Patents

Literature

195 results about "Potassium sulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium sulfite (K₂SO₃) is a chemical compound which is the salt of potassium cation and sulfite anion. As a food additive it is used as a preservative under the E number E225 (INS number 225). It is approved for use in Australia and New Zealand and is not approved in the EU or US.

Fenton and Fenton-like system fortifier and using method thereof

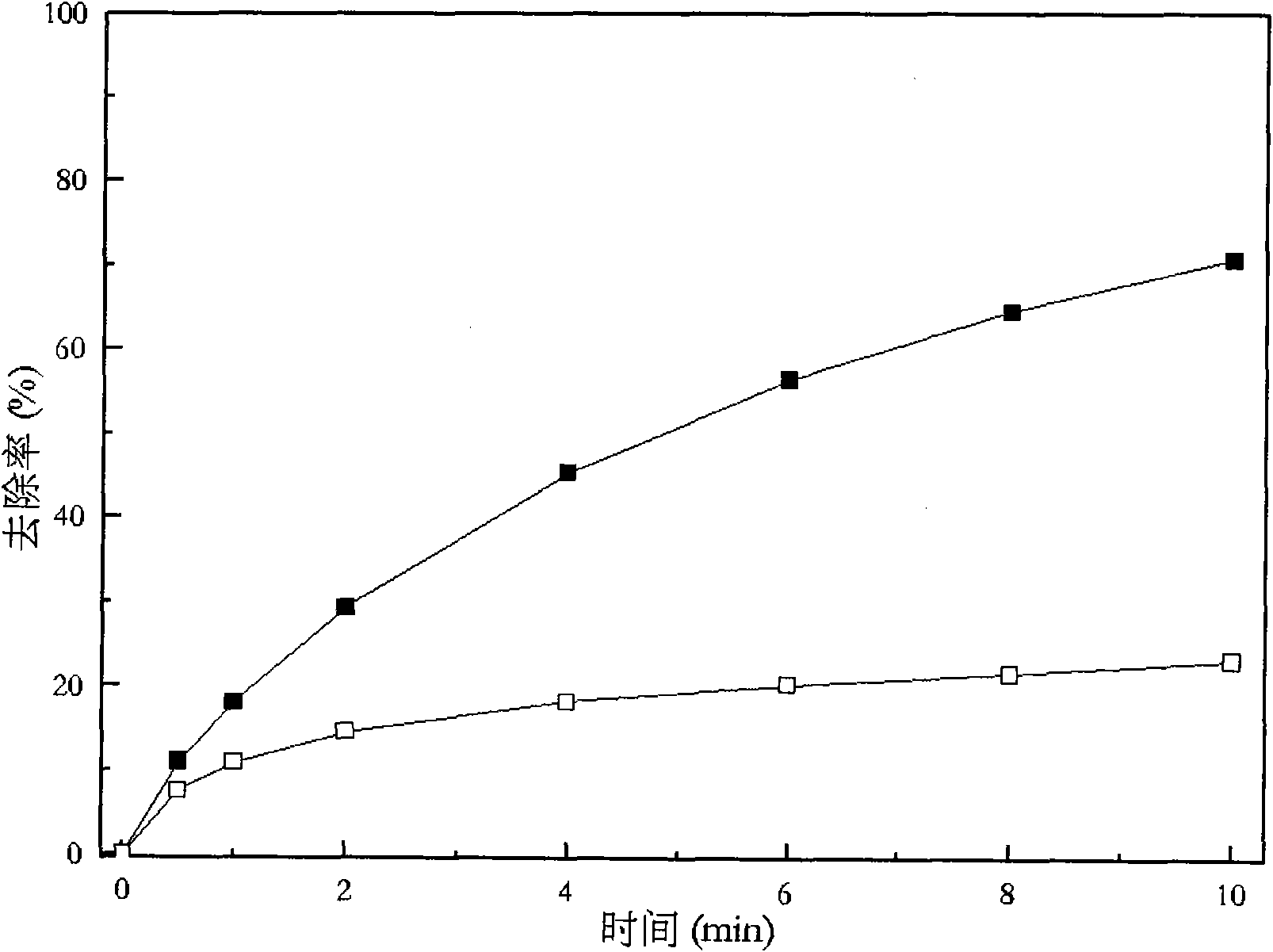

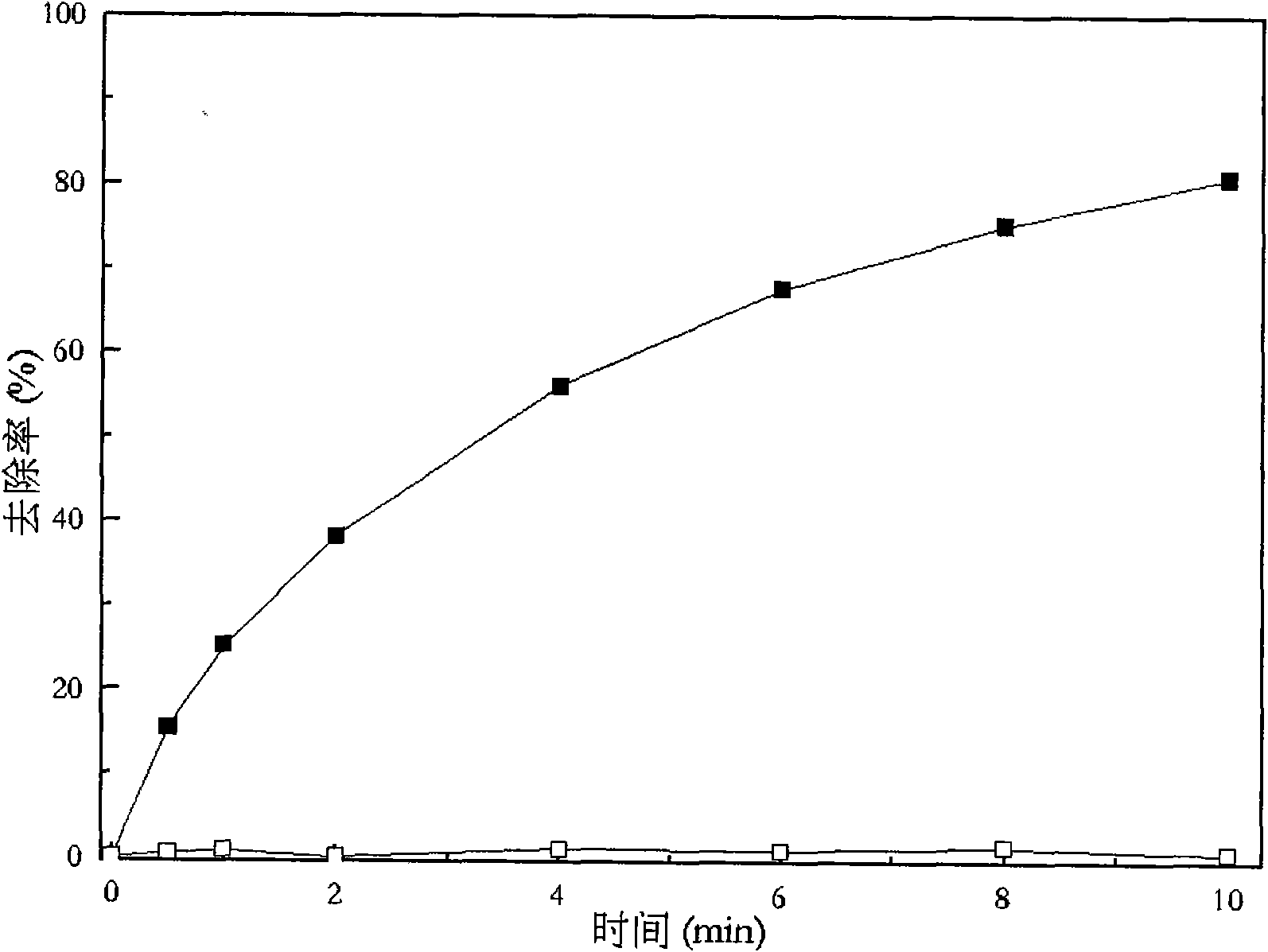

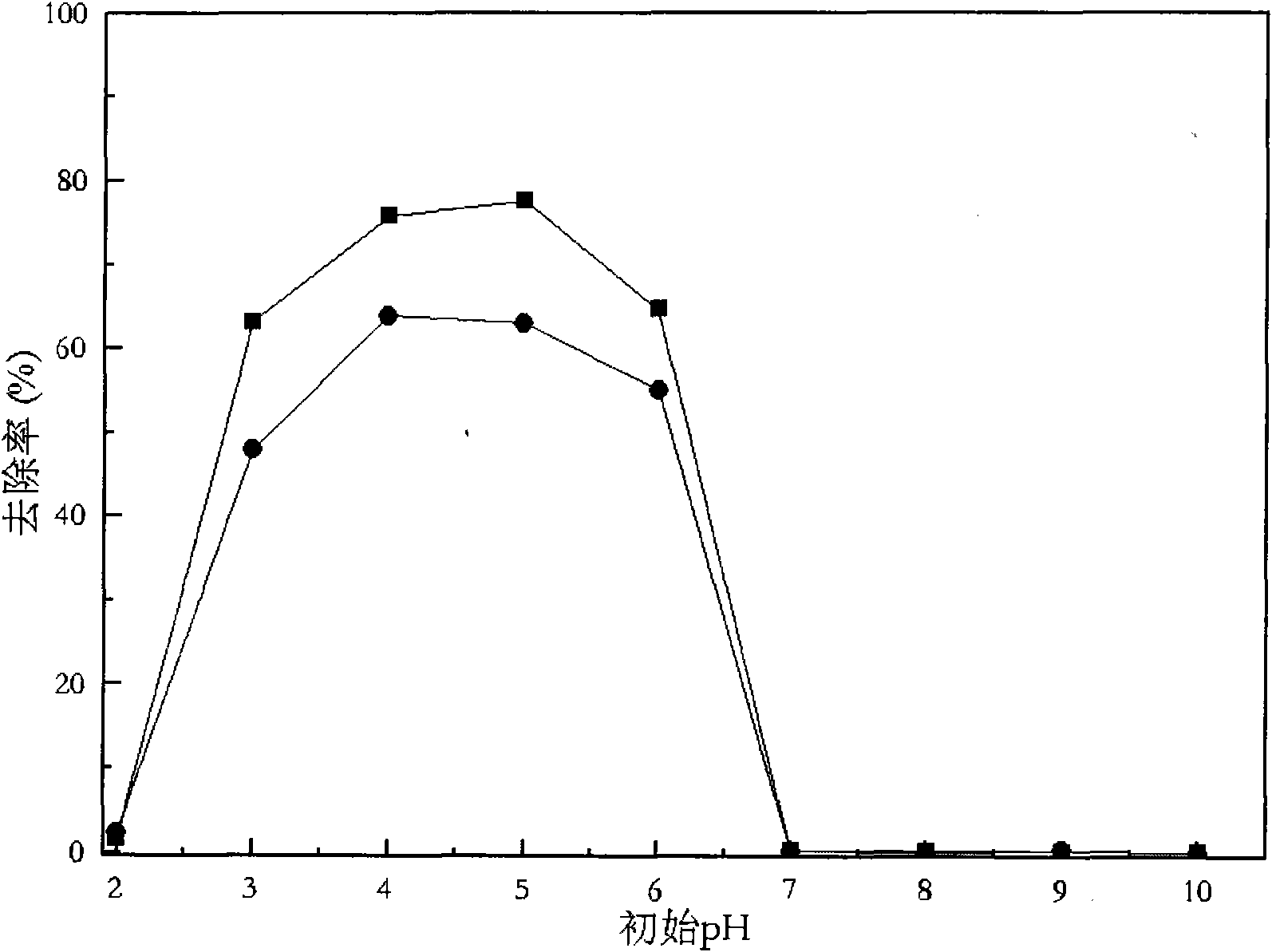

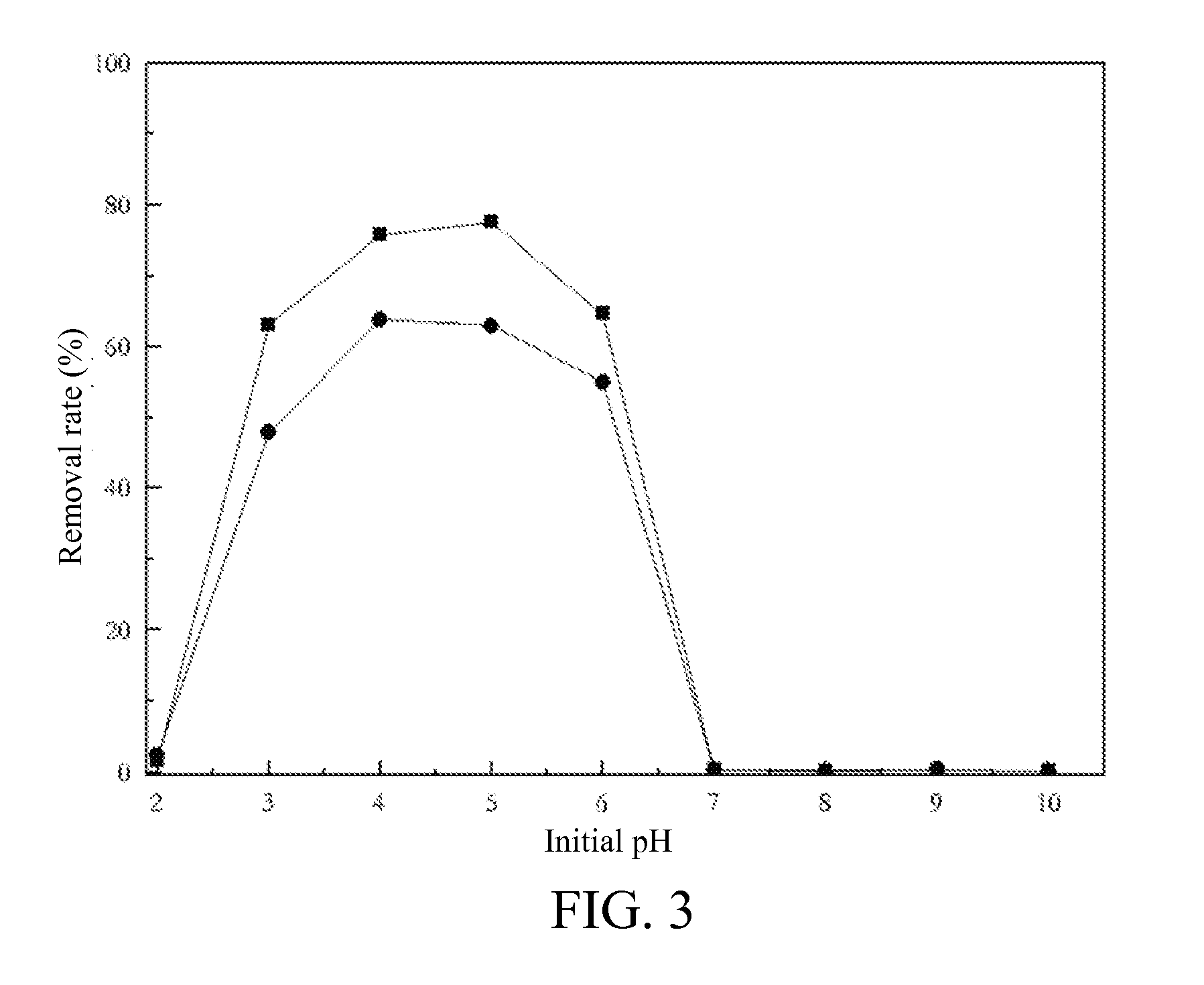

ActiveCN101792205AReduce dosageEasy to useWater treatment parameter controlWater treatment compoundsSulfite saltHydrazine compound

The invention provides a Fenton and Fenton-like system fortifier and a using method thereof, which relate to a water treating fortifier and a using method thereof and overcomes the defects that the pH value of the Fenton and Fenton-like system reaction water body is limited, the adding amount of Fe<2+> is overhigh in the Fenton reaction, and the reaction speed is low in Fenton-like reaction. The fortifier is selected from ascorbic acid, sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine, hydroxyl-ammonium perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, carbohydrazide, ethanolamine, a hydroxylamine solution or N,N,N',N'-tetra substituted phenylenediamines. The using method has the following steps of: adding the Fenton and Fenton-like system fortifier, fortificated chemicals and peroxide into the treated water body; and then, uniformly stirring to react. The fortifier can accelerate the reaction of water treatment and decrease the using amount of the fortificated chemicals.

