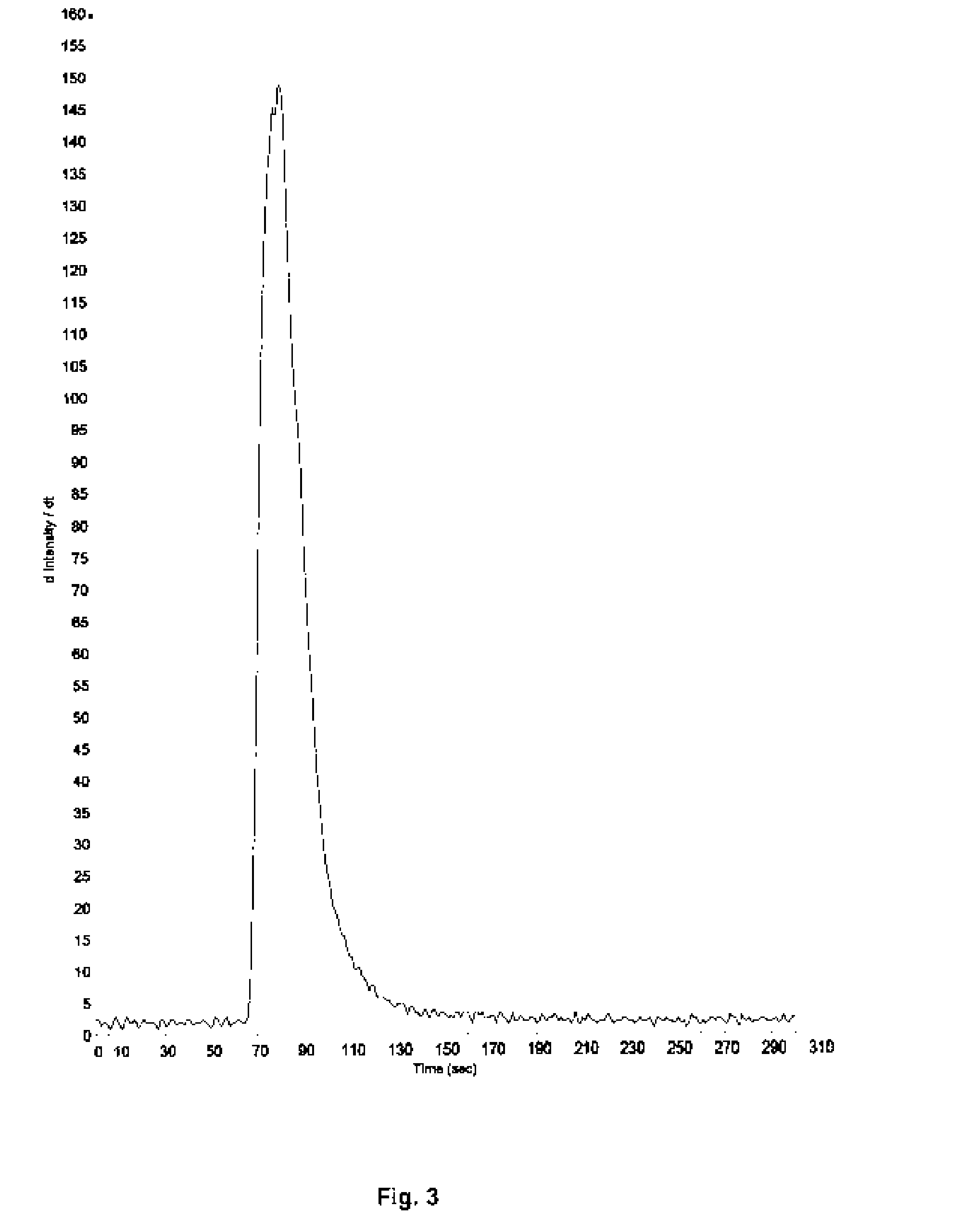

The production of polyaluminum hydroxychlorosulfates (PACS) suitable for effective use as flocculants and coagulants in water treatment is described. The product is a fluid, clear solution that is stable with respect to precipitation and gelling for extended periods of time. Key features of the process include: i) the production of a PACS solution of about 12-16% Al2O3 and about 40-60% basicity at moderate temperatures (50-60° C.) using a zerovalent aluminum source, such as aluminum powder, ii) the addition of an alkali metal or alkali earth metal base at low temperatures (20-30° C.) to produce PACS products ranging from 9-12% Al2O3 with basicities ranging from 70-80%, iii) the addition of an alkali metal base at low temperatures without the use of high shear mixing, iv) a PACS product that does not contain significant amounts of the Al13-mer Keggin complex , v) a product with greater than 80-95% of the aluminum polymers bimodally distributed in the range of 20,000-40,000 Daltons and 135-750 Daltons, and vi) the formation a PACS whereby greater than 95% of the sulfate is bound to aluminum and is contained in the aluminum polymers distributed in the range of 20,000-40,000 Daltons.

Owner:GENERAL CHEM LLC

Process for producing a copper thiometallate or a selenometallate material

ActiveUS8409541B2Phosphorus sulfur/selenium/tellurium compoundsSelenium/tellurium compundsPhysical chemistryOxidation state

A method for producing a thiometallate or selenometallate material is provided in which a first salt containing an anionic component selected from the group consisting of MoS42−, MoSe42−, WS42−, WSe42− and a second salt containing a cationic component comprising copper in any non-zero oxidation state are mixed under anaerobic conditions in an aqueous mixture at a temperature of from 50° C. to 150° C.

Owner:SHELL USA INC

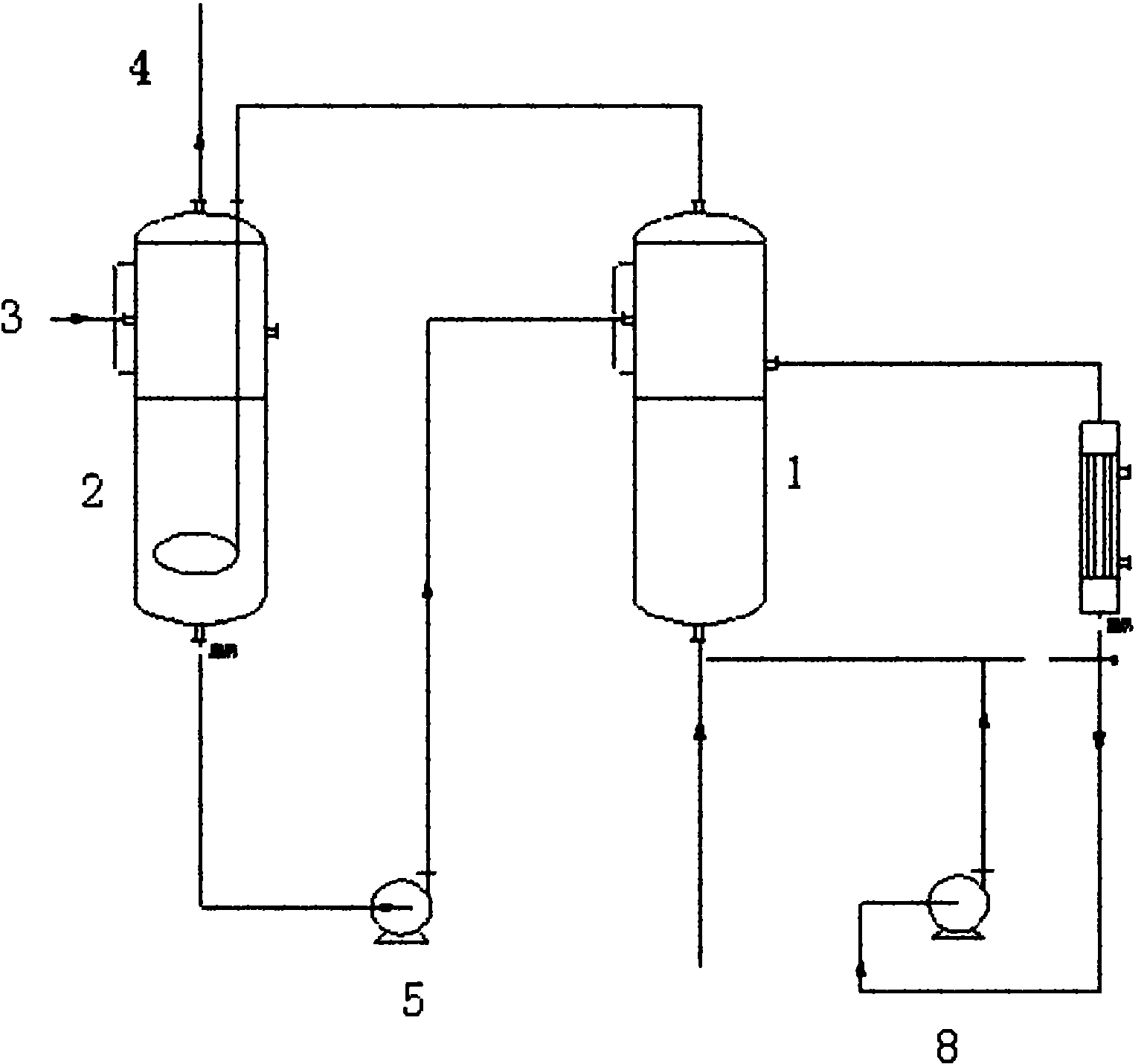

Dechloridation device and process in chlorinated paraffin production process

ActiveCN102145251AIncrease profitHigh puritySulfur-halogen-hydrogen-oxygen compoundsDispersed particle separationEthyl ChlorideChlorinated paraffins

The invention relates to a dechloridation device and process in a chlorinated paraffin production process. The dechloridation process comprises the following steps: connecting a tail gas discharge pipe of a chlorination reaction kettle with a dechloridation kettle; introducing the chlorination tail gas produced by the chlorination reaction into hot liquid wax to perform a dechloridation reaction;eliminating the gas after the dechloridation reaction from a hydrogen chloride outlet; and eliminating the generated liquid material containing the liquid wax and using the eliminated liquid materialcontaining the liquid wax as a raw material for continuous chlorination reactions. The process provided by the invention is a gas-gas two-phase material separation technology, can improve the chlorine utilization rate and the hydrogen chloride purity and remove impurities in the liquid wax and improve the product quality of chlorinated paraffin, and has tremendous economical benefits and practicability. By adopting the technology, the chlorine content in hydrogen chloride is less than or equal to 0.1%, the hydrogen chloride purity is improved to satisfy the use of a chlorosulfonic acid device; and meanwhile, the quality of liquid wax is improved, and the improvement of comprehensive quality of the product is facilitated.

