Patents

Literature

55results about "Sulfite preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

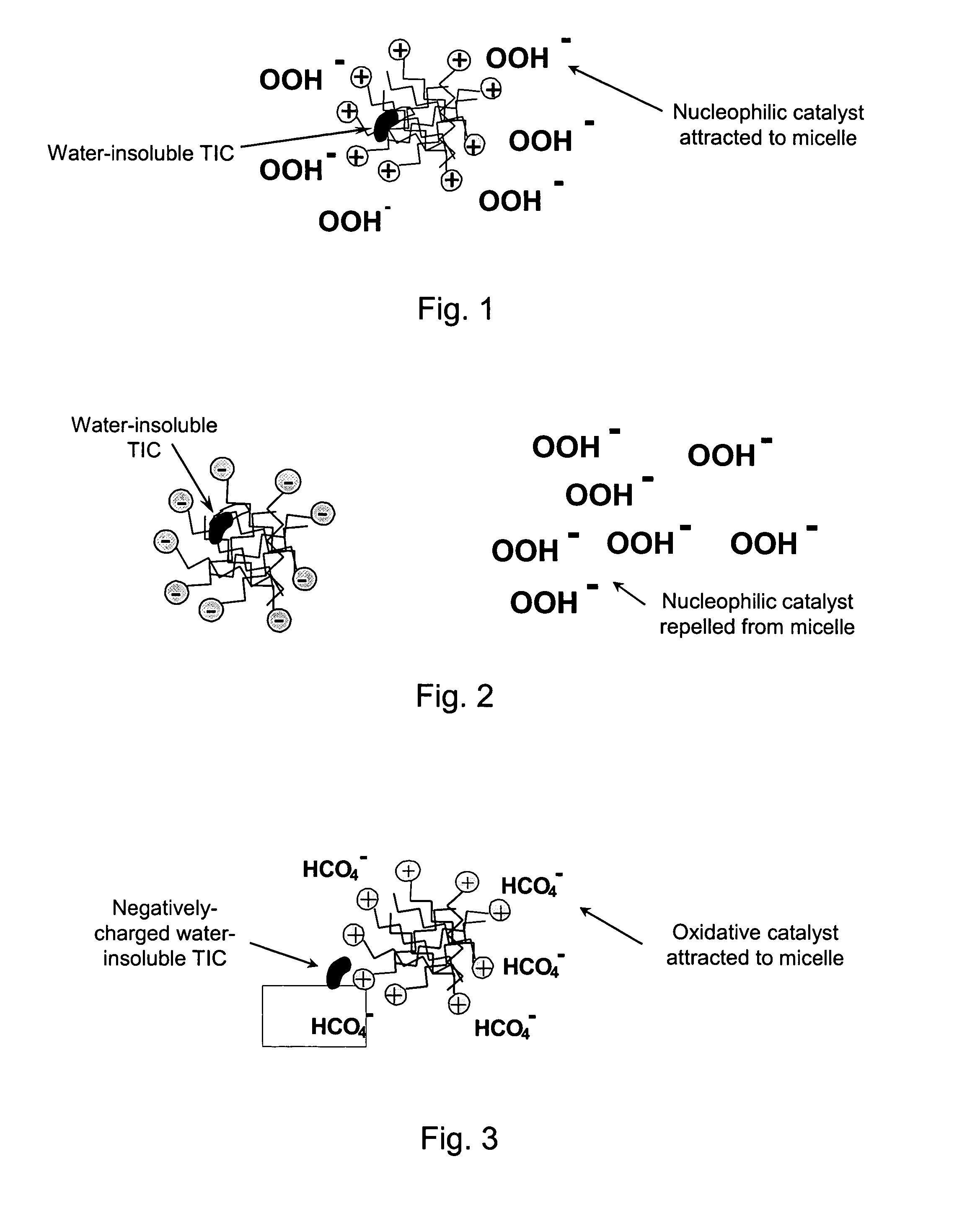

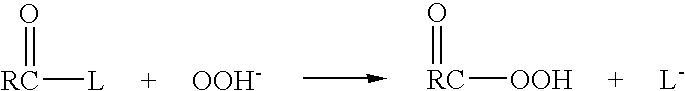

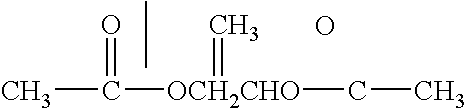

Reactive formulations for a neutralization of toxic industrial chemicals

InactiveUS7125497B1Efficiently neutralizedHydrogen peroxideLiquid degasificationBoron trichlorideMalathion

Decontamination formulations for neutralization of toxic industrial chemicals, and methods of making and using same. The formulations are effective for neutralizing malathion, hydrogen cyanide, sodium cyanide, butyl isocyanate, carbon disulfide, phosgene gas, capsaicin in commercial pepper spray, chlorine gas, anhydrous ammonia gas; and may be effective at neutralizing hydrogen sulfide, sulfur dioxide, formaldehyde, ethylene oxide, methyl bromide, boron trichloride, fluorine, tetraethyl pyrophosphate, phosphorous trichloride, arsine, and tungsten hexafluoride.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Scavenger for aldehyde(s) and a manufacturing method of a woody panel using the same

InactiveUS20090130474A1Ease of evaluationImprove trapping efficiencyOrganic chemistrySulfate/bisulfate preparationScavengerRoom temperature

Regarding the scavenger for aldehyde(s) used at the time of manufacturing a woody panel using woody materials and formaldehyde-based binders, the scavenger for aldehyde(s) without lowering of trapping properly even when a surface of said woody panel is sanded and having an excellent trapping property of trapping formaldehyde is provided. Further, the method of manufacturing a woody panel using a scavenger for aldehyde(s) and a woody panel are provided.At least one kind of compound for trapping aldehyde(s) being solid at a room temperature is included and said compound for trapping aldehyde(s) is defined to be a powdery scavenger for aldehyde(s) having a property of generating acidic gas, in particular, sulfurous acid gas by heating and said compound for trapping aldehyde(s) is added to a binder or woody materials followed by a hot press, thereby manufacturing a woody panel.

Owner:IPPOSHA OIL INDS

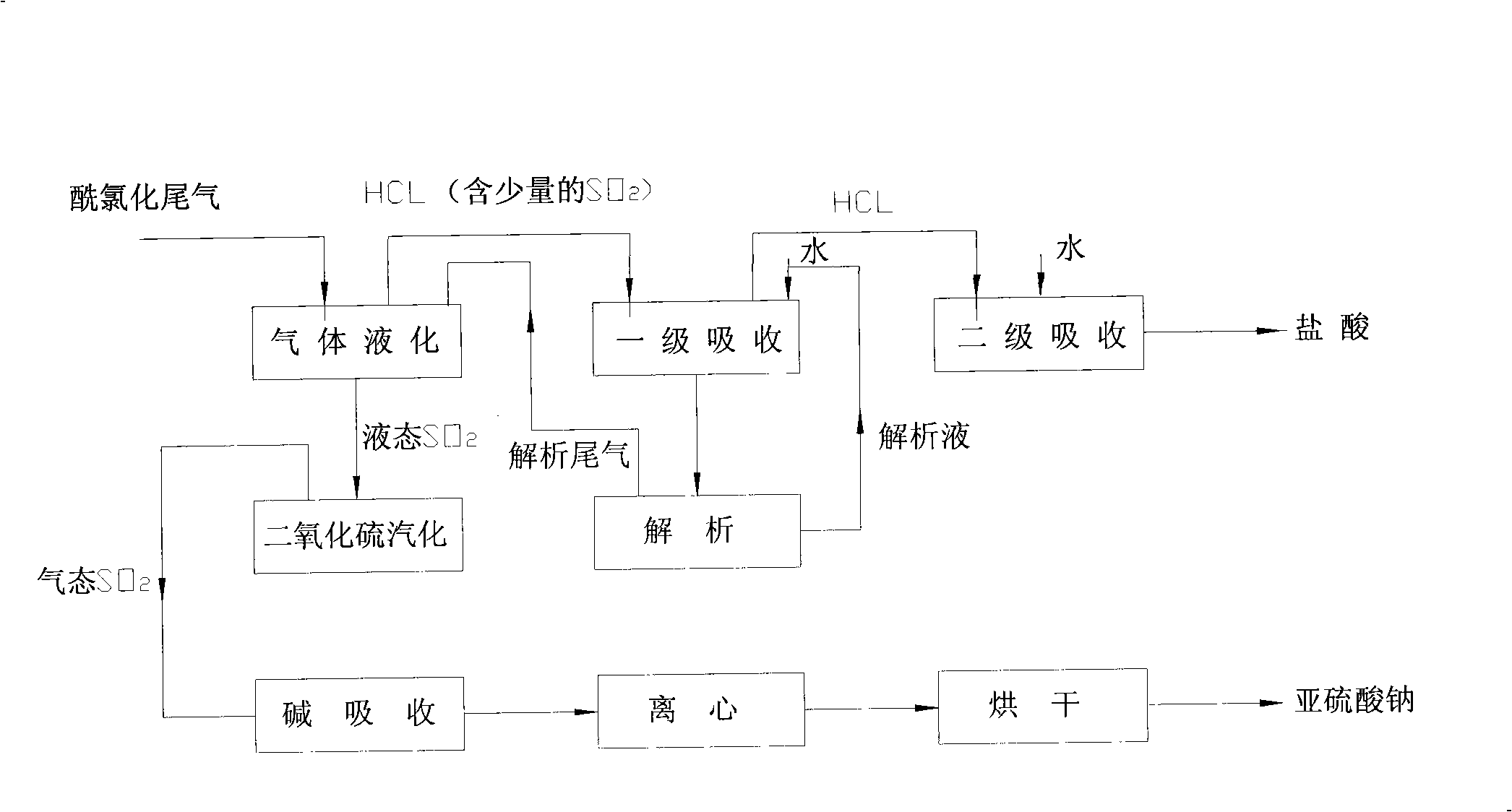

Method for treating tail gas of acyl chlorination

The invention relates to a processing method of thionyl chloride acyl-chlorinated tail gas. Mixed tail gas produced by a acyl chlorinating process contains hydrogen chloride and sulfur dioxide; the sulfur dioxide is liquefied under a certain temperature condition; the incondensable hydrogen chloride and a little sulfur dioxide are absorbed in two stages by water; the absorbed tail gas in a first stage is pure hydrogen chloride gas; after being absorbed in a second stage, the qualified chlorhydric acid is obtained; first-stage falling film absorption liquid is resolved by heating; then the tail gas is sent to a liquefying process again; the liquid sulfur dioxide can be canned as a product; or after being vaporized, the liquid sulfur dioxide is absorbed by 30 percent of sodium hydroxide solution to obtain sodium sulfite aqueous solution which is further dried after low temperature crystallization or distillation to obtain 97 percent of sodium sulfite solid. With the method, the hydrogen chloride, the sulfur dioxide and a little thionyl chloride produced by an acyl chlorination synthetic process can be separated out to obtain the chlorhydric acid and the pure sodium sulfite solid. The processing method of the thionyl chloride acyl-chlorinated tail gas of the invention is capable of effectively recovering the thionyl chloride acyl-chlorinated tail gas, which has the advantages of safety process and easy control.

Owner:JIANGSU YANGNONG CHEM +2

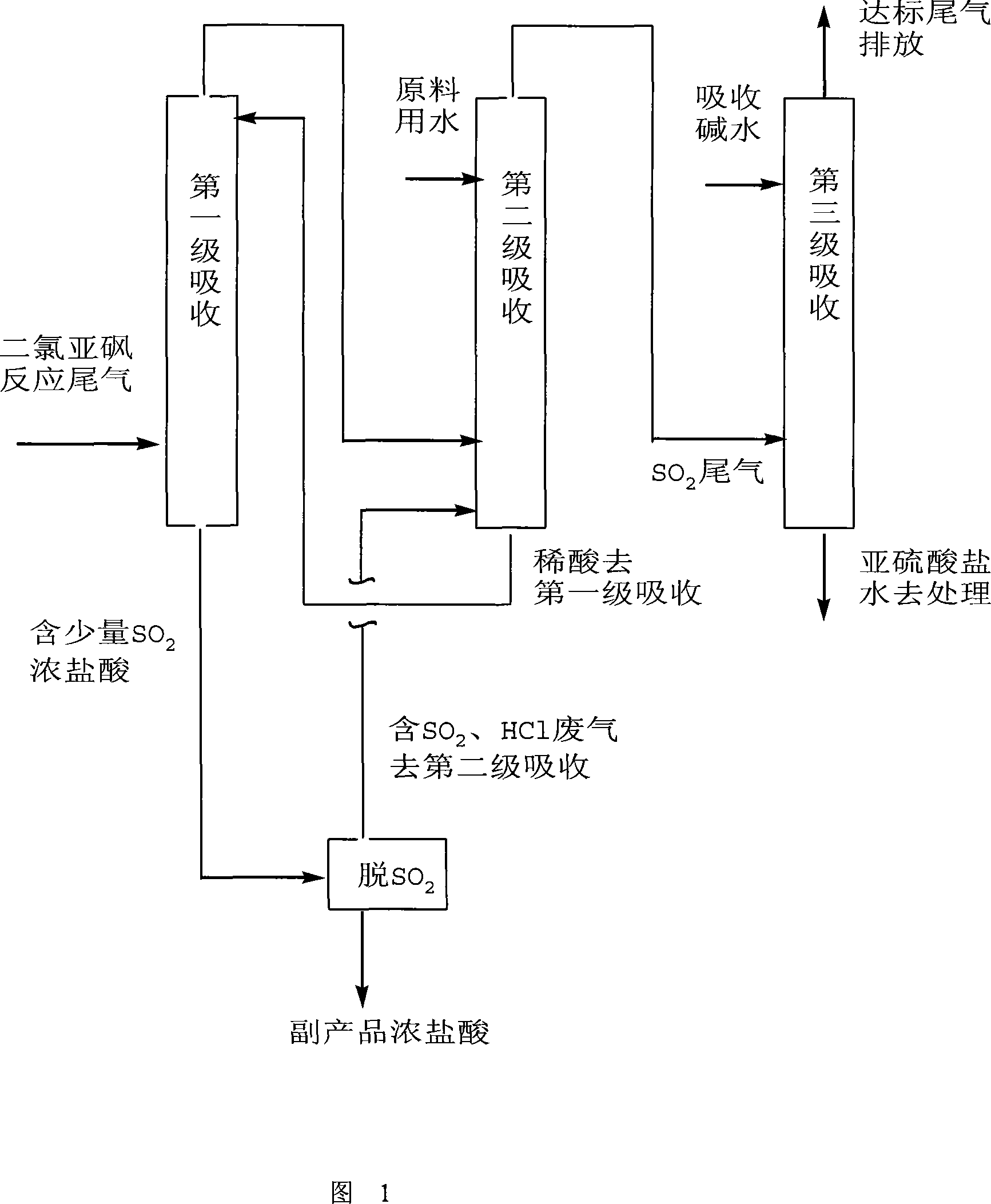

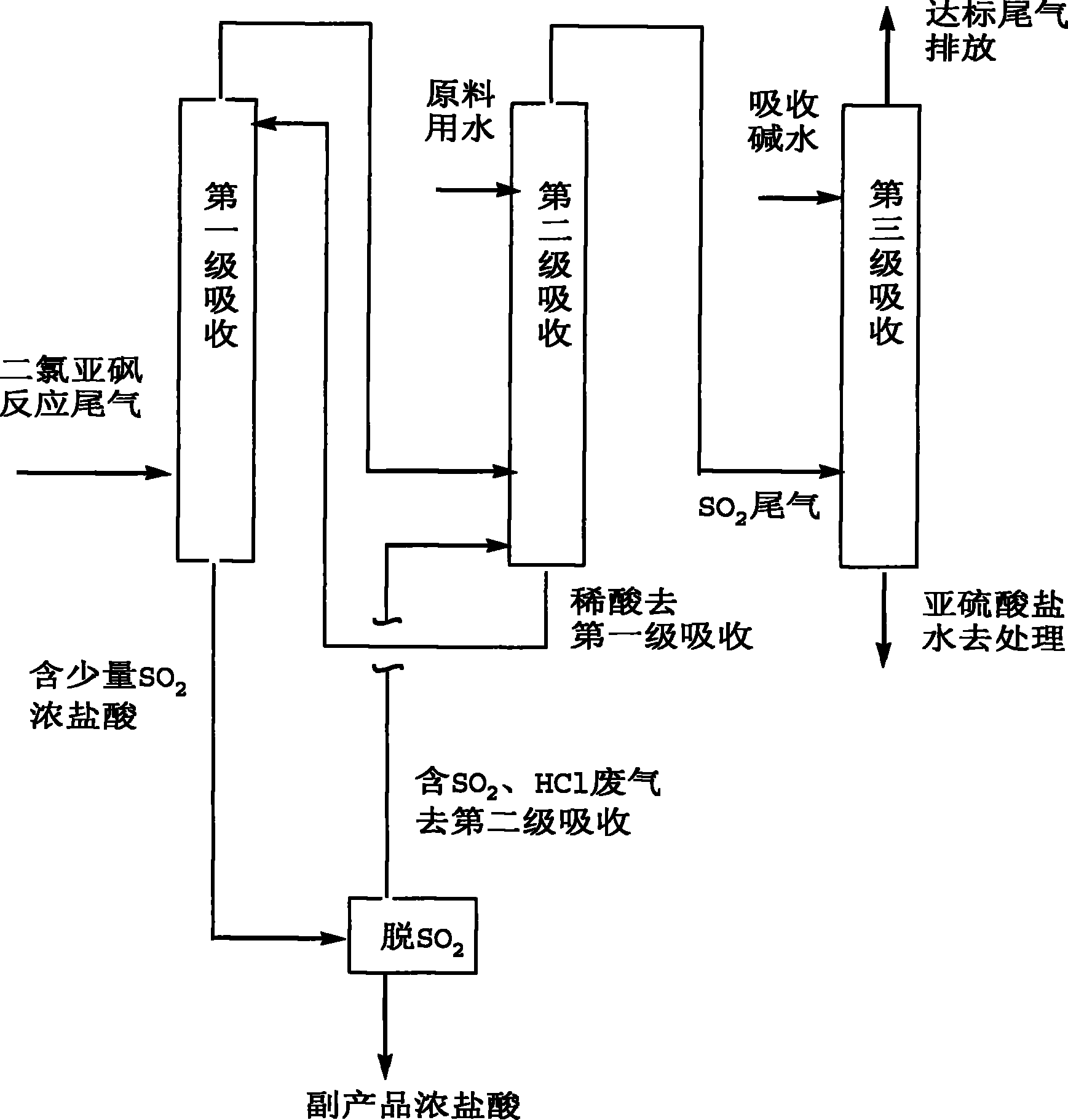

Method for treating tail gas of thionyl chloride chlorination

InactiveCN101121094AFully absorbedReduce dosageChlorine/hydrogen-chlorideSulfur-halogen-hydrogen-oxygen compoundsSulfite saltWastewater

The invention discloses a method for treating tail gas generated in chlorination reaction by using thionyl chloride. The existing traditional tail gas treatment method is costly due to a large amount of alkali consumption, and the pressure on environmental protection is high due to the final generation of a large amount of waste water containing heteroions. In the present invention, by controlling the amount of water, the hydrogen chloride in the tail gas is subjected to two-stage absorption with water, and the concentrated hydrochloric acid with a hydrogen chloride content close to saturation and a small amount of sulfur dioxide is obtained through the first-stage absorption; the second-stage absorption: after the first-stage absorption, the The exhaust gas is subjected to the second-stage absorption, and the added water is not discharged to obtain dilute hydrochloric acid containing a small amount of hydrogen chloride and a small amount of sulfur dioxide. The dilute hydrochloric acid is used as the raw material water for the first-stage absorption; after the above-mentioned secondary absorption treatment, it is then treated with alkali or alkali The third level of water absorption is used to absorb sulfur dioxide in the tail gas to obtain a relatively pure aqueous solution of sodium sulfite. The invention has high treatment efficiency, complete tail gas absorption, and reduces the pressure on environmental protection.

Owner:GAOYOU CITY ORGANIC CHEM FACOTRY

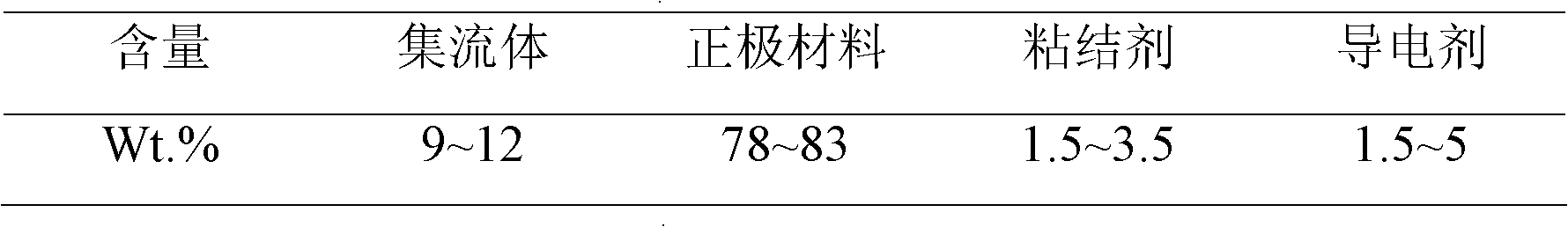

High-purity polymetallic-element solid mixed salt and preparation method and application thereof

InactiveCN102088124AMeet production requirementsIncrease productivityChloride preparationCell electrodesManganeseCobalt

The invention discloses a high-purity polymetallic-element solid mixed salt. The solid mixed salt is prepared from raw materials of waste secondary lithium batteries, the content of impurities such as calcium, magnesium, copper, zinc, ferrum, aluminum, lead, cadmium and chromium in the solid mixed salt is lower than 10 ppm respectively. The invention also discloses a preparation method and application of the high-purity polymetallic-element solid mixed salt. The nickel, cobalt and manganese in waste batteries are treated and prepared into high-purity polymetallic solid mixed salt which is then used for preparing the anode material and the front-body material of batteries, thus the non-ferrous metal resources are recycled, and the high-purity polymetallic-element solid mixed salt has higher economic benefit and social benefit.

Owner:GUANGDONG BRUNP RECYCLING TECH

Methods for recovering at least one metallic element from ore

ActiveUS7323150B2Reduce and eliminate needEasy extractionCalcium/strontium/barium carbonatesSolvent extractionSulfateSolvent

Owner:CABOT SPECIALTY FLUIDS

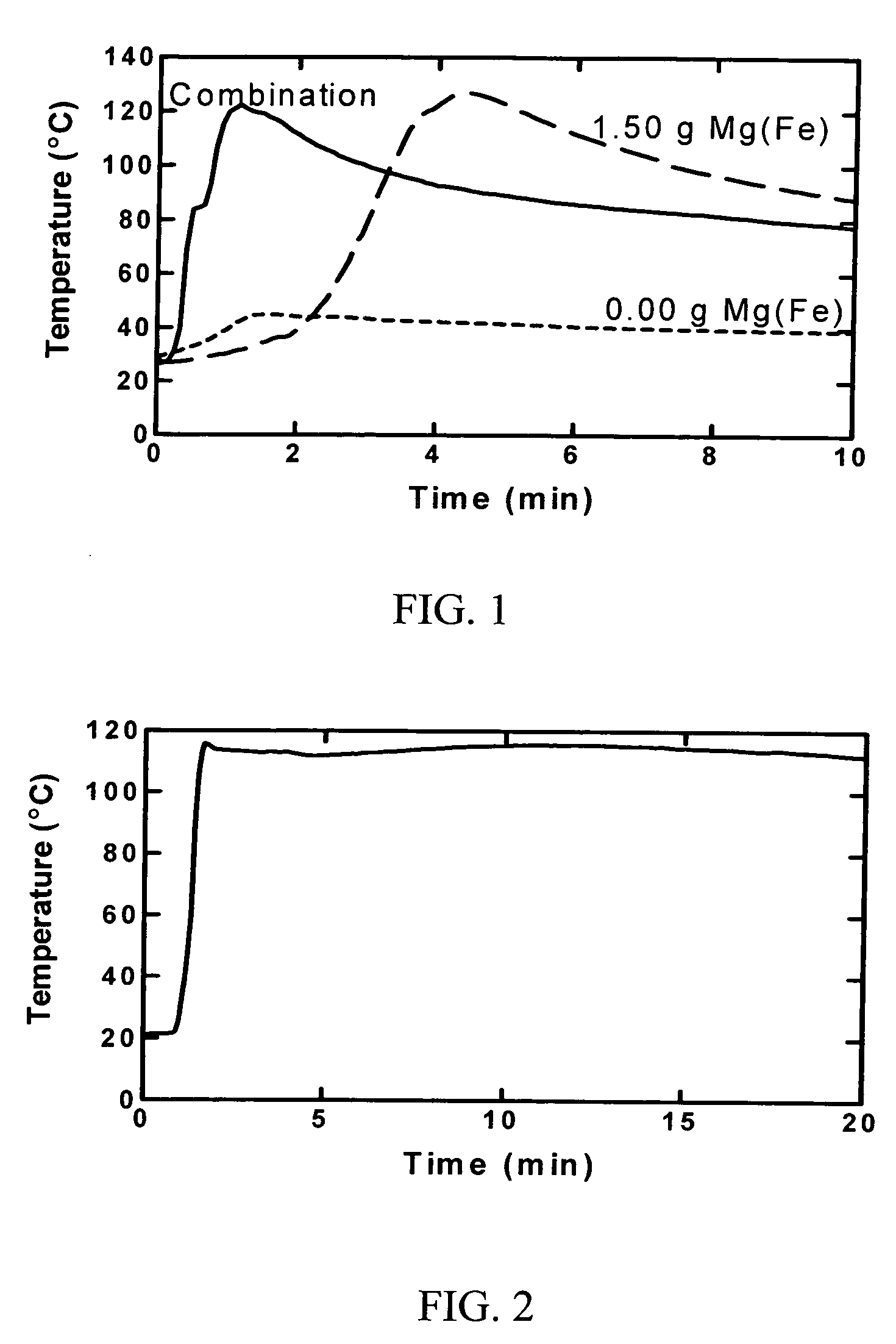

Chemical combination for generation of disinfectant and heat

InactiveUS20060097222A1Eliminate the problemExothermal chemical reaction heat productionLiquid degasificationChlorine dioxideDisinfectant

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Building and other materials containing treated bauxite tailings and process for making same

A process and product are described whereby a waste stream containing bauxite tailings is treated to neutralize alkaline material present, and the resulting material incorporated, for example, into building or other materials to provide enhanced properties.