Owner:HARBIN INST OF TECH

Animal hair solvent and preparation method and use of keratin solution

InactiveCN101979428AHigh molecular contentGuaranteed stabilityFibre treatmentAdditive ingredientSulfite salt

The invention discloses an animal hair solvent and the preparation method and use of keratin solution. The solvent is characterized in that tris(2-carboxyethyl)phosphine hydrochloride, tris(2-cyanoethyl)phosphine or trisphosphine is used as a main ingredient and is mixed with 1 to 8 percent of assistant which may be at least one of mercaptoacetic acid, mercaptoethanol, sodium hydrogensulfite, potassium bisulfate, sodium sulfite, potassium sulfite, sodium hypophosphite, ethanol, methanol and urea. The preparation method adopts the following processes: 1, preparing animal hair solution by using the animal hair solvent of the invention; 2, dissolving animal hair in the solution to prepare keratin solution; and 3, adding a proper amount of acid to perform the post-treatment of the keratin solution. The use is to use the keratin solution as textile finishing liquor or the main functional ingredient of the textile finishing liquor.

Owner:TIANJIN POLYTECHNIC UNIV +1

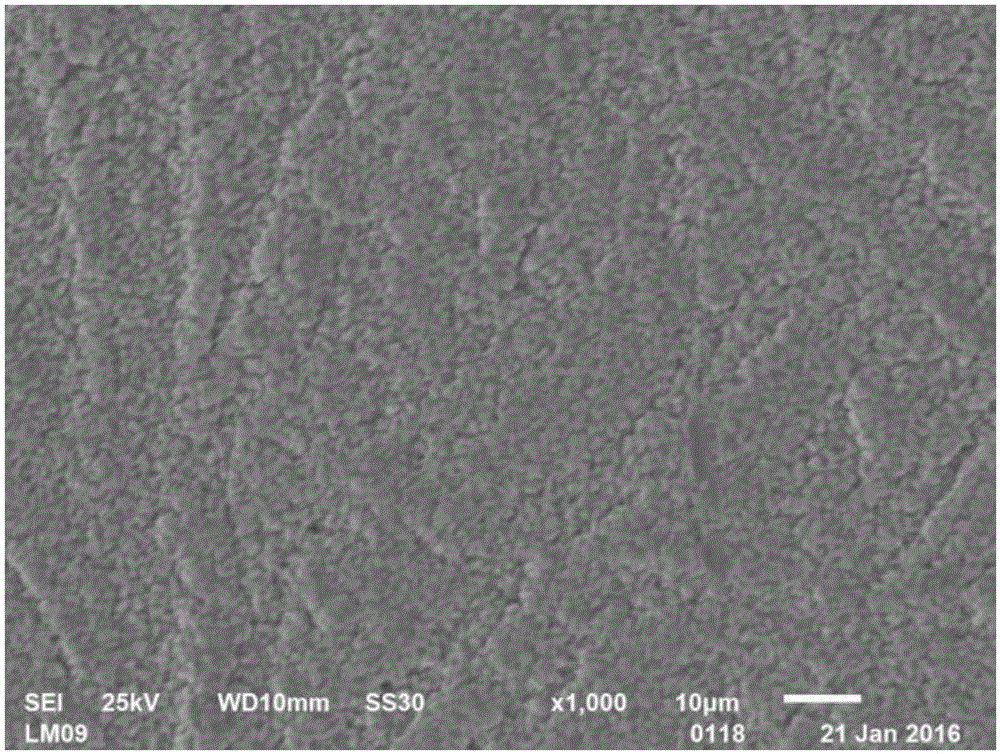

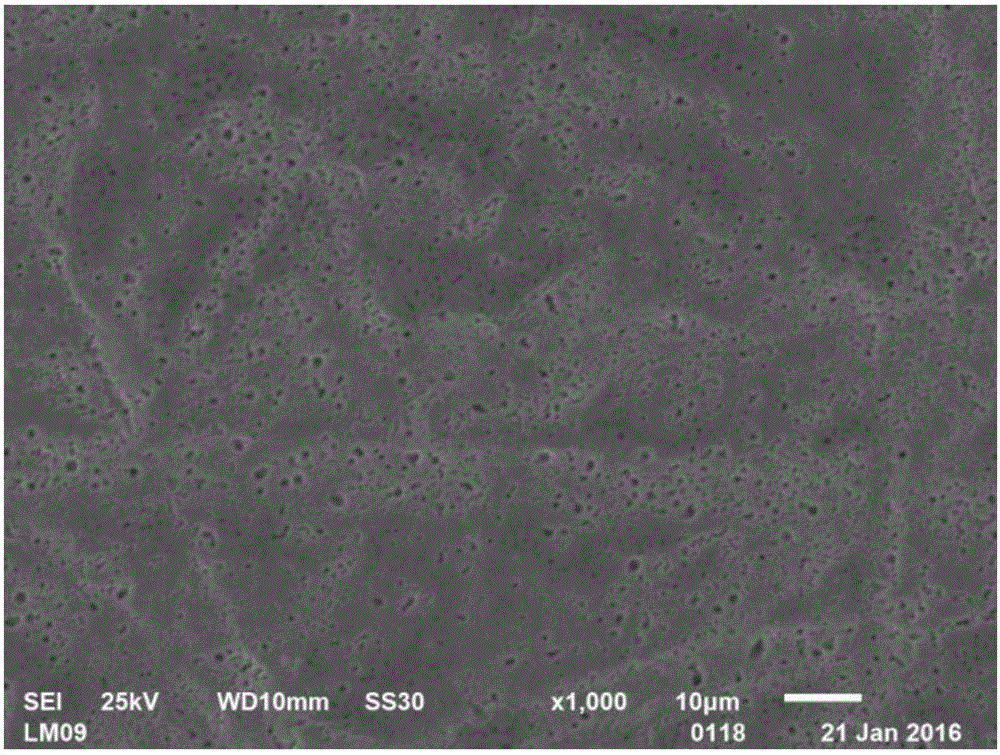

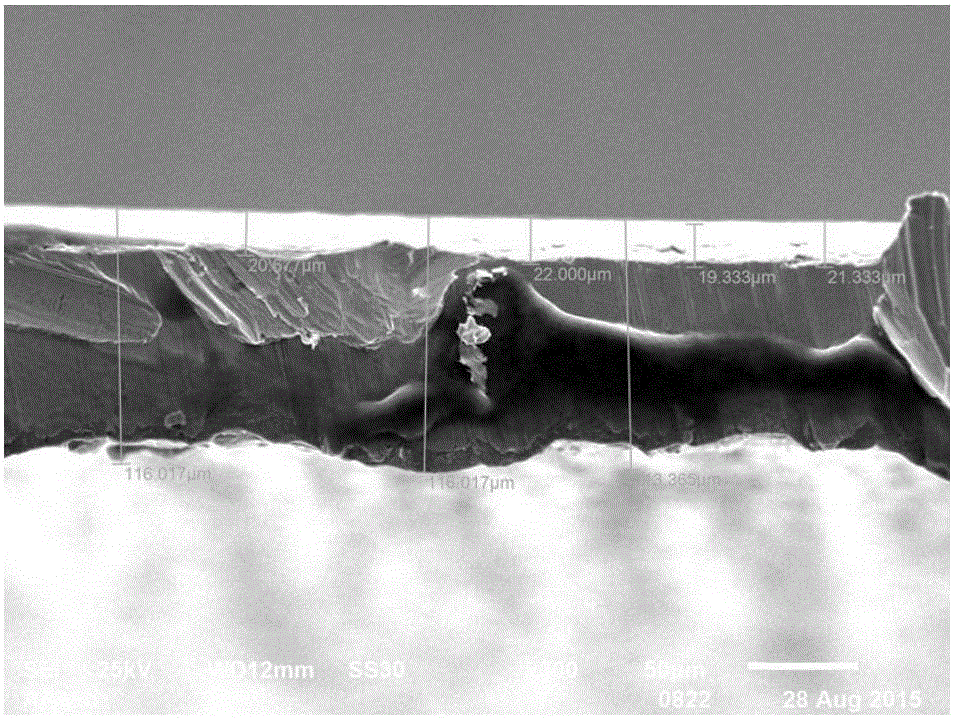

Preparation method for silver and graphene composite coating of cyanide-free system

The invention discloses a preparation method for a silver and graphene composite coating of a cyanide-free system. Due to the fact that common problems that cyanide silver plating pollution is serious, the human body will be harmed, and meanwhile a silver coating has some defects exist, the preparation method is characterized in that dispersed grapheme is added in the cyanide-free system, and composite plating is carried out on a copper substrate. The preparation method comprises the basic steps that (1) a substrate is subject to oil removing and polishing, and silver soaking treatment is carried out; (2) sodium thiosulfate, potassium metabisulfite and silver nitrate are prepared into silver plating liquid, graphene powder, a certain amount of deionized water and a certain number of dispersing agent are mixed to be added into the silver plating liquid, and ultrasonic dispersion is carried out; and (3) a silver plate serves as an anode, the substrate serves as a cathode, the silver plate and the substrate are placed into the silver plating liquid to be subject to electroplating, and the silver-graphene composite coating is obtained. Compared with the prior art, the method is simple in process, good in controllability and wide in application scope; and the prepared silver-graphene composite coating is good in resistance to high temperature oxidation, high in resistance to sulfur, high in mechanical property and high in resistance to corrosion.

