Device and method for purifying flue gas

A purification device and flue gas purification technology, applied in chemical instruments and methods, separation methods, sulfur trioxide/sulfuric acid, etc., can solve the problems of increasing the complexity of the structure of the desulfurization tower, and achieve excellent corrosion resistance and short construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] A 440T / h fluidized bed boiler, burning coal with a sulfur content of 1.5%, and a flue gas flow rate of 500,000 Nm 3 / hr, SO 2 The content is 3200mg / Nm 3 , the content of other pollutants in the flue gas is: dust = 80mg / Nm 3 , SO 3 =55mg / Nm 3 , HCl=35mg / Nm 3 , HF=20mg / Nm 3 , NOx=100mg / Nm 3 , the flue gas temperature is 120°C.

[0099] In this embodiment, the ammonia method is used for desulfurization and purification. The desulfurization raw material is an ammonia water mixture with an ammonia weight concentration of 18%, and the desulfurization by-product is ammonium sulfate.

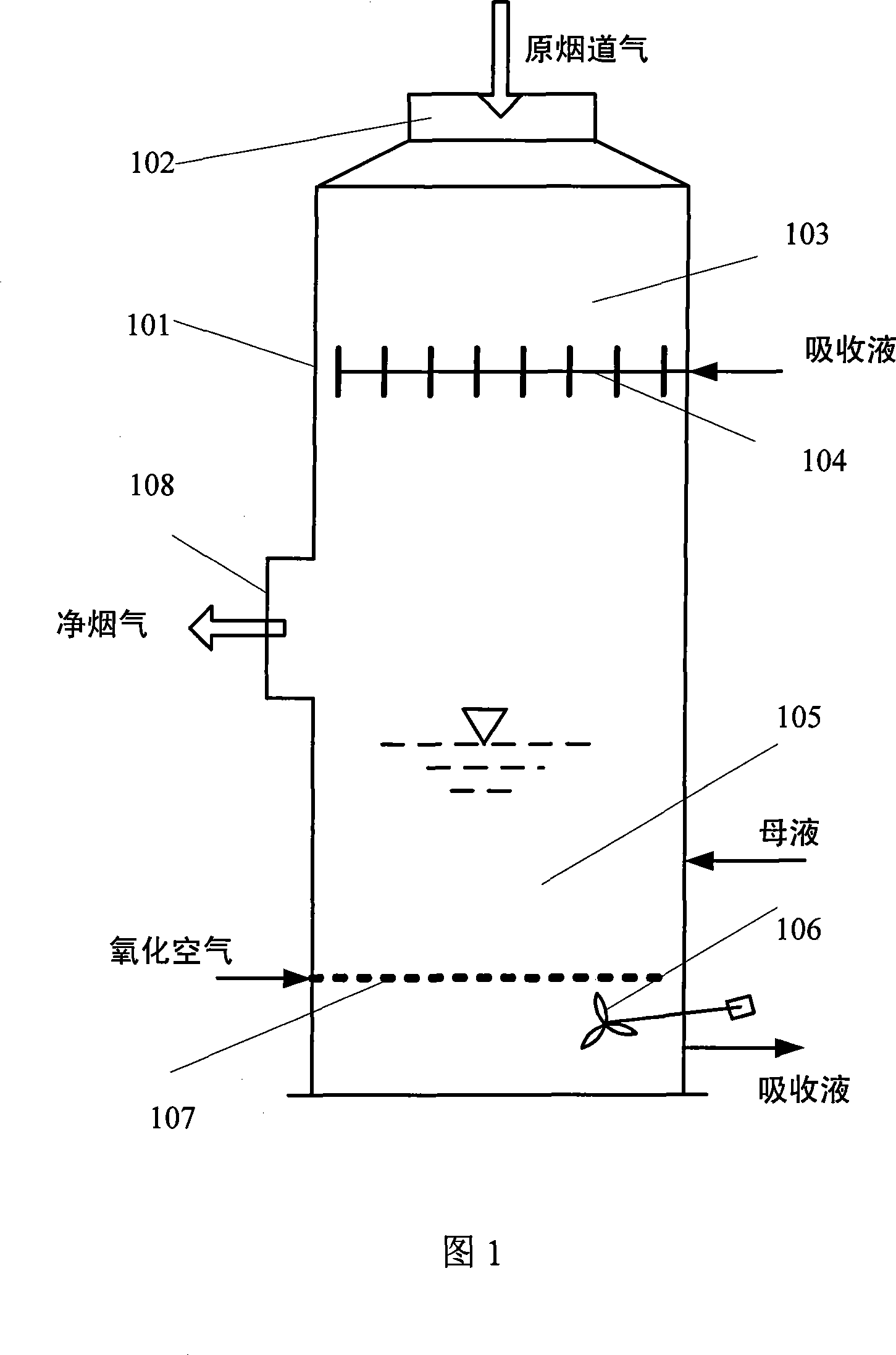

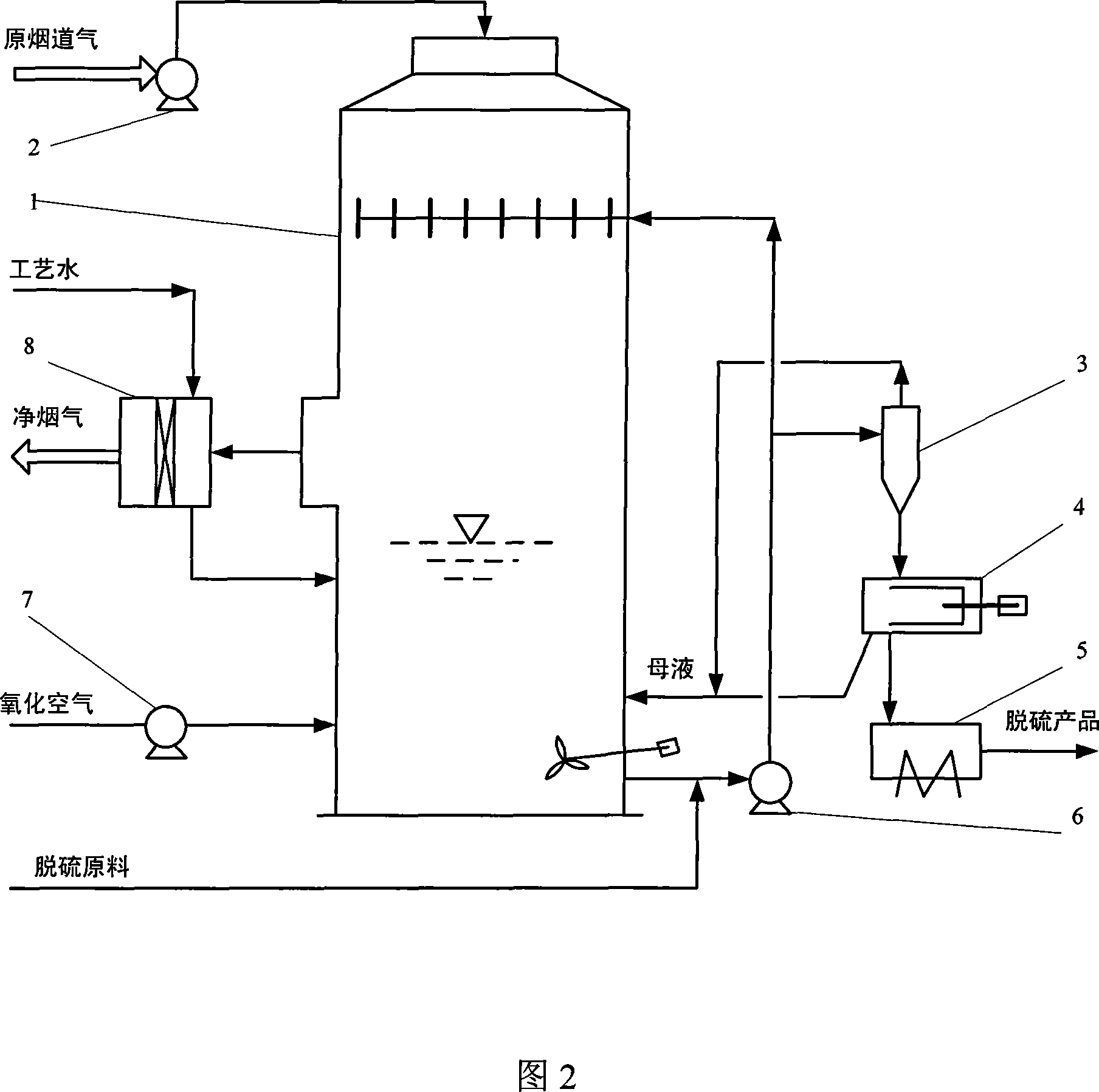

[0100] The washing and purification device mainly includes the following equipment:

[0101] A booster fan 2, a purification tower 1, a circulation pump 4 (one can also be used as a backup), a set of ammonium sulfate dehydration device 3 (composed of hydrocyclones, centrifuges and dryers), a Oxidation fan 5 (one can also be spared), and a demister 8 arranged in the outlet flue.

[0102]...

Embodiment 2

[0112] Example 1 is desulfurized and purified by calcium method. The raw material for desulfurization is crushed and ground limestone with a particle size of less than 325 mesh and greater than 90%. The limestone slurry with a solid content of 15% of limestone is prepared.

