Chlorosulfonic acid production process and equipment thereof

A production process, chlorosulfonic acid technology, applied in the direction of sulfur-halogen-hydrogen-oxygen compounds, etc., can solve the problems of high energy consumption of circulating water, increase of equipment and pipelines, large cooling capacity of reaction gas, etc., to reduce tail gas The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

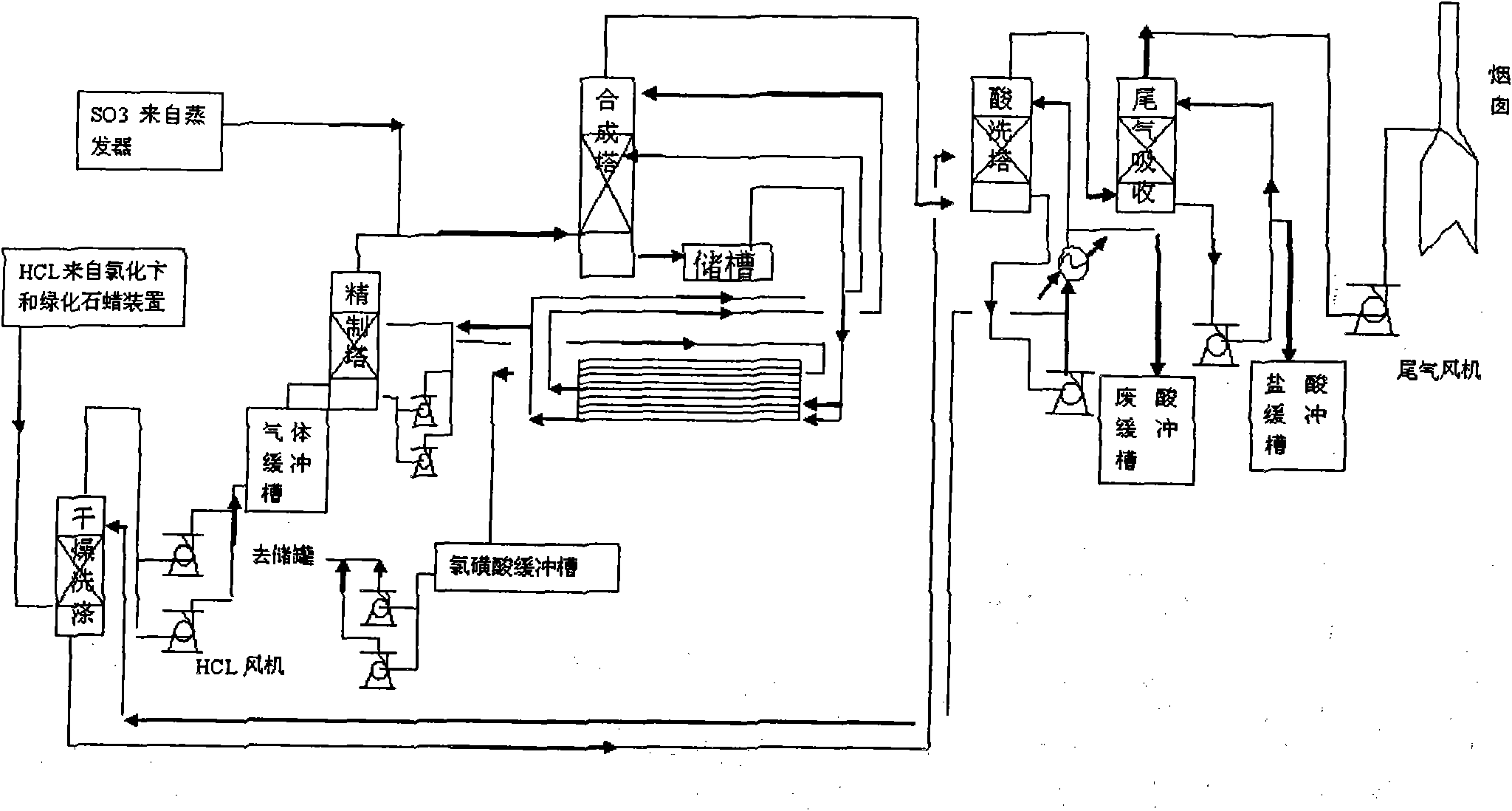

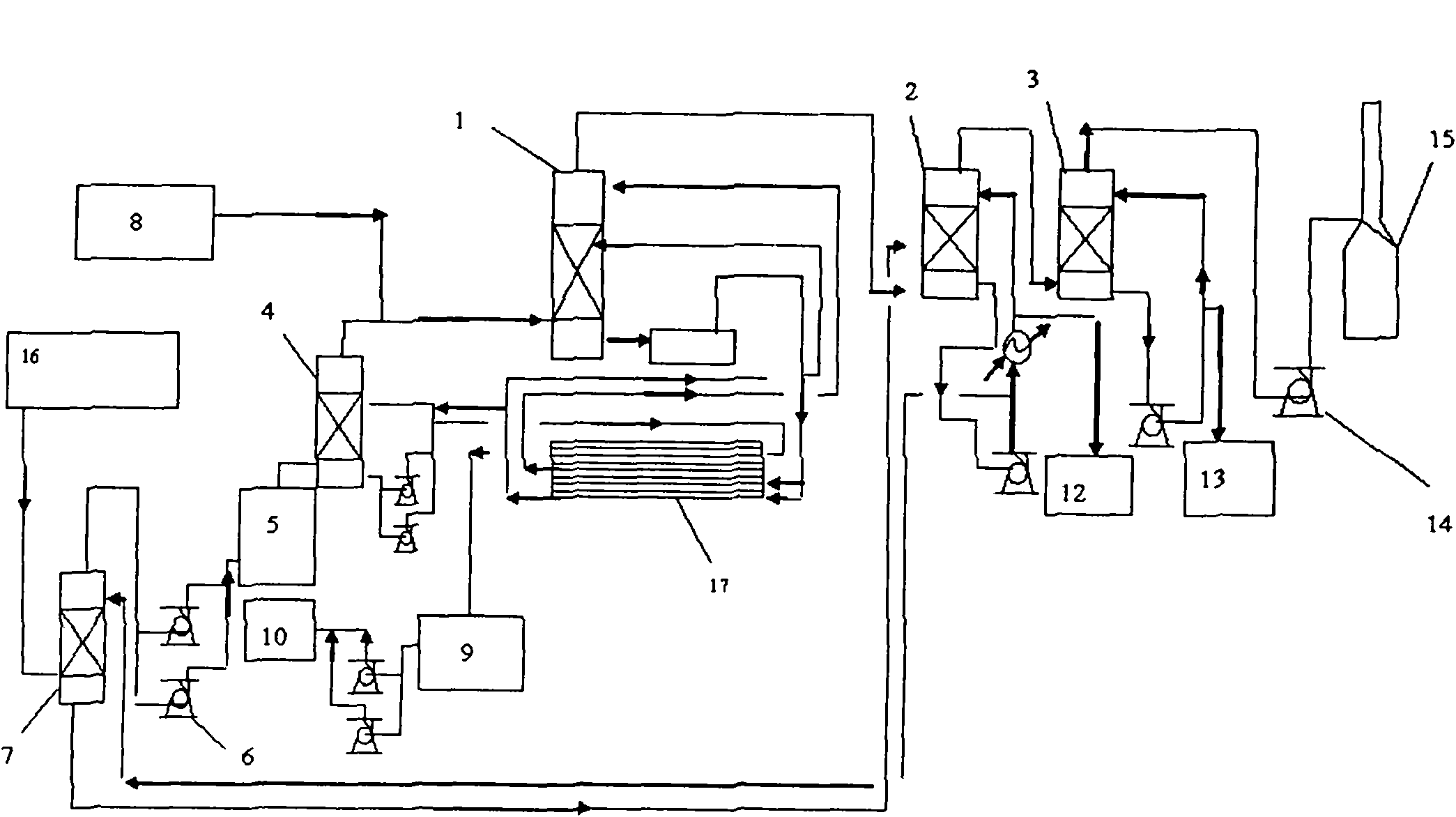

[0024] A kind of chlorosulfonic acid production technique:

[0025] The tail gas HCL gas from Lanwei benzyl chloride unit and chlorinated paraffin unit is cryogenically cooled to -30°C and then sent to the HCL dry scrubber. The HCL dry scrubber uses 98% sulfuric acid to circulate and absorb the moisture in the HCL gas. At the outlet of the dry scrubber, two fans, one on and one on, are used to pump the dry HCL gas to the gas buffer tank, and the HCL gas enters the refining tower from the gas buffer tank. At this time, the HCl gas concentration is above 99.5%. The chlorosulfonic acid crude product returned from the synthesis tower is recycled to absorb HCL gas, so that the excess SO in the chlorosulfonic acid crude product 3 The gas reacts completely with HCL gas, and the high-concentration chlorosulfonic acid finished product flows into the cold row from the bottom of the refining tower, flows into the chlorosulfonic acid buffer tank after exchanging heat in the cold row, and ...