Owner:NANCHANG HANGKONG UNIVERSITY

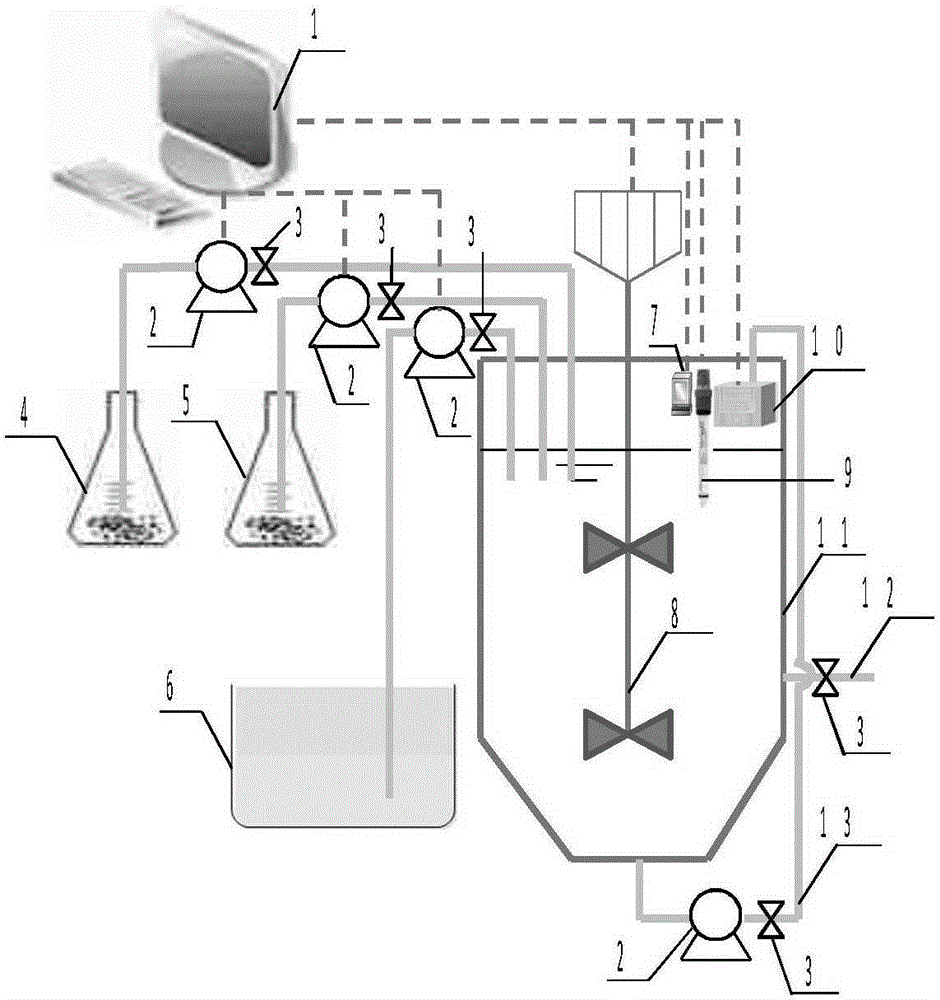

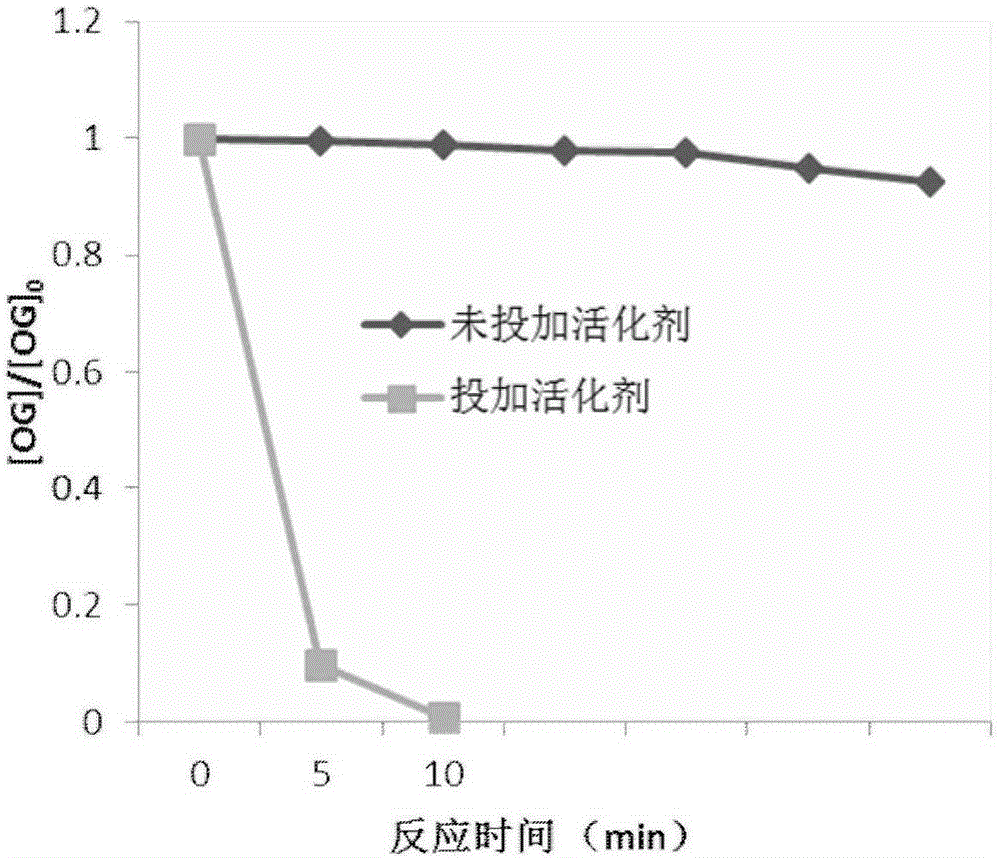

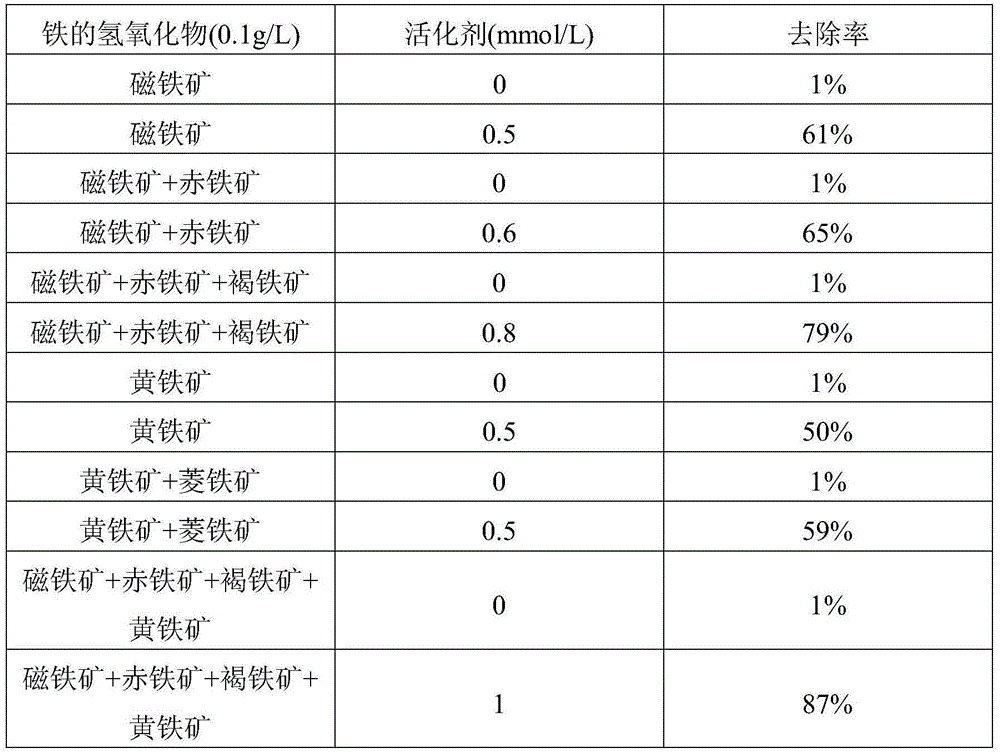

Method for recycling iron waste for fenton technology and water treating device of method

InactiveCN105174413AIncrease reaction rateRealize resource utilizationWater/sewage treatment by oxidationPotassium borohydrideSulfite salt

The invention discloses a method for recycling iron waste for the fenton technology. The method comprises the following steps that hydrogen peroxide, the iron waste and an activating agent are added to waste water to be treated, stirring is conducted so that the iron waste can be dispersed in a reaction system, a reaction is conducted, and then solid and liquid separation is conducted, wherein the activating agent is any one or a mixture of sodium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, sodium thiosulfate, potassium thiosulfate, calcium thiosulfate, magnesium thiosulfate, sodium borohydride, potassium borohydride, hydroxylamine hydrochloride and ascorbic acid. By means of the method, various kinds of iron waste are recycled, meanwhile, zero iron mud emission is achieved, and thus pollution to the environment is effectively reduced. The invention further provides a water treating device capable of achieving the method. By means of the method and the water treating device, the reaction speed of the iron waste in the fenton system is greatly increased, the effective pH range of the fenton system is expanded, meanwhile zero iron mud emission is achieved, and thus pollution to the environment can be easily reduced.

Owner:HOHAI UNIV

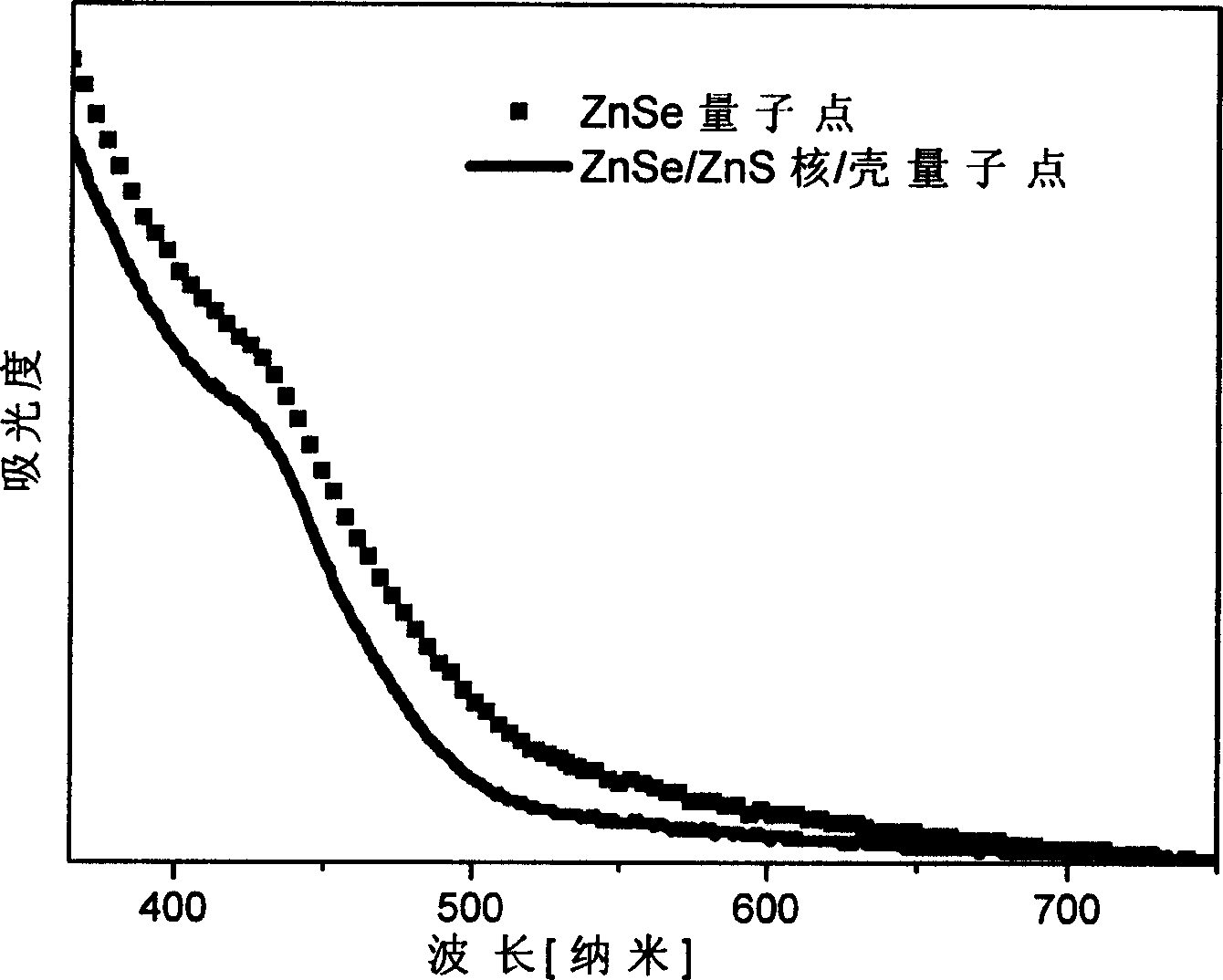

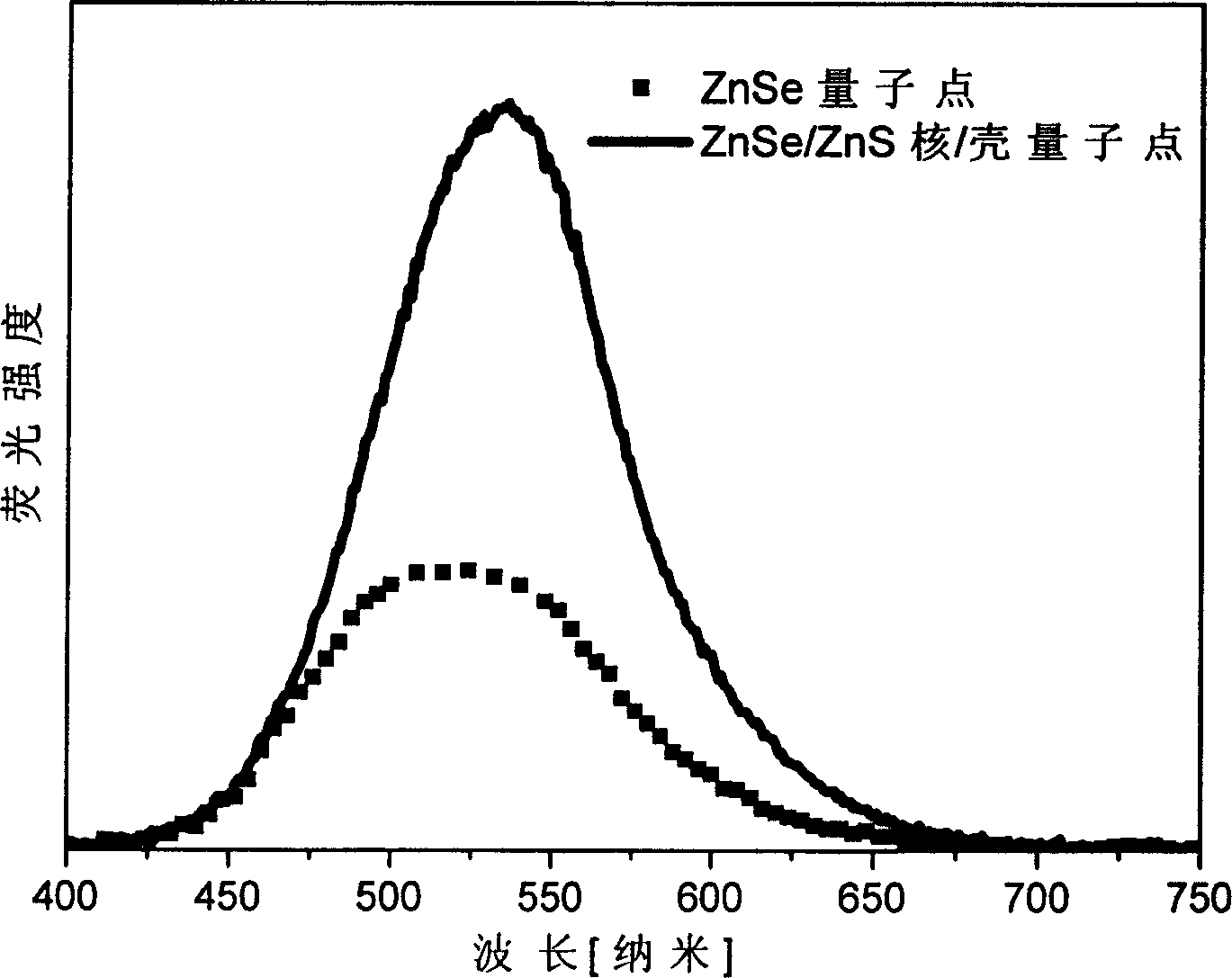

Prepn. process of ZnSe/ZnS kernel/shell type quantum points

InactiveCN1834198AOperational securitySimple and fast operationLuminescent compositionsSolubilityFluorescence

Owner:FUDAN UNIV

Multicomponent moisture holding agent in low cost and preparation method

The present invention provids a preparation method of multicomponent low-cost water-retaining agent. Said water-retaining agent is prepared by adopting two organic monomers of acrylamide and acrylic acid as main agent, adding attapulgite and bentonite as reinforcing agent, using ammonium persulate or potassum persulfate as oxidant, using sodium sulfite and potassium metabisulfite as reducing agent and using N,N'-methylene-diacrylamide as cross-linking agent through a certain preparation process.