Owner:JAQUAYS CHARLES D

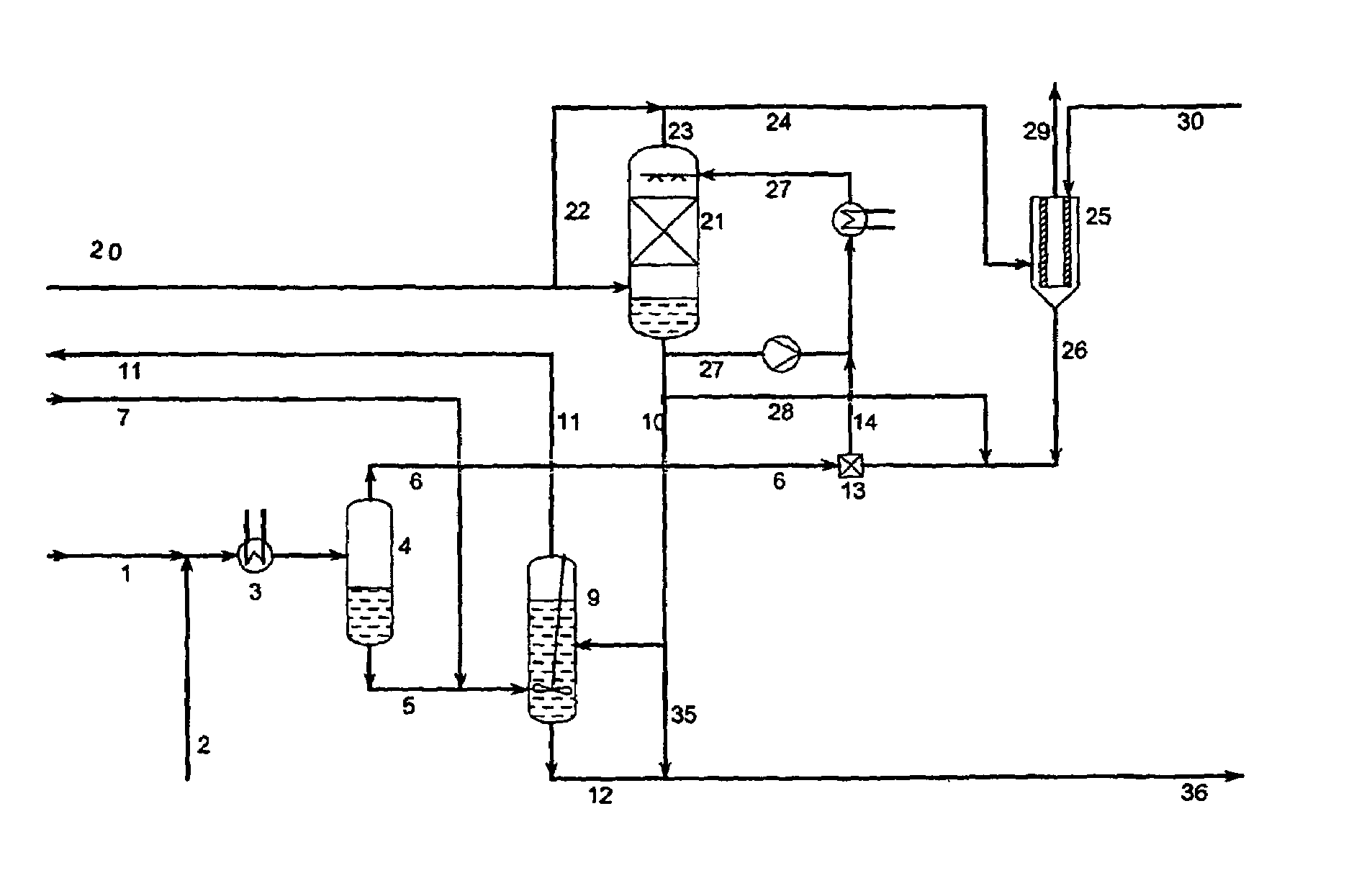

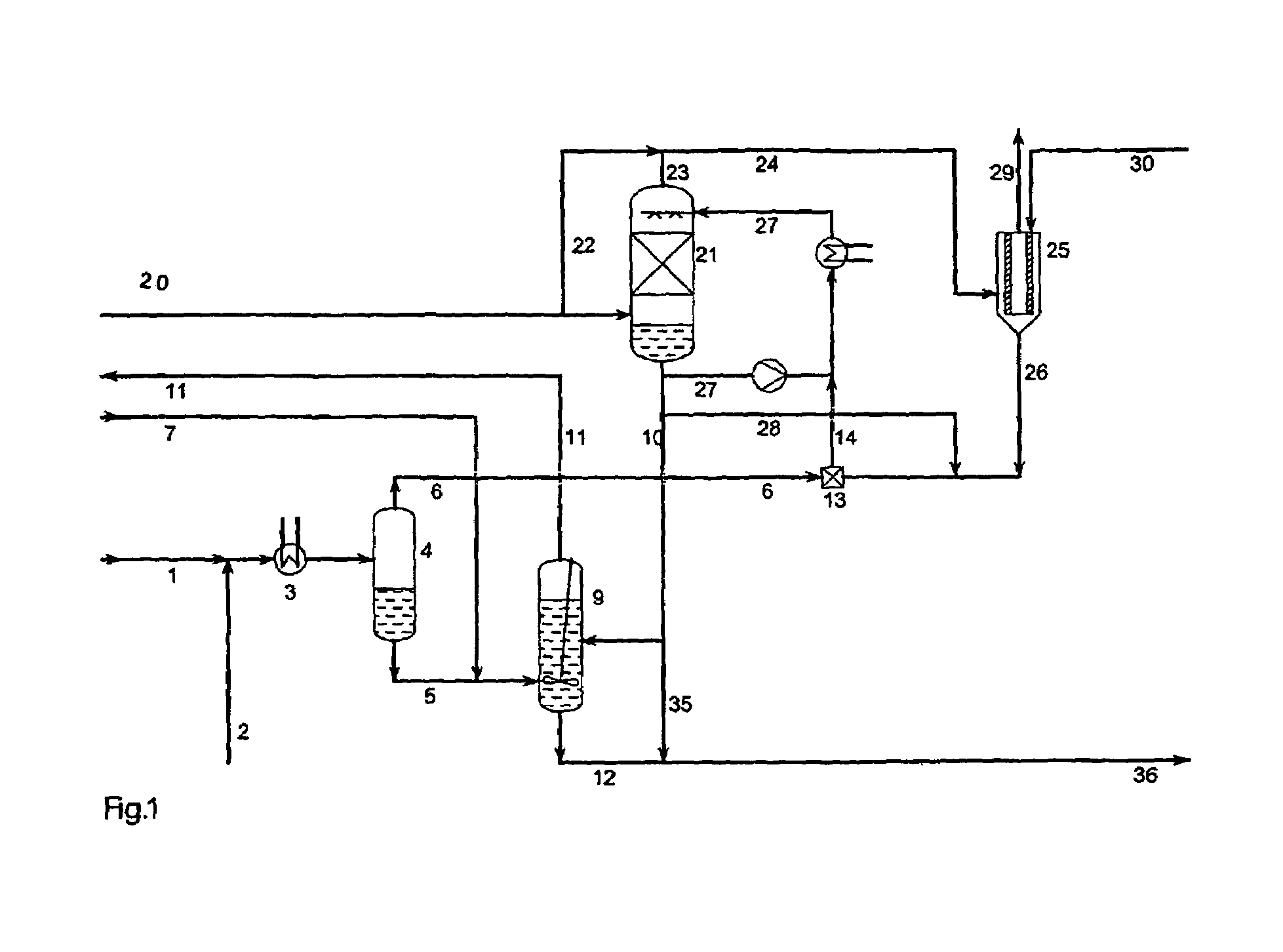

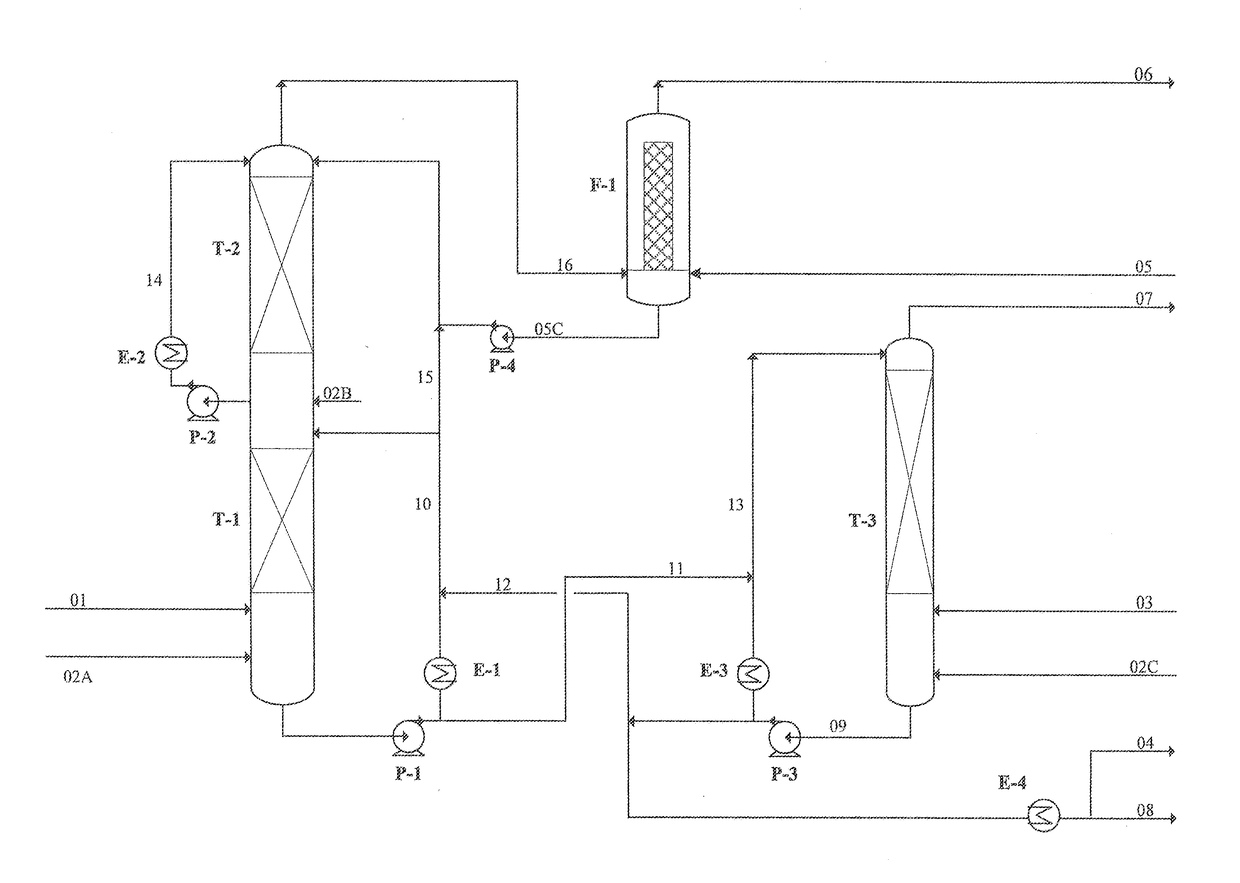

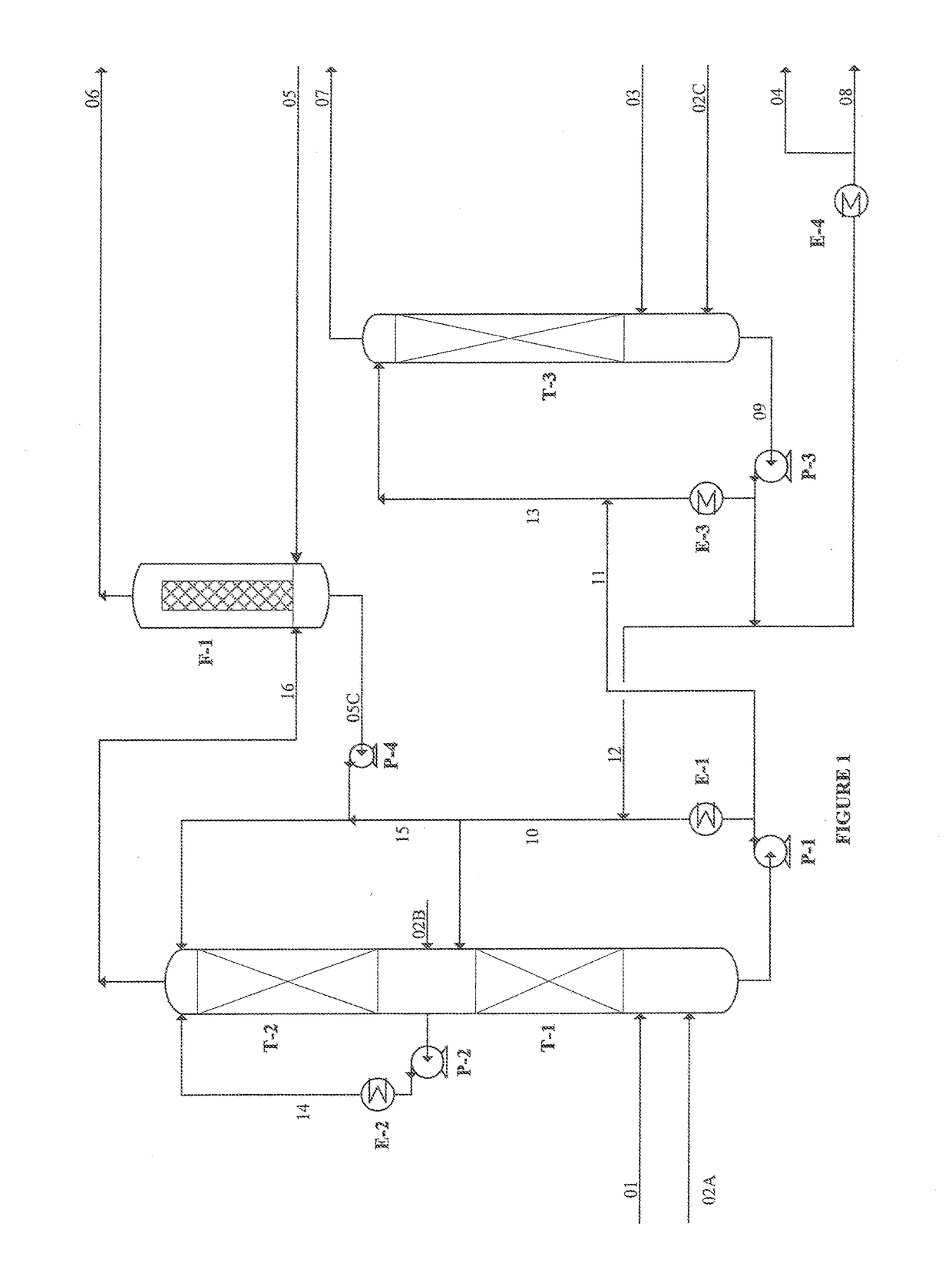

Process for production of ammonium thiosulphate

InactiveUS20030223930A1Speed up the processThiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