Owner:LUXI CHEM GRP

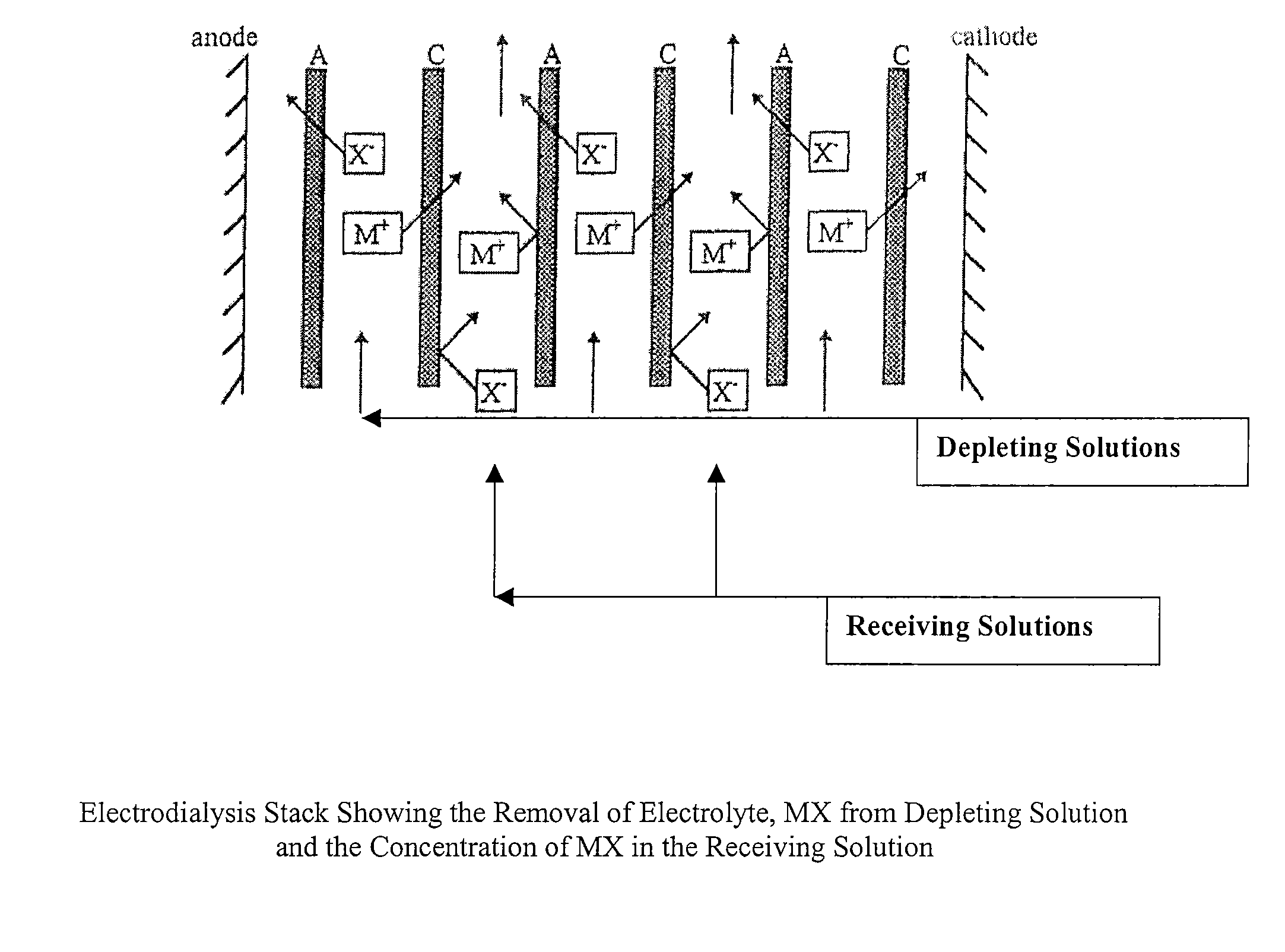

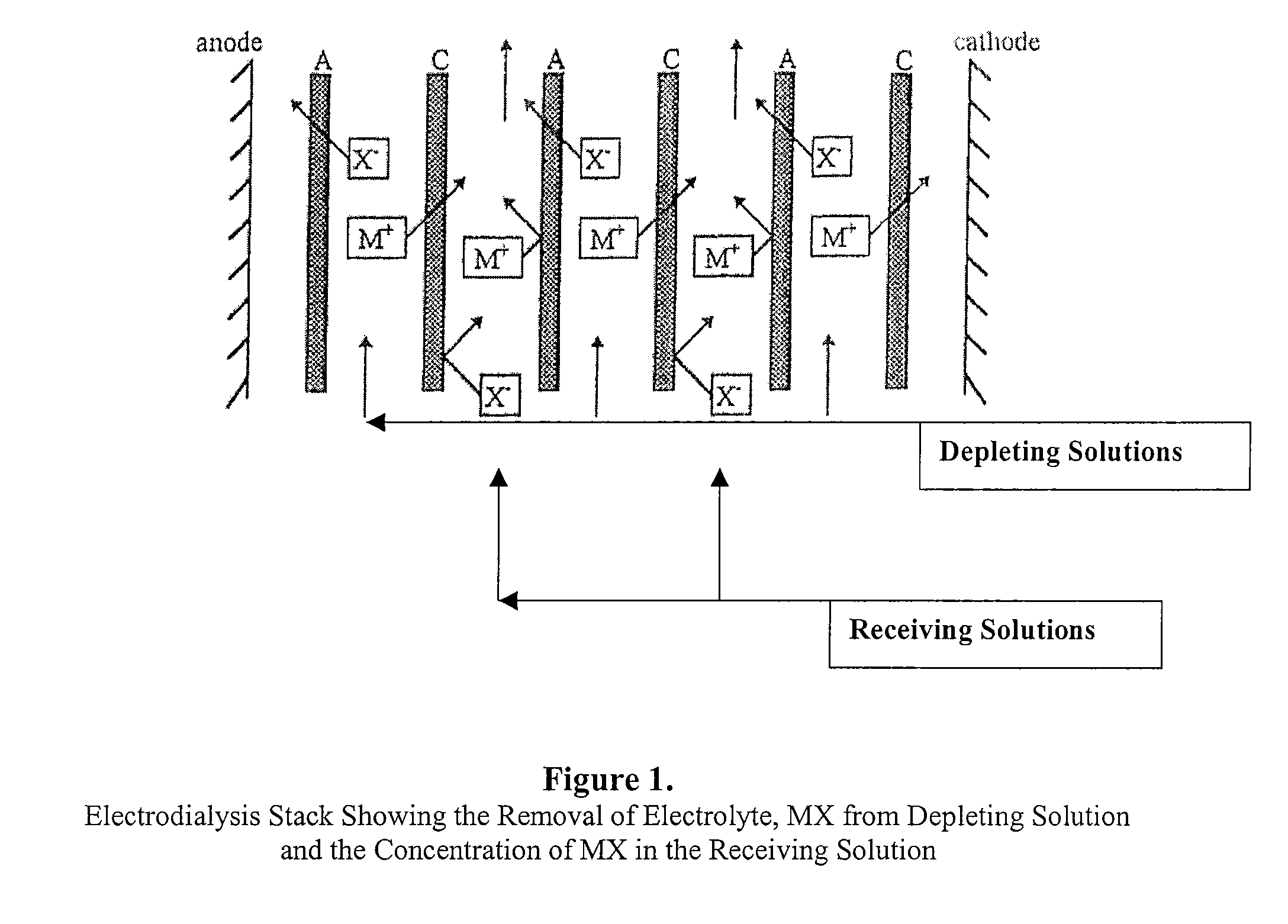

Polyaluminum Chloride and Aluminum Chlorohydrate, Processes and Compositions: High-Basicity and Ultra High-Basicity Products

ActiveUS20070187256A1Increase concentrationIncrease hydroxide contentCosmetic preparationsElectrolysis componentsAntiperspirantsAlkalinity

The invention relates generally to processes for the production of high-basicity and ultr-high basicity polyaluminum chlorides including aluminum chlorohydrate. The processes can produce products of a wide range of basicities and are particularly useful in producing high basicity products. The process can produce a wide range of solution concentrations and are particularly useful in producing high solution concentrations. The processes described generate high purity products, which are free of by-product salt(s). The processes described herein can also be utilized to produce enhanced efficacy polyaluminum chlorides including aluminum chlorohydrate. When compared to conventional processes for manufacturing these compounds the processes disclosed herein are unique in so far as the disclosed processes do not require aluminum metal as a starting material. The products of the processes are suitable in applications including water purification, catalysts, and antiperspirants. In addition, the invention is directed to the products prepared by the processes described herein.

Owner:NEXT CHEM LLC

Process for the synthesis of BrSF5

InactiveUS6869582B2Shorten the overall cyclePigmenting treatmentSulfur-halogen-hydrogen-oxygen compoundsSufficient timeAlkaline earth metal

A process for producing BrSF5 includes providing a first reactant including a metal fluoride of fluorine and a metal M selected from the group consisting of alkali metals, alkaline earth metals, and Ag, providing a second reactant including BrF3, combining the first reactant and the second reactant to form a mixture, wherein the first reactant and the second reactant are allowed to contact for a period of time sufficient to produce MBrF4 in an amount stoichiometrically equivalent to a quantity of BrF3, and providing a third reactant including SF4, wherein the third reactant reacts with MBrF4. The process for producing BrSF5 can further include providing a fourth reactant including Br2, wherein the fourth reactant is provided before, during and / or after providing the first reactant, the second reactant and / or the third reactant. BrSF5 is produced in a yield of from about 50% to about 99.99% based on the amount of SF4.

Owner:VERSUM MATERIALS US LLC

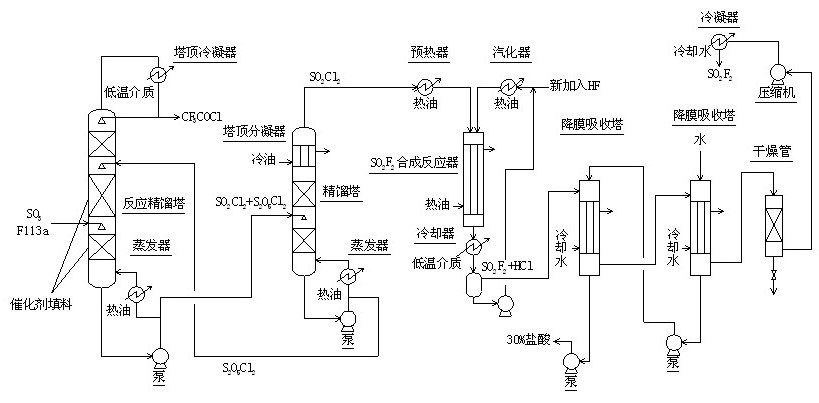

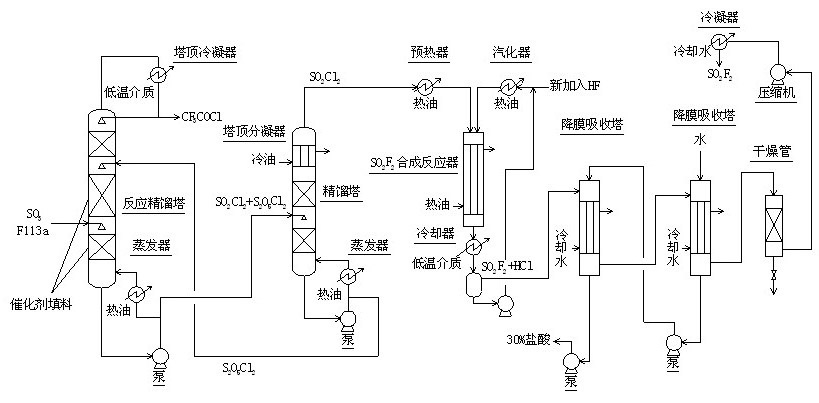

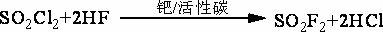

Method for continuously synthesizing trifluoroacetyl chloride and sulfuryl fluoride