Owner:师进

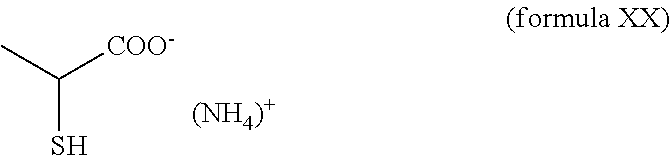

Decolorization of dyed keratin fibers

The invention relates to agents for the reductive decolorization of dyed keratin fibers, in particular human hair, containing in an aqueous cosmetic carrier (a) one or more reduction agents from the group consisting of sodium dithionite, zinc dithionite, potassium dithionite, sodium sulfite, sodium hydrogen sulfite, potassium sulfite, potassium hydrogen sulfite, ammonium sulfite, sodium thiosulfate, potassium thiosulfate, ammonium thiosulfate, hydroxymethanesulfinic acid, aminomethanesulfinic acid, cysteine, thiolactic acid, sulfanylacetic acid (thioglycolic acid), and / or ascorbic acid, and (b) one or more zwitterionic surfactants, each of which has at least one quaternary ammonium group and a grouping of —SO3— as structural units.

Owner:HENKEL KGAA

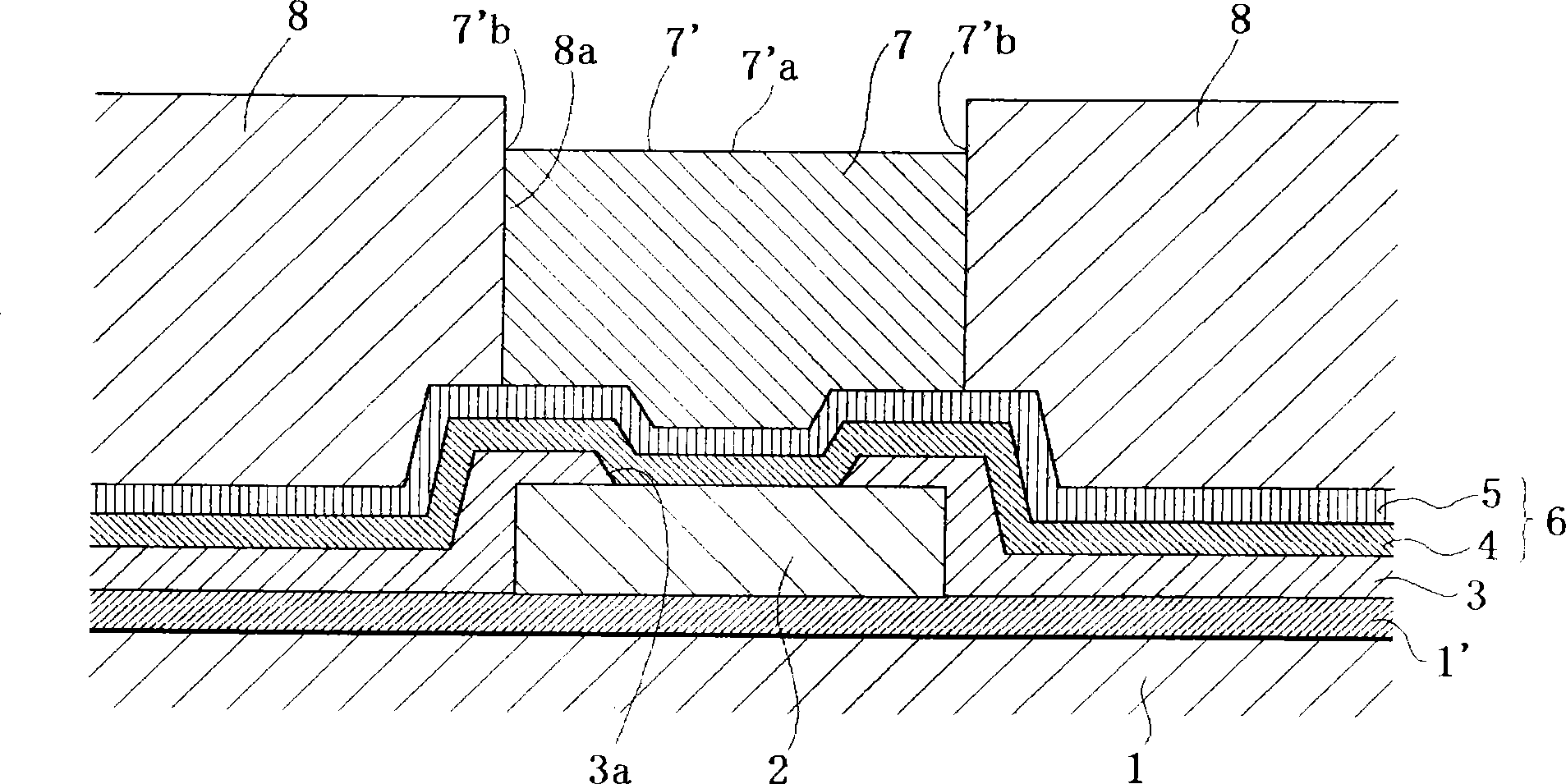

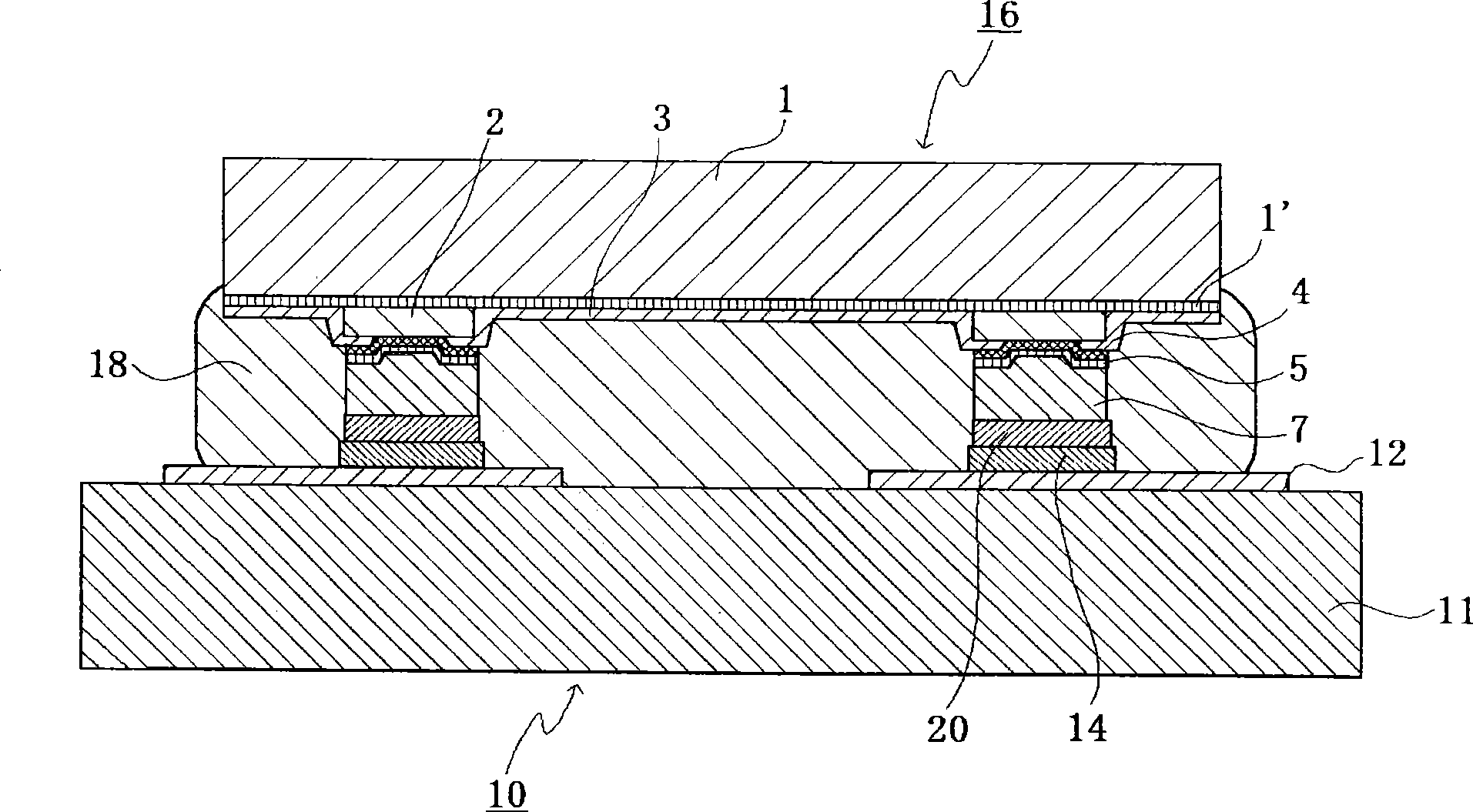

Non-cyanogen type electrolytic gold plating bath for bump forming

ActiveCN101363128AHigh hardnessControl protrusion hardnessSolid-state devicesSemiconductor/solid-state device manufacturingElectrolysisActive agent

The invention discloses non-cyanogens-like electrolysis golden electroplate liquid used for forming protrusion, in which comprises 5 g / L to 150 g / L of conductive salt consisting of sulfurous acid gold alkali salt or sulfurous acid gold ammonium as the gold source, a crystal regulator, and potassium sulfite, 1 mg / L to 6 g / L of polyalkylene glycol with molecular weight 200 to 6000 and / or 0.1 mg to 1 g / L of ampholytic active agent, water-soluble amine and / or buffering agent; after electroplate gold plating on a patterned wafer by used of the gold electroplate liquid of the invention, protrusion with film hardness at 50 Hv to 90 Hv, and surface height difference less than 1.8 microns is formed after heat treatment at 200 degrees centigrade to 400 degrees centigrade for 5 min.