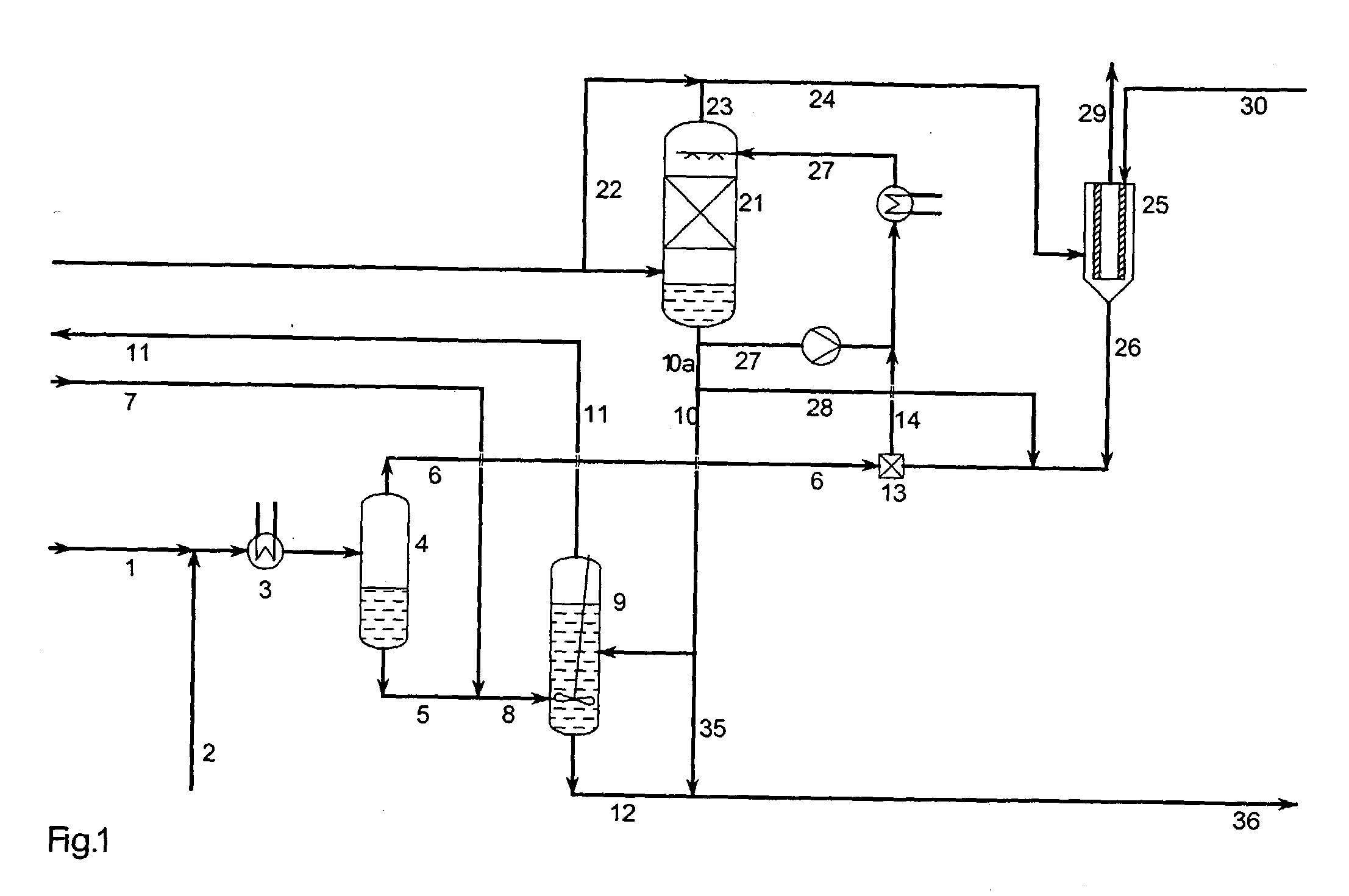

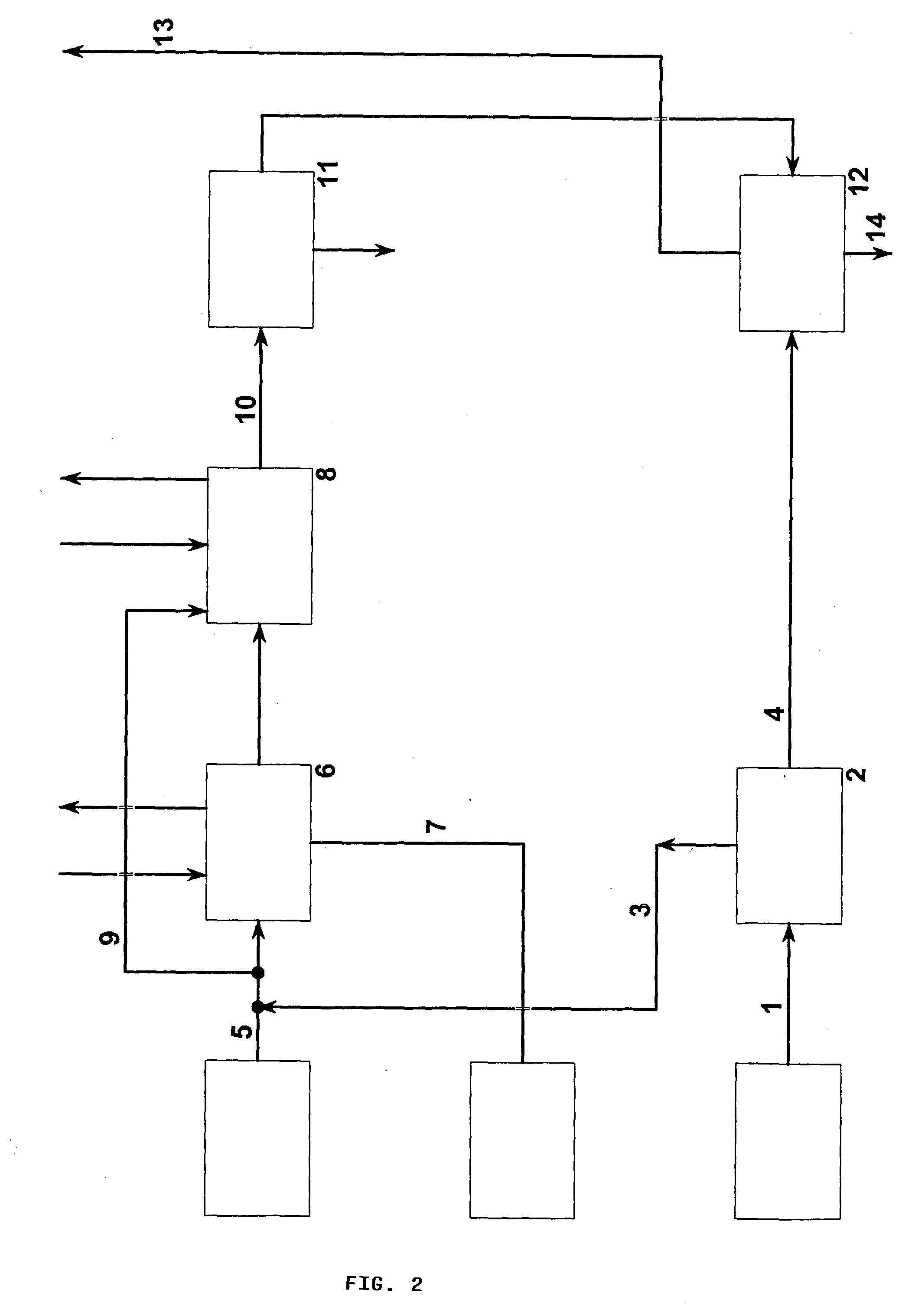

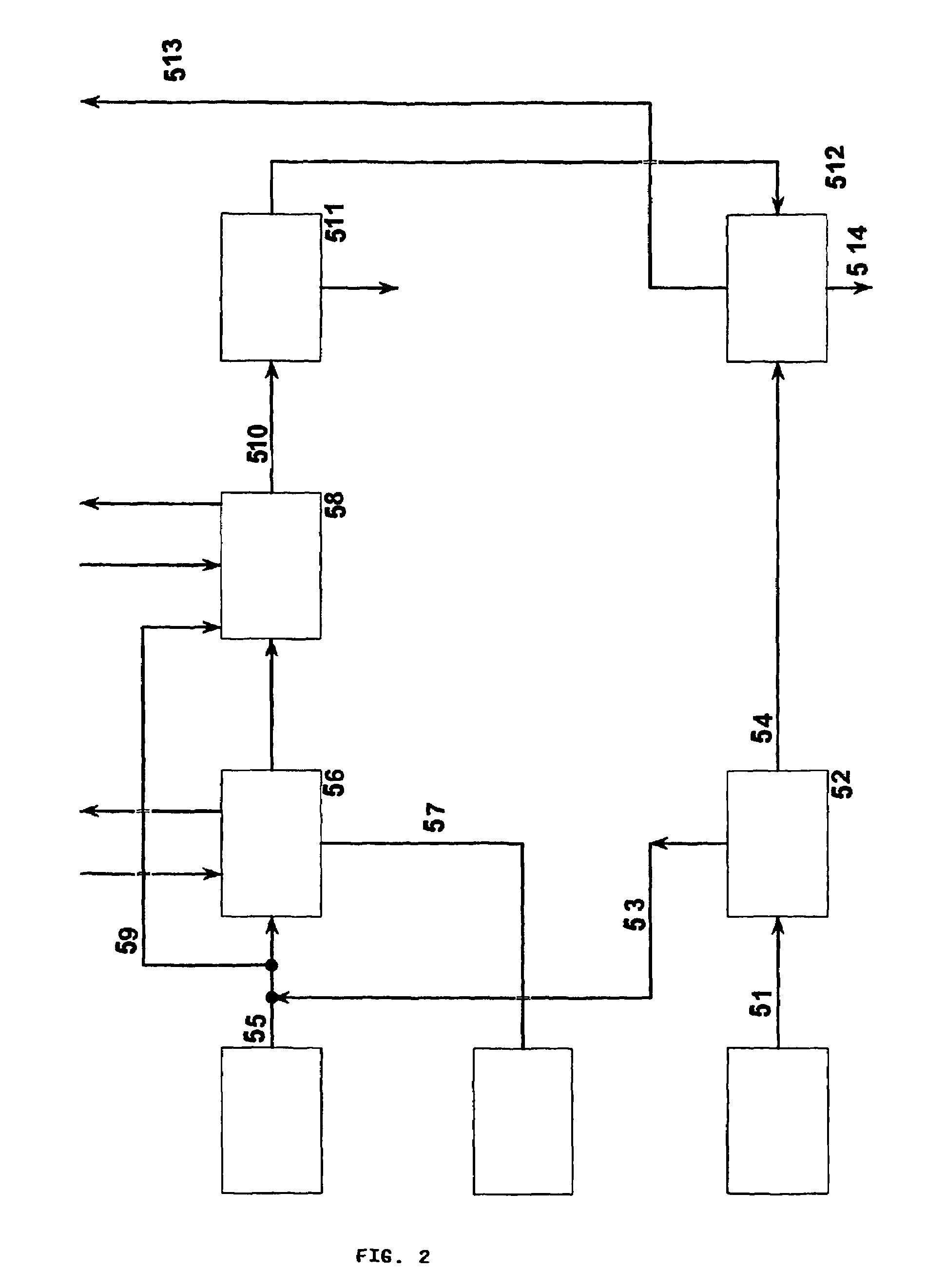

A process for continuous production of ammonium thiosulphate, (NH4)2S2O3 (ATS) from NH3, H2S and SO2 comprising steps of: (a) partial condensation in a partial condenser 4 of a first gaseous or partial liquid feed stream comprising H2O, H2S and NH3 with a molar H2S:NH3 ratio <0.4; (b) passing the aqueous condensate comprising NH4HS and NH3 from the partial condenser 4 to a reactor 9 in which said condensate is contacted with a third feed gas stream 7 comprising H2S and with an aqueous solution 10 comprising NH4HSO3 and (NH4)2SO3 under formation of an aqueous solution of (NH4) 2S2O3; (c) passing the gas stream comprising NH3 and H2S from the partial condenser 4 to a mixing device 13 in which said gas stream is completely dissolved in the water drained off from the aerosol filter 25; (d) passing a second feed gas stream 20 comprising approximately 2 / 3 mole SO2 per mole of NH3 contained in the first feed stream to a SO2 absorber 21 and the aerosol filter 25; (e) passing the aqueous solution produced in mixing device 13 to the SO2 absorber 21; (f) passing the off gas from the absorber 21 to the aerosol filter 25 and (g) adding to the aerosol filter 25 a balance amount of water required for obtaining approximately 40-65 wt % (NH4)2S2O3 in the aqueous of solution of (NH4)2S2O3 being withdrawn from the reactor 9.

Owner:HALDOR TOPSOE AS

Dechlorinating tablet and method of manufacture

InactiveUS20050139805A1Decreases friability of tabletProlong dissolution timeOther chemical processesSpecific water treatment objectivesSulfite saltSodium sulfite

A dehalogenating agent is disclosed that is useful for treating aqueous media. The agent contains at least one sulfite salt, such as sodium sulfite. In the agent, the salt is in mixture with a lubricant, an excipient and a saccharide binder. Then a dry, blended mixture of the agent components is directly compressed to form tablets not only of desirable strength and hardness, but also of desirably controlled dissolution rate.

Owner:EXCEL TECH INT CORP

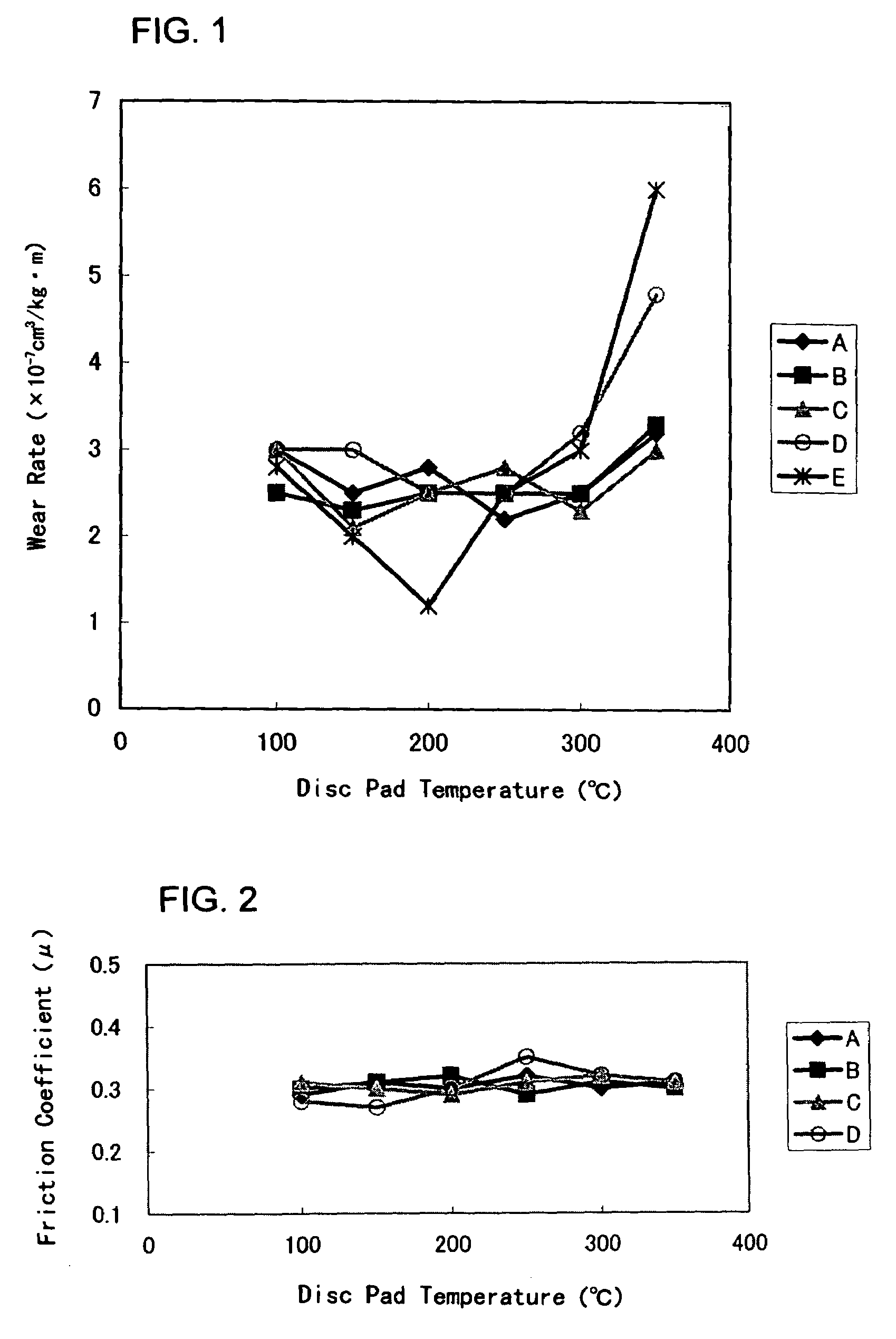

Lepidocrocite type lithium potassium titanate, method for preparation thereof, and friction material

InactiveUS7078009B2Stable frictional wear propertyImproves and stabilizes functionAlkali titanatesSolvent extractionLithiumPotassium titanate

Lepidocrocite lithium potassium titanate characterized as having a composition represented by the formula K0.5-0.7Li0.27Ti1.73O3.85-3.95, and preferably having an arithmetic mean of major and minor diameters of 0.1–100 μm, a proportion of a major to minor diameter of from 1 to below 10, a mean thickness of 50–5,000 nm and a flaky shape. A friction material characterized as containing 1–80% by weight of the lepidocrocite lithium potassium titanate as a friction control agent.

Owner:OTSUKA CHEM CO LTD

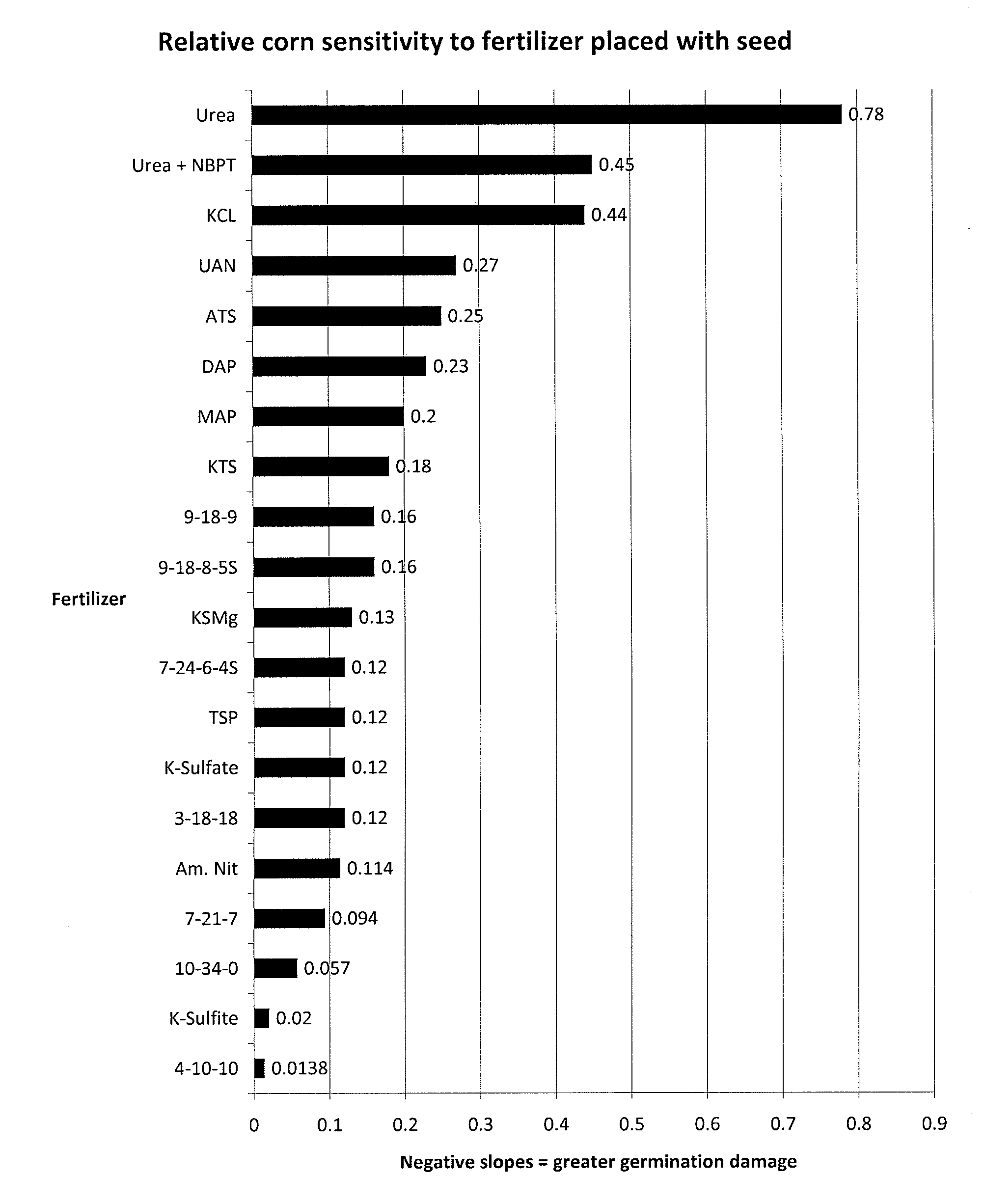

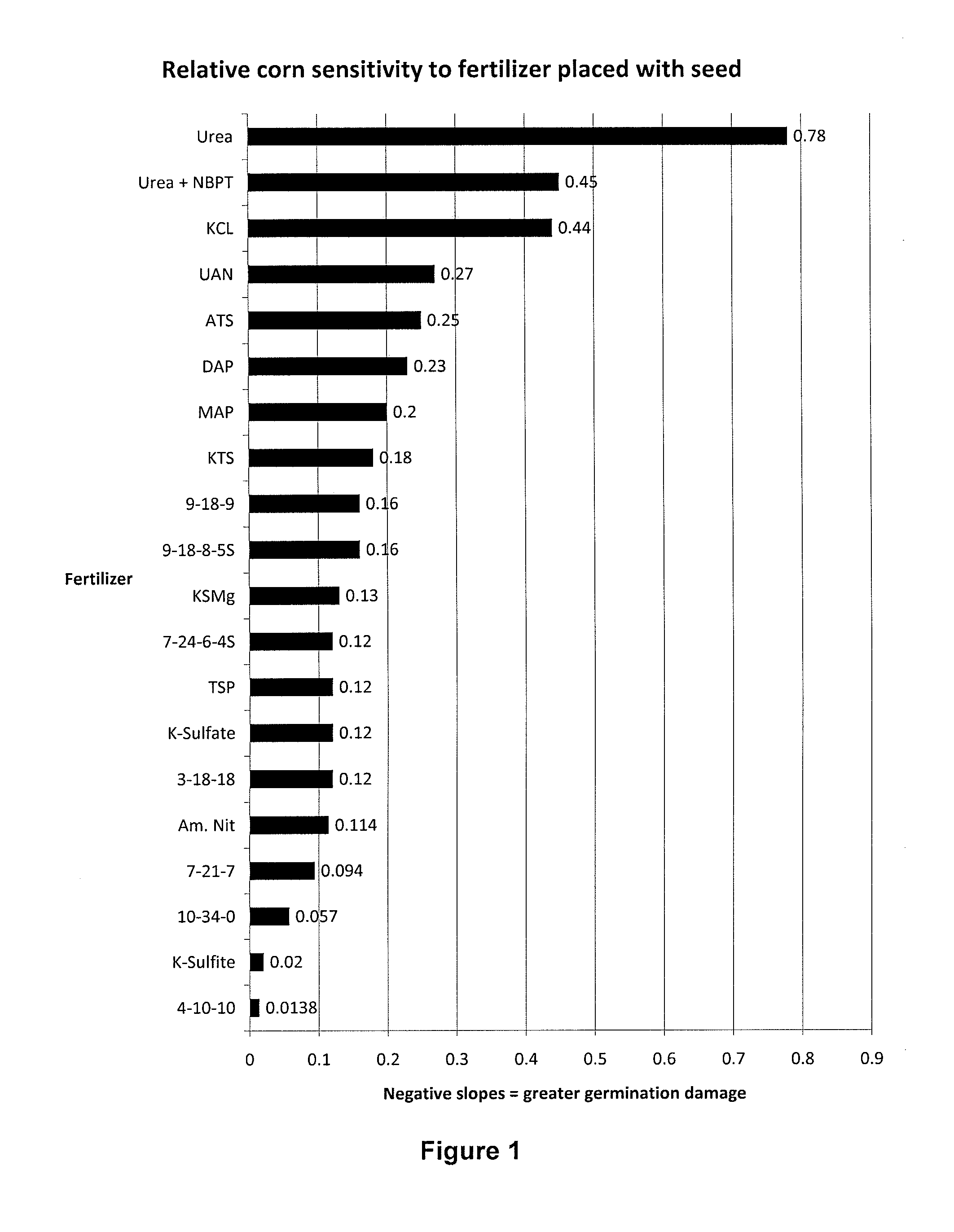

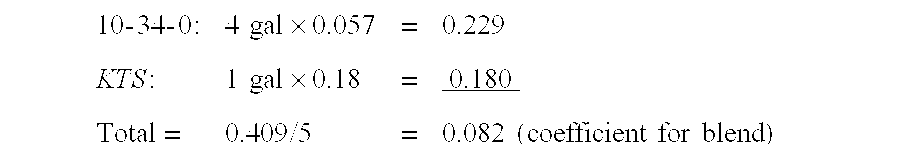

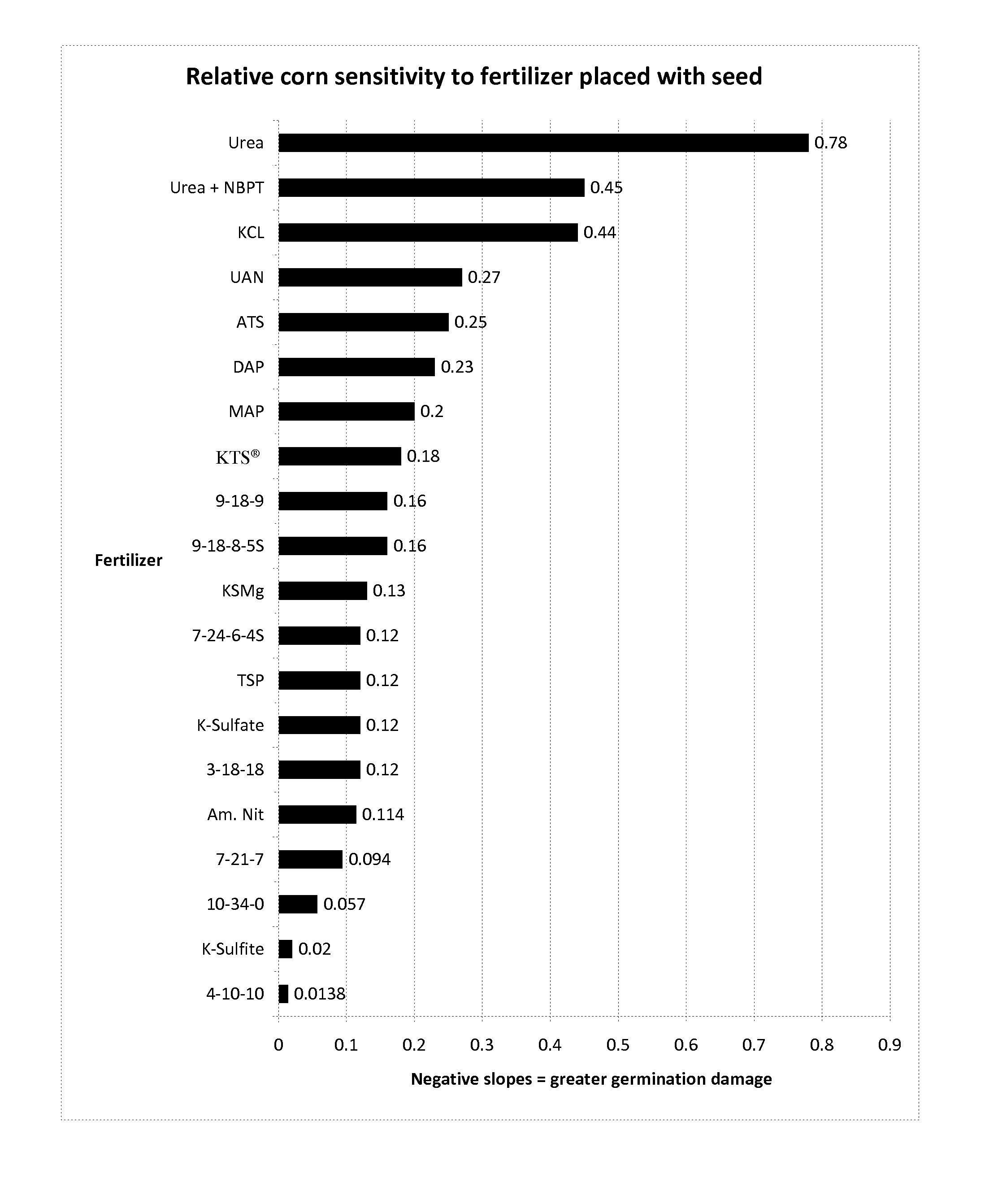

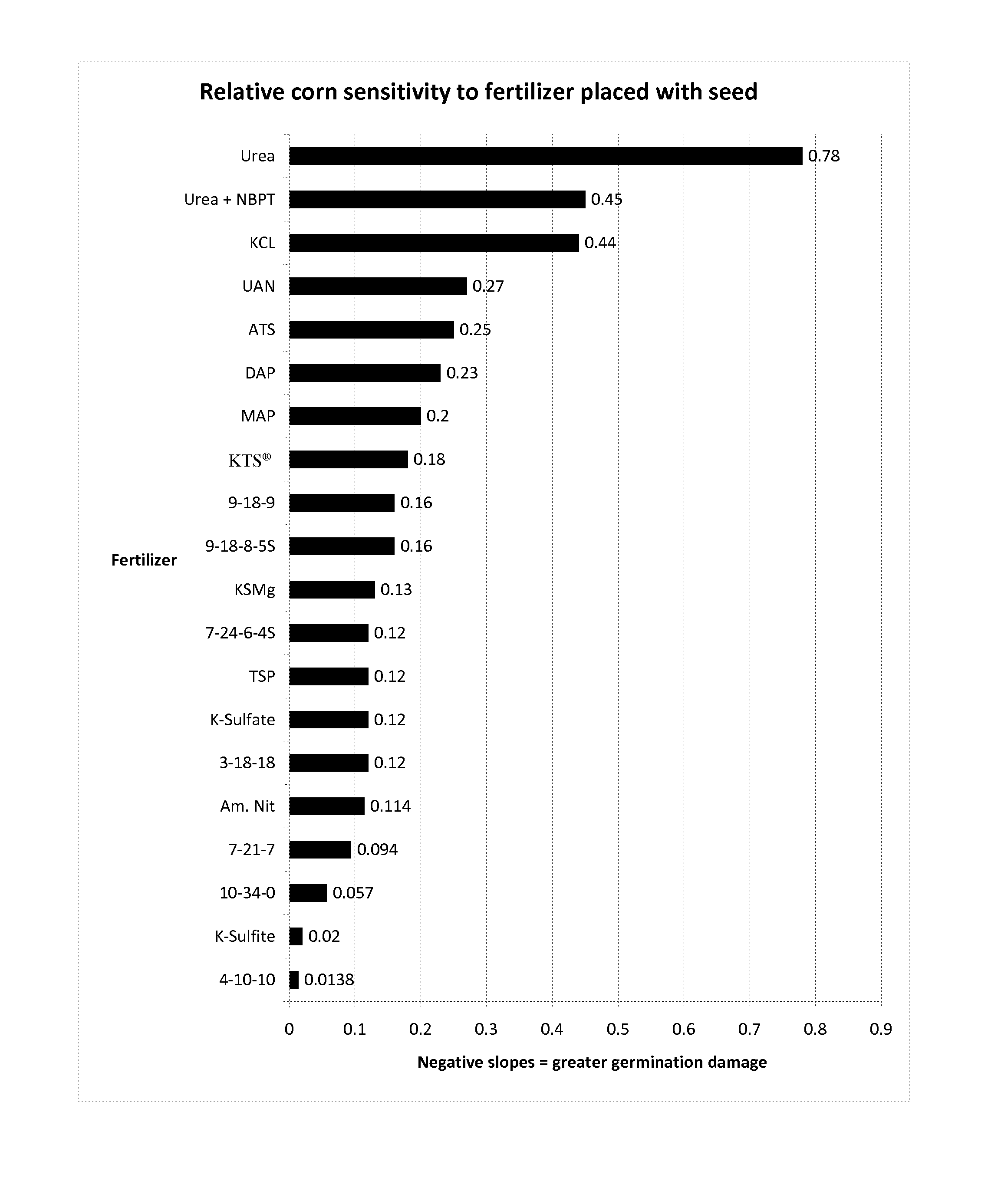

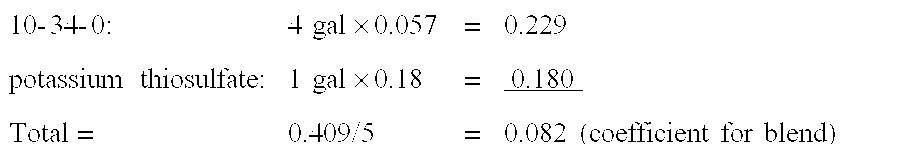

Potassium sulfite/potassium bisulfite (ks/kbs) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

ActiveUS20120255335A1Low indexReduce drug damageBiocideSulfite preparationSulfur productPhytotoxicity