InactiveCN102351681AHigh reaction yieldThree wastes lessSulfur-halogen-hydrogen-oxygen compoundsCarboxylic acid halides preparationReaction temperatureTrifluoroacetyl chloride

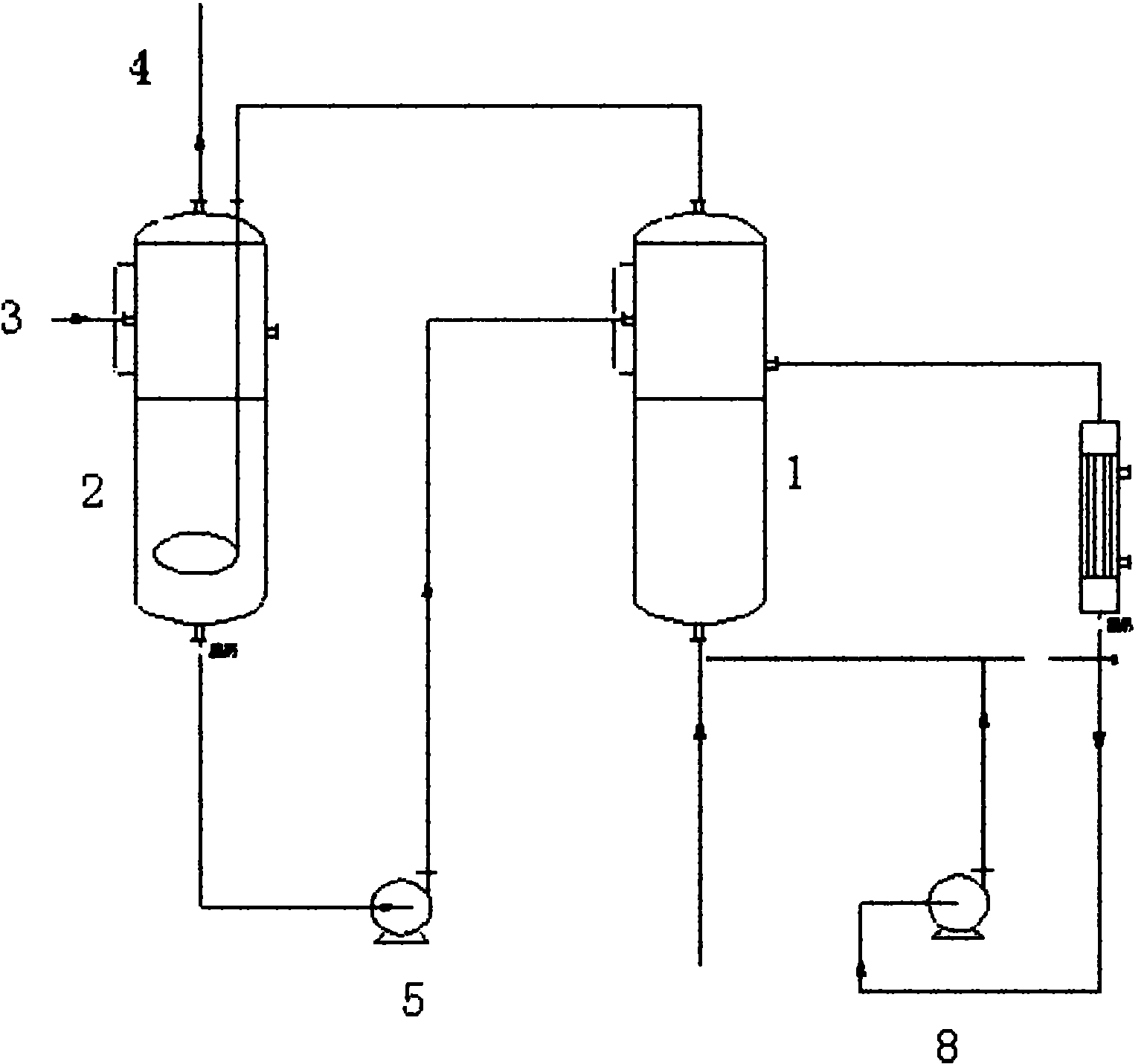

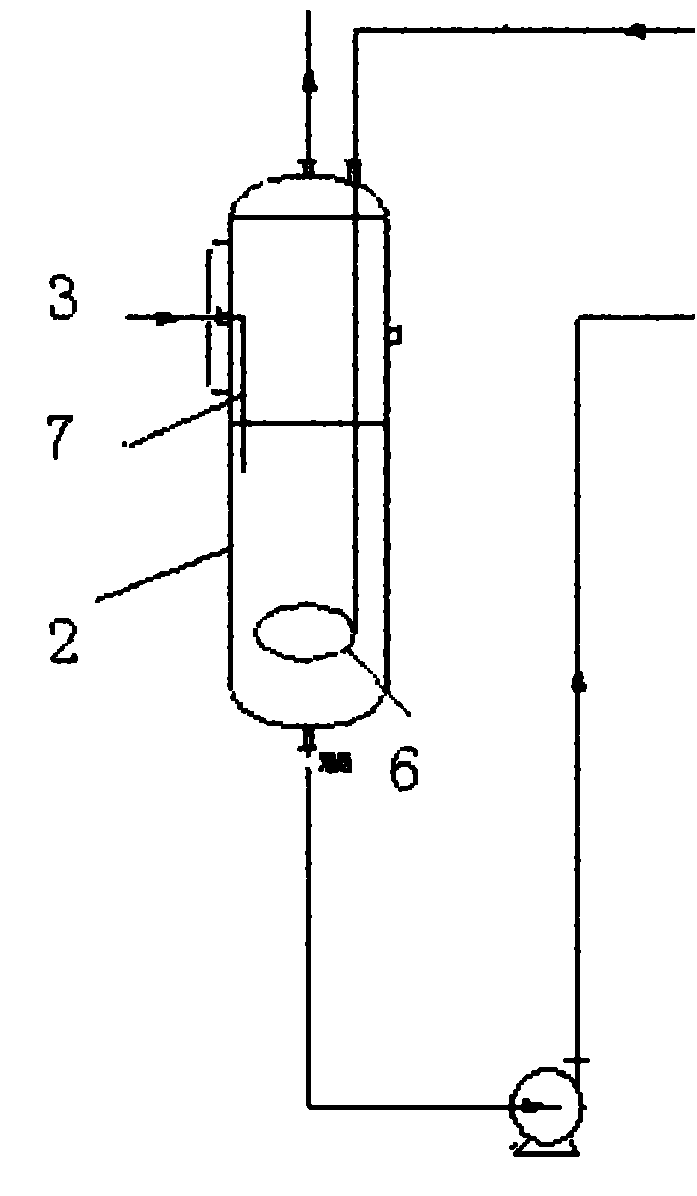

The invention relates to a method for continuously synthesizing trifluoroacetyl chloride and sulfuryl fluoride, which comprises the following process: continuously introducing sulfur trioxide and trifluorotrichloroethane (F113a) into a reaction rectifying tower containing a catalyst and a filler thorough the lower part in the tower according to a mol ratio of 1:1, wherein the temperature of the tower is controlled to range between 120 DEG C and 130 DEG C, and the reflux ratio at the top of the tower is 2.5-3; introducing tower bottoms into a sulfuryl chloride separating tower for rectification and separation, wherein the tower temperature is 145-150 DEG C, and the reflux ratio is 0.5-1.0; returning pyrosulfuryl chloride in the separating tower to the middle upper part of the reaction rectifying tower, heating the sulfuryl chloride rectified off from the top of the tower to 150 DEG C, and then introducing the rectified sulfuryl chloride and preheated recycled and newly-added hydrogen fluoride gas into a reactor containing a palladium / charcoal catalyst, wherein the reaction temperature is controlled to range between 150 DEG C and 160 DEG C; separating out unreacted hydrogen fluoride from the reaction product through a cold trap, and returning to the reactor for further use; and then absorbing and separating hydrogen chloride through a falling film, drying, compressing, and condensing to obtain the sulfuryl fluoride. The invention has the advantage of easy acquisition of raw materials, and the sulfuryl chloride byproduct can be directly used for the synthesis of sulfuryl fluoride.

Owner:ZHEJIANG UNIV +1

Polyaluminum chloride and aluminum chlorohydrate, processes and compositions: high-basicity and ultra high-basicity products

ActiveUS7846318B2Increase hydroxide contentCosmetic preparationsChloride preparationAntiperspirantsAlkalinity

The invention relates generally to processes for the production of high-basicity and ultra-high basicity polyaluminum chlorides including aluminum chlorohydrate. The processes can produce products of a wide range of basicities and are particularly useful in producing high basicity products. The process can produce a wide range of solution concentrations and are particularly useful in producing high solution concentrations. The processes described generate high purity products, which are free of by-product salt(s). The processes described herein can also be utilized to produce enhanced efficacy polyaluminum chlorides including aluminum chlorohydrate. When compared to conventional processes for manufacturing these compounds the processes disclosed herein are unique in so far as the disclosed processes do not require aluminum metal as a starting material. The products of the processes are suitable in applications including water purification, catalysts, and antiperspirants. In addition, the invention is directed to the products prepared by the processes described herein.