Owner:EEJA LTD

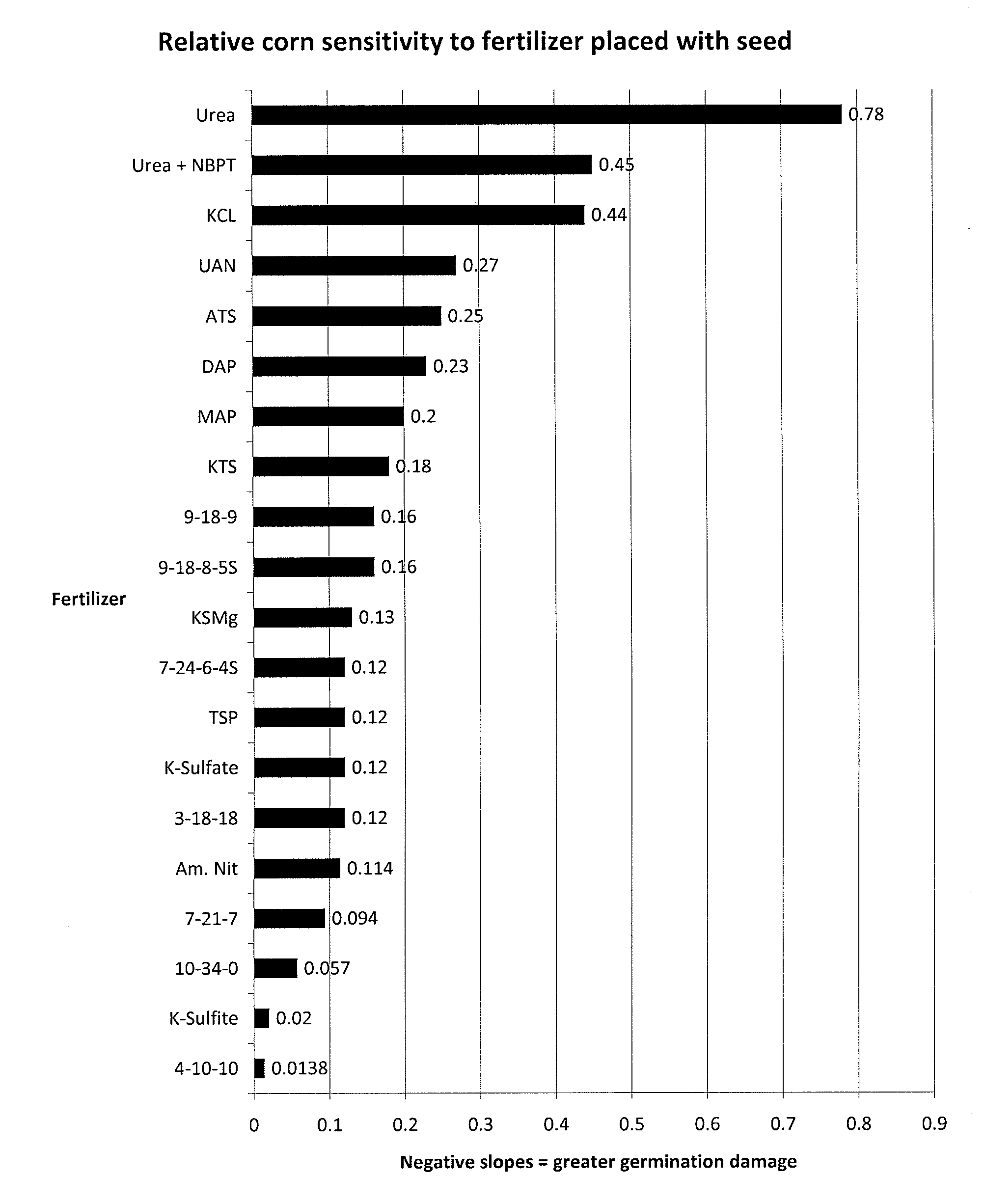

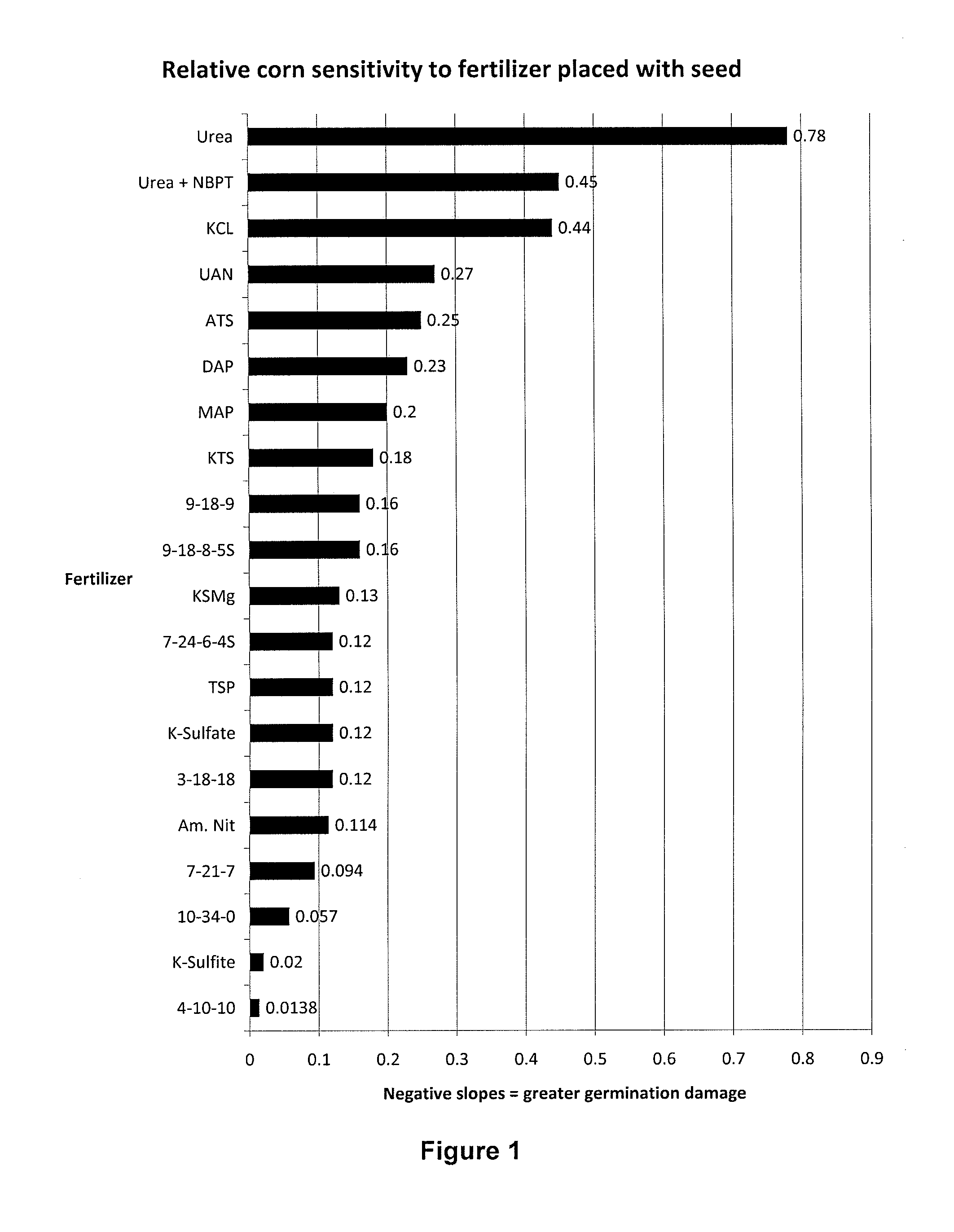

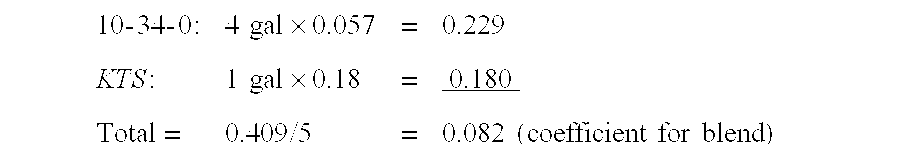

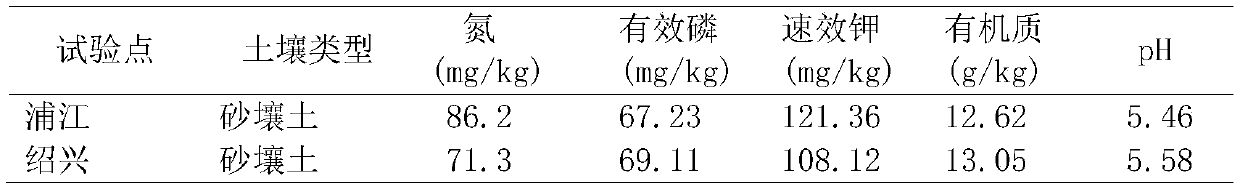

Potassium sulfite/potassium bisulfite (ks/kbs) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

ActiveUS20120255335A1Low indexReduce drug damageBiocideSulfite preparationSulfur productPhytotoxicity

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

Cyanide-free gold electroplating liquid

The invention relates to cyanide-free gold electroplating liquid, and belongs to the field of surface modification of metal materials. The cyanide-free gold electroplating liquid has the advantages that: the electroplating liquid is non-toxic, simple in a formula and high in stability, does not have the phenomenon of turbidity and color change after being stood at normal temperature and still can be used. The cyanide-free gold electroplating liquid comprises the following main ingredients: gold trichloride, sodium sulfite or potassium sulfite serving as a main complexing agent, ethylene diamine tetraacetic acid (EDTA) or sodium citrate serving as an auxiliary complexing agent and sodium chloride or potassium chloride serving as inorganic salt. In the cyanide-free gold electroplating liquid, a new formula proportion is adopted, the cost is low, a plating layer is high in bonding force and bright, and the preparation of the functional gold plating layer is realized. The popularization and application of the cyanide-free gold electroplating liquid can create economic and social benefit.

Owner:BEIJING UNIV OF TECH

Multifunctional water treatment agent

InactiveCN102344202AReduce water hardnessReduce and prevent the formation ofScale removal and water softeningPhosphoric acidWater processing

The invention relates to a multifunctional water treatment agent which comprises the following components by weight: 15-30 wt% of polyepoxysuccinic acid, 15-30 wt% of polyacrylic acid, 6-18 wt% of acrylic acid / sulfo allylamine / maleic acid, 10-15 wt% of potassium sulfite, 2-8 wt% of ethylene diamine tetraacetic acid, 10-15 wt% of trisodium phosphate, 15-25 wt% of sodium carbonate, and 3-7 wt% of sodium hydroxide. The boiler water treatment agent of the invention can decrease boiler water hardness, reduce and prevent the formation of scale; with the water treatment agent, the oxygen content of boiler water is within national standard ranges; the boiler water treatment agent of the invention also has the functions of residual hardness removal and scale prevention.

Owner:DALIAN JINZHOU JINHE CHEM BUILDING MATERIALS FACTORY

Preparation method of pumpkin wine

InactiveCN102876535AHigh glossNo precipitationMicroorganism based processesAlcoholic beverage preparationBiotechnologyPectinase

The invention relates to a preparation method of a product with pumpkins as raw materials, more specifically to a preparation method of a pumpkin wine. The pumpkin wine processed by the preparation method provided in the invention has mellow wine flavor and rich nutrition. The technological steps of the method include: conducting washing, peeling, dicing and pulping on pumpkins, immediately adding potassium metabisulfite, then adding 0.03-0.05mg of pectinase into every 100ml of pumpkin juice, and conducting thermal preservation at a temperature of 40-60DEG C for 2-3h; adding white sugar, adjusting the sugar content of the pumpkin juice to 15-20%, adding citric acid to adjust the acidity of the pumpkin juice to 0.5-0.7; inoculating 10-20% of active dry yeast into a sucrose solution with a concentration of 8%, and carrying out activation at 25-30DEG C for 1-2h so as to obtain a yeast activation solution; then inoculating 10-20% of the yeast activation solution into pumpkin juice clarified by pasteurization, and carrying out activation at 25-30DEG C for 20-24h; and performing fermentation, aging, blending, clarification as well as sterilization.

Owner:张慧

Ginseng and blueberry fermented wine and preparation method of fermented wine

ActiveCN103103071AGood for healthIncrease profitMicroorganism based processesAlcoholic beverage preparationFruit wineYeast

The invention relates to the technical field of wine brewing and discloses ginseng and blueberry fermented wine and a preparation method of the fermented wine. The preparation method comprises the steps of: soaking ginseng in water after washing ginseng; mashing the soaked ginseng and then adding water in ginseng mash to obtain ginseng juice for later use; mashing blueberry after washing the blueberry; then adding potassium sulfite in blueberry mash to obtain blueberry juice for later use; adding white granulated sugar after mixing the blueberry juice with the ginseng juice; adjusting the content in percentage by weight of the white granulated sugar to 13-17%; then adding fruit wine yeast for fermenting for 6-8d; filtering to obtain filtrate; placing the filtrate for 55-65d in a sealing way after sterilizing the filtrate; then treating the filtrate by bentonite clarification; and carrying out filtration again to obtain filtrate, thereby obtaining the fermented wine. The blueberry material is added on the basis of the ginseng material, and the preparation of the ginseng and blueberry fermented wine is carried out through a fermentation technology matched with the blueberry material and the ginseng material; and the nutritional ingredients of ginseng and blueberry in the ginseng and blueberry fermented wine are reserved, and beneficial substances synthesized by metabolism of multiple microorganisms can be obtained under the action of the fruit wine yeast.

Owner:白山市林海雪原酿酒有限公司

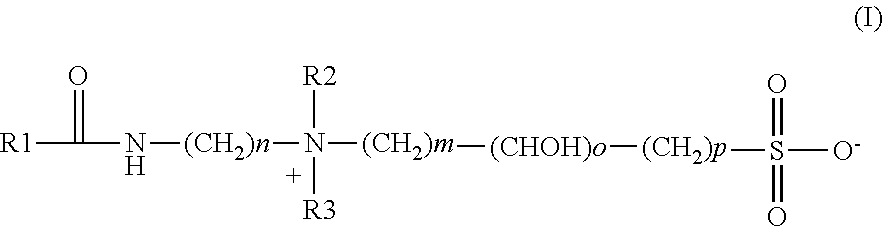

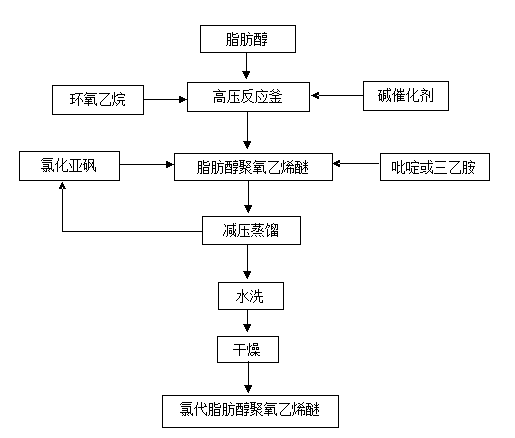

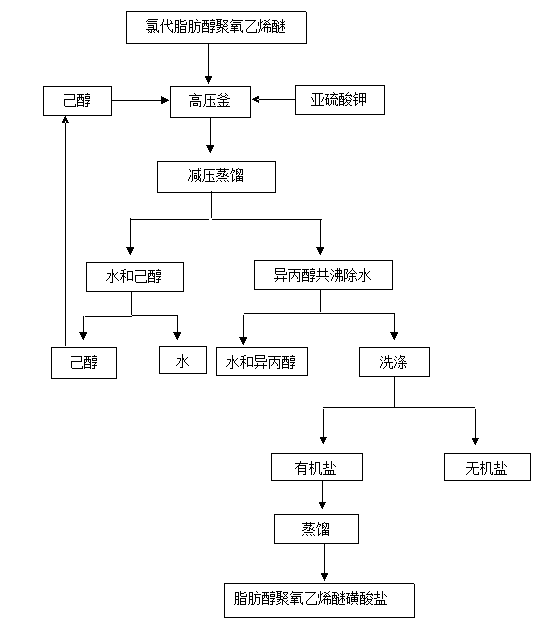

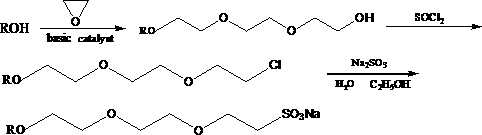

Preparation method of fatty alcohol polyethenoxy ether sulfonate

InactiveCN103288687AIncrease concentrationHigh yieldSulfonic acids salts preparationSulfonateActive agent

The invention particularly relates to a preparation method of a fatty alcohol polyethenoxy ether sulfonate surfactant, which comprises the following steps: preparing fatty alcohol polyethenoxy ether from raw materials fatty alcohol and epoxyethane under high pressure; chlorinating the fatty alcohol polyethenoxy ether by a solvent process; and finally, by using potassium sulfite as a sulfonating agent, preparing the end product fatty alcohol polyethenoxy ether sulfonate under high pressure in the presence of a diluter. Compared with the prior art, the invention has the following advantages: in the chlorination process by the solvent process, the solvent has the catalytic action on the reaction to increase the reaction rate, and can be used as an acid-binding agent to absorb tail gas; the potassium sulfite with high solubility in water is used as the sulfonating agent to increase the reaction rate and reduce the water quantity, thereby preventing the system from gelling; and the diluter is introduced to lower the viscosity of the system in the reaction process, thereby preventing the side reaction and being beneficial to azeotropic dehydration in the after-treatment process.

Owner:NANJING UNIV OF SCI & TECH

Dragon fruit and mulberry fruit wine and preparation method thereof

ActiveCN104194996AFull bodiedSweet and sour tasteMicroorganism based processesAlcoholic beverage preparationFruit wineFruit juice

The invention discloses a preparation method of dragon fruit and mulberry fruit wine. The preparation method comprises the following steps: 1) preparing fruit juice of dragon fruits and fruit juice of mulberries for later use; 2) weighing the fruit juice of dragon fruits and the fruit juice of mulberries in a weight ratio of (7-10) to (1-2), and uniformly mixing to obtain mixed fruit juice; and 3) adding glucose, brewer's yeast, a yeast nutrient and potassium metabisulfite into the mixed fruit juice, fermenting till the alcoholic strength is 10-12vol% under a condition of 18-25 DEG C, removing the activity of brewer's yeast, sealing and aging the fermentation liquor for over 18 months under a constant temperature condition, filtering and sterilizing to obtain the dragon fruit and mulberry fruit wine. The fruit wine prepared by using the method is clear and transparent and ruby red in color, and the color can be maintained for a long time (at least three years). The body of the brewed fruit wine has special fragrance of original fruits and rich aroma, and the fragrance and aroma are very harmonically mixed together. The fruit wine prepared by the preparation method is sour and sweet and palatable in taste, mellow pure and free from extraneous odor.