Embodiment 2

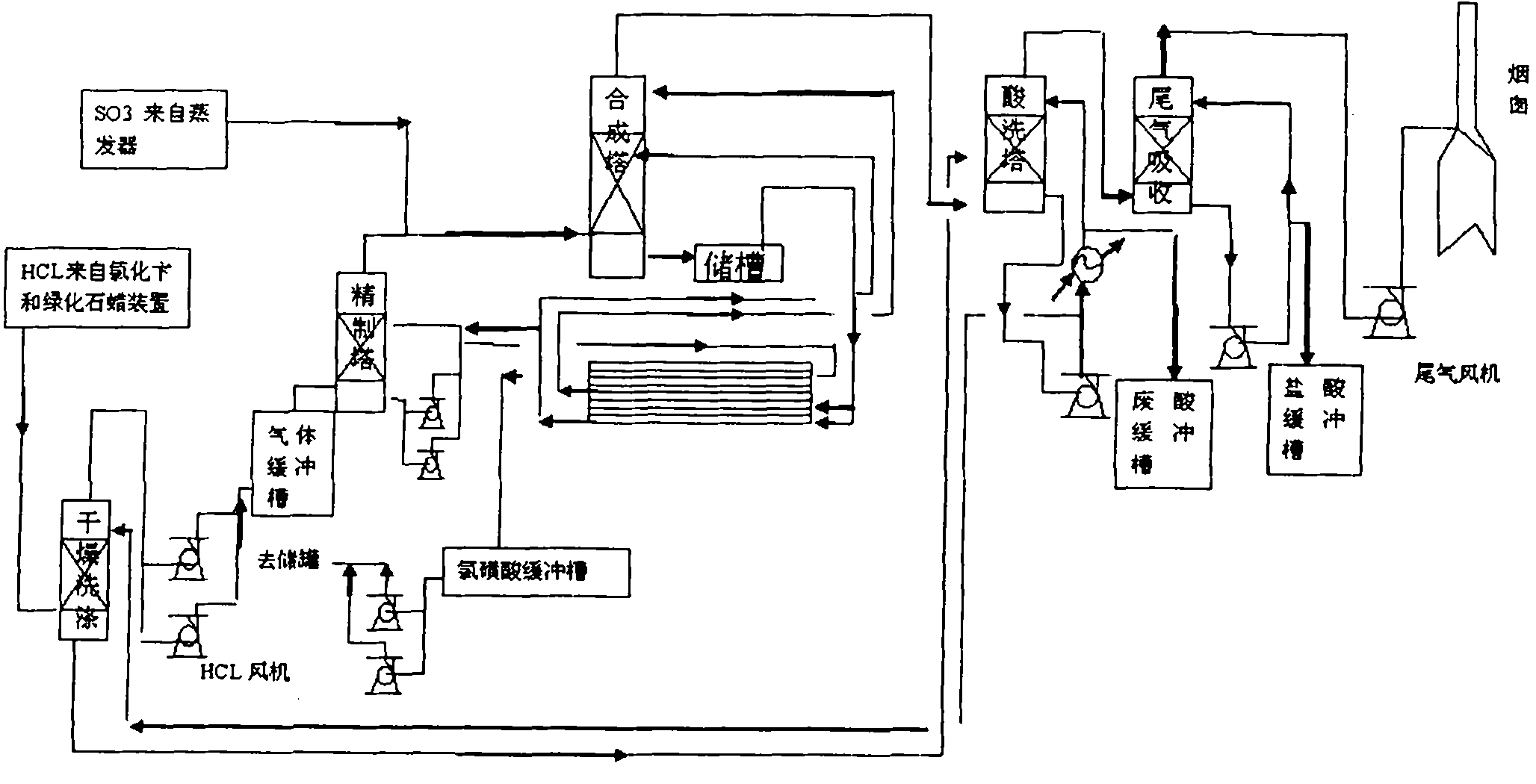

[0029] A kind of chlorosulfonic acid production technique:

[0030] The tail gas HCL gas from Lanwei benzyl chloride unit and chlorinated paraffin unit is cryogenically cooled to -20°C and then sent to the HCL dry scrubber. The HCL dry scrubber uses 98% sulfuric acid to circulate and absorb the moisture in the HCL gas. At the outlet of the dry scrubber, two fans, one on and one on, are used to pump the dry HCL gas to the gas buffer tank, and the HCL gas enters the refining tower from the gas buffer tank. At this time, the HCl gas concentration is above 99.5%. The chlorosulfonic acid crude product returned from the synthesis tower is recycled to absorb HCL gas, so that the excess SO in the chlorosulfonic acid crude product 3 The gas reacts completely with HCL gas, and the high-concentration chlorosulfonic acid product flows into the cold row from the bottom of the refining tower, and flows into the chlorosulfonic acid buffer tank after exchanging heat in the cold row, and is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com