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

Process for production of ammonium thiosulphate

InactiveUS7052669B2Thiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

Owner:HALDOR TOPSOE AS

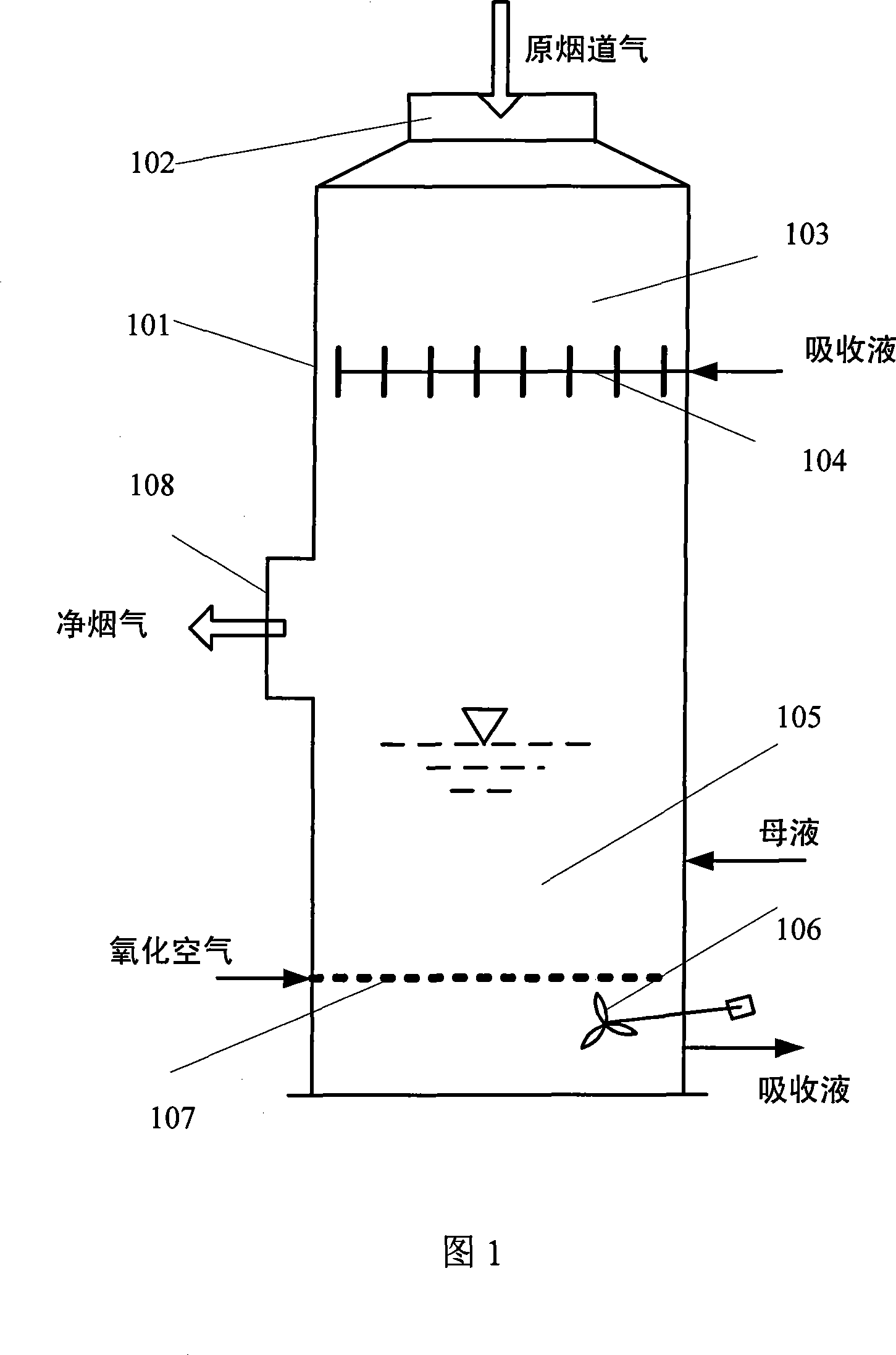

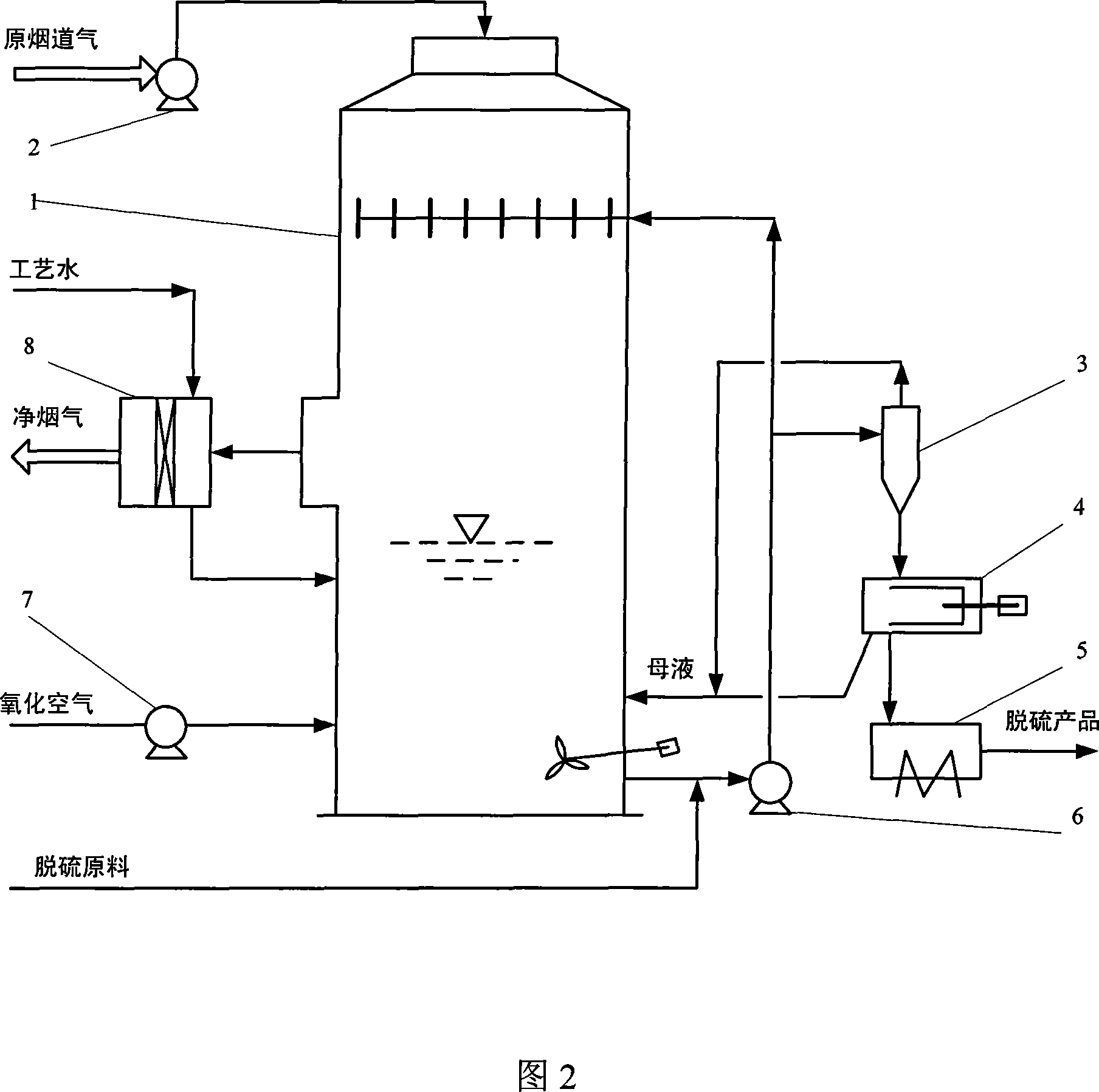

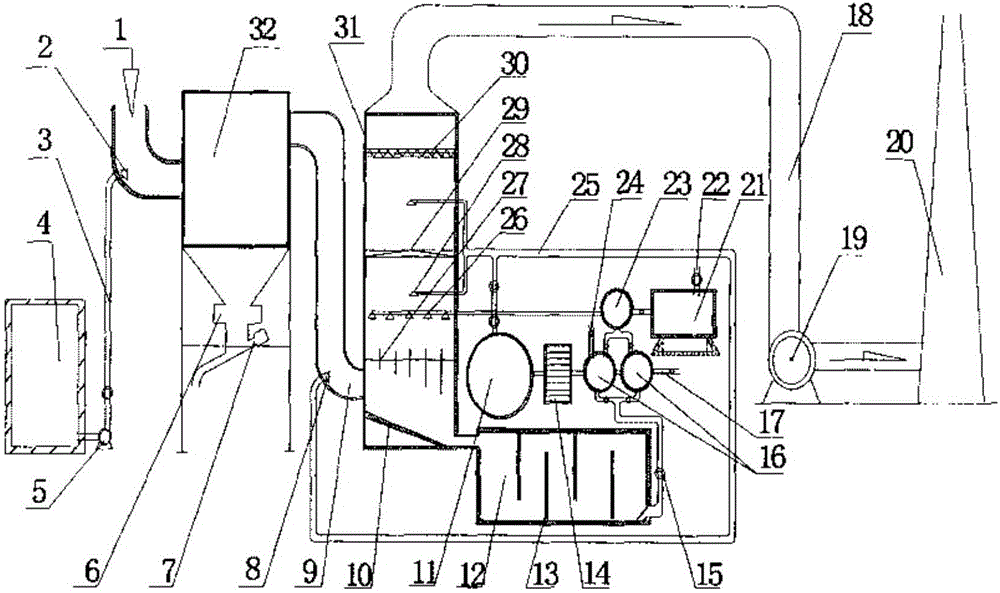

Device and method for purifying flue gas

InactiveCN101085411AImprove corrosion resistanceShort construction periodUsing liquid separation agentSulfite preparationLow latitudeFlue gas

The boiler smoke purification device comprises a cleaning and absorbing component at the relatively higher position, being able to absorb slid grain wastes, poisonous gas, particularly an alkali lye diffusion component for absorbing oxides of sulfur wastes. Smoke goes into the above cleaning absorbing component, then the cleaning absorbing circulation component of lower latitude, with the latter connected to the said cleaning absorbing component. The cleaning absorbing circulation component can be used for the separation of solid grain wastes and treatment of poisonous gases. It is low in investment, small in energy consumption, strong in gas treatment ability, high in efficiency, applicable for mass mode industrial application.

Owner:娄爱娟

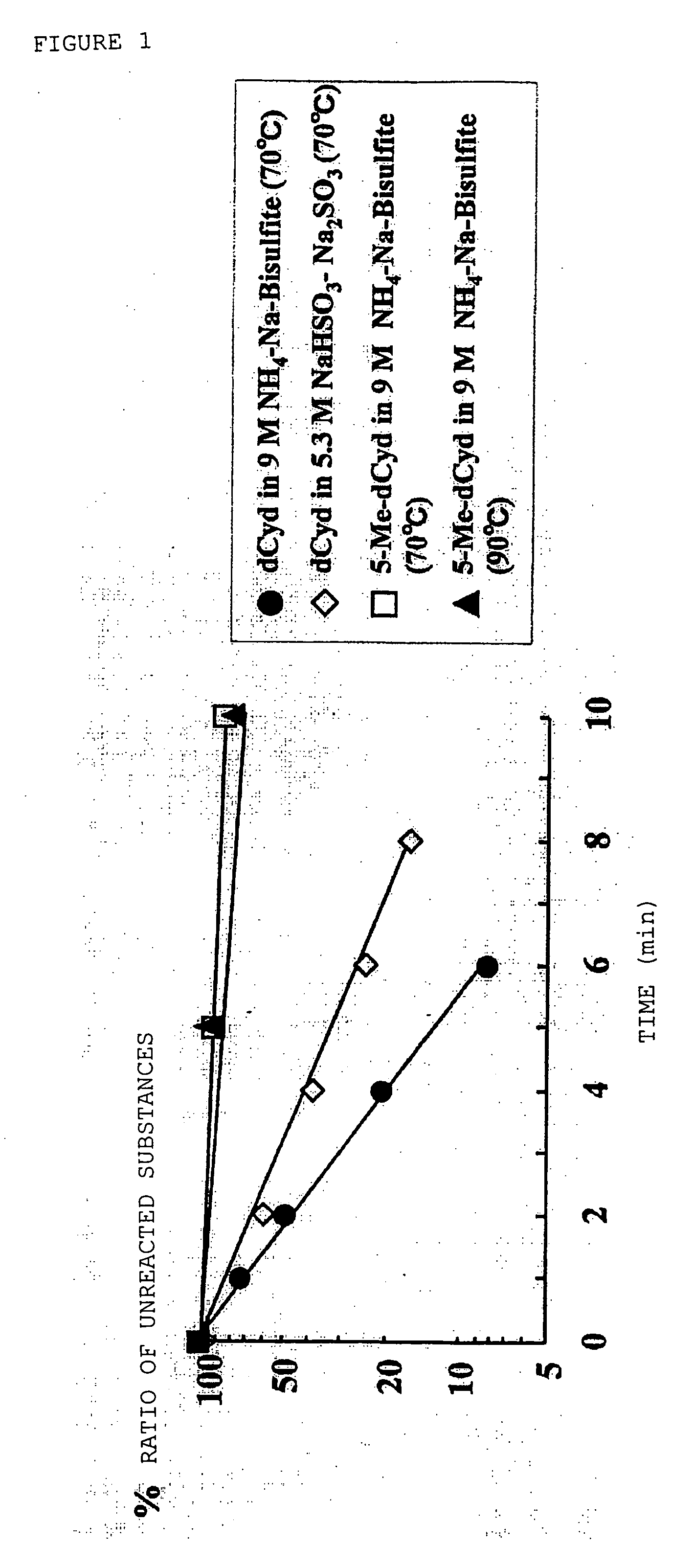

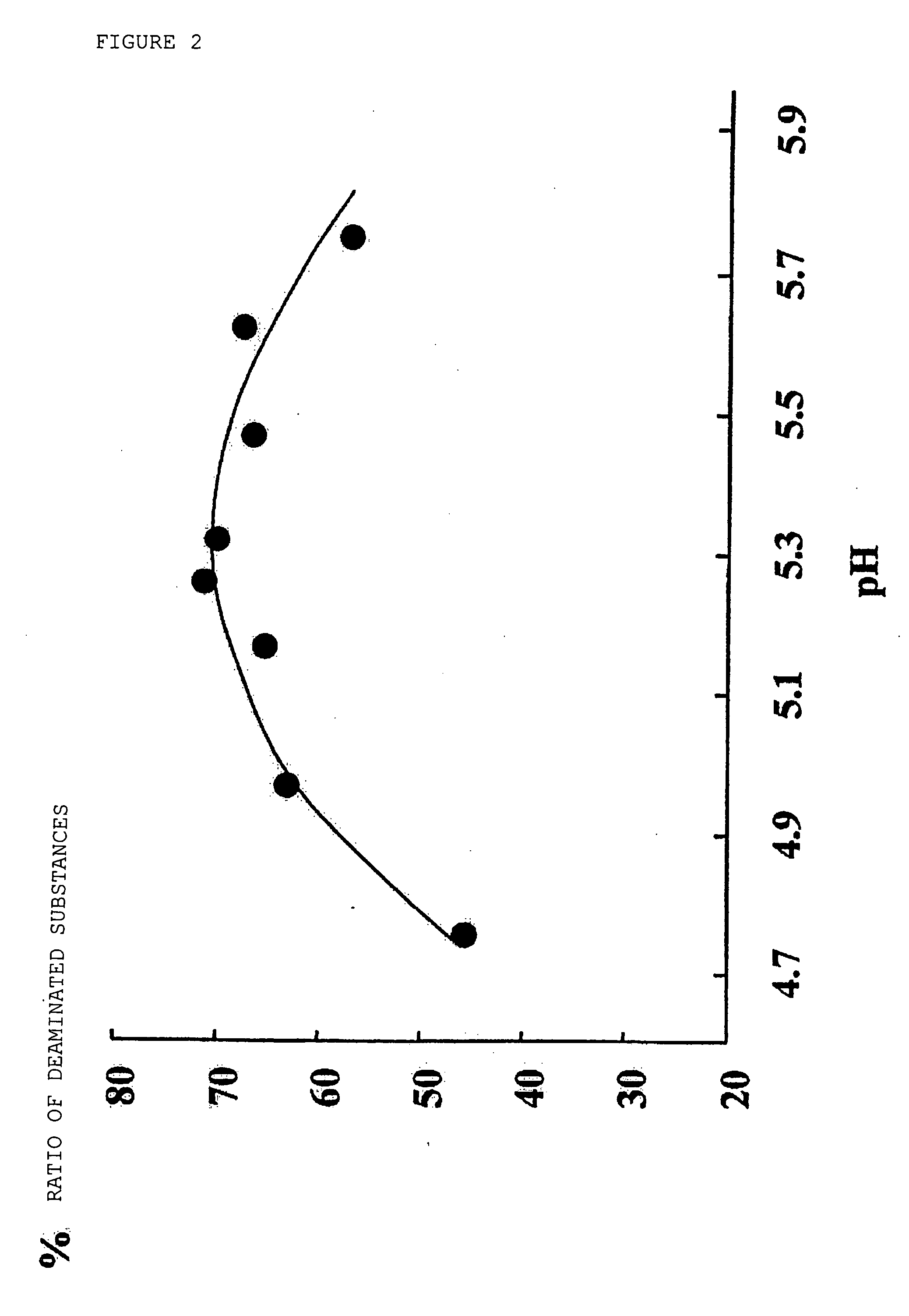

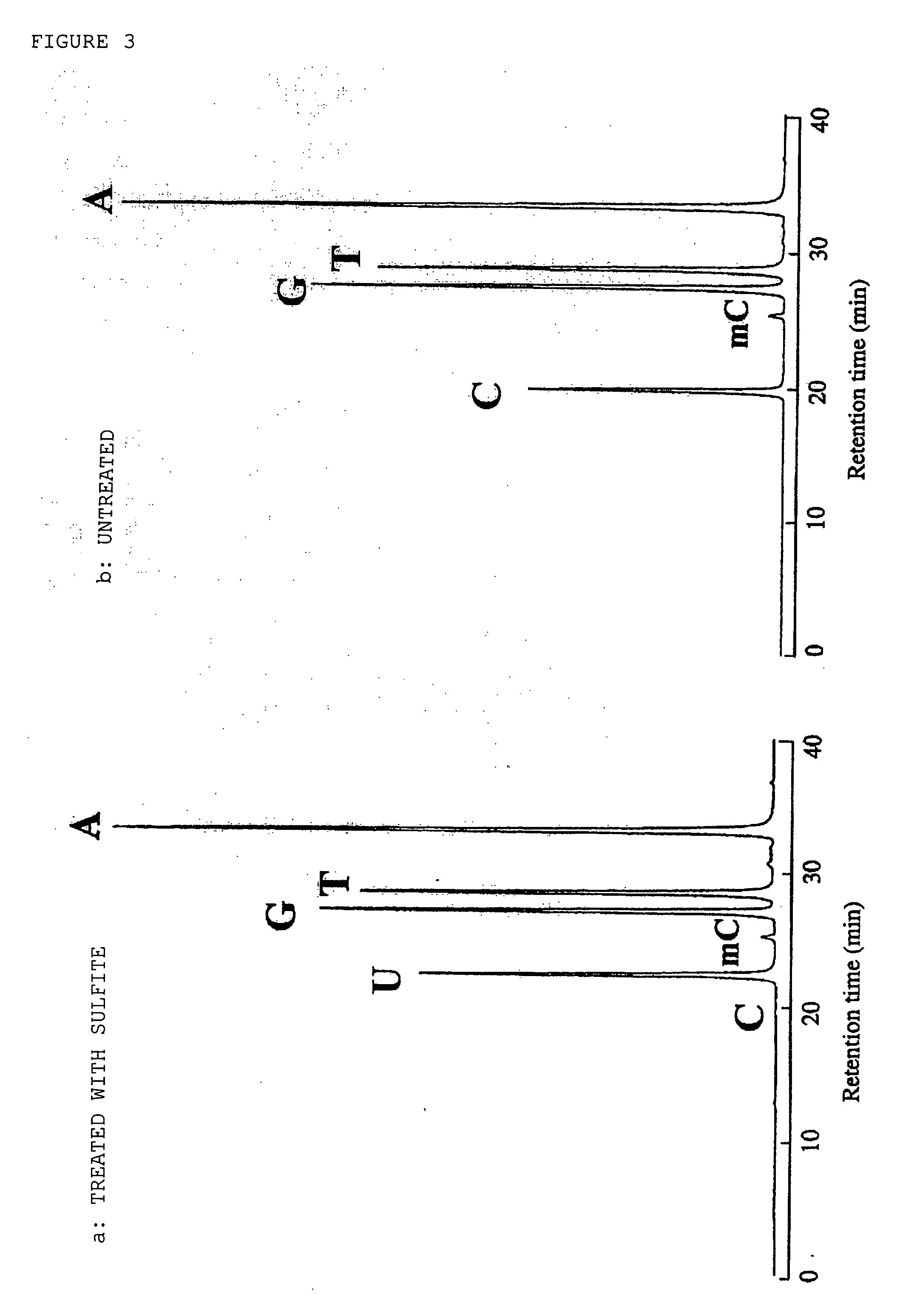

Composition for deaminating dna and method of detecting methylated dna

InactiveUS20070178466A1Short timeAddressing slow performanceSugar derivativesMicrobiological testing/measurementSulfiteDNA

(1) A sulfite composition having a sulfite concentration of more than 6.2 M, (2) a method for deaminating DNA using a sulfite composition described in (1), (3) a method for detecting methylated DNA using a sulfite composition described in (1), (4) a kit for deaminating DNA or for detecting methylated DNA comprising a sulfite composition described in (1).