[0113] The by-product of desulfurization is dihydrate gypsum, CaSO4.2H 2 O.

[0114] The main equipment configuration is as follows:

[0115] One booster blower 2, one purification tower 1, one circulation pump 4 (one can also be spared), one set of ammonium sulfate dehydration device 3 (composed of hydrocyclone and vacuum filter), one oxidation blower 5 (one can also be spared), and the demister 8 arranged in the outlet flue.

[0116] The size of the purification tower 1 is the same as in Embodiment 1.

[0117] The tower body 101 of the purification tower 1 is made of glass fiber reinforced plastic, namely FRP material.

[0118] The desulfurization raw material is supplemented on the inlet pipeline of...

Embodiment 3

[0126] Example 1 is desulfurized and purified by the magnesium method. The raw material for desulfurization is magnesium oxide, and the particle size is less than 150 mesh and greater than 90%. It is prepared into a magnesium oxide slurry with a solid content of 15%.

[0127] Desulfurization by-product is magnesium sulfate heptahydrate, MgSO4.7H 2 O.

[0128] The main equipment configuration is as follows:

[0129] A booster blower 2, a purification tower 1, a circulating pump 4 (one can also be spared), a set of ammonium sulfate dehydration device 3 (by hydrocyclone and centrifuge), an oxidation blower 5 ( Also can spare one), and the demister 8 arranged in the outlet flue.

[0130] The size of the purification tower 1 is the same as in Embodiment 1.

[0131] The tower body 101 of the purification tower 1 is made of glass fiber reinforced plastic, namely FRP material.

[0132] The desulfurization raw material is supplemented on the inlet pipeline of the circulating pump, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com