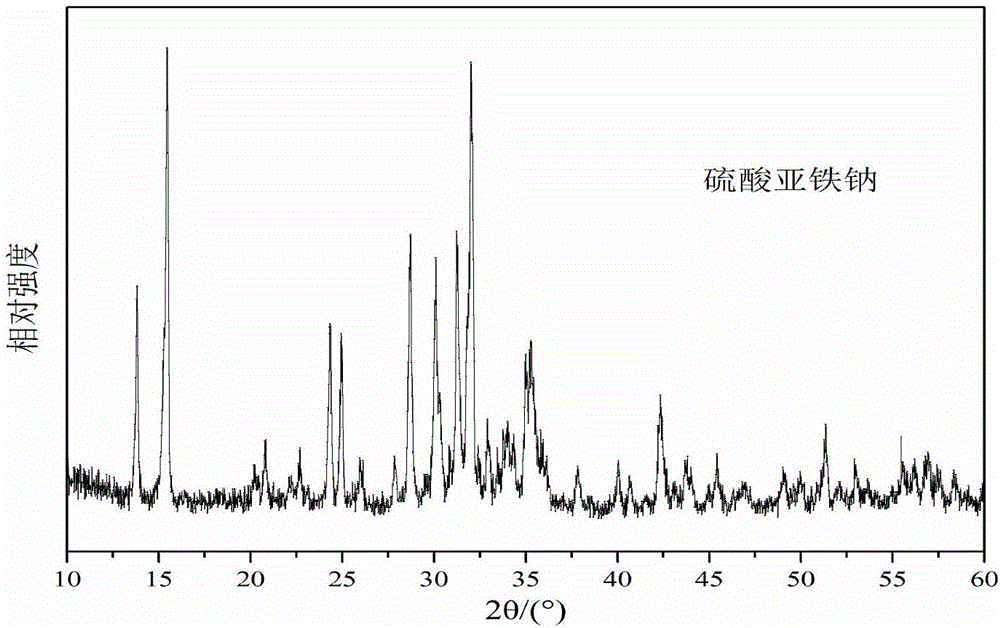

Method for recycling sodium sulfate waste liquid

A technology of sodium sulfate waste liquid and sodium sulfate, which is applied in the fields of sulfite preparation, electrical components, electrochemical generators, etc., can solve the problems of complicated preparation process, difficulty in realizing large-scale production, and high equipment requirements, and achieves simple operation, Good economic and environmental benefits, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

