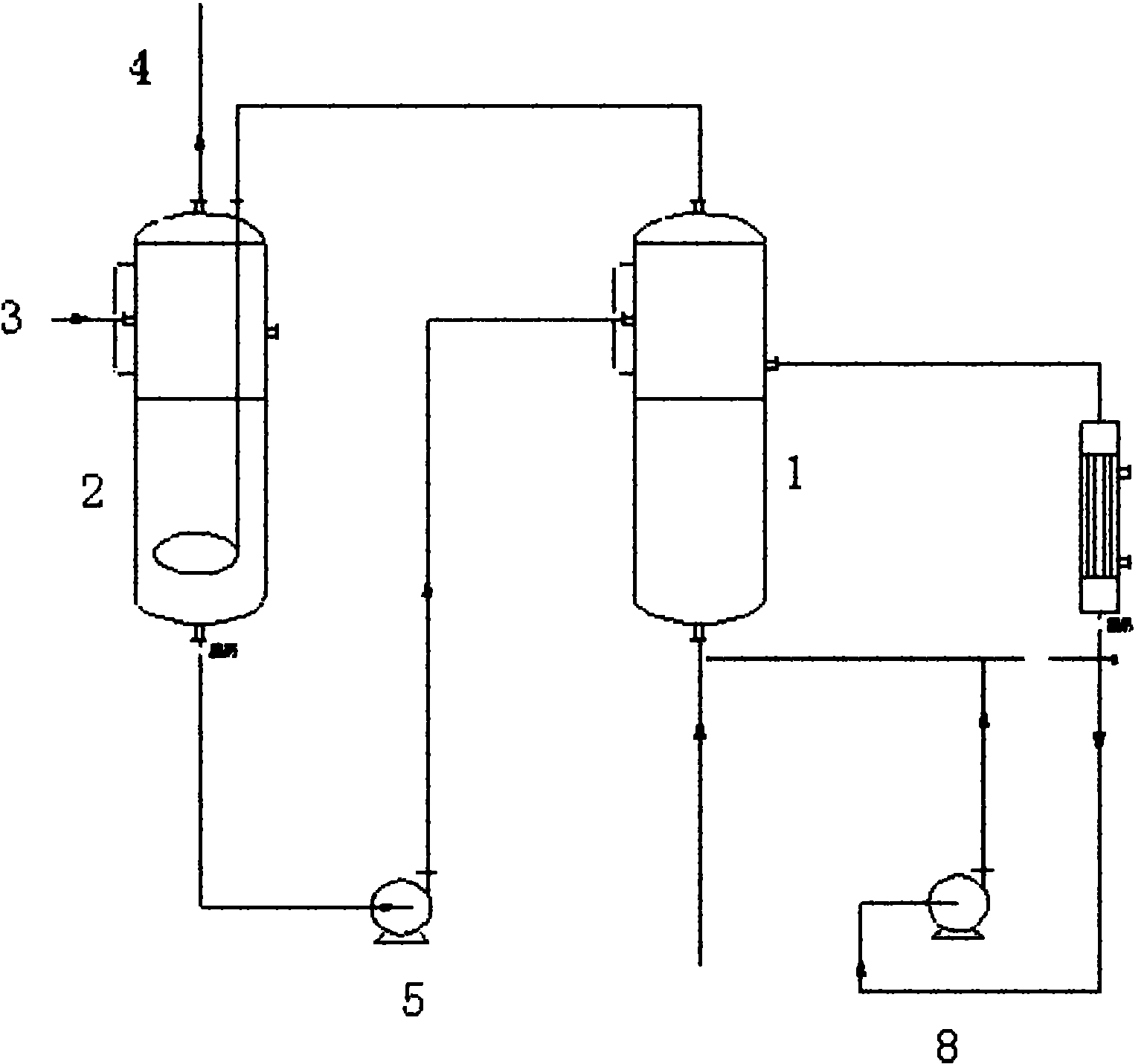

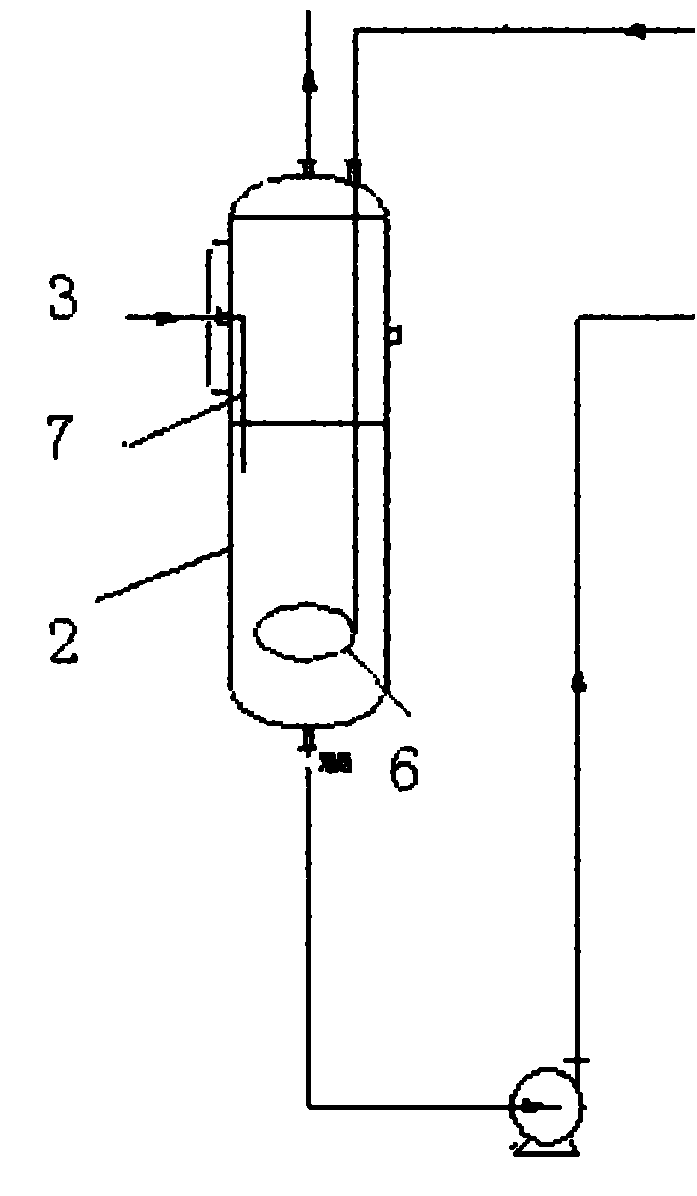

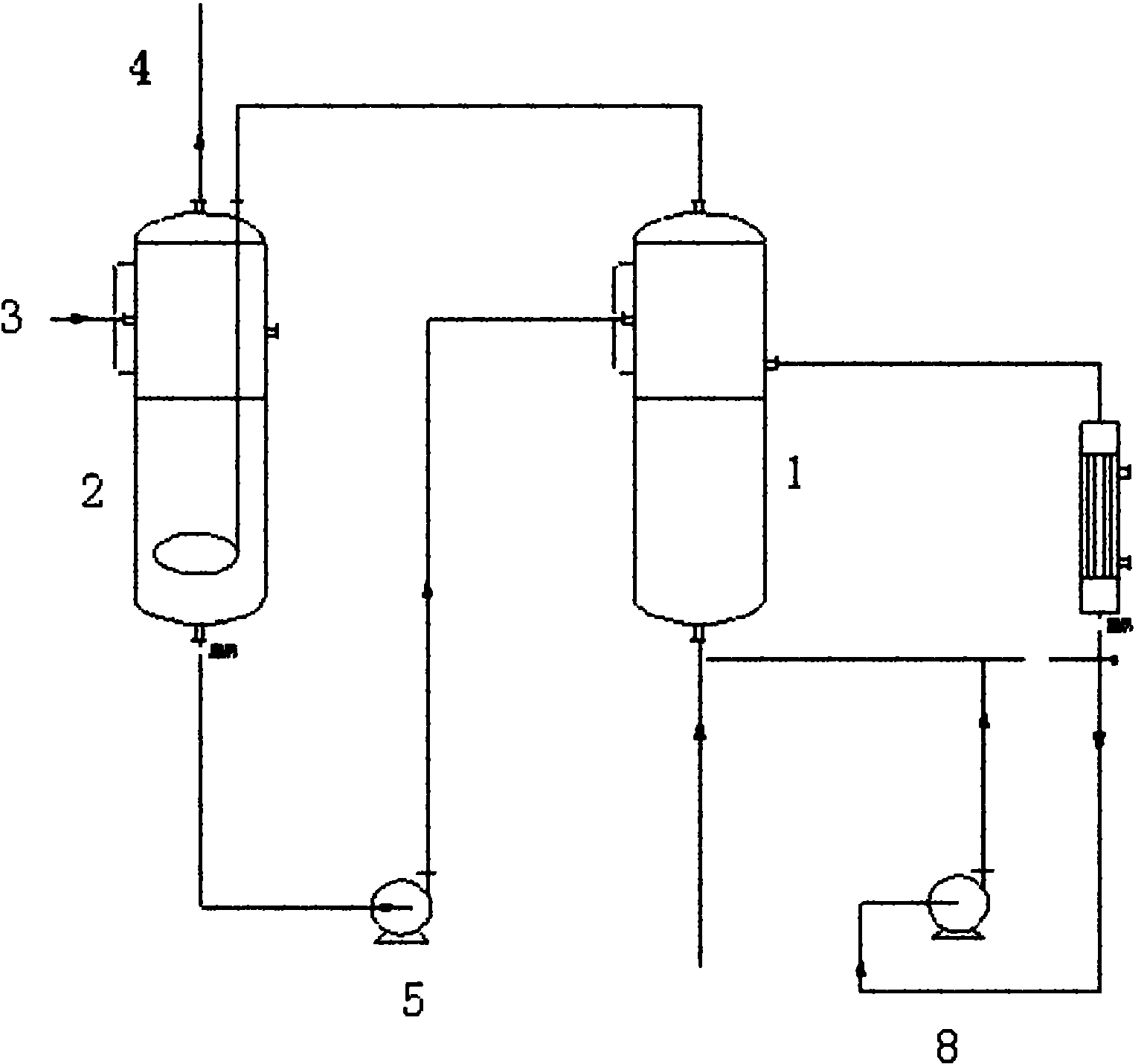

Dechloridation device and process in chlorinated paraffin production process

A production process and technology for chlorinated paraffin, applied in the field of chlorine devices, can solve the problems of excess chlorine, hydrogen chloride can not meet the production of chlorosulfonic acid, large consumption of chlorine, etc., to achieve improved utilization, considerable economic benefits and practicality, and improved The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A dechlorination process in the production process of chlorinated paraffin. The chlorination tail gas produced by the chlorination reaction is passed into the hot liquid wax for dechlorination reaction. The gas after the dechlorination reaction is discharged from the hydrogen chloride outlet, and the resulting liquid wax contains The liquid substance is used as the raw material for continuing the chlorination reaction after removing impurities.

[0019] step

[0020] 1. Put the liquid wax into the dechlorination kettle. (The temperature of liquid wax is 90℃, the flow rate is 3m 3 / h, powered by a centrifugal pump)

[0021] 2. The liquid wax level in the dechlorination kettle is controlled at two-thirds.

[0022] 3. Introduce chlorine and hydrogen gas from the chlorination system. (hydrogen chloride gas temperature 50°C, flow rate 500m 3 / h, pressure 0.02-0.06MPa)

[0023] 4. Dechlorination and other reactions are carried out in the kettle: chlorine gas and wax oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com