Owner:GUANGXI QINZHOU MASHI FOOD

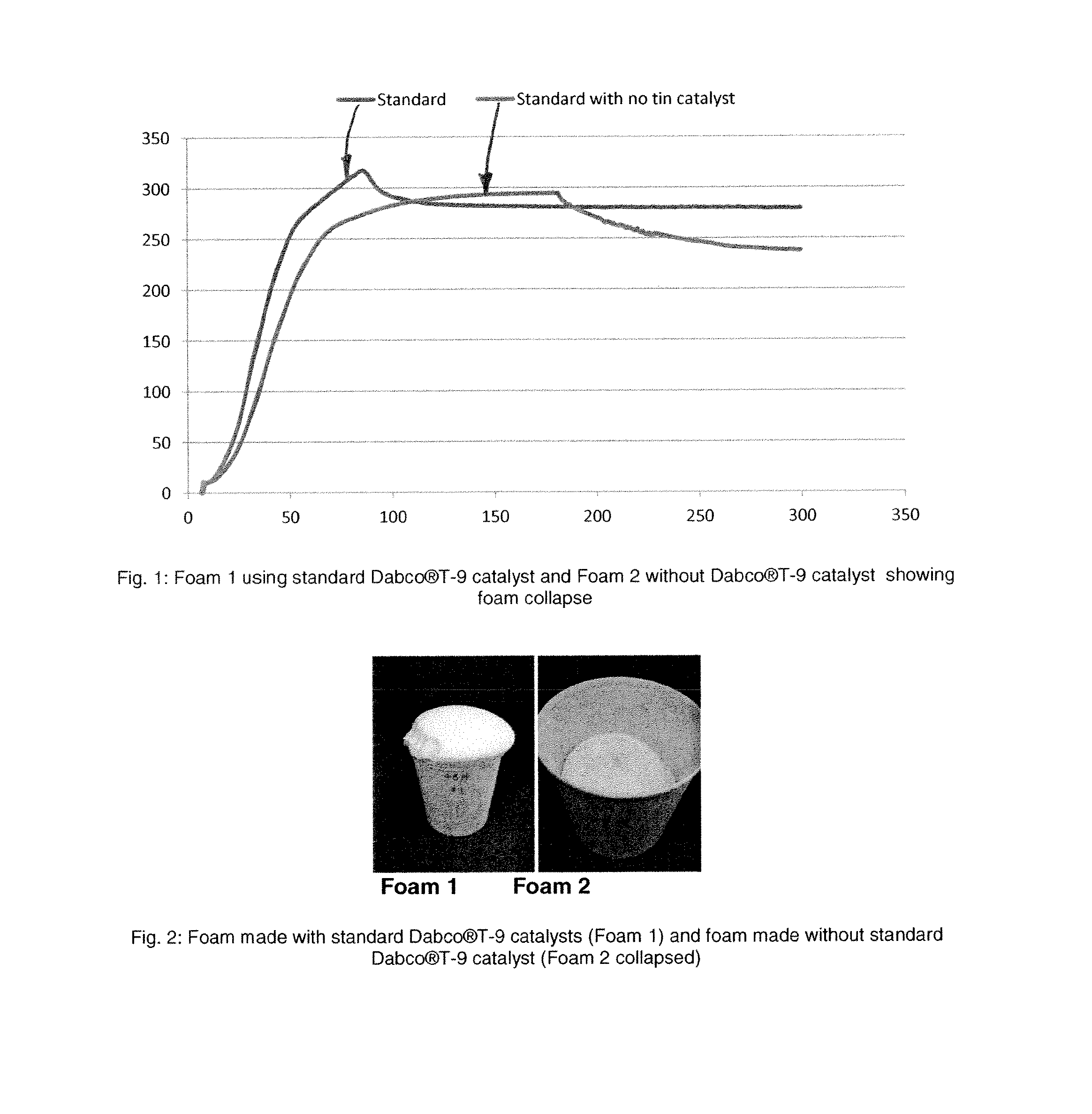

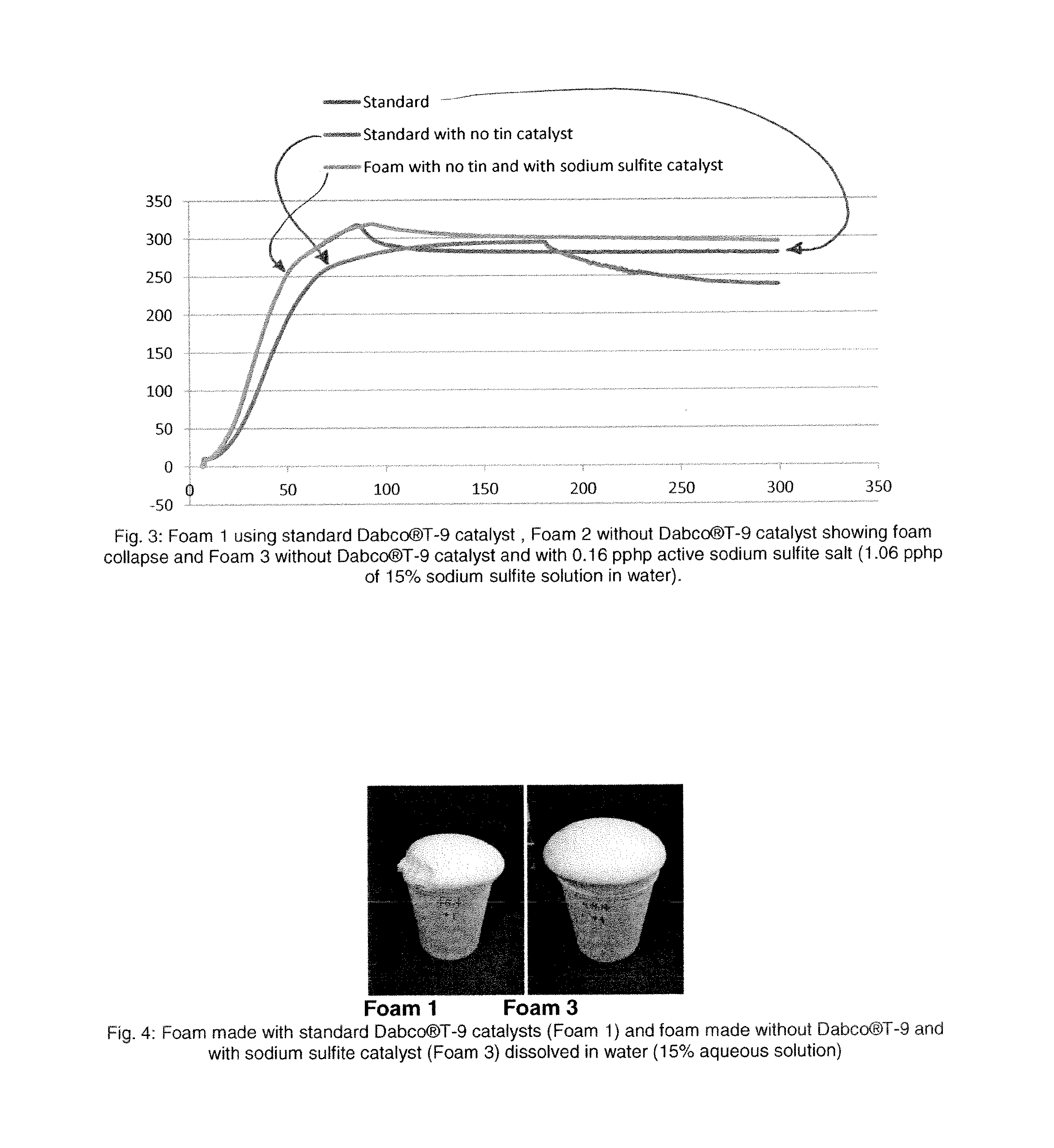

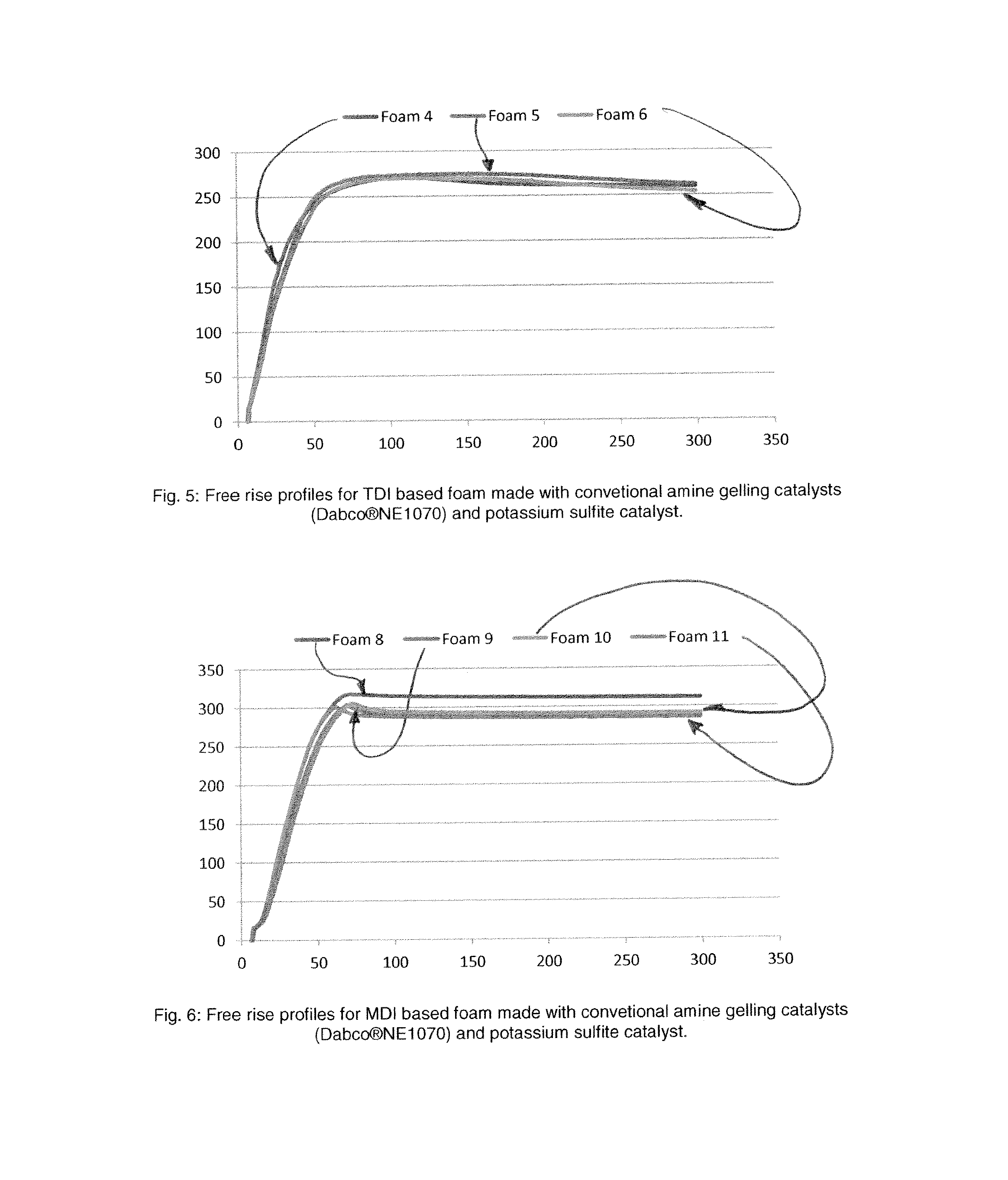

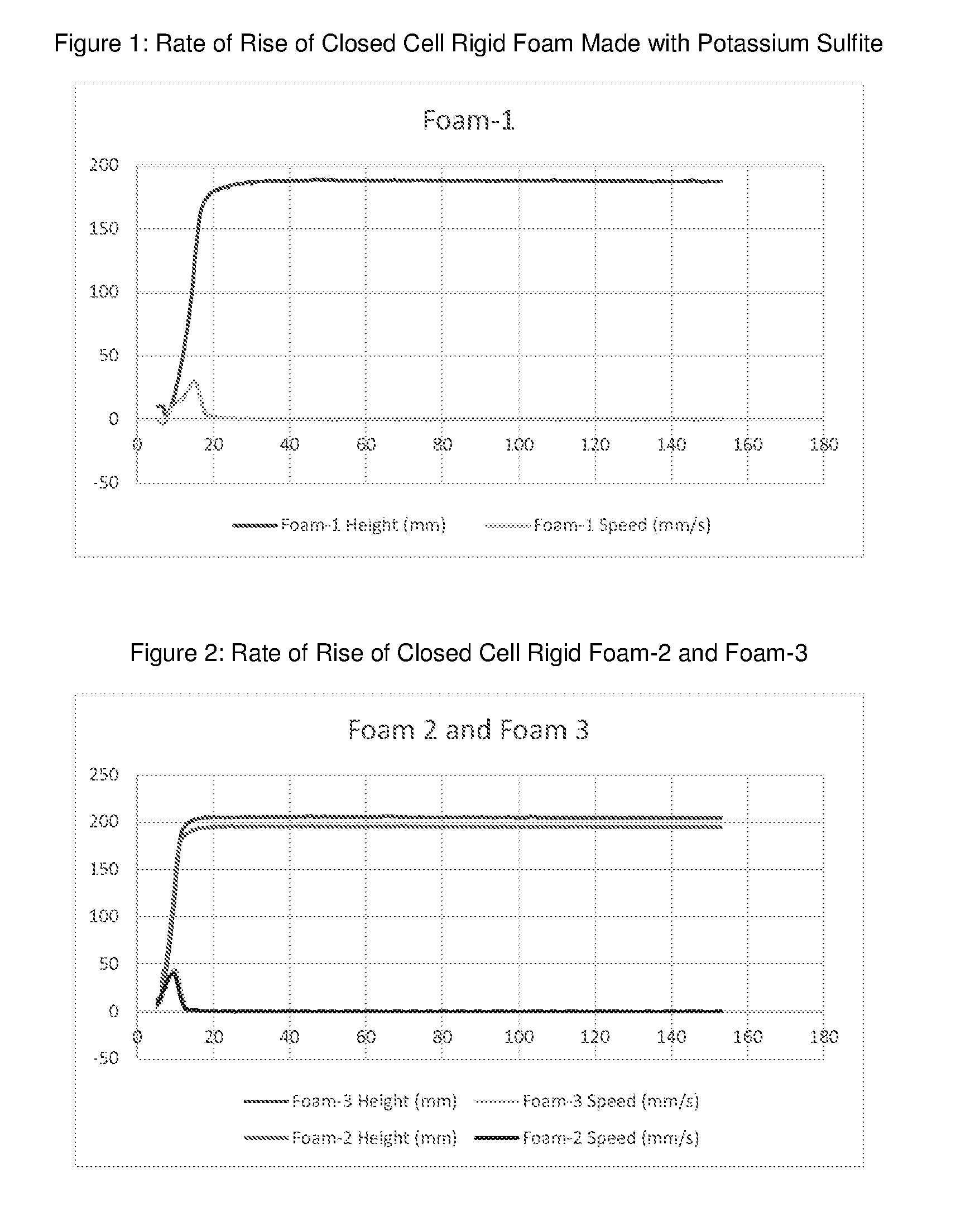

Polyurethane Catalysts from Sulfur Based Salts

ActiveUS20160102169A1Increase response rateReduction and elimination of emissionOrganic-compounds/hydrides/coordination-complexes catalystsMagnesium/calcium/strontium/barium sulfides/polysulfidesAdhesiveLacquer