Owner:NEXT CHEM LLC

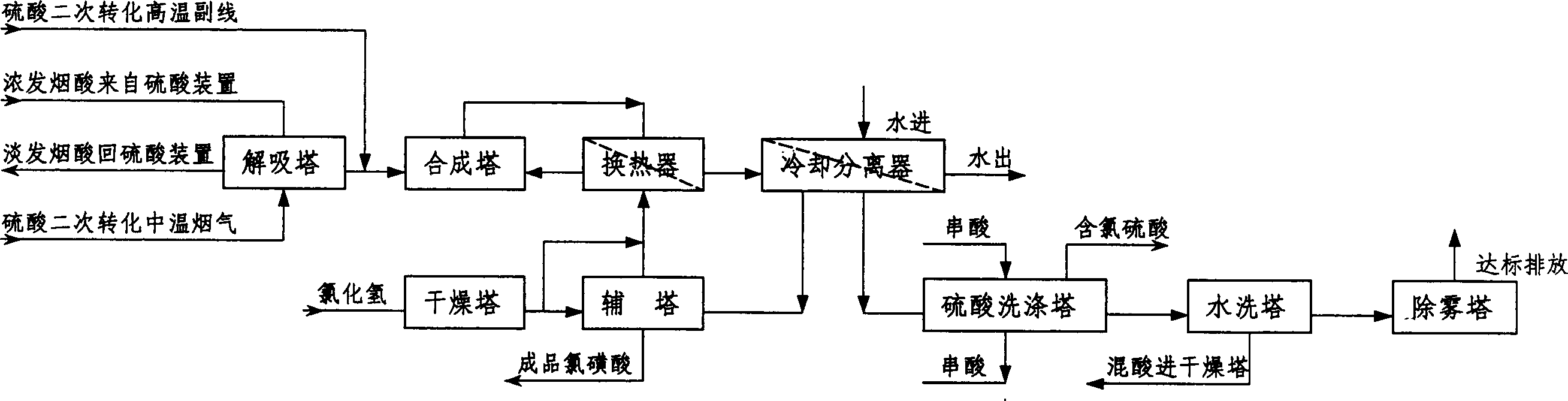

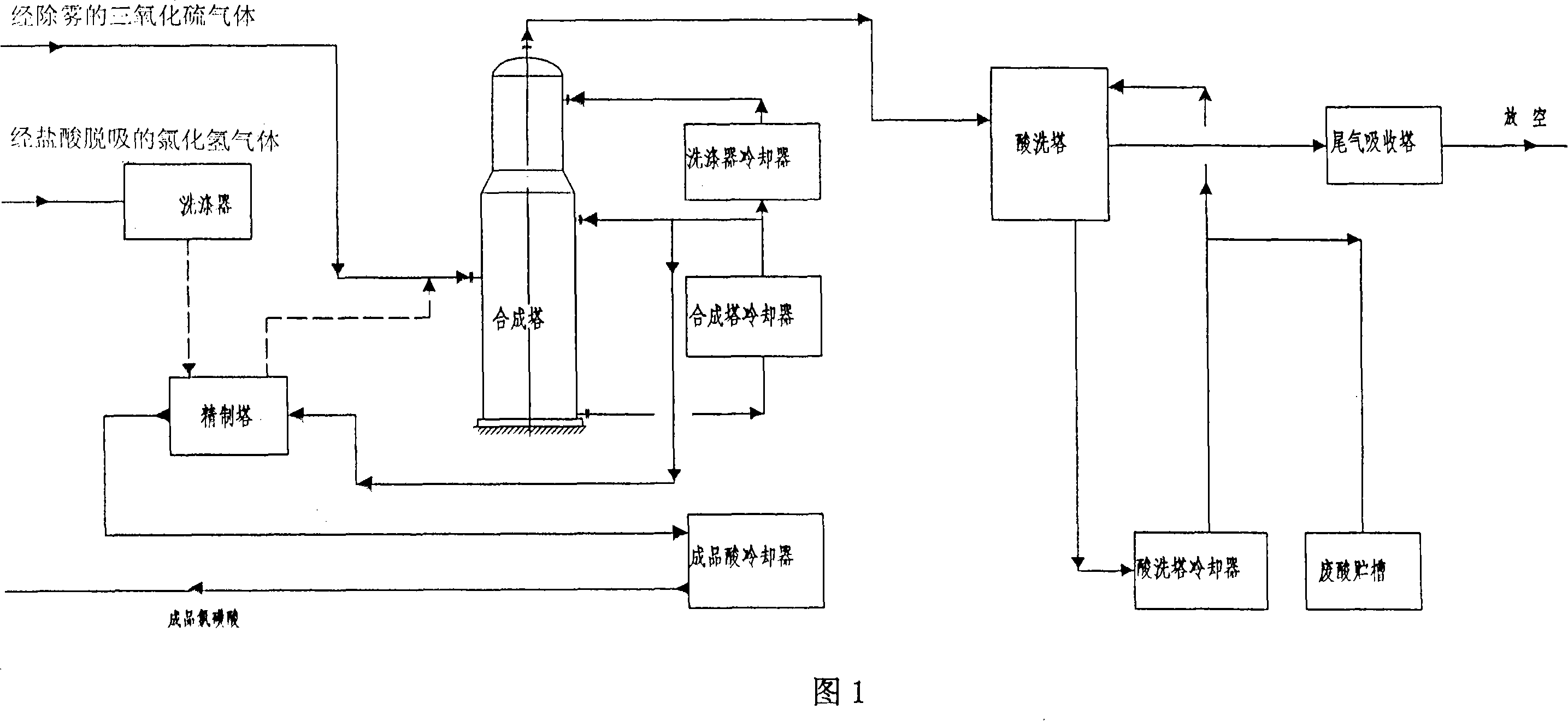

Technology of synthesizing high concentration chlorosulfonic acid using low concentration salfur trioxide

InactiveCN1410347AReduce manufacturing costLower working temperatureSulfur-halogen-hydrogen-oxygen compoundsHigh concentrationSulfur trioxide

A process for synthesizing high-concentration chlorosulfonic acid from low-concentration SO2 features that the SO3 generated by directly decomposing the fuming sulfuric acid by the fume converted from sulfuric acid and the hydrogen chloride are used as raw materials. Its advantages are wide range of the concentrations for hydrogen chloride, and little environmental pollution.

Owner:顾林建

Lithium ion conducting lithium sulphur oxynitride thin film, and a process for the preparation thereof

InactiveUS7883800B2Improve ionic conductivityNitrosyl chlorideConductive materialLithiumElectronic systems

The disclosure herein relates to a lithium ion conducting electrolyte. This electrolytic material has improved ionic conductivity. The material disclosed herein is an amorphous compound of the formula LixSMwOyNz wherein x is between approximately 0.5 and 3, y is between 1 and 6, z is between 0.1 and 1, w is less than 0.3 and M is an element selected from B, Ge, Si, P, As, Cl, Br, I, and combinations thereof. The material can be prepared in the form of a thin film. The electrolyte material can be used in microbatteries and electronic systems.