Owner:TOYOBO CO LTD +1

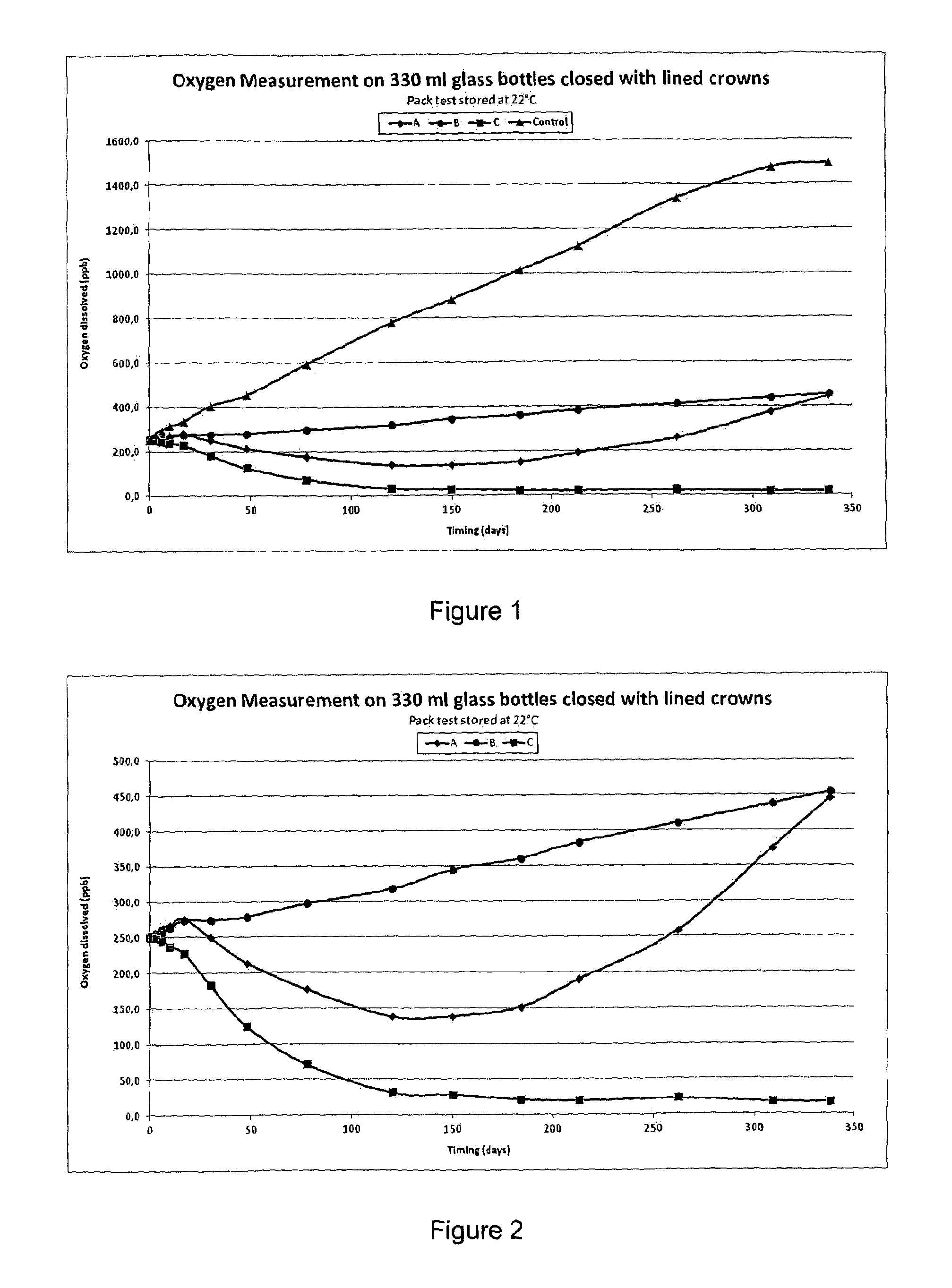

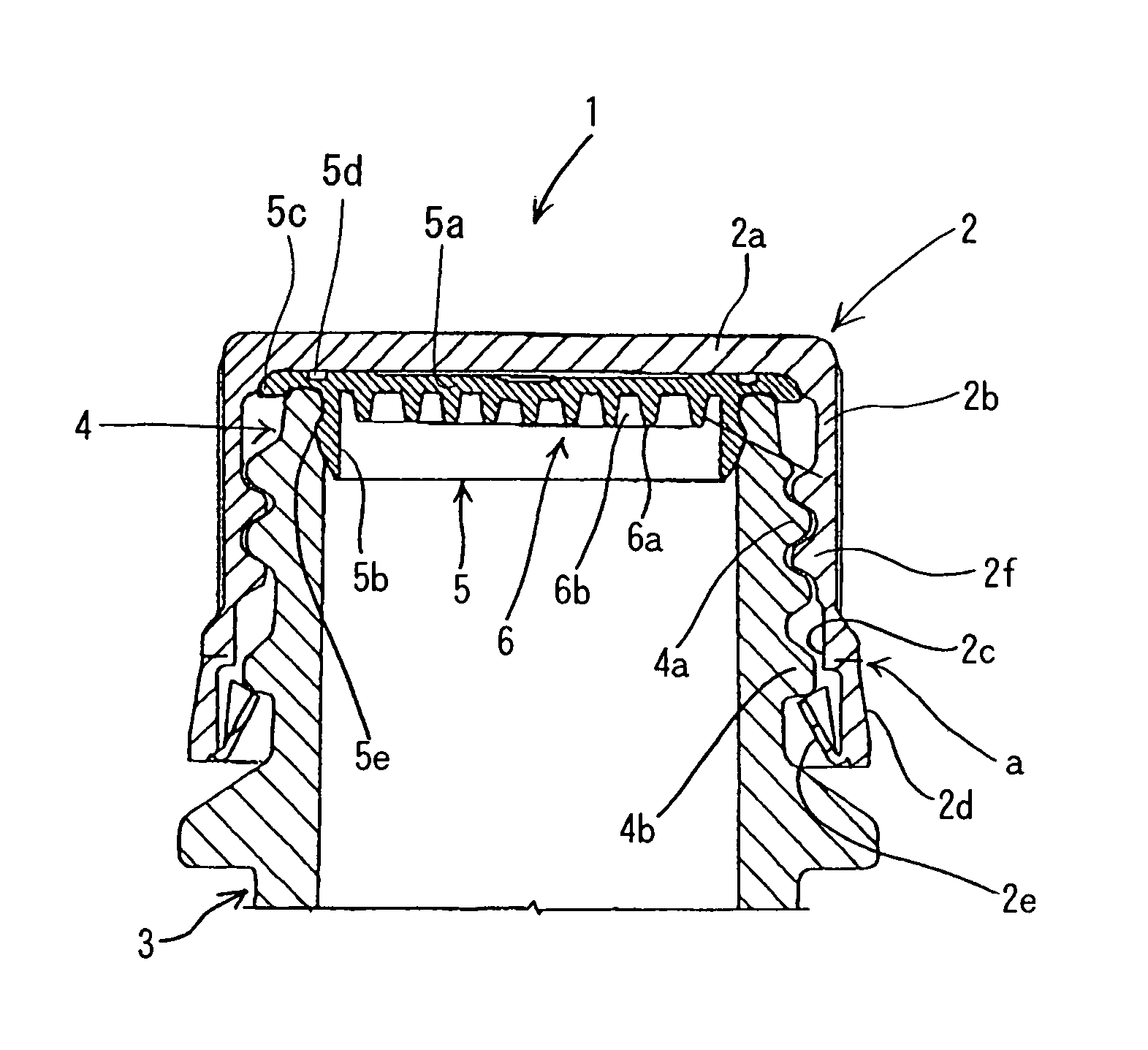

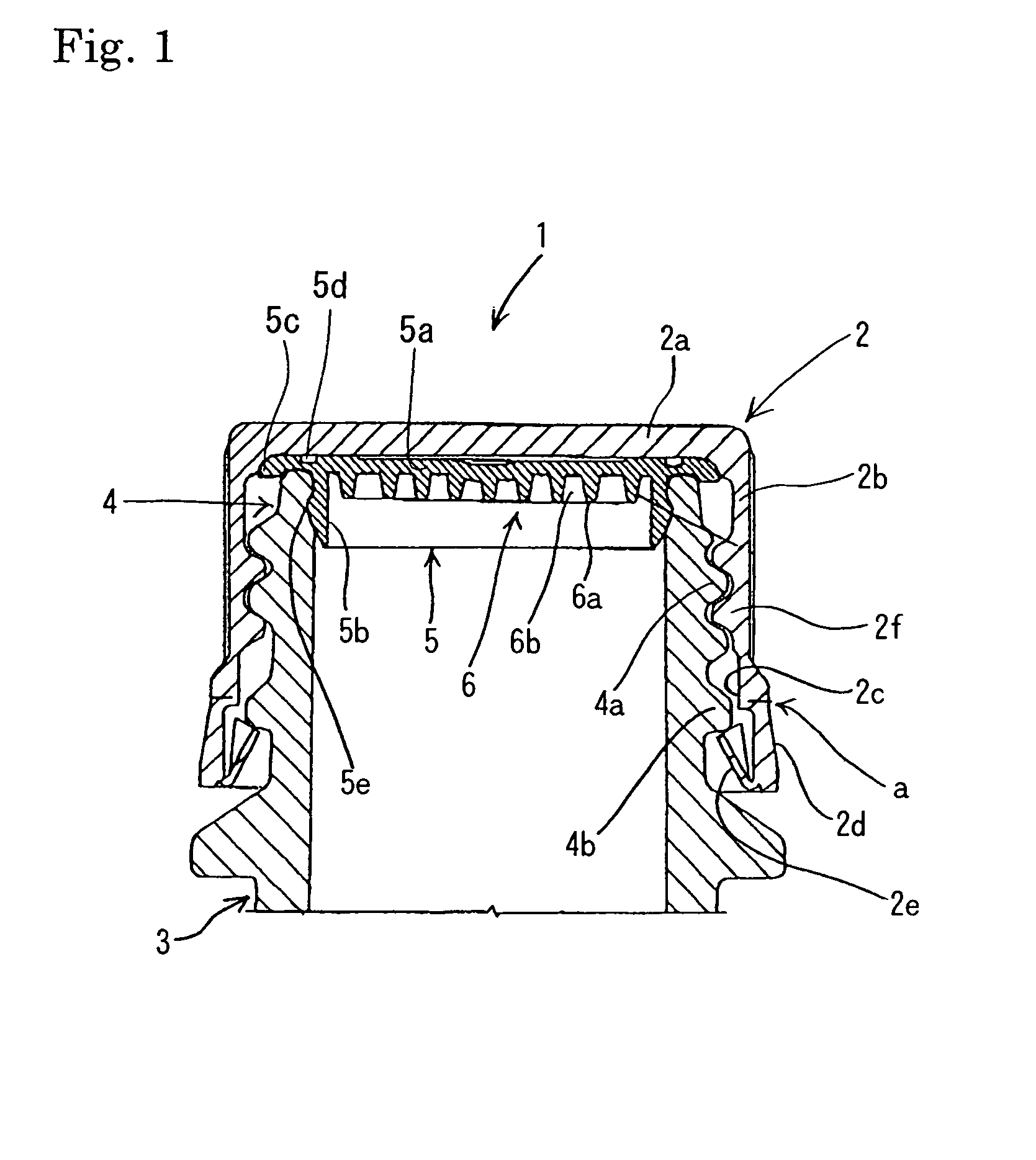

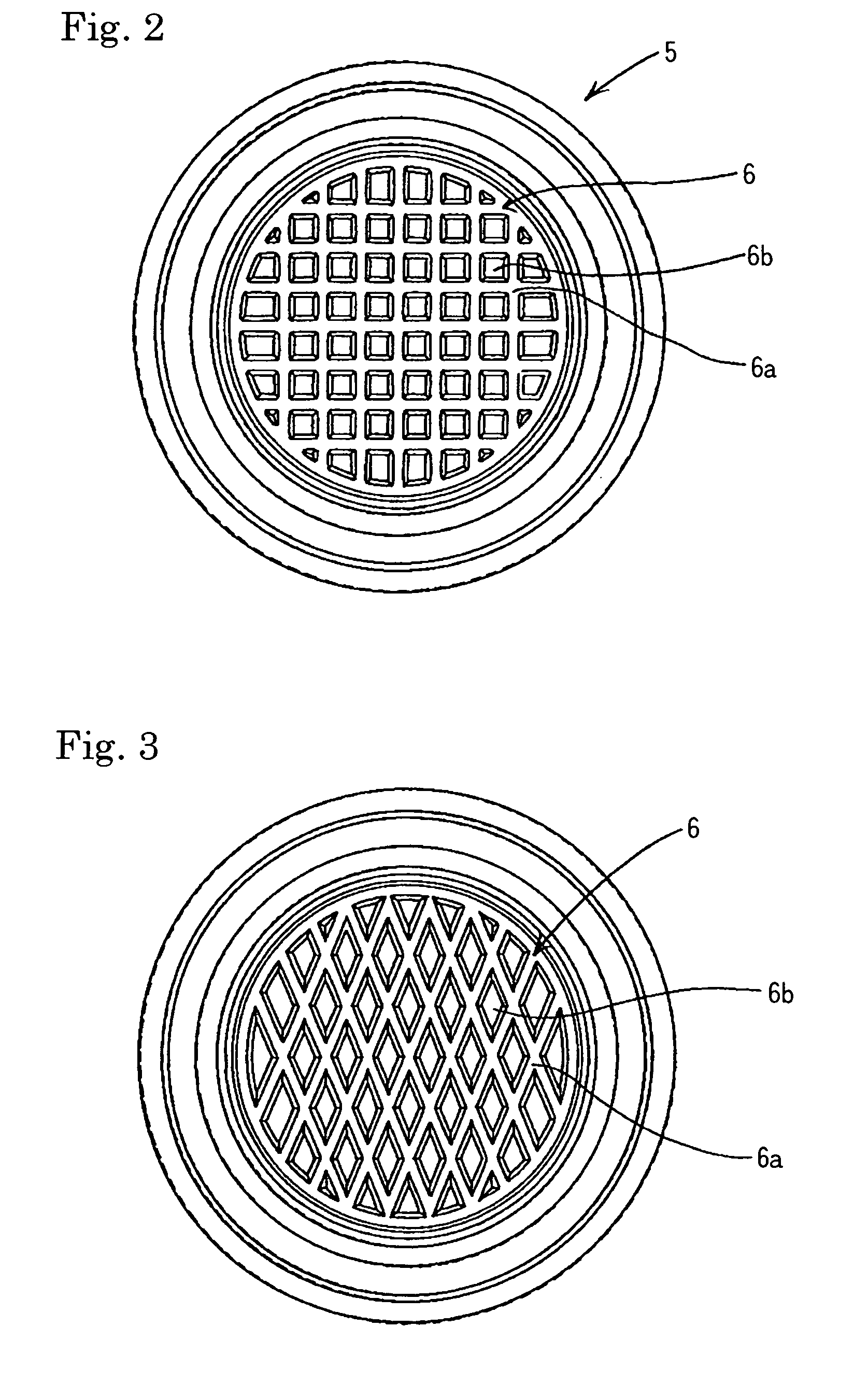

Closure Liner Composition With Improved Oxygen Reduction

InactiveUS20150118366A1Improve oxygen reduction performanceExtended shelf lifeClosures with oxygen absorbersCapsParticulatesOxygen

Disclosed is a closure liner composition comprising a mixture (or blend) of a thermoplastic polymer, an oxygen barrier polymer, and a particulate oxygen scavenging material. The oxygen barrier polymer preferably comprises polyisobutylene. The particulate oxygen scavenging material preferably is selected from the group consisting of an alkali metal salt of sulfite, ascorbate, isoascorbate, and a mixture of two or more of these materials. The closure liner composition may be used to fabricate a liner for a closure (e.g., a metal crown used to cap a bottle) that provides superior oxygen reduction properties and improved shelf life.

Owner:HENKEL IP & HOLDING GMBH

Fume purification system with tower box

The invention provides a fume purification system with a tower box, belonging to the technical field of fume treatment and environmental equipment. According to the fume purification system, absorbing boxes are longitudinally arranged so as to form a tower box structure; a gas resolving space separated from a fume passage is constructed; an alkaline absorbant is used for absorbing SO2 and NOx in fume in the absorbing box; according to the theory that the alkaline absorbent dynamically absorbs and resolves NOx, then the resolved NOx is conveyed to an NOx recovery system so as to be recovered, products generated by liquid phases in the absorbing boxes absorbing SO2 are mainly sulfites which are directly discharged out from an absorbing system, and a larger usable space is left. The fume purification system has the beneficial effects (1) the absorbing tanks are longitudinally combined to form a tower box structure, so that convenience in combination is achieved; (2) absorbing slurry pumps are applicable to liquid-phase pumps, and the liquid phase flows smoothly; (3) the fume and absorbing slurry in the absorbing box at each level are in cross-flow contact, but an overall countercurrent contact structure is formed; (4) the desulfurization rate is greater than or equal to 99%, the denitration rate is greater than or equal to 90%, the NOx recovery rate is greater than or equal to 90%, and the pure value of byproducts is high.

Owner:JIANGSU TANDGE ENVIRONMENTAL ENG

Oxygen-absorbing container cap

InactiveUS7704407B2Reduction in sealabilityPeelingHydrogenLiquid degasificationHigh oxygenPhotochemistry

The present invention provides an oxygen-absorbing resin composition, which is superior in oxygen absorbability, absorbs oxygen remaining in the container after sealing, keeps the contents in the container in good preservation, and improves moldability, dispersibility of the oxygen absorbent, stability of the oxygen absorbing performance, performance of preventing peeling and separation of the oxygen absorbent from the base resin, rigidity of the sealing part, and the like, which become problems in the case of including an oxygen absorbent having high oxygen absorbability and low compatibility with the base resin, as well as provides an oxygen-absorbing container cap and an oxygen-absorbing container plug using the same.The present invention provides an oxygen-absorbing resin composition characterized by being obtained by dispersing and blending an oxygen absorbent containing 20% or more of particles having a particle diameter of 1000 μm or less at a ratio of 20% or less to a base resin.

Owner:NIHON YAMAMURA GLASS CO LTD

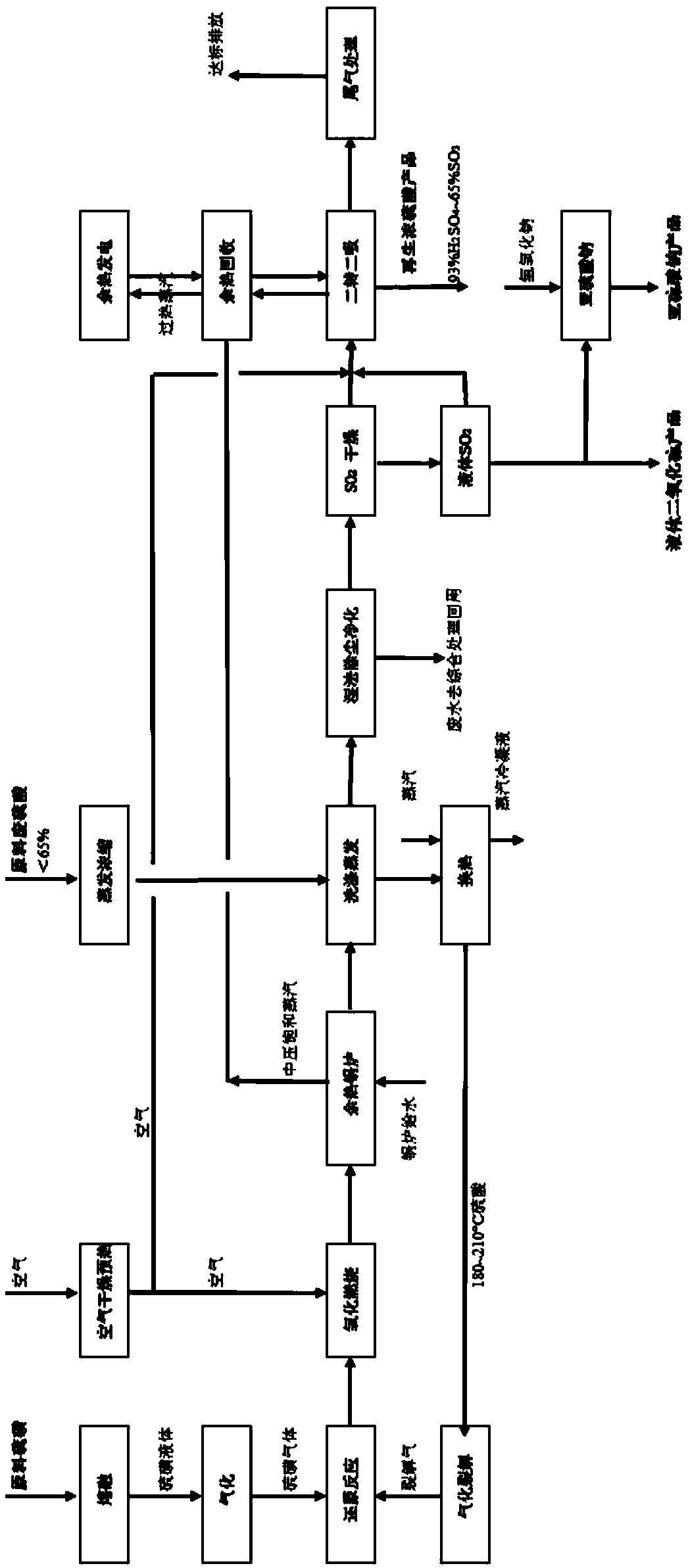

Method for using sulphur gas for reducing waste sulfuric acid to prepare liquid sulfur dioxide and sulfuric acid

ActiveCN109052335AResponsive and thoroughReduce energy consumptionEnergy inputSulfite preparationResource utilizationNitrogen gas

The invention relates to a method for using sulphur gas for reducing waste sulfuric acid to prepare liquid sulfur dioxide and sulfuric acid. Sulphur is gasified into the high-temperature sulphur gas,the raw material waste sulfuric acid is washed, evaporated, concentrated and split into gas, the two streams of gas is reacted in a reduction furnace to make sulfur trioxide in the waste sulfuric acidsplit gas reacted with the gas sulphur to generate sulfur dioxide gas, organic matters, powdered carbon and the like in the waste sulfuric acid split gas generate sulfur dioxide, carbon dioxide, carbon monoxide, nitrogen, hydrogen chloride, water and the like, reduced furnace gas is subjected to complete combustion, waste heat recovery, purification and drying to obtain sulfur dioxide gas, part of the sulfur dioxide is liquefied to prepare a high-purity liquid sulfur dioxide product, and sulfur dioxide-containing gas which is not liquefied and the other part of the sulfur dioxide gas are mixed, and are subjected to conversion and absorption to prepare the concentrated sulfuric acid. Compared with the prior art, the method has the advantages that low temperature is used for conducting purification, concentration and regeneration resource utilization on the waste sulfuric acid to prepare high-quality liquid sulfur dioxide and concentrated sulfuric acid products, meanwhile, impurities ofthe organic matters, salt and the like in the waste sulfuric acid are subjected to proper harmless treatment, no secondary pollutants are generated, and resource recycling and environmental friendliness are achieved.

