Method for treating tail gas of thionyl chloride chlorination

A chlorination reaction, thionyl chloride technology, applied in the directions of chlorine/hydrogen chloride, chemical instruments and methods, separation methods, etc., can solve the problems of unapplied mixed acid, high environmental pressure, and high processing cost, and achieve complete absorption and lightening. The effect of environmental protection pressure and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

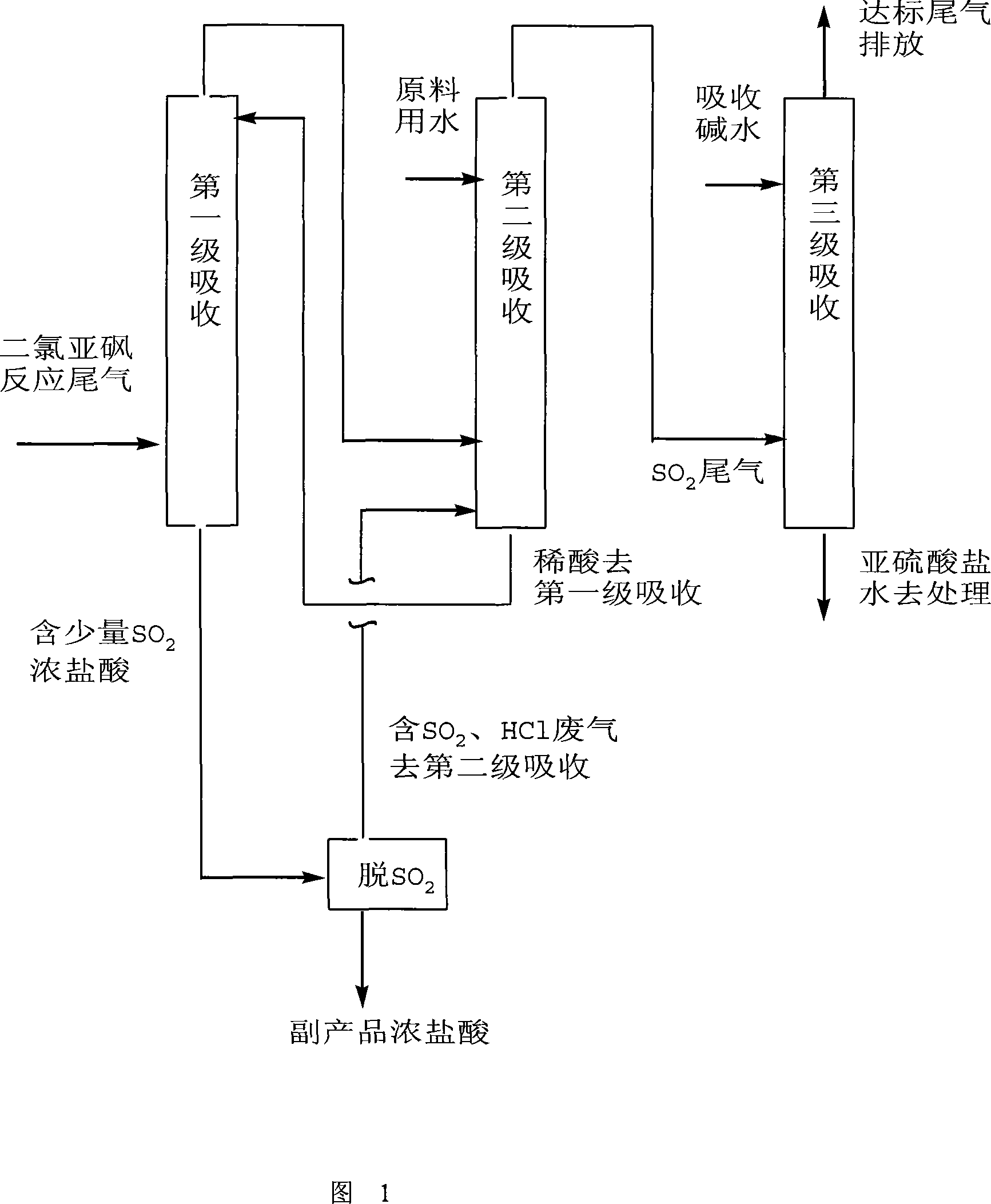

Embodiment 1

[0027] The tail gas produced after the reaction of one mole of thionyl chloride with the alcoholic hydroxyl group is absorbed at 20°C by 70 grams of water (first-stage absorption), absorbed at 20°C by 70 grams of water (second-stage absorption) and composed of 40 grams of sodium hydroxide and 100 The aqueous solution prepared with gram of water is absorbed at 20°C (the third level of absorption) and then discharged. The exhaust gas is tested according to the method of the State Environmental Protection Administration standard HJ / T56-2000, and the sulfur dioxide content is 60mg / m 3 (to meet the emission requirements of the State Environmental Protection Administration). The sulfur dioxide content is 5.35 grams / 100 gram solution in the first stage absorption liquid (the concentrated hydrochloric acid that is obtained containing a small amount of sulfur dioxide), and the hydrogen chloride content is 38.50 grams / 100 gram solution; Sulfur dioxide content in the dilute hydrochloric ...

Embodiment 2

[0029] The tail gas produced after the reaction of one mole of thionyl chloride with the alcoholic hydroxyl group is absorbed through 76 grams of dilute acidic water at 20°C (the first level of absorption, the second level of absorption solution in Example 1, i.e. the dilute hydrochloric acid obtained), 70 grams Water is absorbed at 20°C (the second level of absorption, fresh water) and an aqueous solution prepared by 40 grams of sodium hydroxide and 100 grams of water is absorbed at 20°C (the third level of absorption) and then discharged. The exhaust gas is in accordance with the standard HJ / T56- 2000 method detection, sulfur dioxide content is 80mg / m 3 (to meet the emission requirements of the State Environmental Protection Administration). The content of sulfur dioxide in the first-stage absorption liquid is 5.27 g / 100 g solution, the content of hydrogen chloride is 37.85 g / 100 g solution; the content of sulfur dioxide in the second-stage absorption liquid is 5.45 g / 100 g ...

Embodiment 3

[0031] The tail gas produced after the reaction of one mole of thionyl chloride and the alcoholic hydroxyl group is absorbed through 79.5 grams of dilute acidic water at 20°C (the first level of absorption, the second level of absorption solution in Example 2), and 70 grams of water at 20°C (the second level of absorption). Secondary absorption, fresh water) and an aqueous solution prepared by 40 grams of sodium hydroxide and 100 grams of water at 20°C (third stage absorption) and then discharged, the exhaust gas is tested according to the method of the State Environmental Protection Administration standard HJ / T56-2000, sulfur dioxide The content is 70mg / m 3(to meet the emission requirements of the State Environmental Protection Administration). The content of sulfur dioxide in the first-stage absorption liquid is 5.43 g / 100 g solution, the content of hydrogen chloride is 38.65 g / 100 g solution; the content of sulfur dioxide in the second-stage absorption liquid is 5.30 g / 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com