Owner:CENT NAT DE LA RECHERCHE SCI

Alunite Type Compound Particles, Manufacturing Process Thereof and Use Thereof

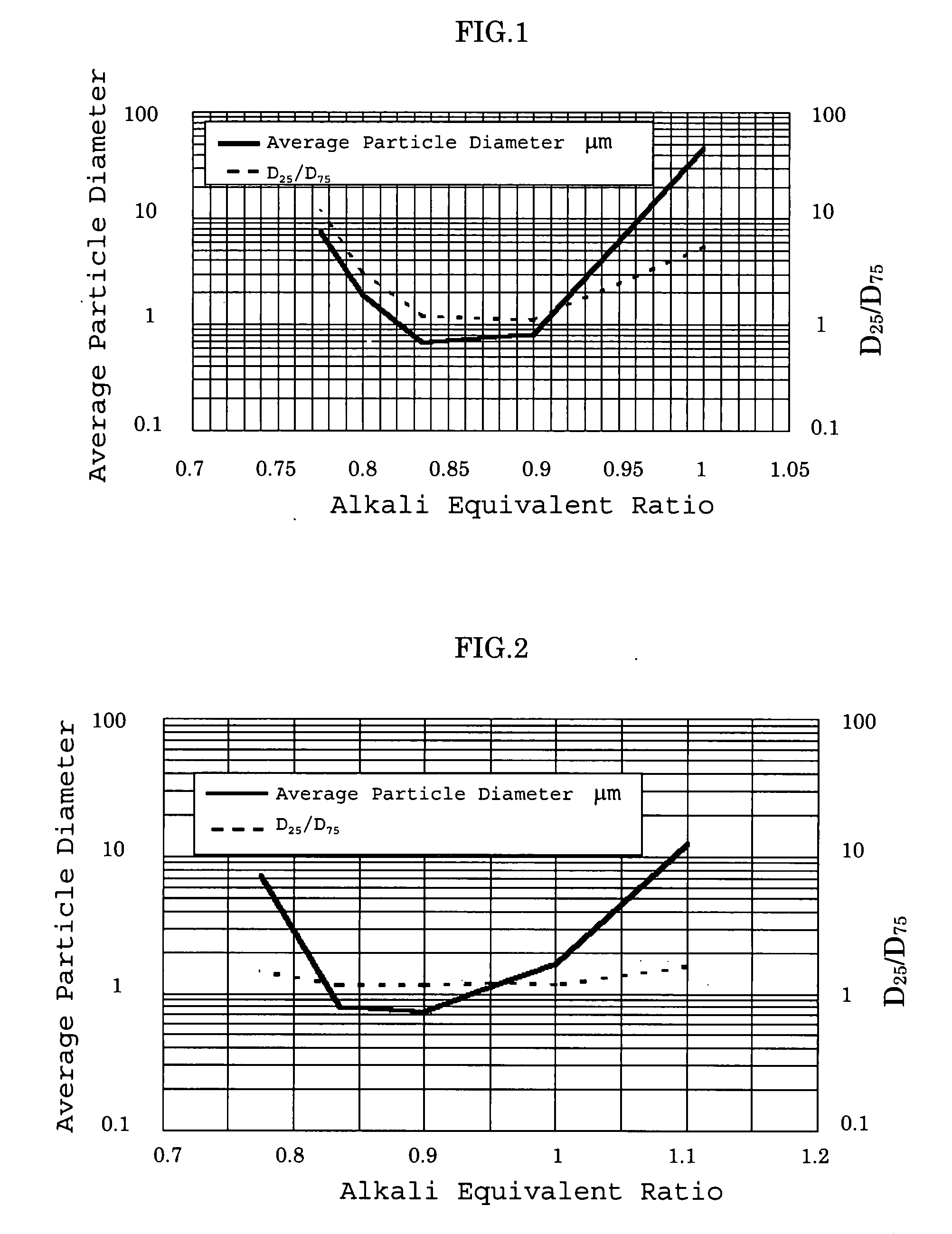

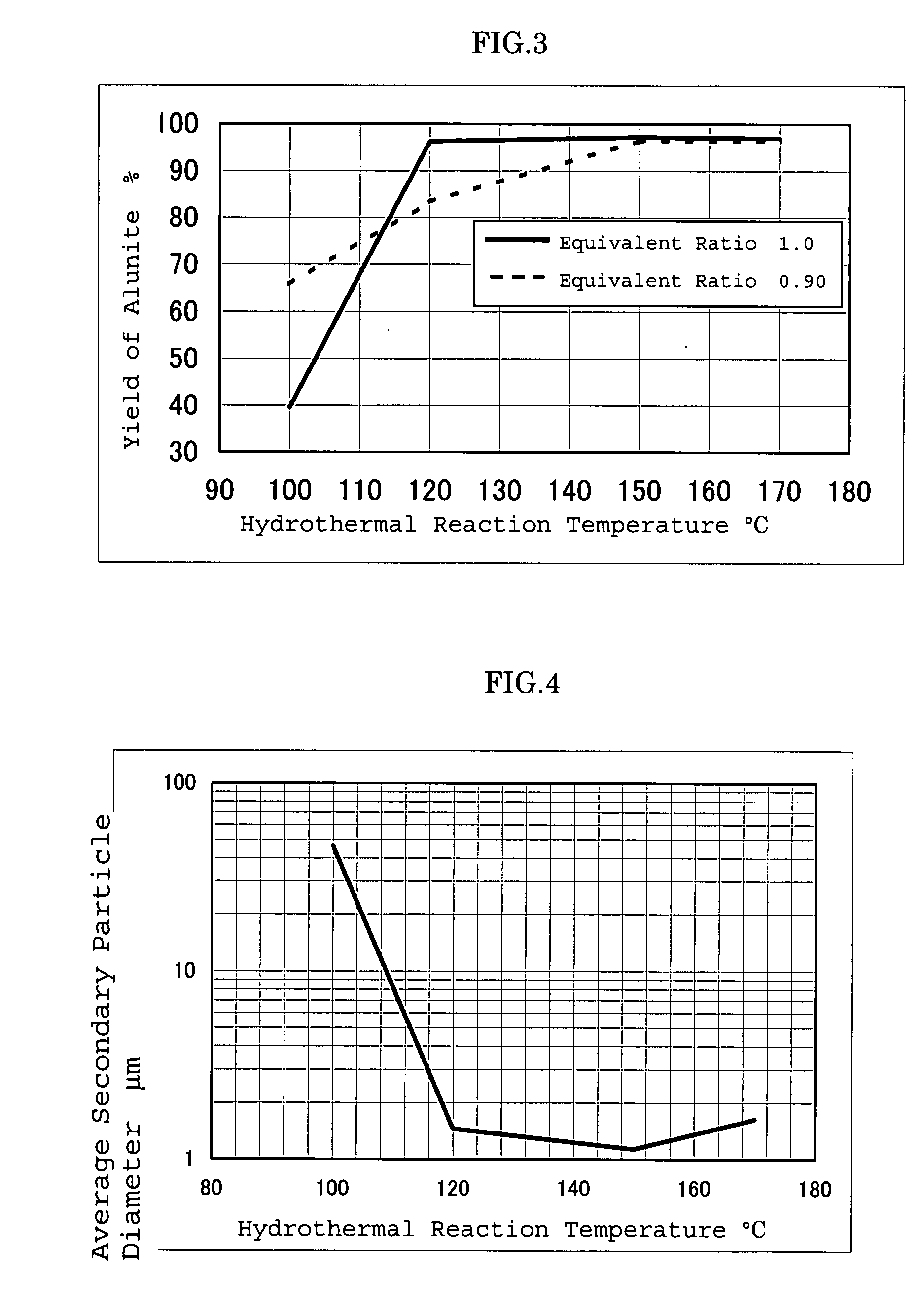

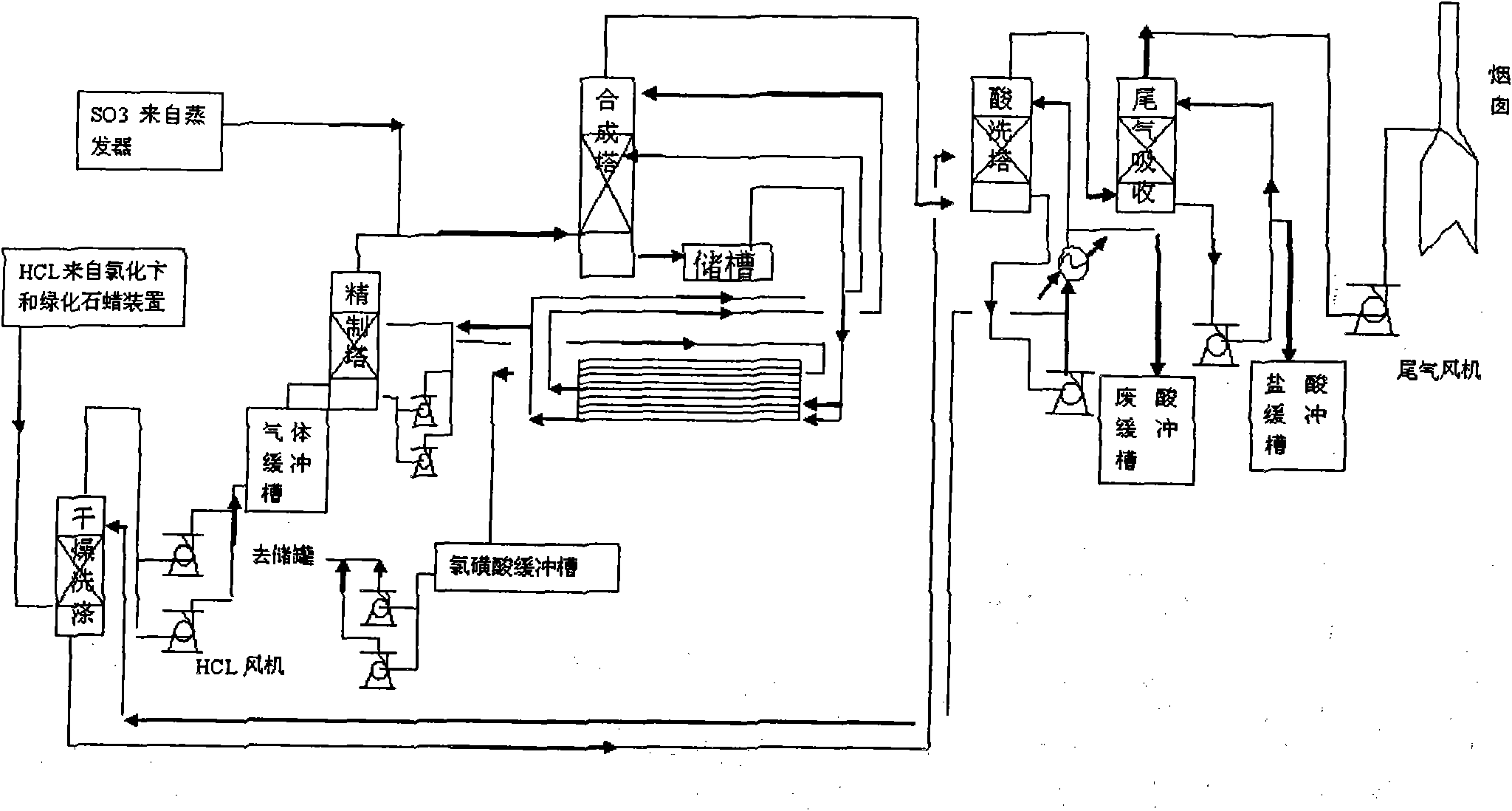

InactiveUS20090012223A1Low costGood reproducibilityPigmenting treatmentSulfate/bisulfate preparationAluniteParticle-size distribution

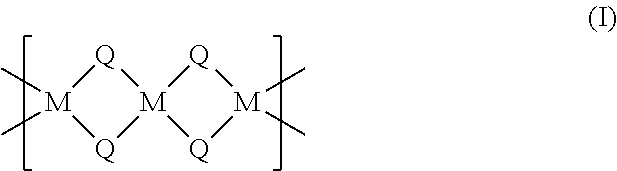

Alunite type compound particles represented by the following general formula (I) and having a specific value of D75 / D25 when D25 is the particle diameter of particles which account for 25% of the total and D75 is the particle diameter of particles which account for 75% of the total in the cumulative particle size distribution curve measured by a laser diffraction method:Ma[Al1-xM′x]3(SO42−)y(OH)z.mH2O (I)wherein M is at least one cation selected from the group consisting of Na+, K+, NH4+ and H3O+, M′ is at least one cation selected from the group consisting of Cu2+, Zn2+, Ni2+, Sn4+, Zr4+ and Ti4+, and a, m, x, y and z satisfy 0.8≦a≦1.35, 0≦m≦5, 0≦x≦0.4, 1.7≦y≦2.5, and 4≦z≦7, respectively.The above particles of the present invention have a small average particle diameter, are spherical, disk-like or hexagonal and have an extremely narrow particle size distribution.