Owner:上海三夫工程技术有限公司

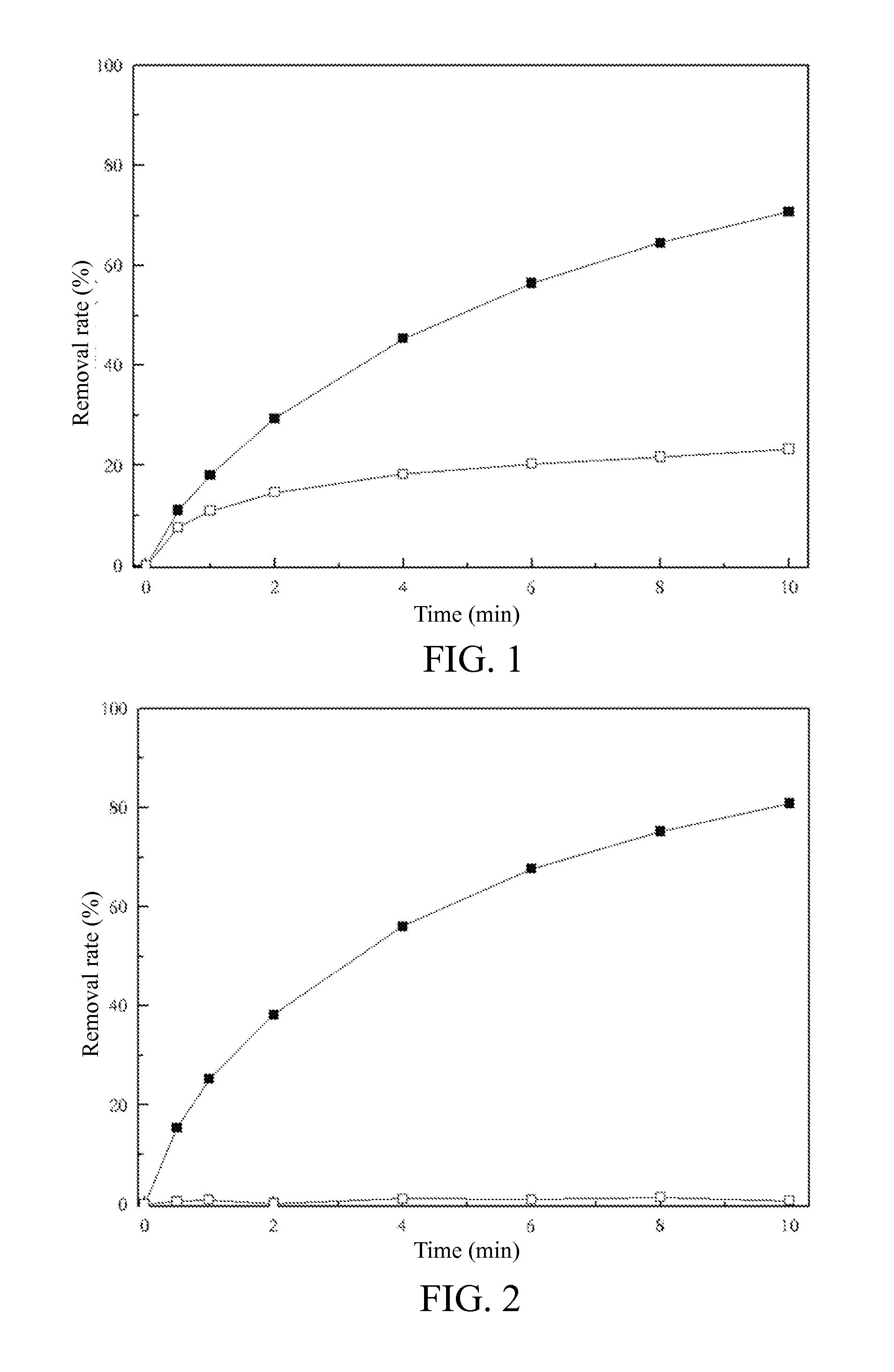

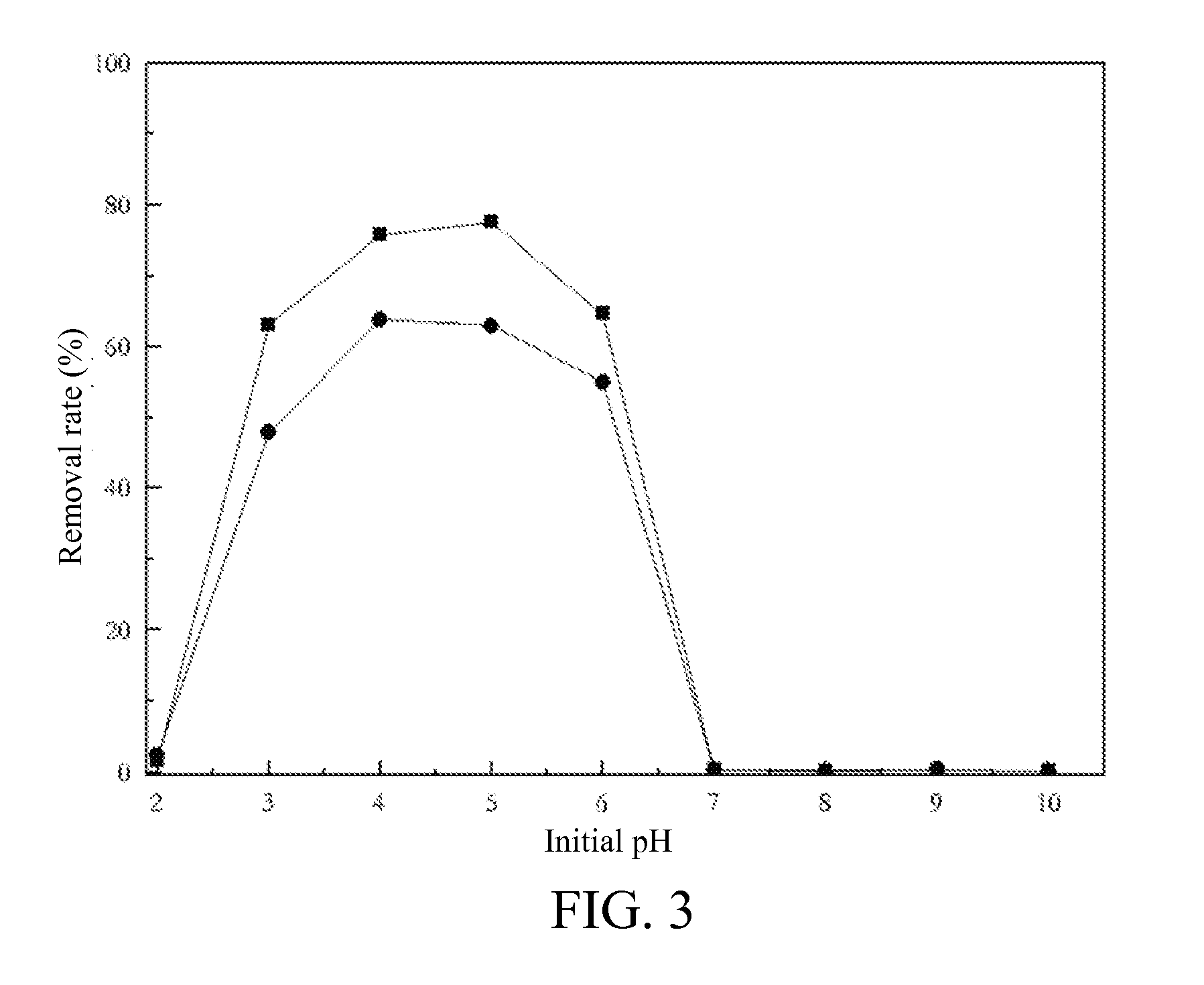

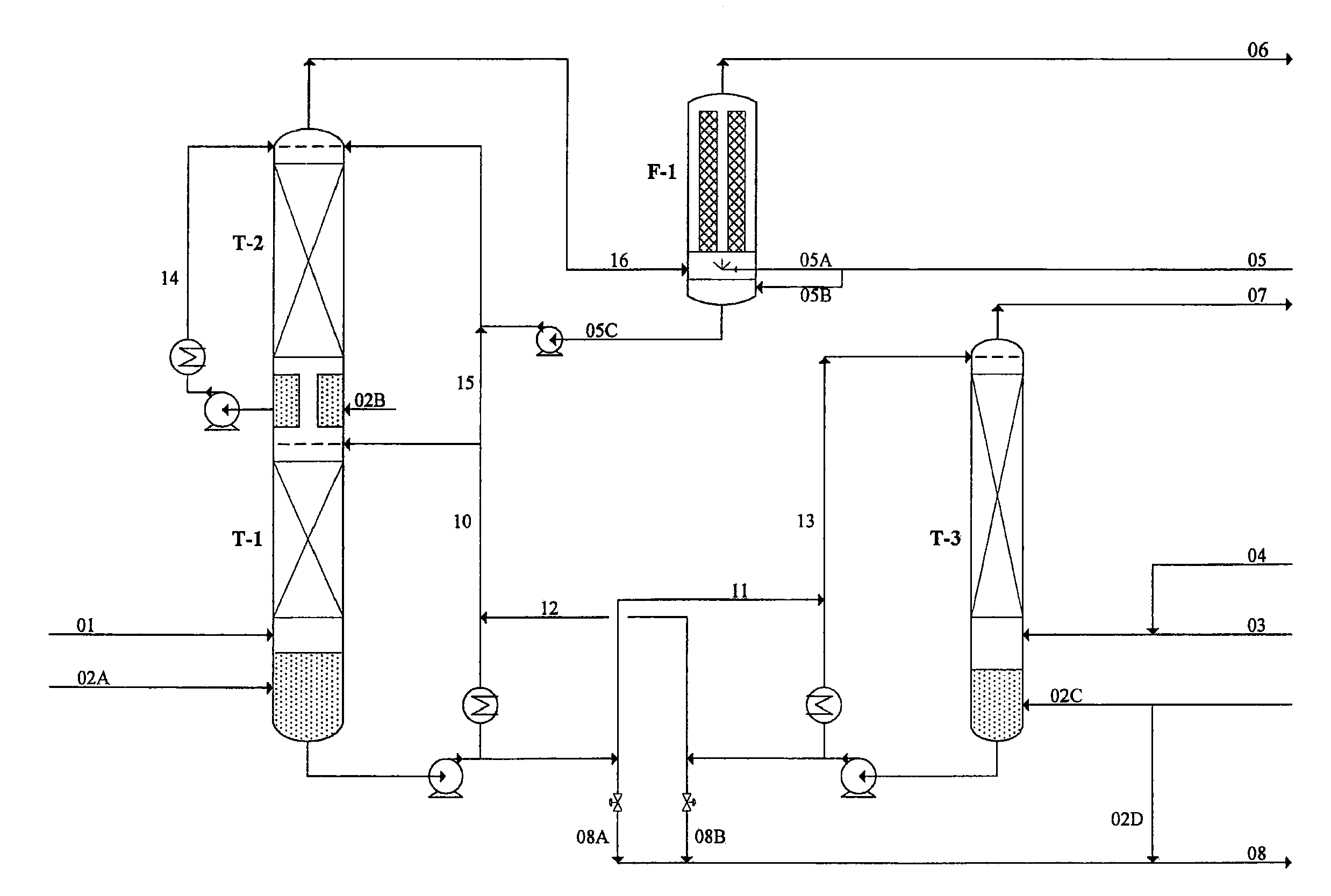

Fenton and Fenton-Like System Hardening Agent and Usage Thereof

InactiveUS20120305497A1Efficient use ofWide rangeWater treatment parameter controlOrganic chemistryHydrazine compoundSulfite salt

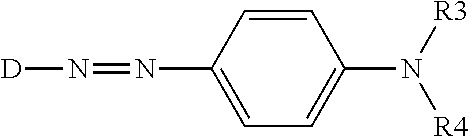

Fenton and Fenton-like system enhancing agent and the usage thereof are provided. It relates to a water treatment enhancer (enhancing agent) and the usage thereof. It widens water pH range of Fenton and Fenton-like system reaction. It reduces amount of Fe2+ required for Fenton reaction. It increases rate of Fenton-like reaction. The enhancing agent is selected from sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine hydrochloride, hydroxylamine perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, amino ethanolamine, hydroxylamine solution or N,N,N′,N′-tetrasubstituted p-phenylenediamine. The method of use of enhancing agent comprises the steps of: adding Fenton or Fenton-like system enhancing agent, an agent for enhancement and hydrogen peroxide into water subject to treatment; and mixing and allowing reaction. The enhancing agent can increase the rate of reaction for the water treatment and reduce the dosage of the agent for enhancement.

Owner:HARBIN INST OF TECH

Closure with oxygen scavenger

InactiveUS20060102875A1Avoid enteringClosures with oxygen absorbersHydrogenPolymer sciencePolypropylene

A closure that is able to prevent oxygen from entering the container upon which the closure is attached. Preferably, the closure is comprised of one piece wholly molded of plastic, oxygen scavenging or anti-oxidant compounds, and catalysts homogenously mixed therein. More preferably, the closure is a composition of polypropylene or high-density polyethylene with an oxygen scavenger and catalyst integrated within the polypropylene or high-density polyethylene.

Owner:PHOENIX CLOSURES

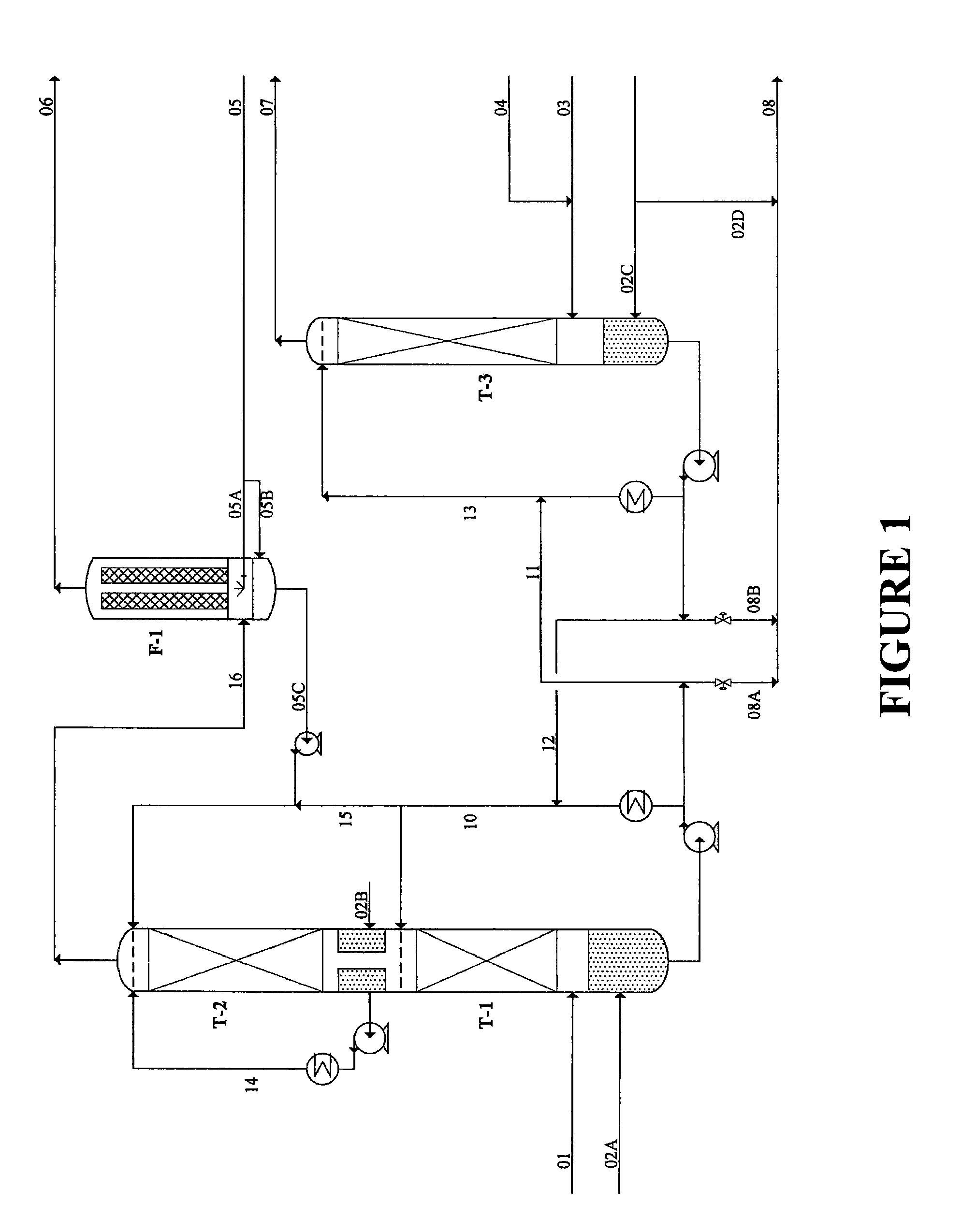

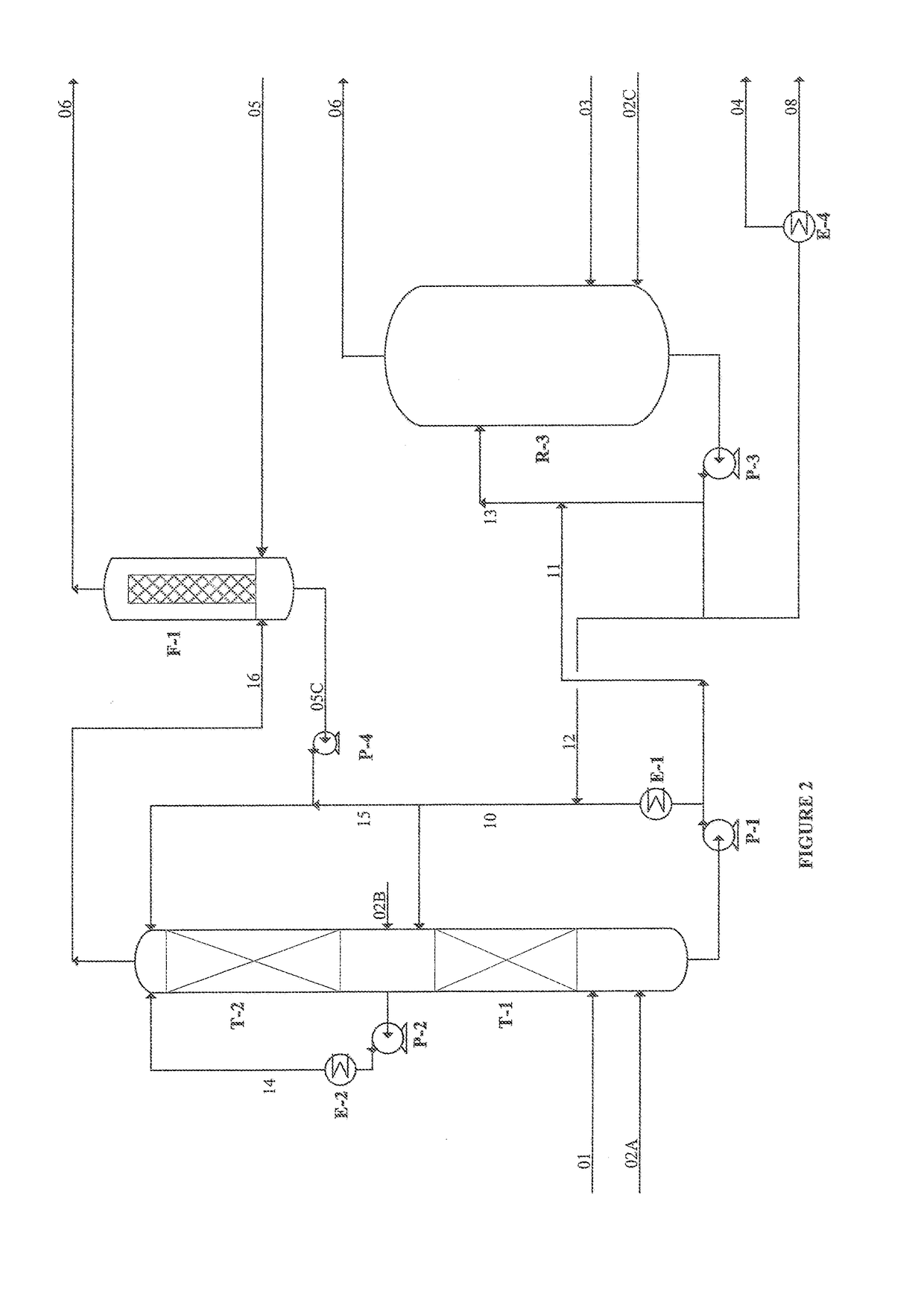

ATS tail gas treating process for SRU and SWS off gases

ActiveUS7824652B1Promote absorptionMaximize recoveryThiosulfates/dithionites/polythionitesSulfite preparationCombustionExhaust fumes

The present invention relates to a system and process utilizing ammonium thiosulfate solution (ATS) as the primary liquid absorption agent that is re-circulated through an SO2 Contactor / Absorber for high efficiency contacting and absorption of sulfur dioxide, SO2 from a combustion gas stream generated by incineration of a Claus Sulfur Recovery Unit (SRU) off gas stream (often referred to as a Claus tail gas stream) and also additional SO2 generated from incineration of additional sulfur containing streams. ATS is also re-circulated through a separate H2S Contactor / Absorber for absorption of and reaction with a Sour Water Stripper (SWS) off gas stream and additional H2S-Acid Gas (A.G.) streams to produce additional concentrated ATS. The process and equipment also provides the ability to readily switch between using ATS and ABS as the primary absorbent solution for SO2 absorption, depending upon the concentration of SO2 in the off gas feed streams.