This invention discloses the use of sulfite salts as catalysts to make polyurethane polymers. In particular, this invention discloses the use of metal salts such as alkali metal salts as well as alkyl ammonium salts such as tetralkyl ammonium salts as catalysts to make polyurethane polymers. The sulfite salts are useful to make a wide variety of polyurethane polymers and polyurethane foam polymer products such as flexible polyurethane foam polymers, rigid foam polyurethane polymers, semi-rigid polyurethane polymer, microcellular polyurethane polymer, and spray foam polyurethane polymer as well as any polymeric material that requires the assistance of catalysts to promote the formation of urethane and urea bonds such as those found in polyurethane emusions for paints, coatings, protective coatings, lacquer, etc as well as other polyurethane or polyurethane containing materials such as thermoplastic polymers, thermoplastic polyurethane polymers, elastomers, adhesives, sealants, etc. Examples of catalysts comprising the invention include sodium sulfite, potassium sulfite, lithium sulfite, tetramethylammonium sulfite and the like.

Owner:EVONIK OPERATIONS GMBH

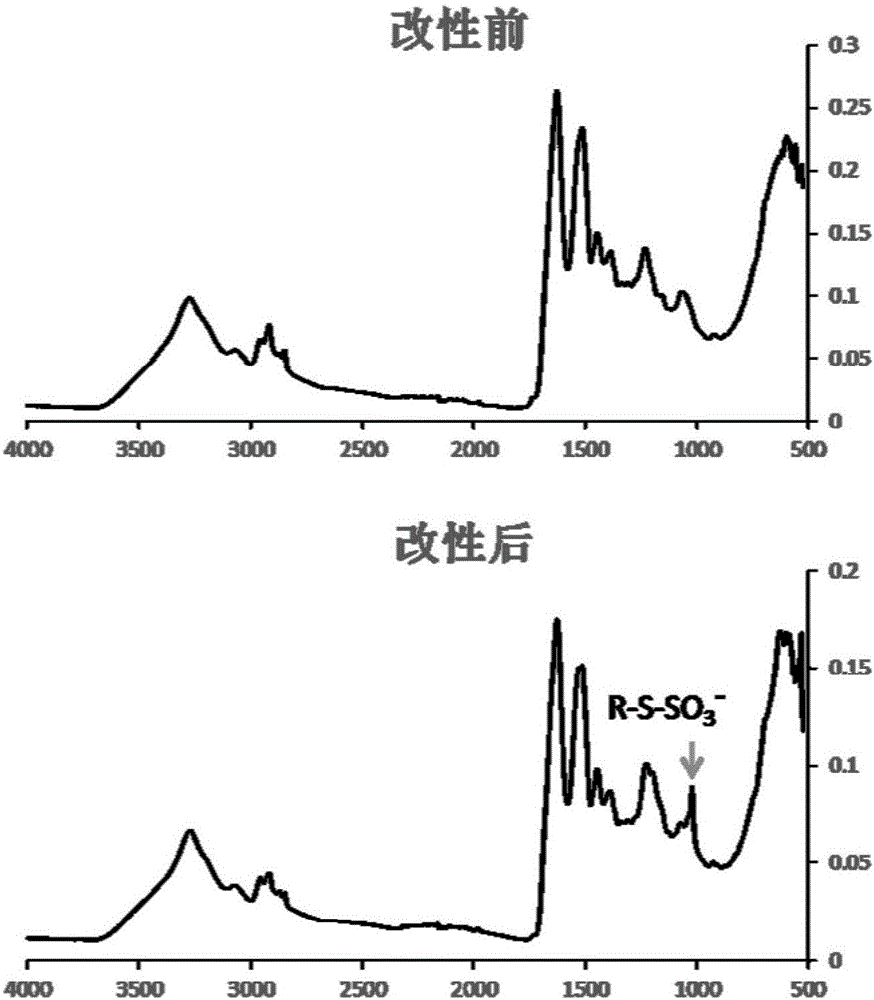

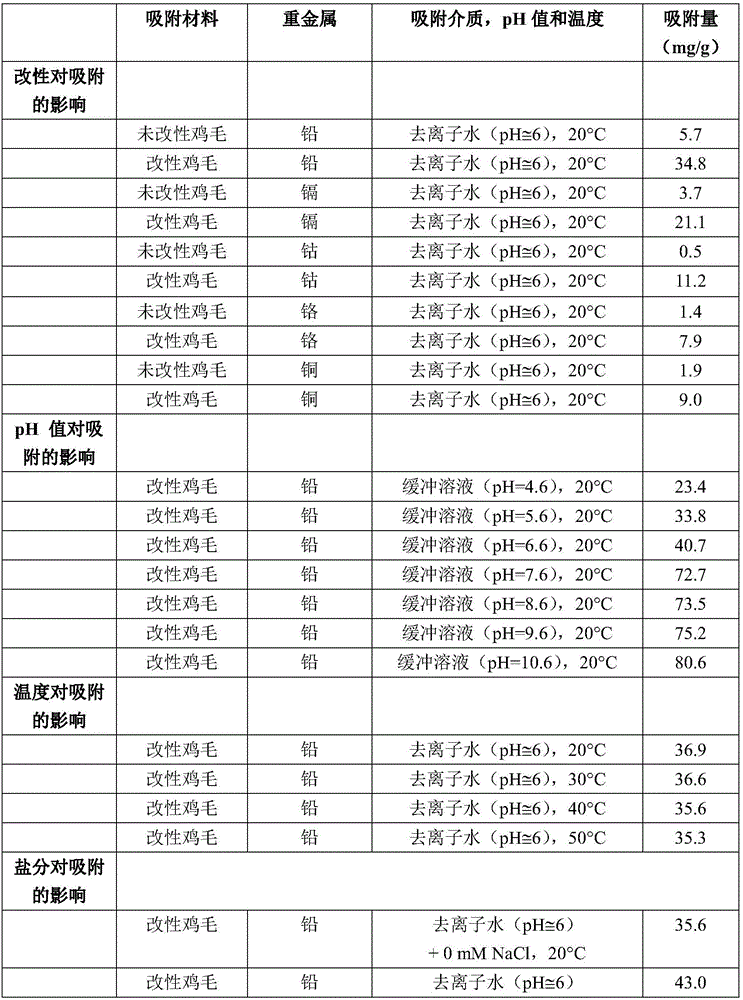

Keratin heavy metal adsorbent and preparation method thereof

InactiveCN106799212ADistinctive featuresLow priceOther chemical processesWater contaminantsSulfite saltSorbent

The invention provides a preparation method of a keratin heavy metal adsorbent. The preparation method comprises the following steps: step I, cleaning and smashing a keratin raw material; step II, carrying out oxidation reaction on the ready keratin raw material: taking the keratin raw material, and putting the keratin raw material in an oxidant aqueous solution to carry out oxidation reaction, wherein an oxidant is a potassium monopersulfate composite salt or a sodium monopersulfate composite salt; and step III, carrying out reduction reaction on the oxidized keratin material: taking the oxidized keratin material, putting the oxidized keratin material in an aqueous solution containing a reducing agent to carry out reaction, and drying the obtained keratin material to obtain the keratin heavy metal adsorbent, wherein the reducing agent is one of sodium sulfite, sodium metasulfite, sodium bisulfite, potassium sulfite, potassium metasulfite and potassium bisulfate. The prepared heavy metal adsorbent has certain selectivity, is high in adsorption efficiency, low in cost, simple and convenient to operate, mild in required condition and does not generate secondary pollution.

Owner:由永峰

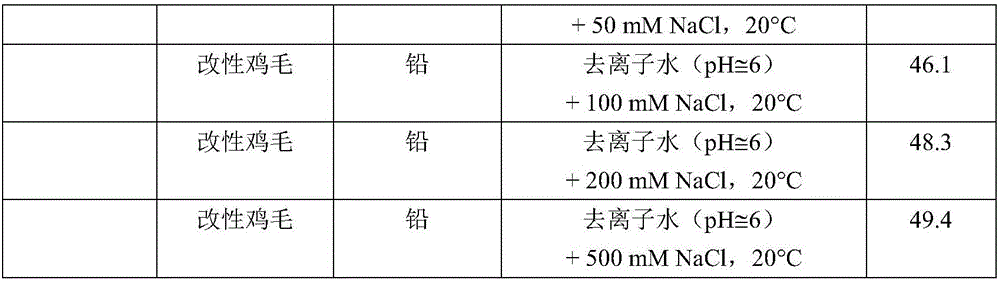

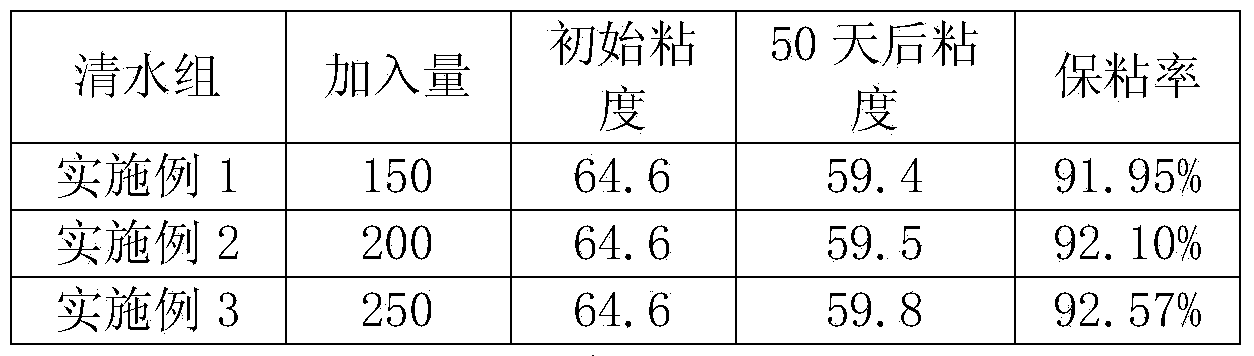

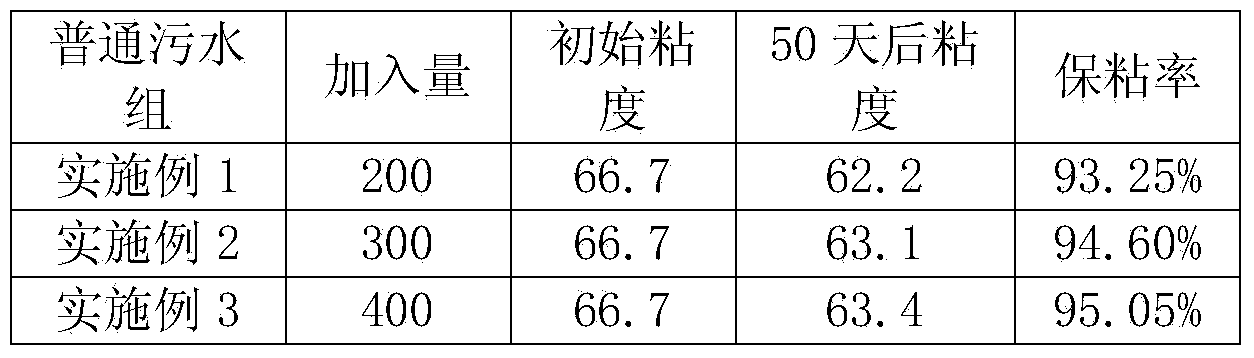

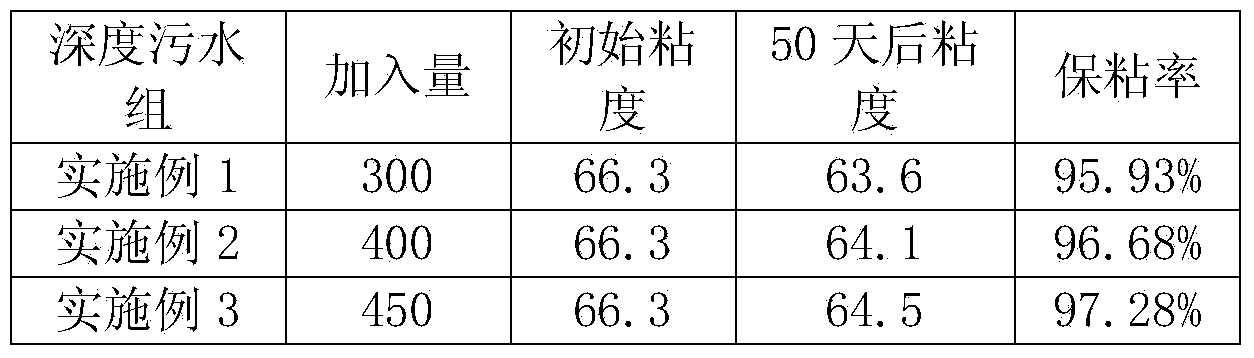

Polymer viscosity stabilizer

ActiveCN103666409AGood viscosity stabilityImproved rheology controlDrilling compositionPolymer scienceThiourea

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

Method for preventing fresh rice bran fats from oxidating

The invention relates to a method preventing fresh rice bran from fat oxidation. The method is characterized in that: the rice bran two hour after rice milling is screened and decontaminated with a 20 meshes screen; then the rice bran is fully blended with anhydrous sulfite (H2SO3), or anhydrous sodium (Na2SO3), or anhydrous potassium sulfate gioia (K2S2O5), or anhydrous gioia sodium (Na2S2O5), or anhydrous sodium bisulfite (NaHSO3) according to a weight portion of 100:0.5-5; and water is added into the mixture, therefore the moisture content is adjusted to 16 percent to 22 percent; then the mixture is squeezed at the temperature of 70 to 90 DEG C by a squeezing press with a screw speed of 105 to 125 round per minute; finally steady rice bran is obtained. By adopting the method provided by the invention, usage amount of chemical reagent and residual quantity thereof are reduced, damage to nutrient substance of the raw rice bran caused by physical squeezing is reduced, and utility value of protein in the raw materials is increased. The preservative period of the processed rice bran at normal temperature reaches 6 to 12 months.