Owner:KYOWA CHEM IND

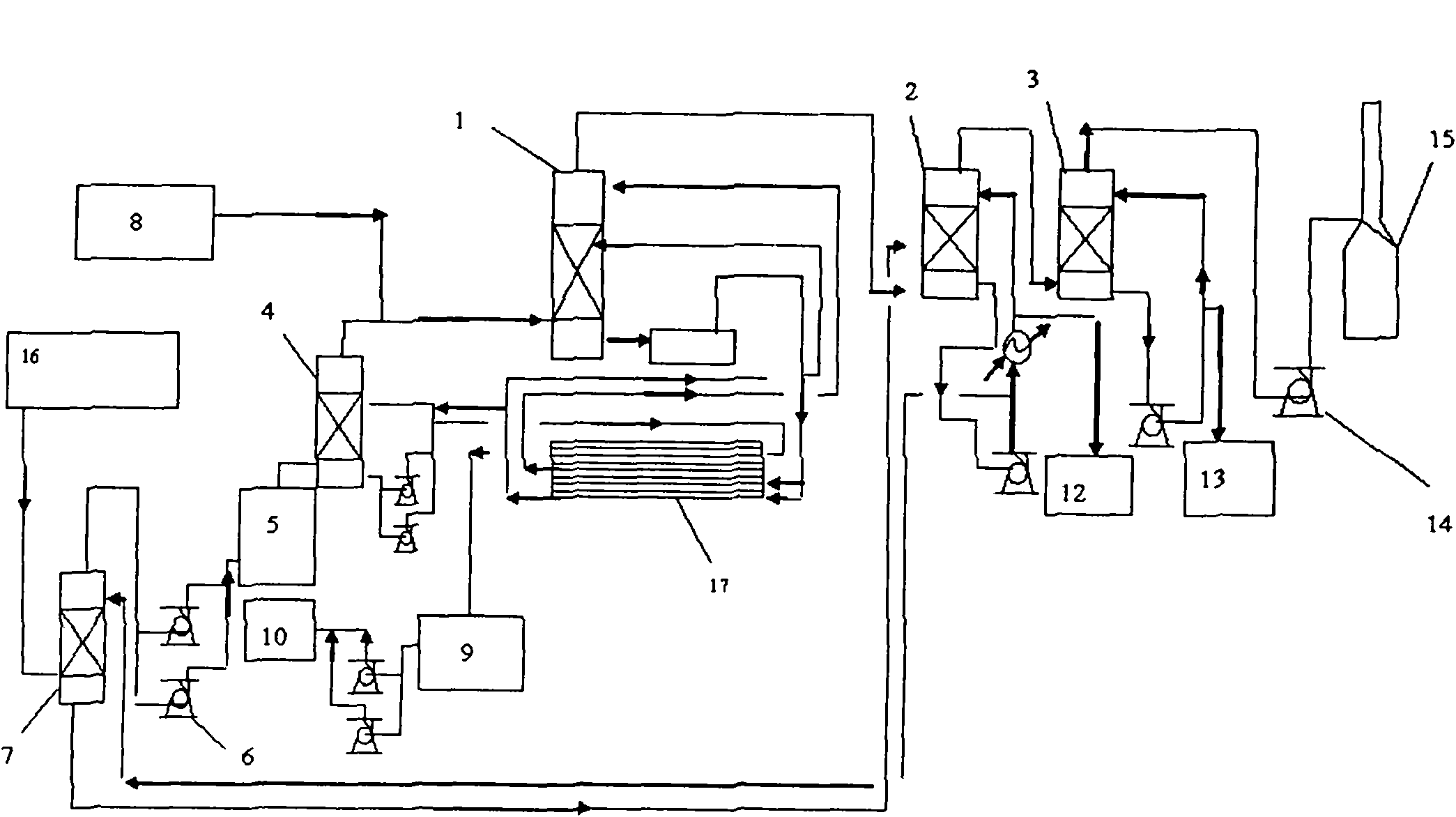

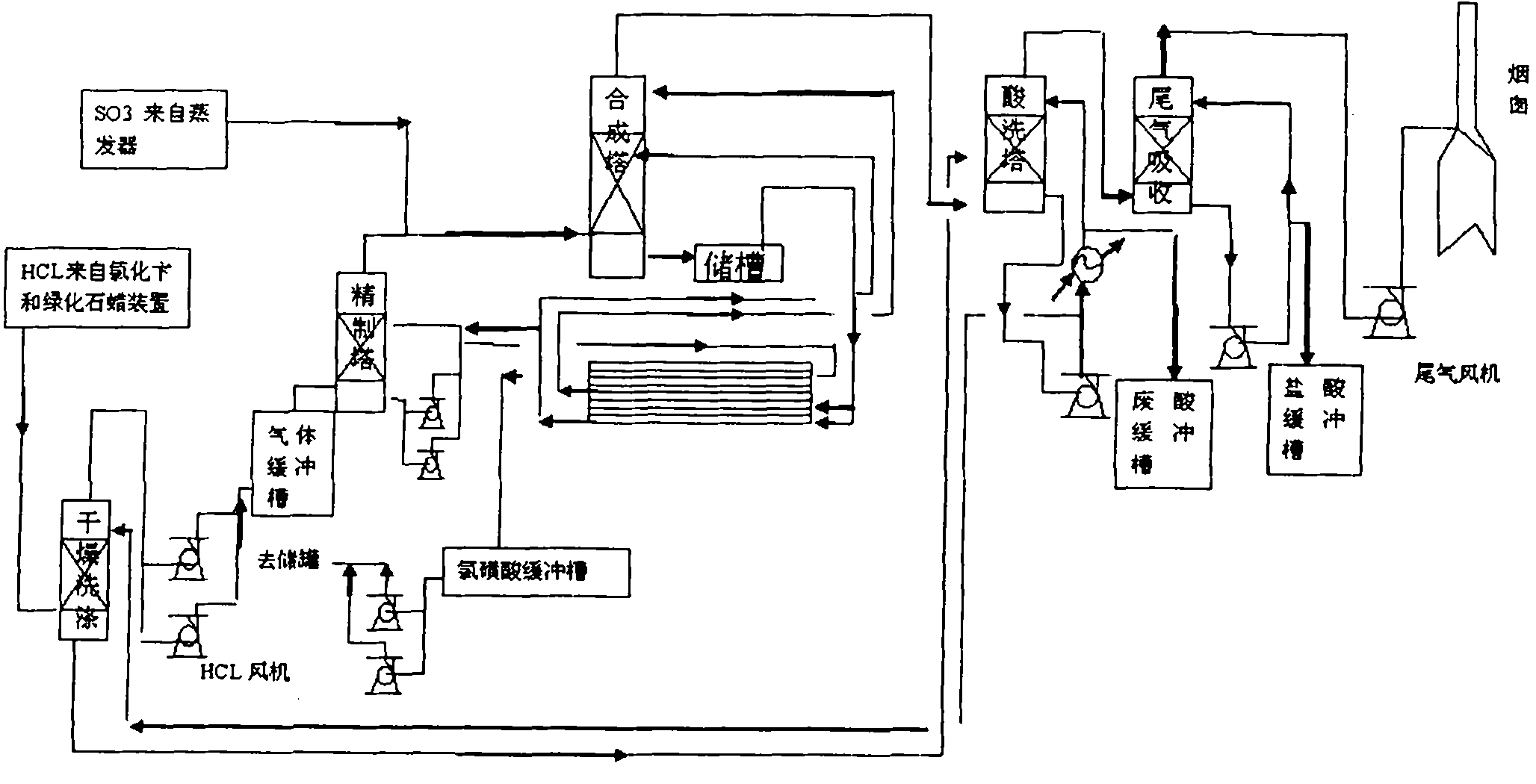

Chlorosulfonic acid production process and equipment thereof

InactiveCN101774549AEmission reductionFor the purpose of saving energy and reducing consumptionSulfur-halogen-hydrogen-oxygen compoundsAcid washingBenzyl chloride

The invention relates to a chlorosulfonic acid production process and equipment thereof, which belong to the technical field of chemical process. In the process, the tail gas of a benzyl chloride device and a chlorcosane device reacts with SO3 gas from a niacin evaporator. The equipment of the chlorosulfonic acid production process comprises a synthesizing tower, an acid-washing tower and a tail gas absorption tower, wherein the synthesizing tower is connected with a treating column; the treating column is connected with a gas buffer slot; the gas buffer slot is connected with an HCL drying washer by two HCL fans; and the HCL drying washer is connected with the benzyl chloride device and the chlorcosane device. The invention sufficiently utilizes the waste gas as the raw material, thereby saving resources, reducing pollution and reducing cost.

Owner:聊城鲁西氯甲烷化工有限公司

Thermocatalytically active coating, substrate having the thermocatalytically active coating at least in parts, and process for producing same

InactiveUS8008225B2Reduce the temperatureNitrogen compoundsSulfate/bisulfate preparationLithiumReflective layer

A substrate, such as a glass, glass ceramic, ceramic or metal substrate, is provided with a thermocatalytically active coating on at least a part of the substrate surface. The thermocatalytic coating contains an inorganic lithium salt or organic lithium-containing compound in an amount that is equivalent to not less than 2 wt. % of lithium ions, based on total coating weight. The thermocatalytic coating has a glass, glass solder or sol-gel matrix in which the lithium salt or organic lithium-containing compound is introduced. Optional barrier and IR-reflecting layers are arranged between the substrate surface and the thermocatalytically active coating.

Owner:SCHOTT AG

Method for production of sulfur hexafluoride from sulfur tetrafluoride

InactiveUS20120164060A1Increase ratingsFacilitated DiffusionInorganic gasesFluoride preparationStationary phaseSulfur tetrafluoride

Disclosed is a method for an energy-efficient improvement in the production of sulfur hexafluoride, and eliminates the generation of other byproducts. The process is an oxidative fluorination of sulfur tetrafluoride by CoF3 / F2, where CoF3 is solid stationary phase that can be regenerated.