Owner:TESSENDERLO KERLEY INC

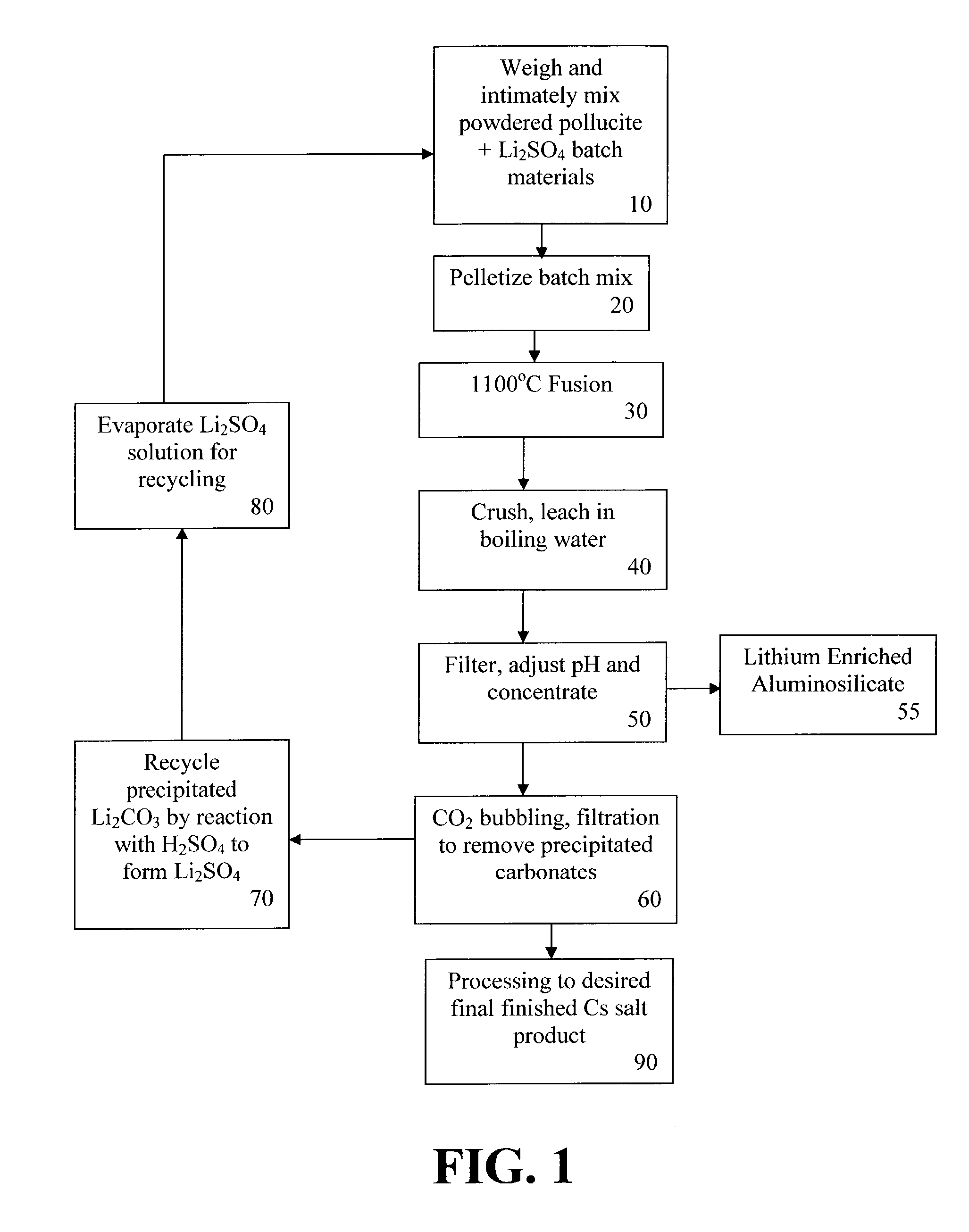

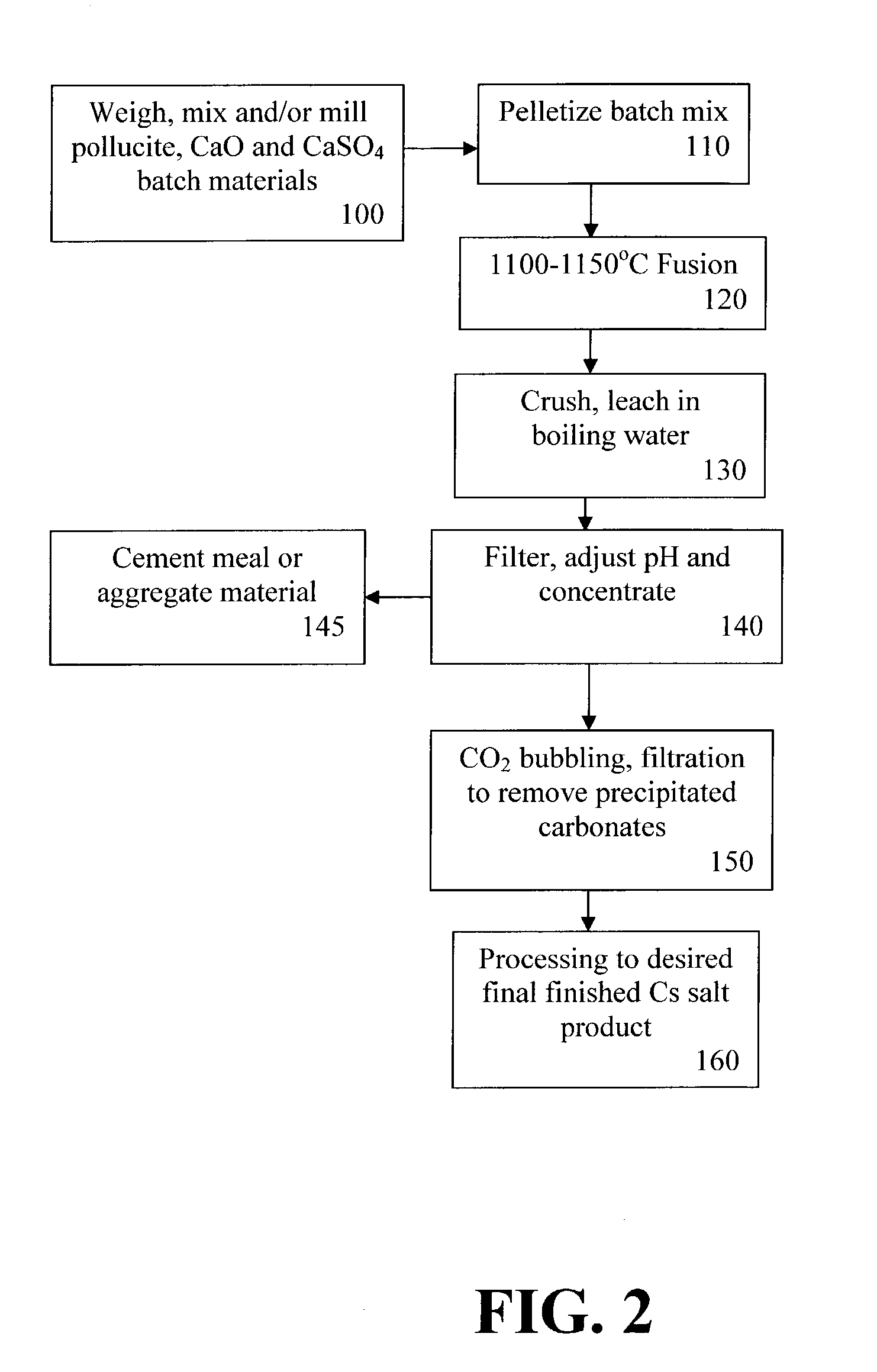

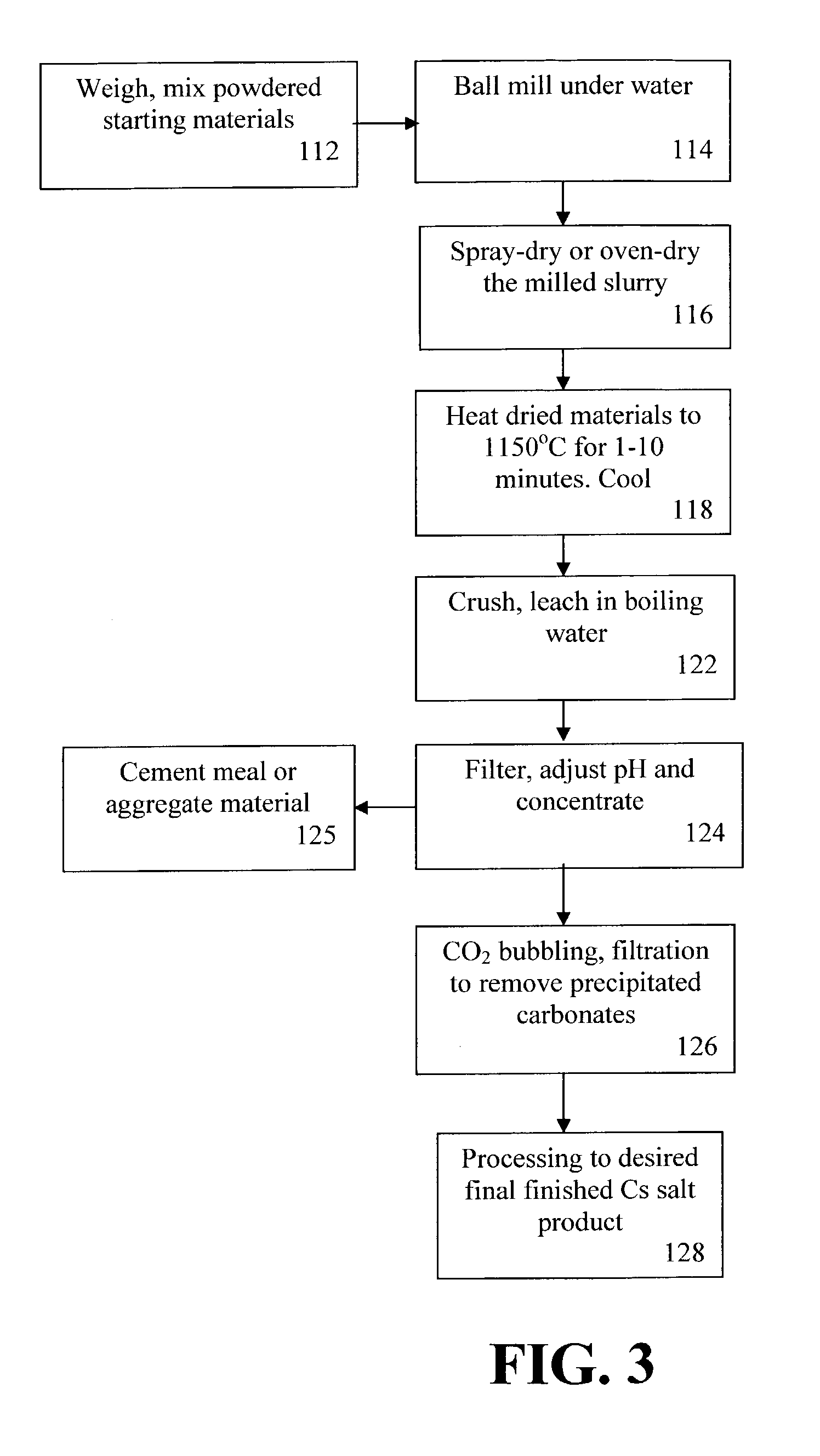

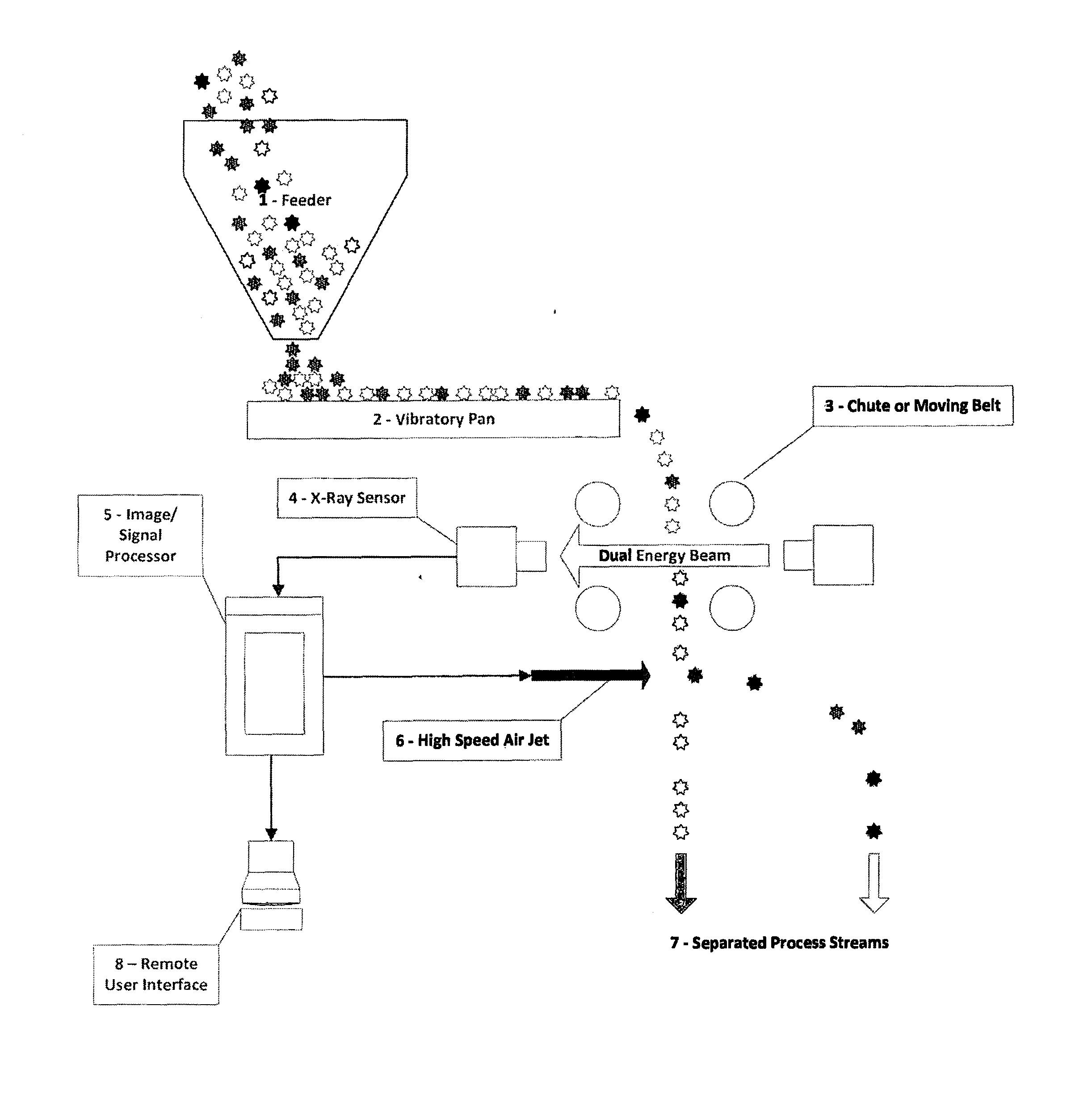

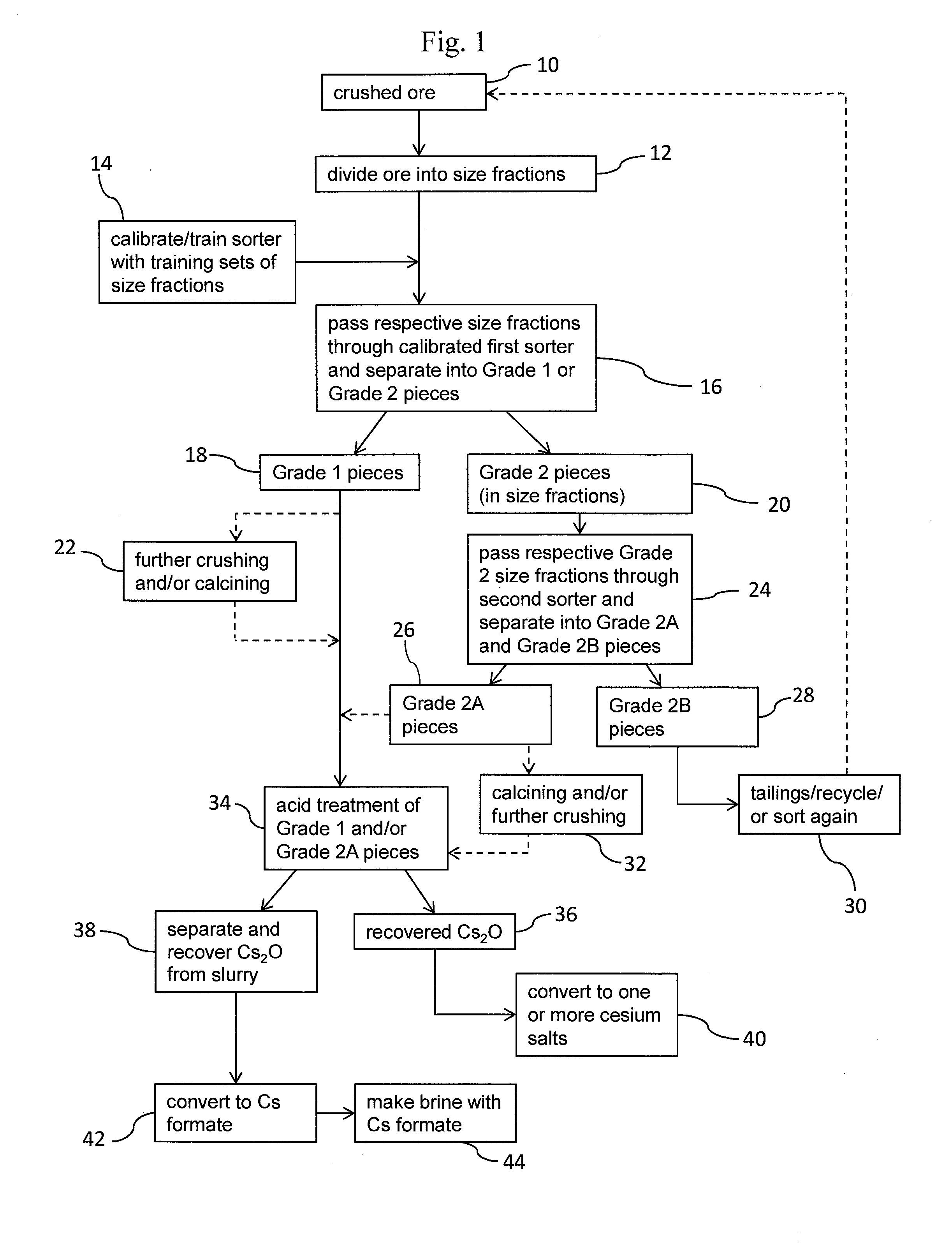

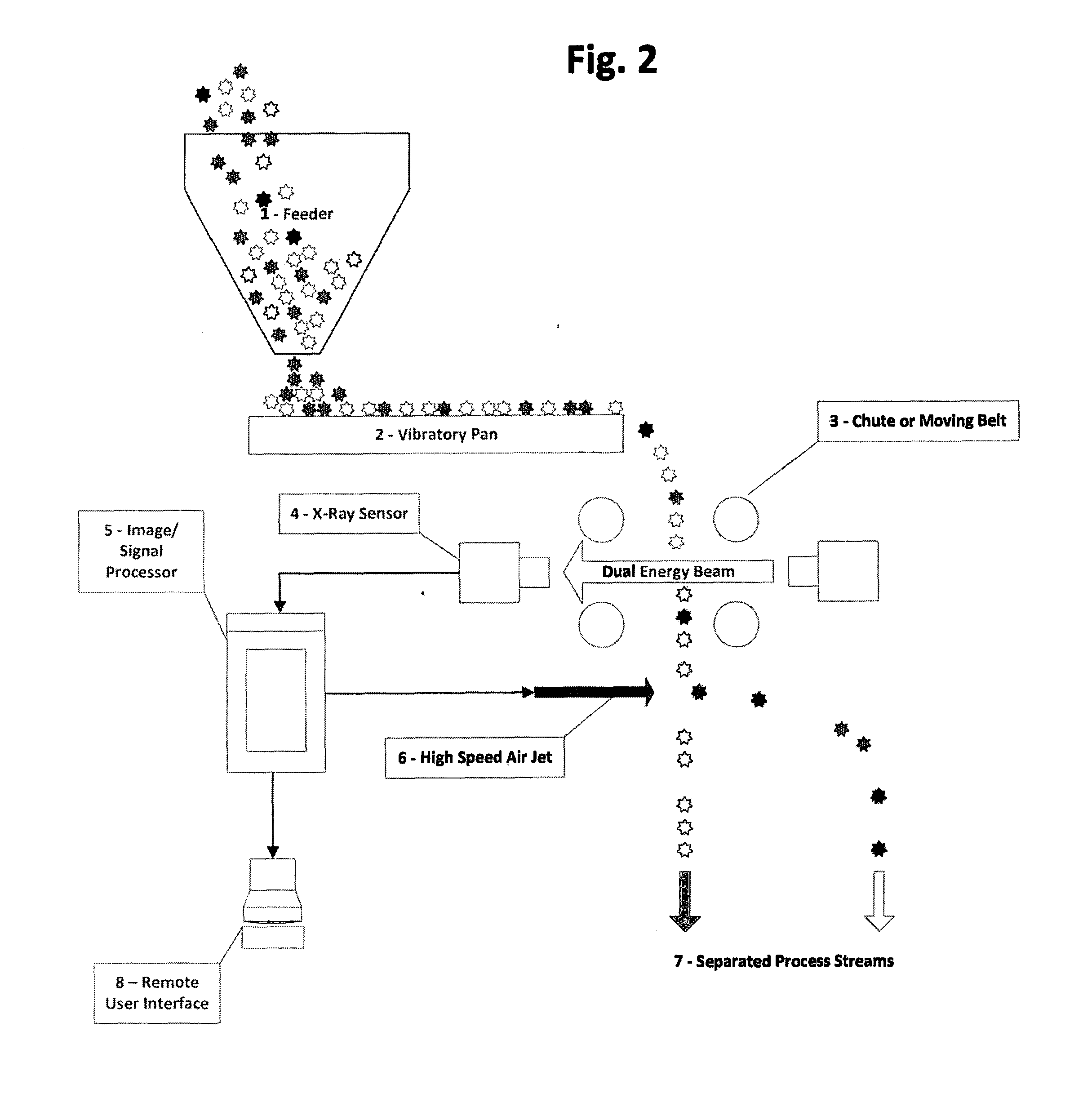

Methods To Recover Cesium Or Rubidium From Secondary Ore

ActiveUS20140255278A1Effective recoveryReduce the amount of solutionSolvent extractionSulfite preparationRubidiumComputer science

A method to recover cesium, rubidium, or both from secondary ore is described and involves using scans and sorting techniques. Refined secondary ore is further described.

Owner:CABOT SPECIALTY FLUIDS

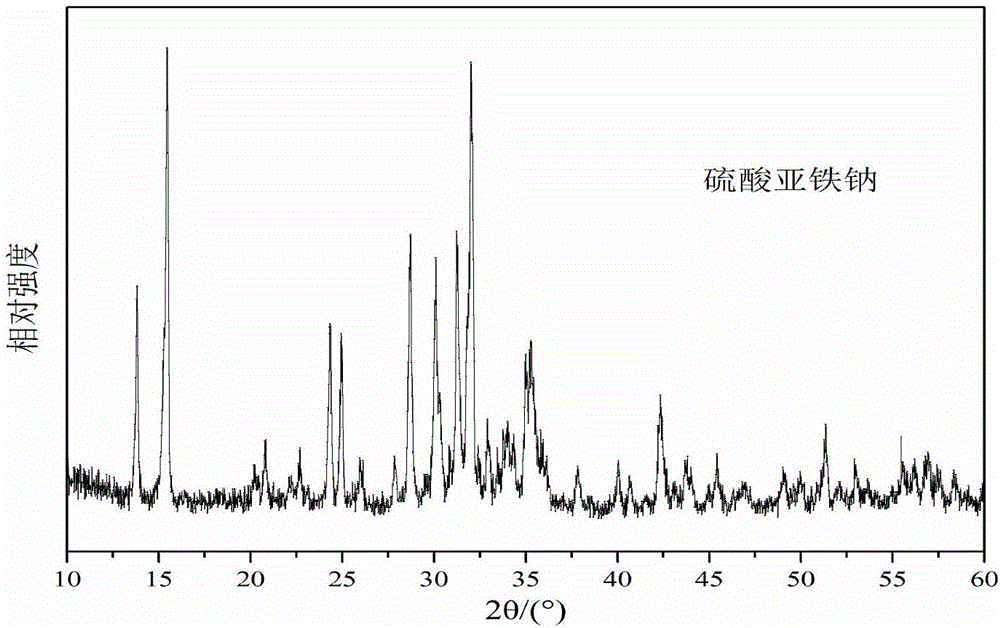

Method for recycling sodium sulfate waste liquid

ActiveCN106803588AAchieve reuseImprove electrochemical performanceCell electrodesSulfite preparationLiquid wasteResource utilization

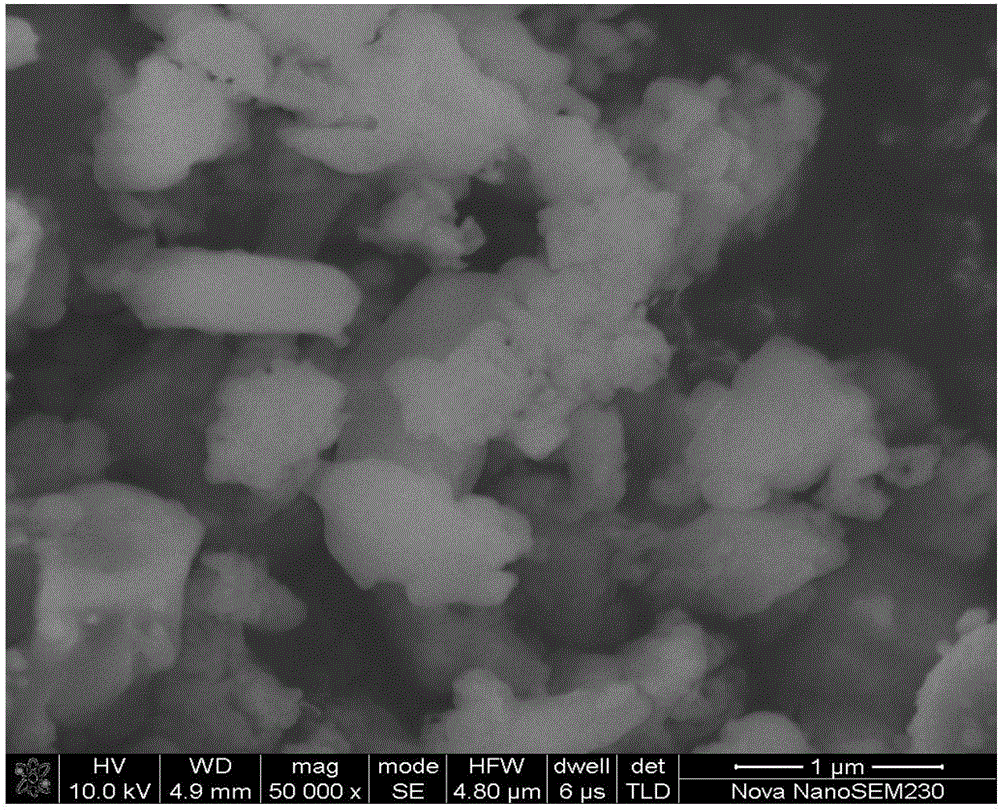

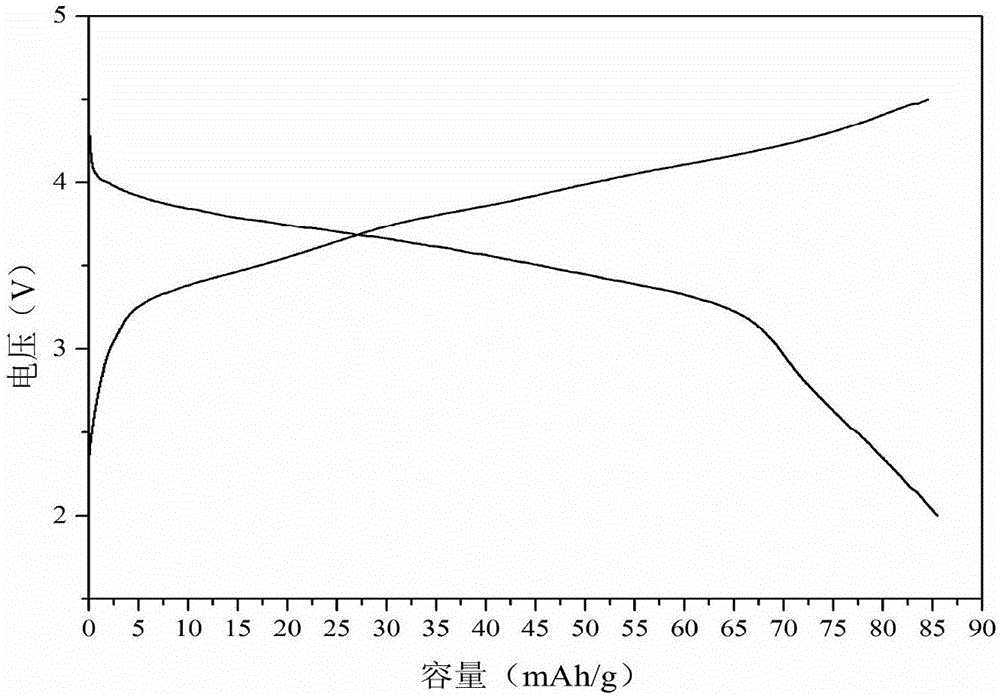

The invention discloses a method for recycling sodium sulfate waste liquid. According to the method, an industrial waste sodium sulfate solution is used, and a precursor of sodium ferrous sulfate can be obtained by steps of adjusting the concentration of the waste sodium sulfate solution, adding an appropriate amount of ferrous sulfate, performing stirring for a period of time at a certain temperature, and drying to remove moisture. A sodium ion battery cathode material, namely sodium ferrous sulfate, can be obtained by sintering the precursor at a certain sintering temperature. The invention finds a recycling way with a high economic added value for the industrial waste sodium sulfate solution, the sodium ion battery cathode material is prepared by using sodium sulfate wastewater as a raw material, the resource utilization of the sodium sulfate waste liquid is realized, good economic and environmental benefits are achieved, and the prepared sodium ferrous sulfate material has the advantages of high specific capacity, high working voltage, good cycling stability and excellent rate performance when used as a sodium ion cathode material.

Owner:CENT SOUTH UNIV

Process for colour neutralizing compositions

The present application relates to a process of colour neutralizing treatment liquids, wherein the treatment liquid comprises a chromophore selected from the group consisting of monoazo, triarylmethane, xanthene, anthraquinone, hydrophobic dyes, and mixtures thereof, wherein the hydrophobic dyes are selected from the group consisting of benzodifuranes; methine; triphenylmethanes; naphthalimides; pyrazole; naphthoquinone; mono-azo, di-azo dyes and mixtures thereof, said process comprising the steps of:i. providing a mixing vessel with the treatment composition comprising the chromophore;ii. providing to the mixing vessel more than 0.045% of a reducing agent selected from the group consisting of sulfite, thiodiurea, formaldehyde bisulfite formaldehyde sulfoxilate and mixtures thereof; andiii. mixing until discolouration by color neutralization of the chromophore is achieved.

Owner:THE PROCTER & GAMBLE COMPANY

Method used for desulphurization and denitration closed cycle and sulfur resource recovery

InactiveCN106039941AImprove scalabilityMeet environmental protection requirementsGas treatmentUsing liquid separation agentSocial benefitsDesorption

The invention provides a method used for desulphurization closed cycle and denitration and sulfur resource recovery. The method comprises the following steps: 1, dedusting; 2, desulphurization and denitration; and 3, sulfur resource recovery. The problems of difficult treatment and secondary pollution of byproducts, high running cost and product singleness in the prior art are effectively solved through the method. Desorption, reduction and regeneration of desulphurization byproducts are fully utilized according to market demands. The purpose of the method is to treat wastes with wastes and kill many birds with one stone, circulate and recovery wasted sulfur resources in coal-fired flue gas with lowest cost, improve the comprehensive added values of the desulphurization byproducts and reduce the running cost, so the method has the advantages of realization of long-term and high-efficiency running and self-sufficiency closed cycle of dedusting, desulphurization and denitration, resource saving, energy saving, consumption reduction, no wastewater discharge, no secondary pollution, resource recovery and environment treatment requirement meeting, and increase of the economic and social benefits of enterprises.

Owner:天津佳晟染料贸易有限公司

Sulfur dioxide scrubbing system and process for producing potassium products

ActiveUS20170190575A1Gas treatmentThiosulfates/dithionites/polythionitesPotassium peroxideOxidation state

The invention relates to a process for preparing potassium thiosulfate, potassium sulfite or potassium bisulfite comprising the following steps:Step (1a): providing a potassium hydroxide or potassium carbonate solution for neutralizing acid forming components such as dissolving SO2 or H2S;Step (1b): providing an SO2 contacting solution, containing at least some potassium sulfite or potassium bisulfite or potassium thiosulfate;Step (2): providing SO2 gas;Step (3): reacting these to absorb the SO2 gas and to form an intermediate reaction mixture comprising potassium sulfite, or potassium bisulfite or a mixture thereof, and optionally recovering the potassium sulfite, or potassium bisulfite or a mixture thereof, and / or optionally using steps 4 and 5;Step (4): adding sulfur or sulfide containing compound containing sulfur having the oxidation state of 0, −2 or of between 0 and −2 to the reaction mixture and optionally potassium hydroxide or potassium carbonate, and reacting the mixture under suitable conditions to form potassium thiosulfate; andStep (5): recovering the potassium thiosulfate, and optionally concentrating the potassium thiosulfate.