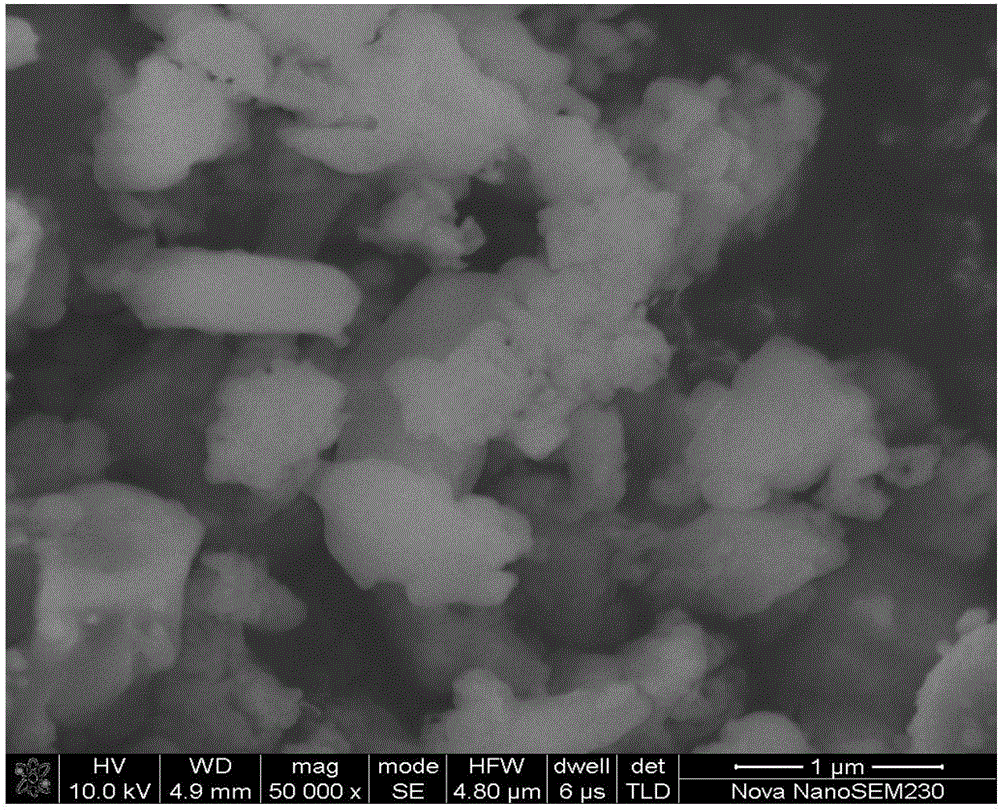

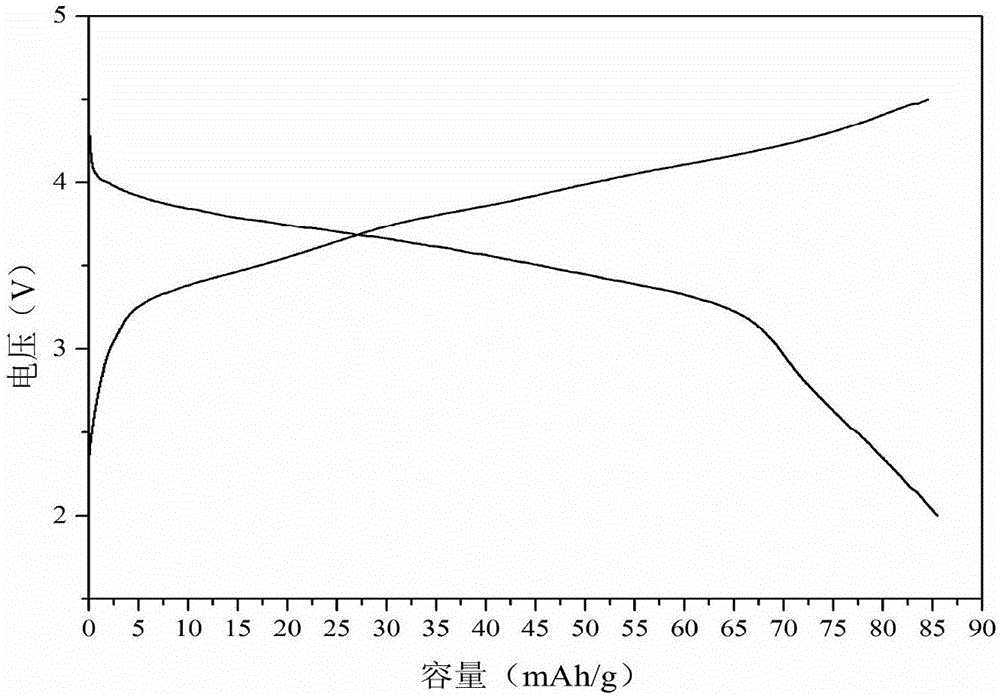

Embodiment 1

[0044] This embodiment includes the following steps:

[0045] (1) Excessive sodium bicarbonate is added to the sodium sulfate waste liquid discarded in the process of preparing the lithium-ion battery ternary material until the solution is no longer precipitated, and then filtered to obtain the filtrate.

[0046] (2) After detection, the concentration of sulfate radicals is 1.5 mol / L, and the concentration of sodium ions is 3 mol / L. This embodiment is designed to generate 1.5mol of the target product sodium ferrous sulfate, take 1L of filtrate, add an appropriate amount of hydrochloric acid solution to adjust the pH of the solution to neutral;

[0047] (3) Add deionized water to adjust the sodium ion concentration in 1L of the mixed solution to 1mol / L, then add 3mol of ferrous sulfate, supplemented by vigorous stirring, stir at 80°C for 8h and evaporate the solvent in the solution to obtain Precursor of sodium ferrous sulfate, a cathode material for sodium ions;

[0048] (4)...

Embodiment 2

[0054] This embodiment includes the following steps:

[0055] (1) Excessive sodium bicarbonate is added to the sodium sulfate waste liquid discarded in the process of preparing the lithium-ion battery ternary material until the solution is no longer precipitated, and then filtered to obtain the filtrate.

[0056] (2) After detection, the concentration of sulfate radicals is 1.5 mol / L, and the concentration of sodium ions is 3 mol / L. This embodiment is designed to generate 1.5mol of the target product sodium ferrous sulfate, take 1L of filtrate, add an appropriate amount of hydrochloric acid solution to adjust the pH of the solution to neutral;

[0057] (3) Add deionized water to adjust the sodium ion concentration in the mixed solution to 1mol / L, then add 3mol of ferrous sulfate, supplemented by vigorous stirring, stir at 80°C for 10h and evaporate the solvent in the solution to obtain sodium The precursor of sodium ferrous sulfate, an ion cathode material;

[0058] (4) The ...

Embodiment 3

[0061] This embodiment includes the following steps:

[0062] (1) The existing waste coal chemical waste liquid contains organic matter and solid waste. First, perform biochemical treatment to reduce the organic matter and filter out the solid matter. After adding excessive sodium bicarbonate until the solution no longer has precipitation, filter to obtain the filtrate;

[0063] (2) After testing, the concentration of sulfate radicals is 1.2 mol / L, and the concentration of sodium ions is 3 mol / L. This embodiment is designed to generate 1.5 mol of the target product sodium ferrous sulfate, take 1 L of filtrate and add 0.3 mol of sulfuric acid, adjust the concentration ratio of sodium ions and sulfate radicals in the solution to 2:1, add an appropriate amount of hydrochloric acid solution to adjust the pH of the solution to neutral;

[0064] (3) Add deionized water to adjust the sodium ion concentration in the mixed solution to 1mol / L, then add 3mol of ferrous sulfate, supplemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com