Owner:OMOTOWA BAMIDELE A

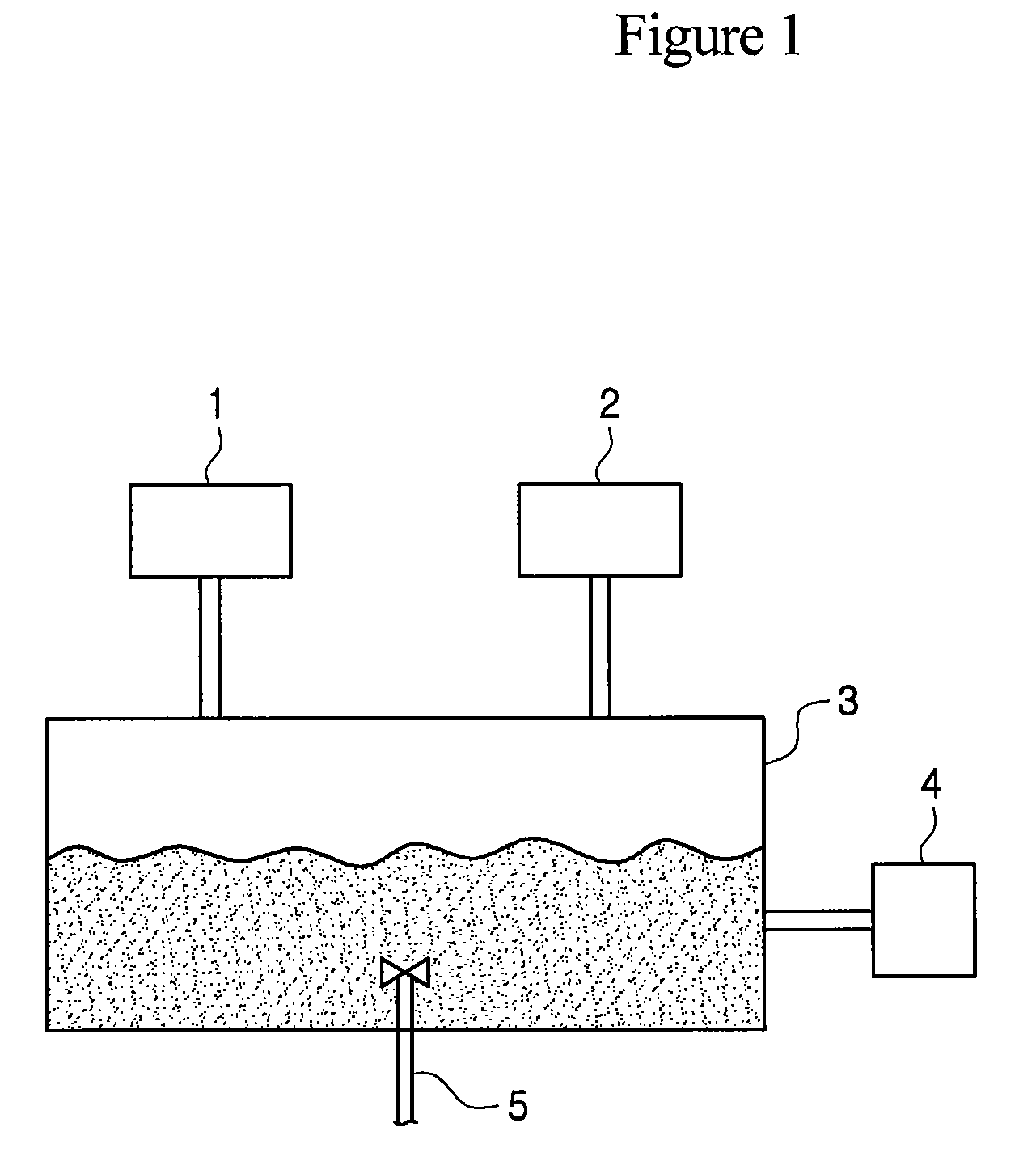

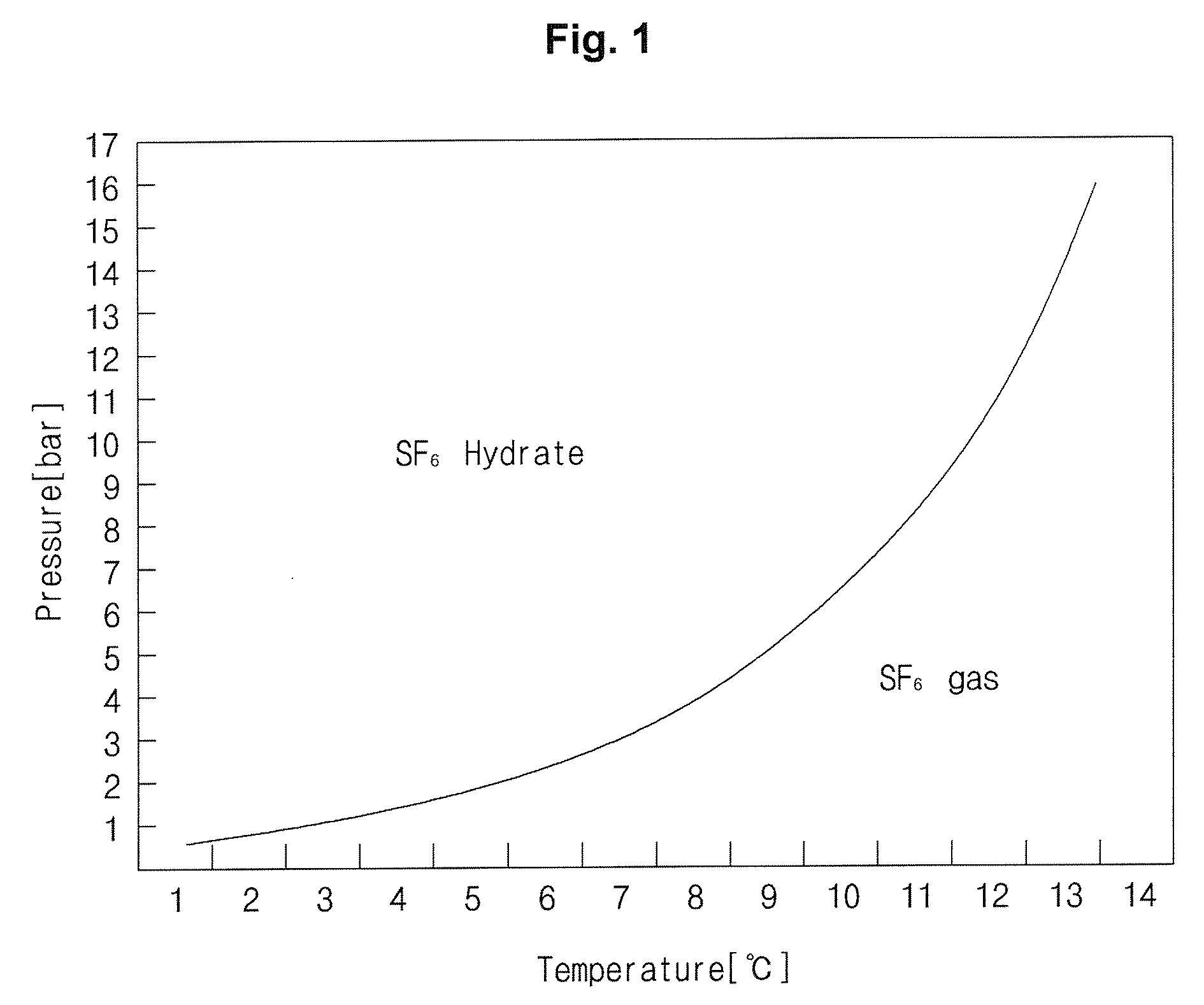

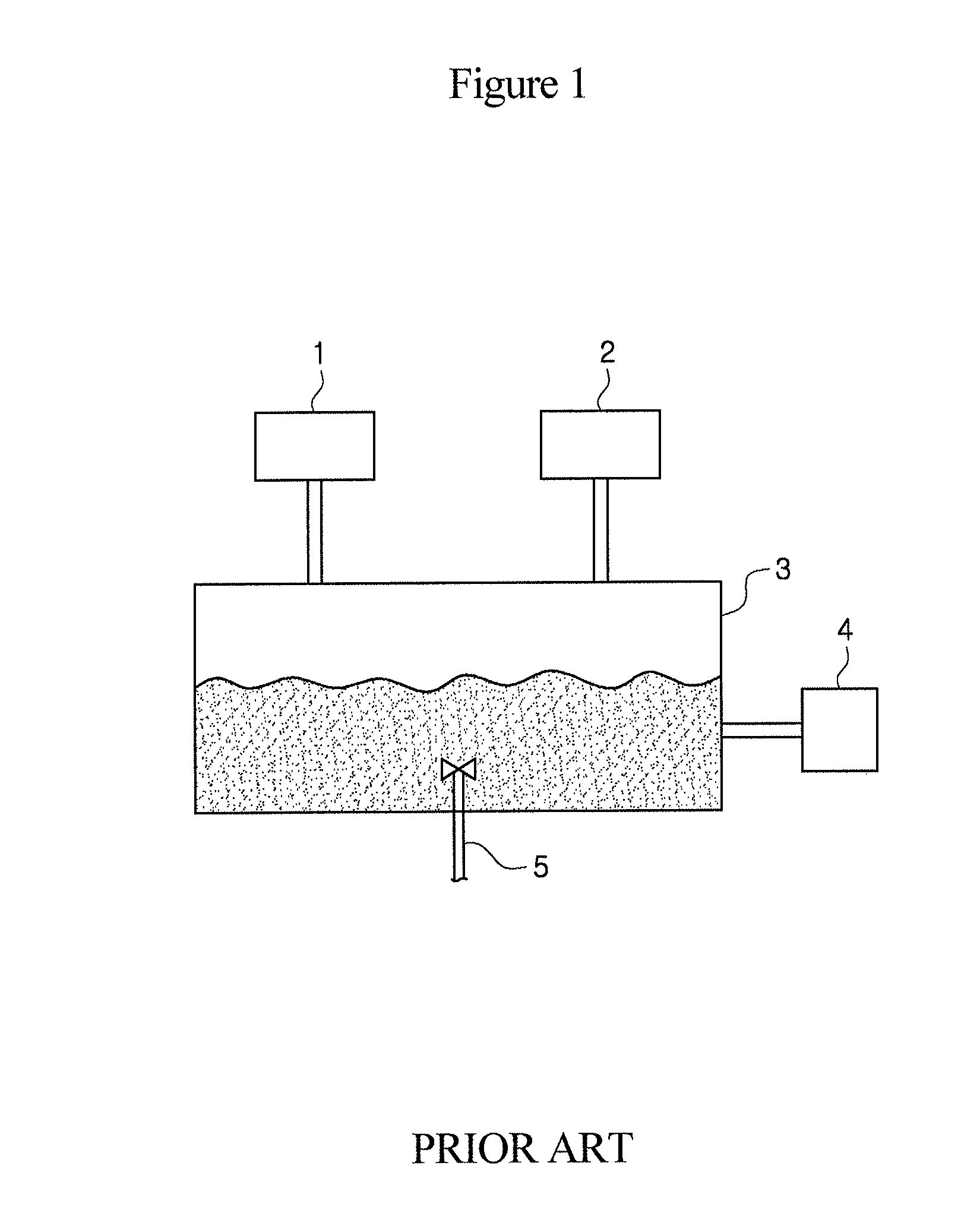

SEPARATION, PURIFICATION AND RECOVERY METHOD OF SF6, HFCs AND PFCs

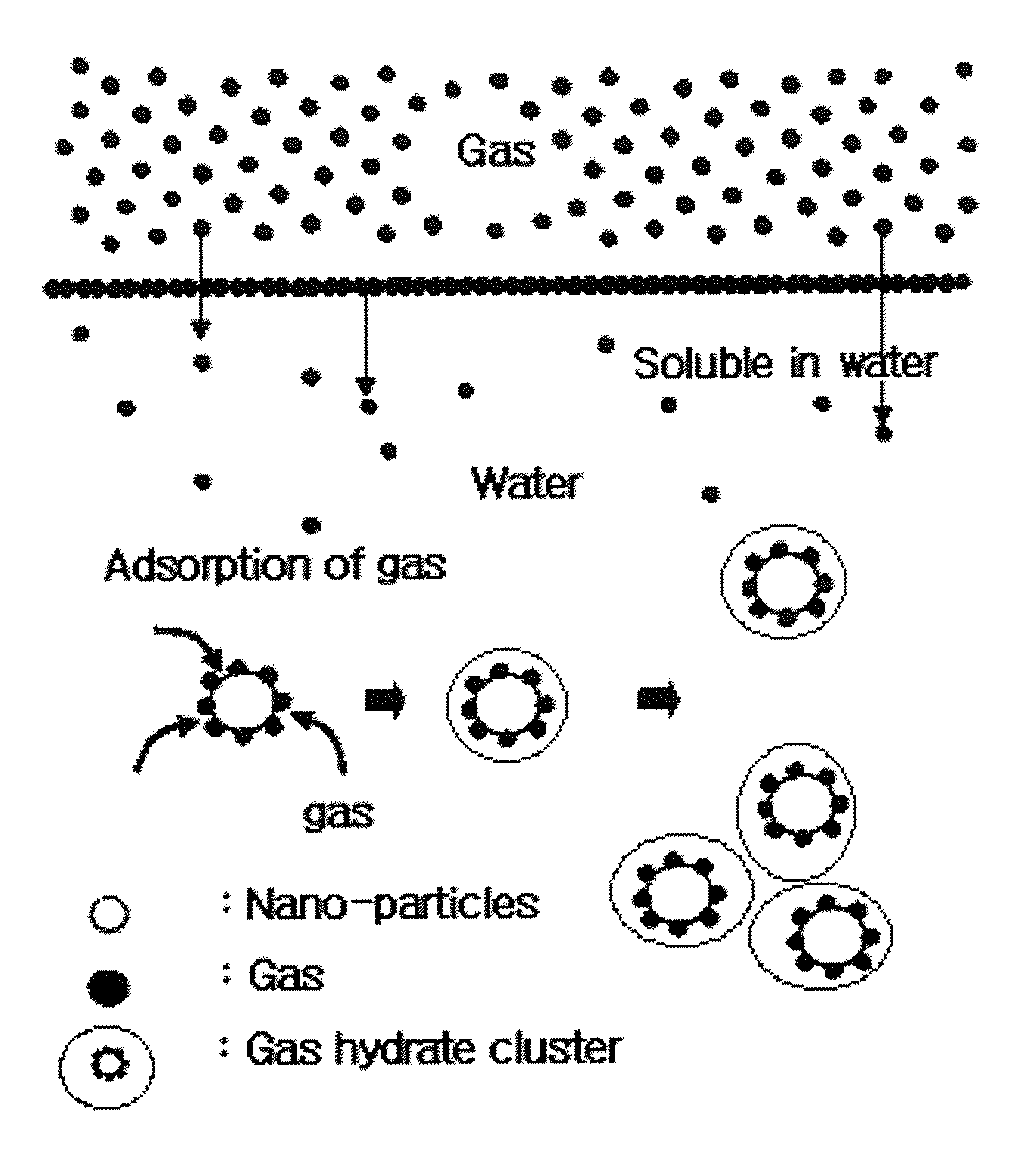

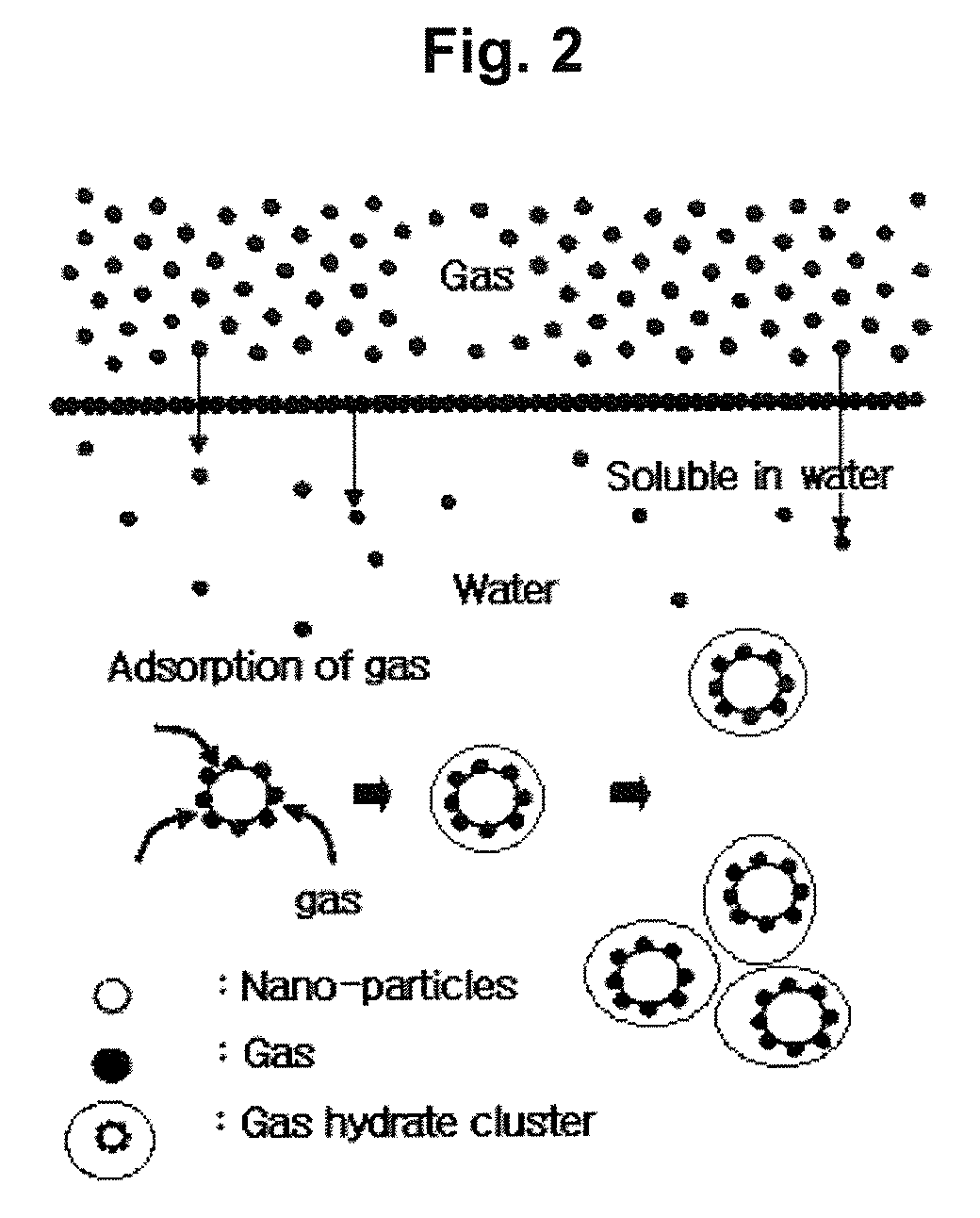

InactiveUS20090114096A1Reduce energy consumptionRespond effectivelyGas treatmentMethane captureRecovery methodProduct gas

