Technology of synthesizing high concentration chlorosulfonic acid using low concentration salfur trioxide

A technology of sulfur trioxide and chlorosulfonic acid, which is applied in the direction of sulfur-halogen-hydrogen-oxygen compounds, etc., can solve the problems of high replacement cost and difficulty, increased cost, and high heat consumption, and reduce equipment maintenance costs and exhaust emissions The effect of reducing the quantity and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

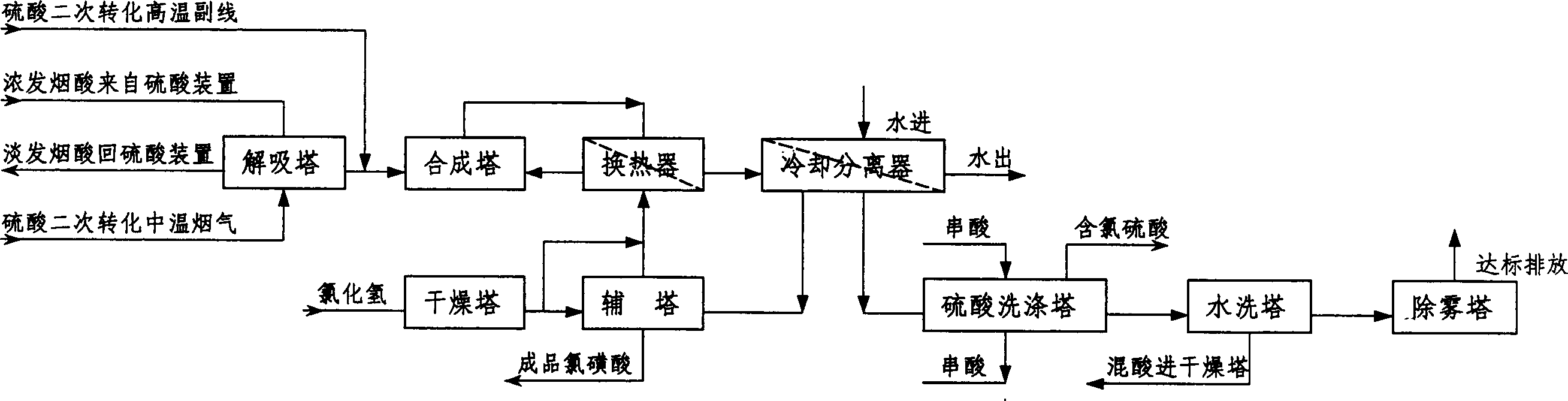

[0022] Example: such as figure 1 Shown, a kind of new technology that adopts low-concentration sulfur trioxide to synthesize high-concentration chlorosulfonic acid comprises the following steps:

[0023] (1) The free sulfur trioxide concentration produced by the sulfuric acid plant is oleum with a concentration of more than 28%. After preliminary preheating, it is sent into the sulfur trioxide desorption tower, and desorbed under normal pressure. The latent heat required for sulfur trioxide desorption It is provided by the flue gas above 330°C after secondary conversion from the sulfuric acid plant. After enhanced heat and mass transfer, the gas leaving the desorption tower with a sulfur trioxide content of 15-25% and a temperature of 120-140°C is combined with the gas from the sulfuric acid plant. After the secondary conversion, the high-temperature auxiliary line flue gas is mixed, the temperature reaches 160-230°C, and the sulfur trioxide concentration reaches 10-15%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com