Owner:TESSENDERLO KERLEY INC

Potassium sulfite/potassium bisulfite (KS/KBS) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite and potassium bisulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

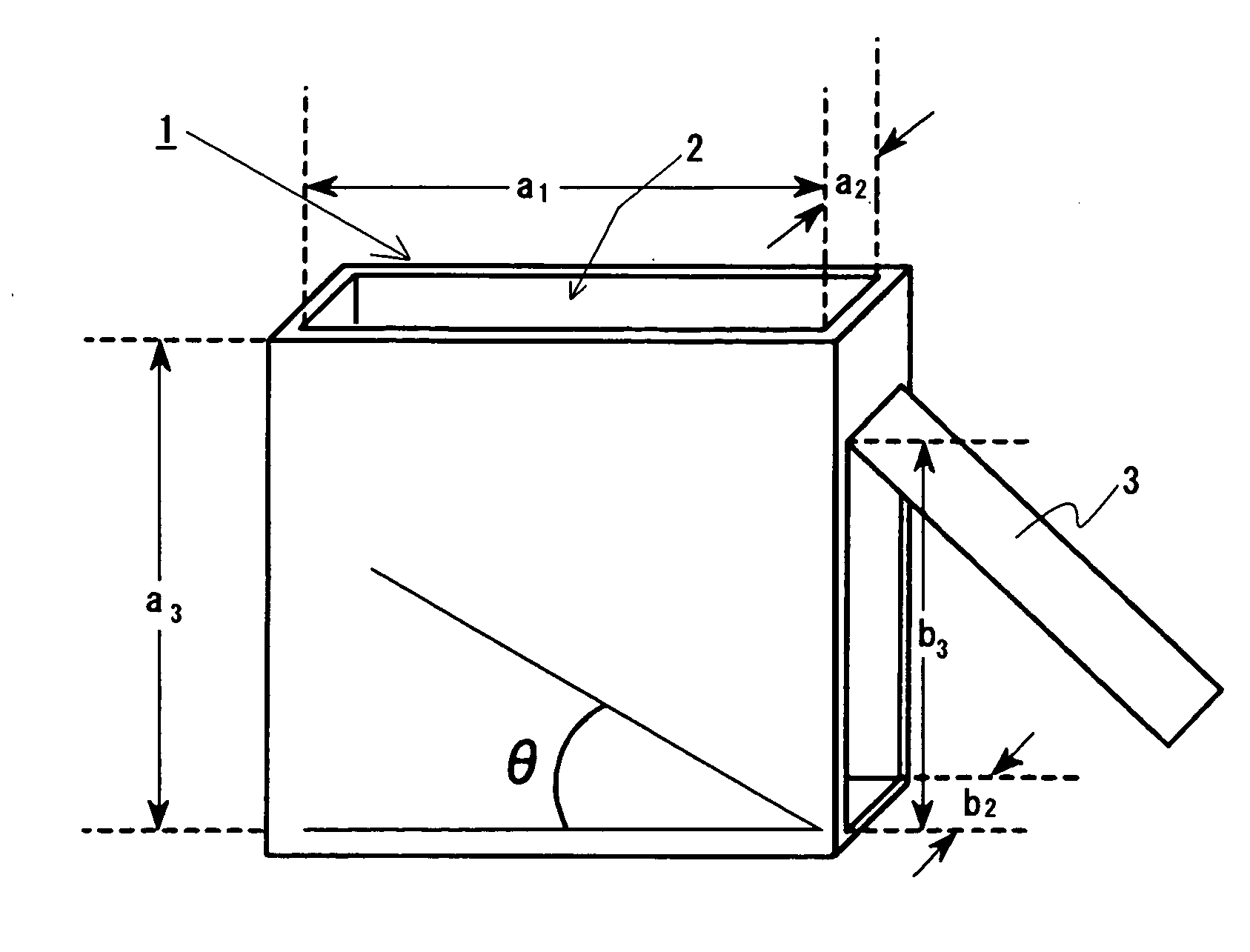

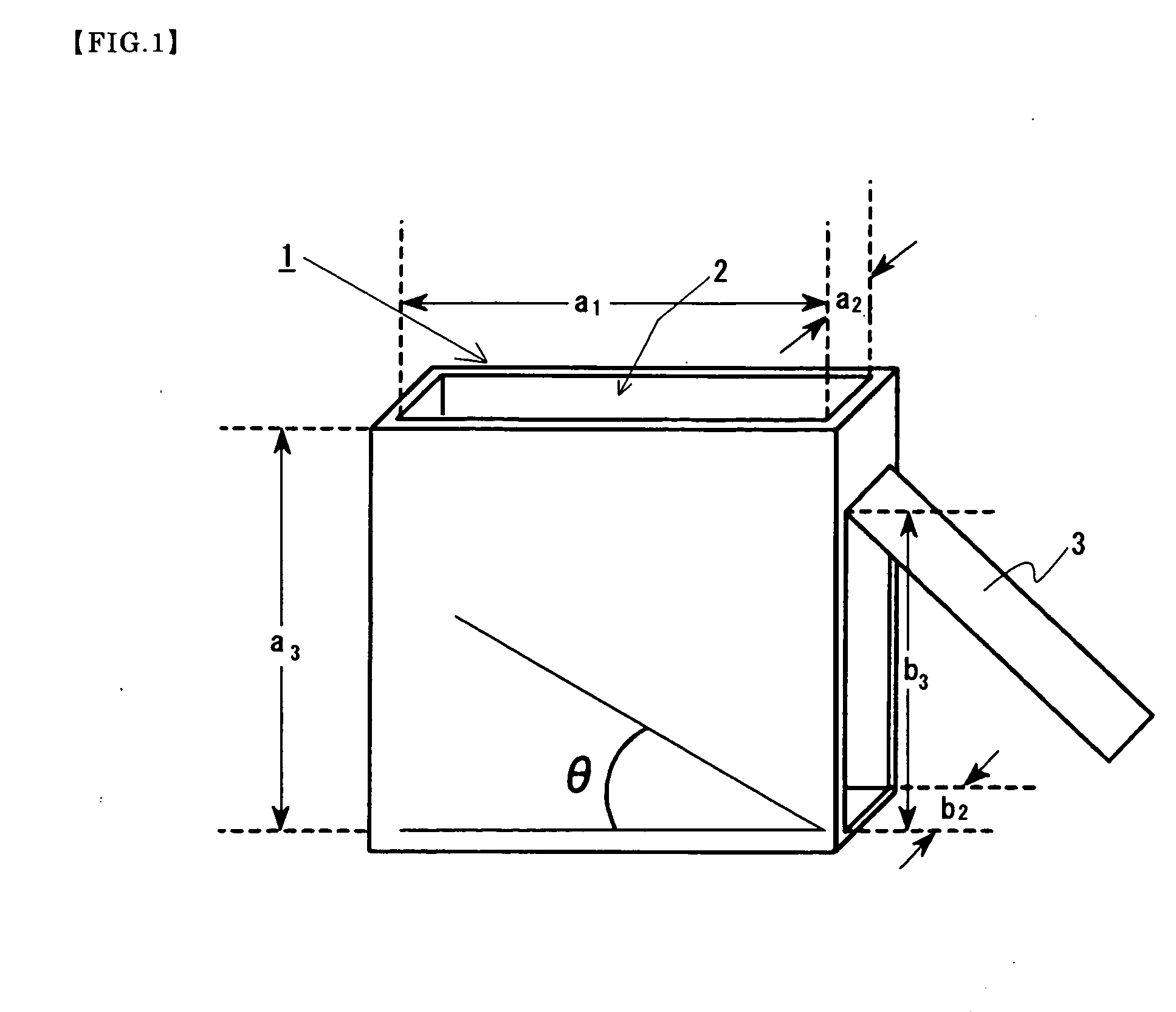

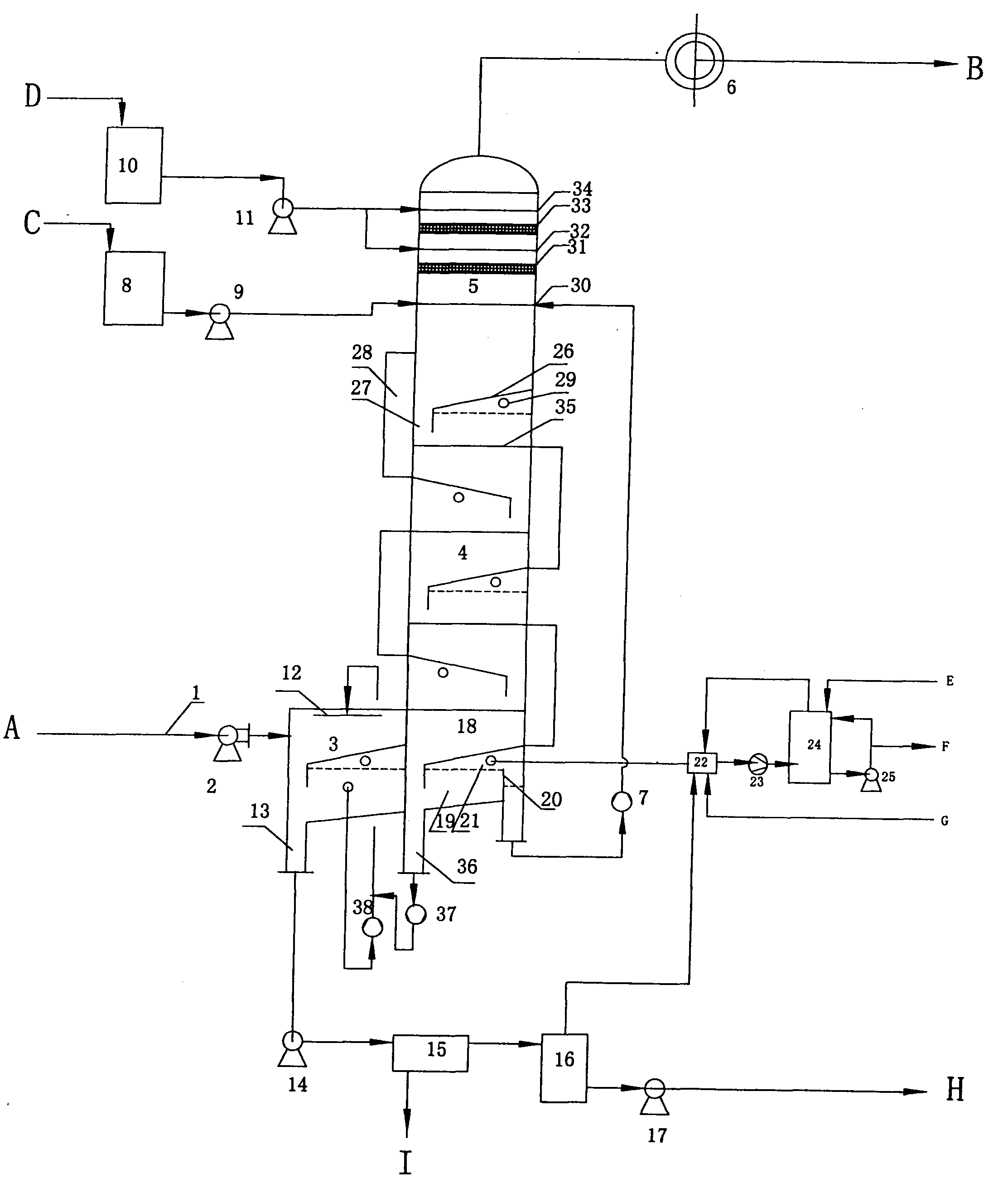

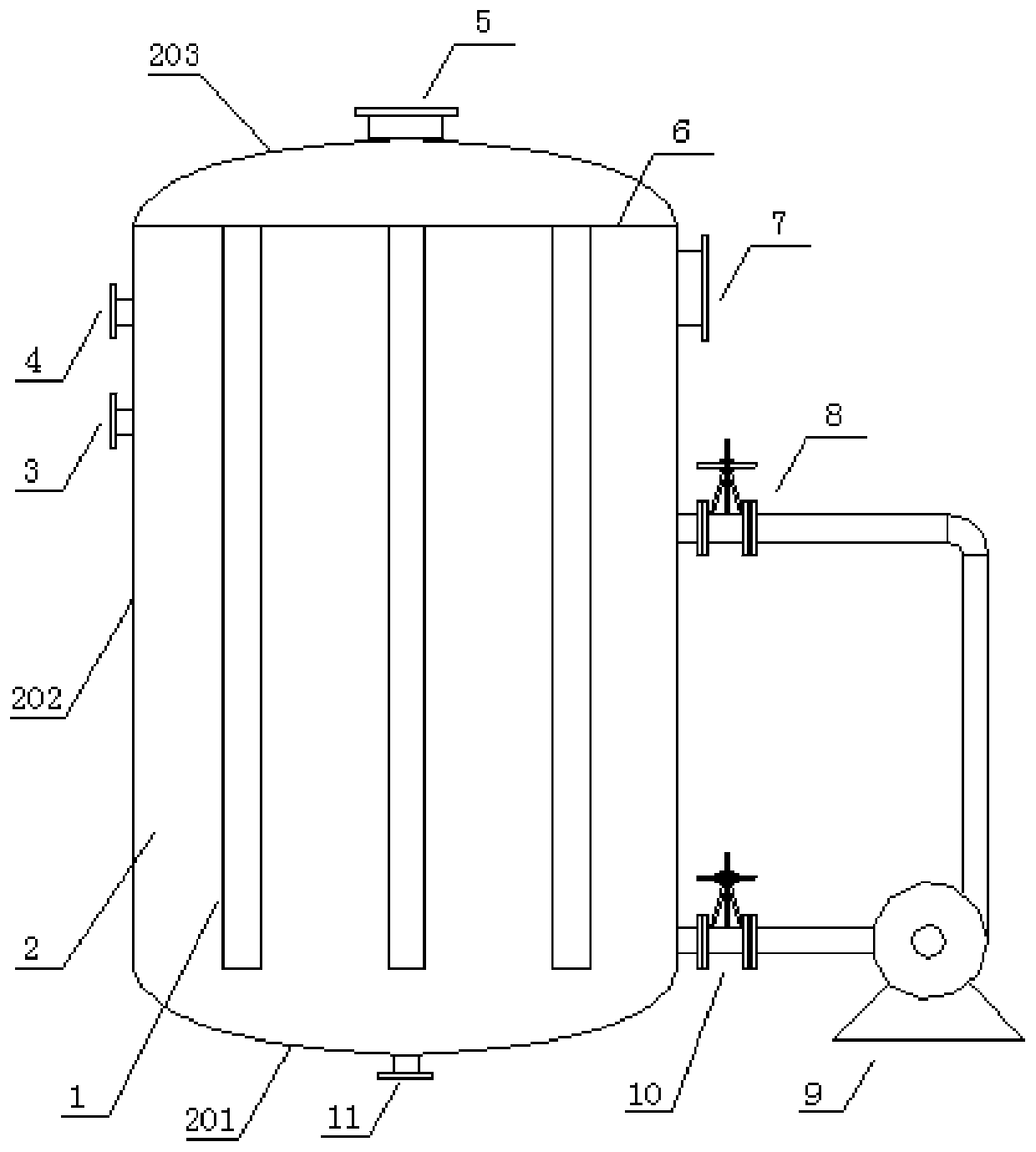

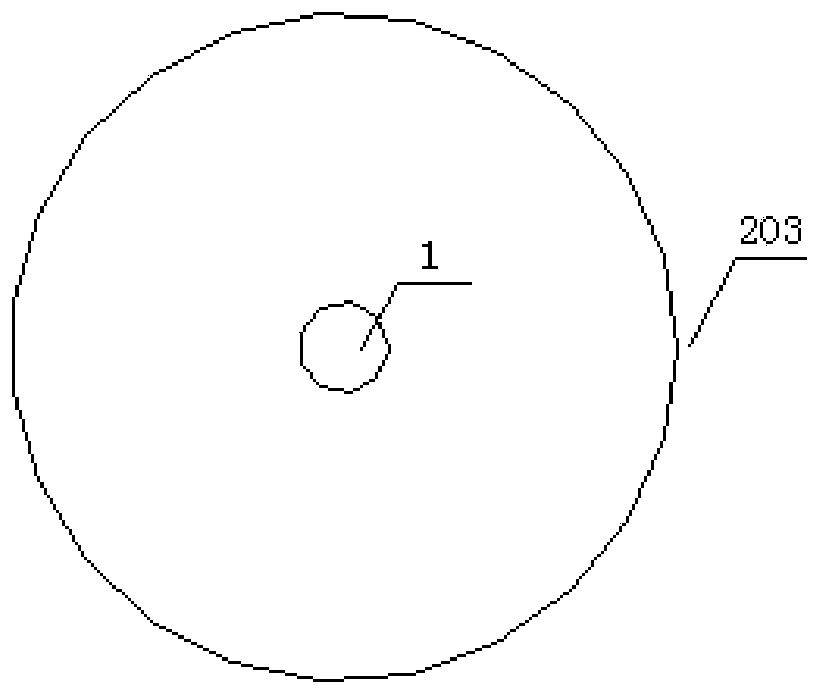

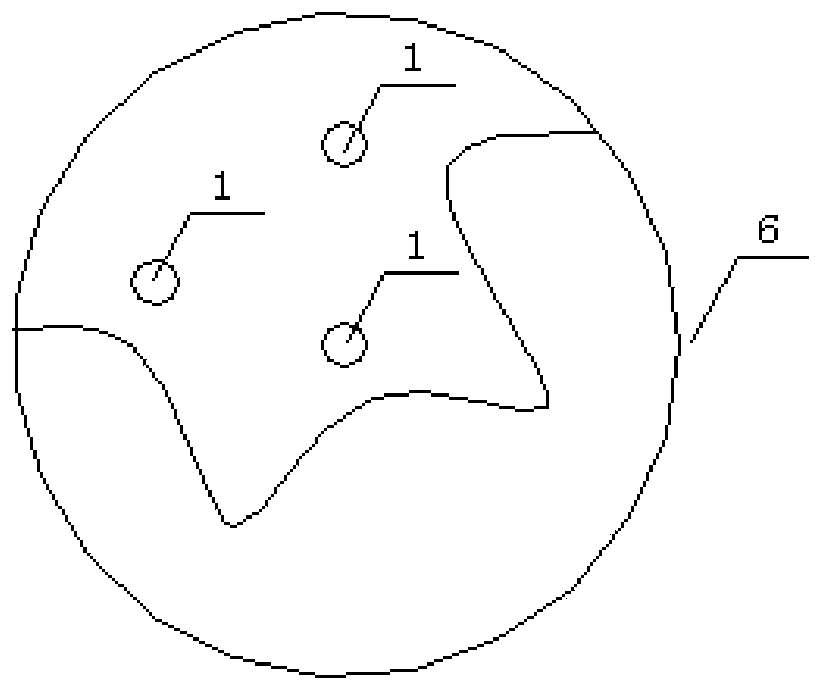

Gas-liquid phase reactor for preparing sulfite

InactiveCN110368878AEven contactImprove reaction efficiencyLiquid-gas reaction as foam/aerosol/bubblesSulfite preparationHigh energyProcess engineering

The invention provides a gas-liquid phase reactor for preparing a sulfite, and belongs to a chemical device. The gas-liquid phase reactor comprises a reactor tank body and a stirring pump, a certain number of bubbling tubes are inserted in the reactor tank body, the bubbling tubes are inserted from the upper part of the reactor tank body into the lower part of the reactor tank body, the reactor isnot internally provided with mechanical rotating equipment, the problems of required sealing and high energy consumption of an existing gas-liquid phase reactor stirring device are effectively avoided, the gas-liquid reactor realizes efficient mass transfer and heat transfer of a gas-liquid phase through gas bubbling and the stirring pump, and the system runs more smoothly.

Owner:NANJING GEKOF INST OF ENVIRONMENTAL PROTECTION TECH & EQUIP CO LTD +3

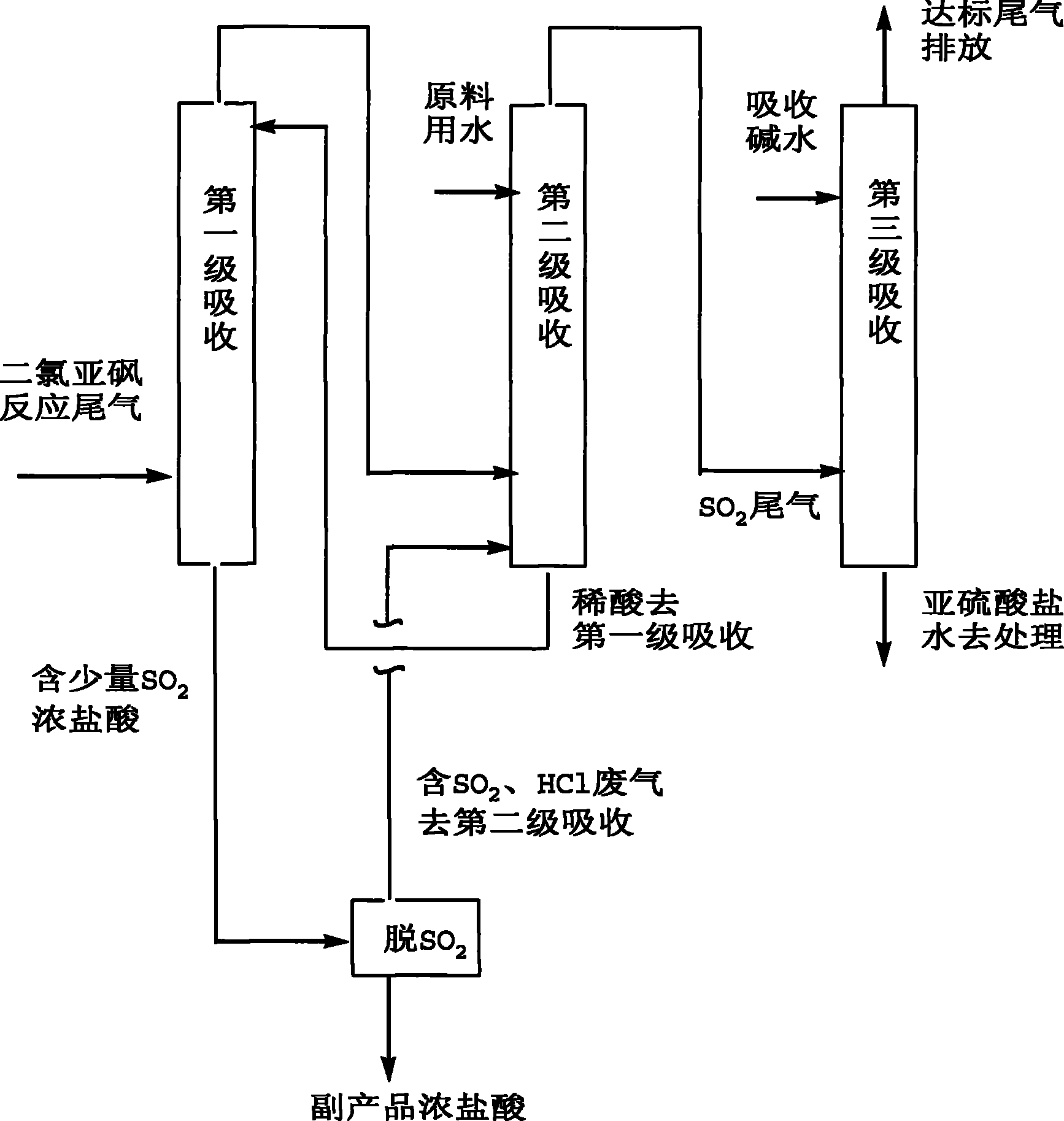

Method for treating tail gas of thionyl chloride chlorination

InactiveCN101121094BFully absorbedReduce dosageChlorine/hydrogen-chlorideSulfur-halogen-hydrogen-oxygen compoundsSulfite saltSulfur dioxide

The present invention discloses a disposal method of a tail gas, which is produced from a thionyl chloride used in a chlorination reaction. The cost of the prior traditional tail gas disposal method is high because of large consumption of alkali, and a high environmental protection pressure is resulted from a plurality of finally produced waste water which contains heteroions. Firstly, the present invention uses water to absorb the hydrogenchloride of the tail gas by controlling the water consumption, and a first grade absorption obtains a concentrated hydrochloric acid, the a hydrogenchloride content of which is approximately saturated and little sulfur dioxide is contained; a second grade absorption is that water is used to process the tail gas after the first grad absorption for the second grade absorption, which is that the added water is not discharged to obtain a diluted hydrochloric acid which contains little hydrogenchloride and little sulfur dioxide, and the diluted hydrochloric acid is used as a liquid of raw material used for the first grade absorption; then the alkali or alkaline water is used to process the tail gas after the second grade absorption for a third grade absorption to absorb the sulfur dioxide in the tail gas and obtain a quite pure sodium sulfite aqueous solution. The disposal efficiency of the present invention is high, and the tail gas absorption is complete, which reduces the environmental protection pressure.

Owner:GAOYOU CITY ORGANIC CHEM FACOTRY

Popular searches

Solid waste disposal Non-surface-active detergent compositions Organic/inorganic per-compounds compounding agents Magnesium/calcium/strontium/barium sulfides/polysulfides Fire extinguisher Water/sewage treatment by reduction Soap detergent compositions Sulfate preparation Wood layered products Thin material handling

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com