A separation, purification and recovery method of SF6, HFCs or PFCs is disclosed, which comprises a step for forming a gas hydrate including components in addition to SF6, HFCs or PFCs. It is possible to separate and recover fluoro-gas at a much lower cost as compared to a conventional method for thereby obtaining an economical effect and preventing an emission of SF6, HFCs or PFCs which corresponds to Non-CO2 having a higher earth warming index, which leads to preventing an earth warming phenomenon. So, the present invention might be widely applied.

Owner:YS CO LTD

Method for production of sulfur hexafluoride from sulfur tetrafluoride

InactiveUS8231855B2Increase ratingsFacilitated DiffusionInorganic gasesFluoride preparationStationary phaseSulfur hexafluoride

Disclosed is a method for an energy-efficient improvement in the production of sulfur hexafluoride, and eliminates the generation of other byproducts. The process is an oxidative fluorination of sulfur tetrafluoride by CoF3 / F2, where CoF3 is solid stationary phase that can be regenerated.

Owner:OMOTOWA BAMIDELE A

Process for producing ammonium polythiomolybdate

ActiveUS20050089462A1Nitrogen compoundsSulfur-halogen-hydrogen-oxygen compoundsMolybdateAmmonium tetrathiomolybdate

A process for producing an ammonium polythiomolybdate of the formula (NH4)2Mo3S13.nH2O where n is 0, 1 or 2 in which an aqueous ammoniacal molybdate solution is reacted with hydrogen sulfide gas in a closed system at superatmospheric pressure until the H2S is no longer absorbed by the solution to form a slurry of solid ammonium tetrathiomolybdate containing a portion of the starting molybdenum in a mother liquor containing the balance of the molybdenum and thereafter heat soaking the reaction product in the presence of elemental sulfur to form the desired product.

Owner:INFINEUM INT LTD

Alkali/transition metal halo-and hydroxy-phosphates and related electrode active materials

InactiveUS8367036B2Increase capacityImprove cycle performancePhosphatesFluoride preparationHalogenPhosphate

The invention provides a novel polyanion-based electrode active material for use in a secondary or rechargeable electrochemical cell, wherein the electrode active material is represented by the general formula AaMb(SO4)2Zd.

Owner:VALENCE TECH INC

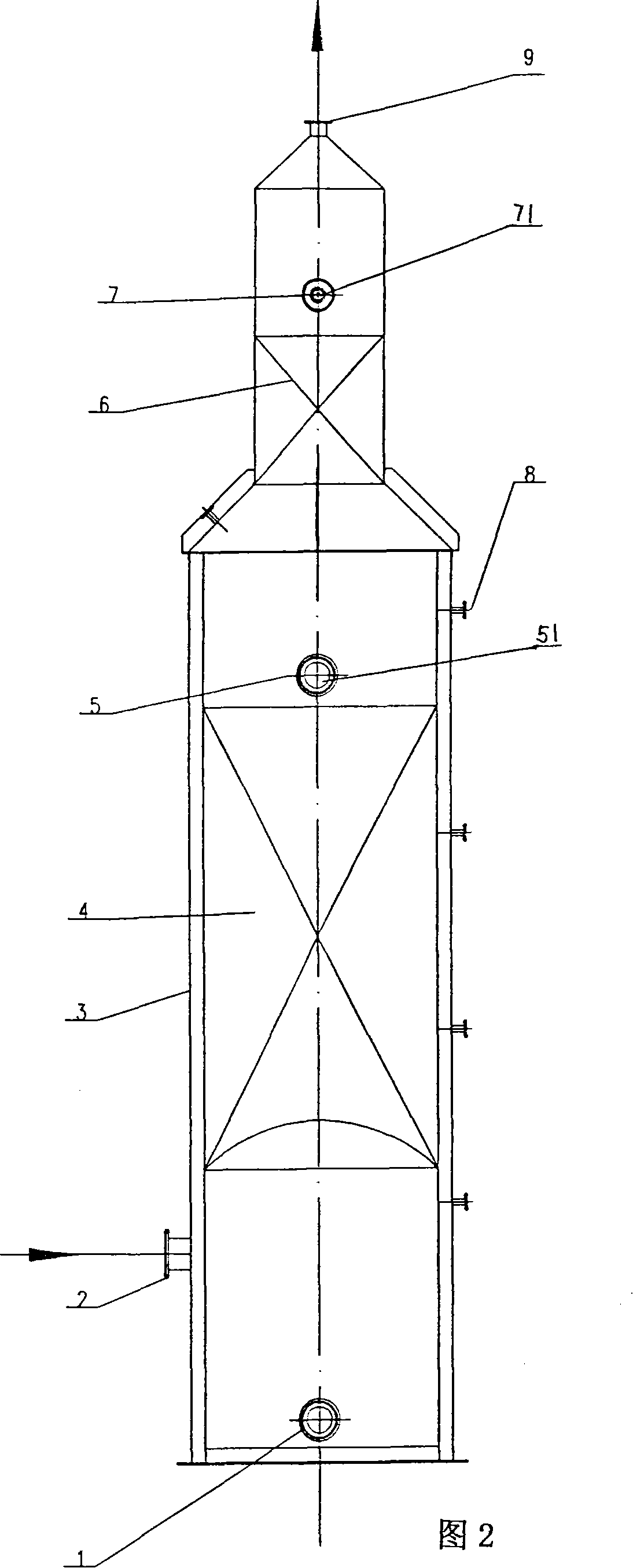

New process for preparing chlorosulfonic acid and equipment thereof

InactiveCN101134565AExtended stayImprove conversion rateSulfur-halogen-hydrogen-oxygen compoundsSulfur trioxidePre treatment

The present invention is process and apparatus for preparing chlorosulfonic acid. The process includes the following steps: pre-treating high purity hydrogen chloride and excessive sulfur trioxide gas, and synthesizing in a synthesizing tower; absorbing the gaseous resultant with the sprayed liquid resultant and reacting to produce small drop as the coarse liquid chlorosulfonic acid product; further reacting the coarse liquid chlorosulfonic acid product with hydrogen chloride gas in a refining tower to operate product, and absorbing un-reacted gas to reach exhaust standard. The present invention has the advantages of high product converting rate, small size of cooler, compact structure of synthesizing tower, high product purity, etc.

Owner:上海海陆昆仑高科技工程有限公司 +1

Method for inhibiting generation of chlorosulfuric acid in thionyl chloride preparation process

InactiveCN104445091AQuality improvementSulfuryl chloride content decreasedSulfur-halogen-hydrogen-oxygen compoundsThionyl chlorideChlorosulfuric acidSulfur dichloride

The invention relates to a method for inhibiting generation of chlorosulfuric acid in a thionyl chloride preparation process. The method comprises the following steps: feeding a raw material gas mixture prepared from sulfur dioxide, sulfur dichloride and chlorine to a catalytic reactor after pre-heating, and reacting to obtain thionyl chloride; and preheating the gas mixture to 120-180 DEG C. Chlorosulfuric acid in a crude product thionyl chloride is inhibited within 1% from 2%, so that the quality of the crude product thionyl chloride is greatly improved; reduction of the content of chlorosulfuric acid in subsequent refined products is facilitated; and the generation condition through chlorosulfuric acid is avoided.

Owner:SHANDONG KAISHENG NEW MATERIALS

Sulfuryl fluoride preparation method

ActiveCN103864022ASimple processSimple equipmentSulfur-halogen-hydrogen-oxygen compoundsSulfuryl fluorideFluoridation reaction

The invention provides a sulfuryl fluoride preparation method using sulfuryl chloride as a raw material by two-stage fluorination reaction, the sulfuryl fluoride preparation method has the advantages of simple technology and equipment, easy enlarging production, high product purity and the like, and prepared sulfuryl fluoride can be used as a fumigant to replace methyl bromide.

Owner:SINOCHEM LANTIAN +1

Apparatus and method for continuously producing and pelletizing gas hydrates using dual cylinder

Owner:KOREA INST OF IND TECH +2

Methods of preparing a polymerization catalyst

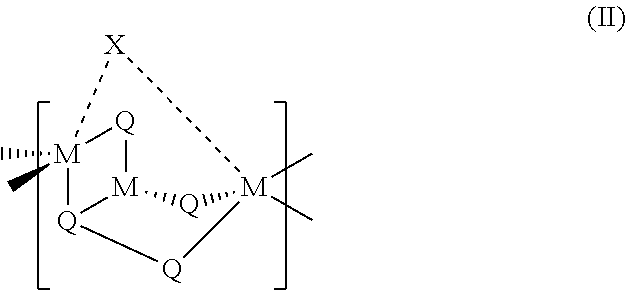

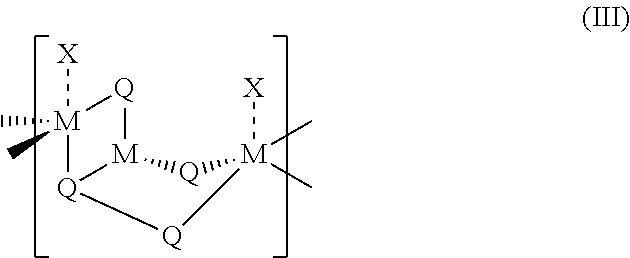

ActiveUS20080287287A1Other chemical processesSulfur-halogen-hydrogen-oxygen compoundsPolymerization catalystsOrganic chemistry

A method of preparing a composition comprising dry mixing commercial grade alumina and a solid sulfating agent to form a mixture and calcining the mixture to form a sulfated alumina support.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Popular searches

Energy based wastewater treatment Glass/slag layered products Wood layered products Natural mineral layered products Bismuth compounds Metal layered products Water/sewage treatment by oxidation Water/sewage treatment by irradiation Water treatment compounds Peroxides/peroxyhydrates/peroxyacids/superoxides/ozonides

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com