Owner:SHENYANG AGRI UNIV

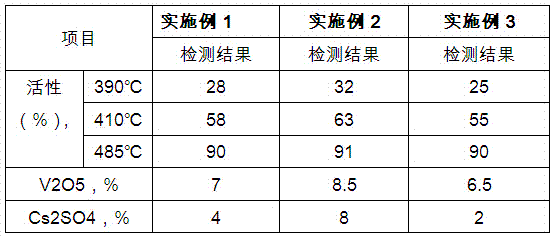

Catalyst containing caesium and vanadium and preparation method thereof

InactiveCN105435772AExtended service lifeQuality improvementSulfur compoundsMetal/metal-oxides/metal-hydroxide catalystsSulfite saltPotassium hydroxide

The invention discloses a catalyst containing caesium and vanadium and a preparation method thereof. With the total mass of the catalyst components as 100% parts, the content of vanadium pentoxide is 5-10%, the content of cesium oxide is 2-14%, the content of potassium oxide is 6-14%, the content of sodium oxide is 1-9%, and the balance is diatomaceous earth. A raw material of the cesium oxide is salt or alkali containing the cesium, such as cesium sulfate (Cs2SO4), cesium carbonate (Cs2CO3) or cesium hydroxide (CsOH). A raw material of the potassium oxide is salt or alkali containing potassium like potassium sulfate, potassium sulfite or potassium hydroxide. A raw material of the sodium oxide is salt or alkali containing sodium like sodium sulfate, sodium sulfite or sodium hydroxide. The catalyst is stable in performance, low in operating temperature, wide in areas, slow in heat fading and high in catalytic efficiency.

Owner:贵州威顿催化技术有限公司

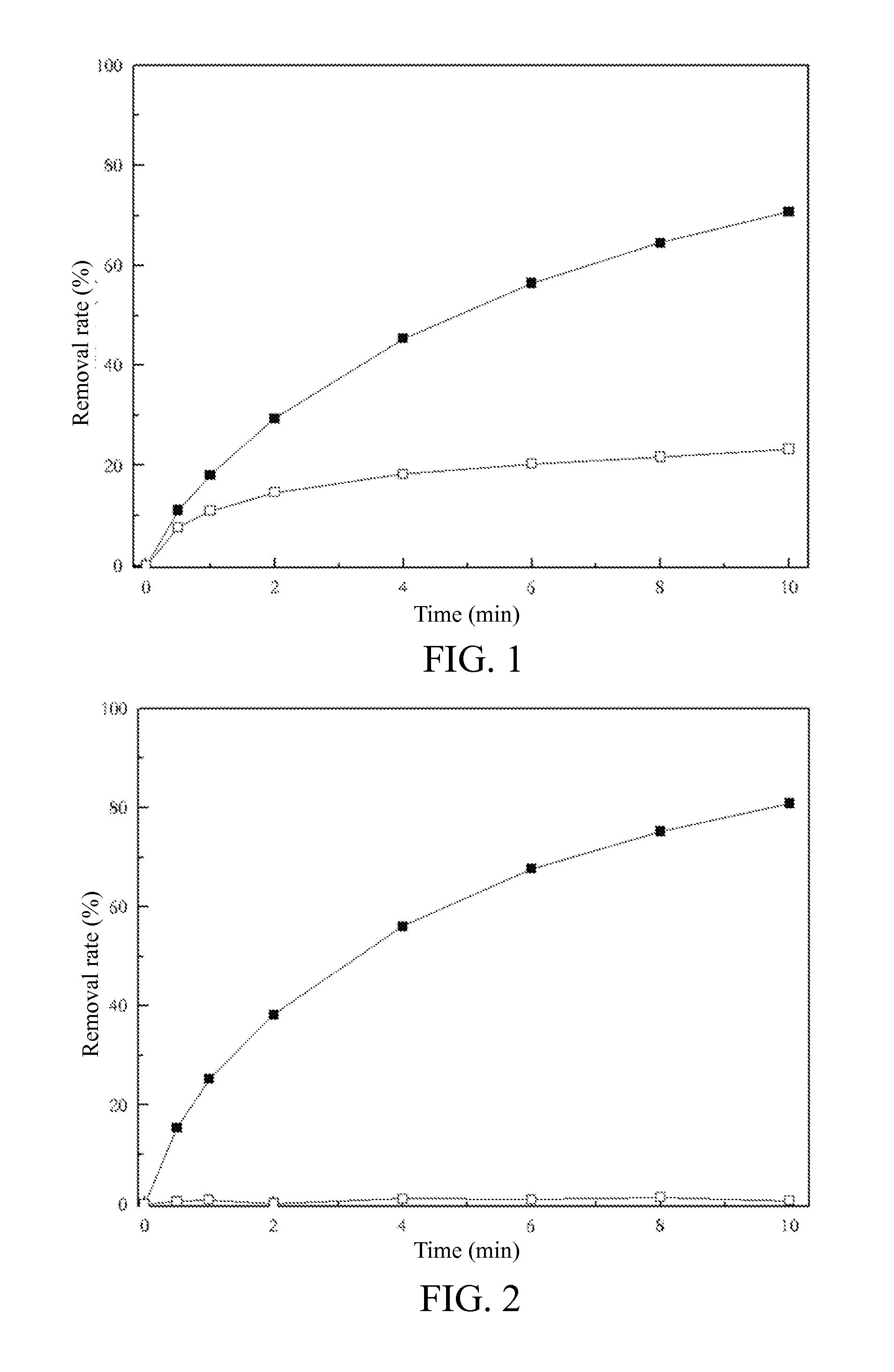

Fenton and Fenton-Like System Hardening Agent and Usage Thereof

InactiveUS20120305497A1Efficient use ofWide rangeWater treatment parameter controlOrganic chemistryHydrazine compoundSulfite salt

Fenton and Fenton-like system enhancing agent and the usage thereof are provided. It relates to a water treatment enhancer (enhancing agent) and the usage thereof. It widens water pH range of Fenton and Fenton-like system reaction. It reduces amount of Fe2+ required for Fenton reaction. It increases rate of Fenton-like reaction. The enhancing agent is selected from sodium sulfite, lithium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, hydroxylamine hydrochloride, hydroxylamine perchlorate, hydroxylamine sulfate, hydrazine, N,N-diethylhydroxylamine, amino ethanolamine, hydroxylamine solution or N,N,N′,N′-tetrasubstituted p-phenylenediamine. The method of use of enhancing agent comprises the steps of: adding Fenton or Fenton-like system enhancing agent, an agent for enhancement and hydrogen peroxide into water subject to treatment; and mixing and allowing reaction. The enhancing agent can increase the rate of reaction for the water treatment and reduce the dosage of the agent for enhancement.

Owner:HARBIN INST OF TECH

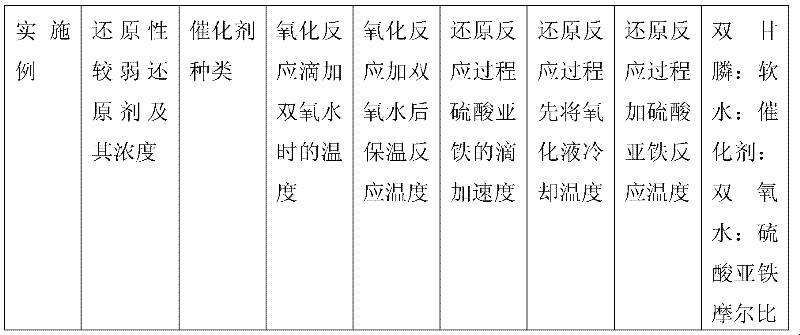

Preparation method for glyphosate

InactiveCN102649799AReduce consumptionLess fixed investmentGroup 5/15 element organic compoundsSulfite saltCatalytic oxidation

A preparation method for glyphosate comprises the steps as follows: oxydol is adopted for catalytic oxidation of a pmida raw material to obtain oxidation liquid, sulfide reductant with weaker reducibility is added into the oxidation liquid to consume excess oxydol in the oxidation reaction, then ferrous sulfate is added for reduction, and finally separation and drying are conducted so as to prepare the glyphosate; and the sulfide reductant with the weaker reducibility is any one or any combination of sodium sulfite, ammonium sulfite, potassium sulfite, ammonium bisulfite, sodium thiosulfate and sodium bisulfite. According to the method provided by the invention, the amount of the ferrous sulfate reductant is low, so as to save the raw material cost; the technical problem that the glyphosate prepared by the process in the prior art is yellowish is solved due to oxidation, reduction and other treatments in the method; meanwhile, the purity of the glyphosate prepared by using the method is high, the content of the glyphosate in solid powder is more than 96 percent, and the yield is more than 82 percent; and through the adoption of the method, the consumption of raw and auxiliary materials is lower, ammonia water, sulfuric acid and other raw materials are not used in the process.

Owner:CHONGQING UNISPLENDOUR CHEM

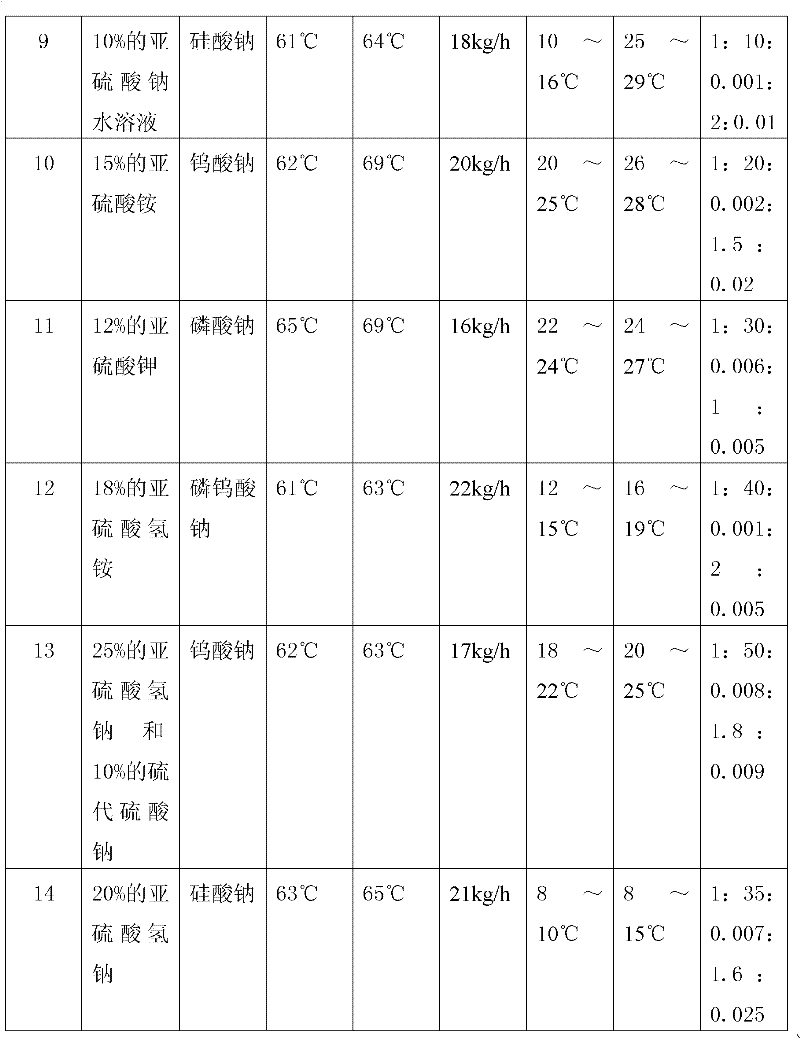

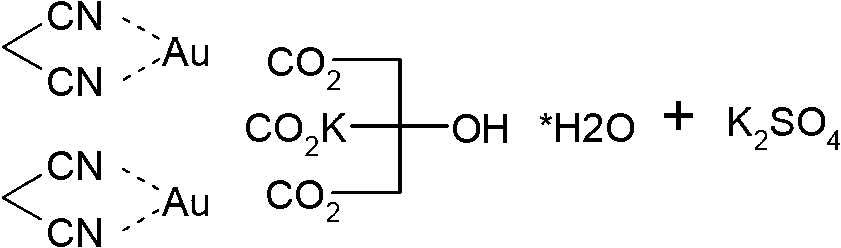

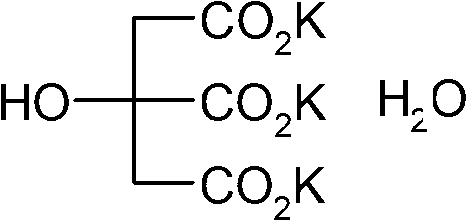

Preparation method for auric potassium citrate for gold plating

The invention discloses a preparation method for auric potassium citrate for gold plating. Potassium citrate and malononitrile are added into auric potassium sulfite aqueous solution and completely dissolved, oxygen or air is then introduced into the solution, after a certain period of time, the condition that sulfite ions do not exist in the solution by testing through a piece of sulfite test paper is ensured, water is distilled out under reduced pressure, the solution is concentrated into solid, the solid is cooled, white solid is obtained by washing, filtered under vacuum and dried, then the auric potassium citrate is obtained, and the reaction molar ratio of the auric potassium sulfite to the malononitrile to the potassium citrate is 1:1:2. The auric potassium sulfite with monovalent aurous ions adopted as material by the preparation method is essentially different from the trivalent gold used as starting material in the prior art, the gold oxidation-reduction process is not involved, the process of oxidizing sulfite with oxygen is stable, preparation equipment is simple, the cost is low, the quality is high, and the product can be mass-produced, and can completely substitute auric potassium cyanide.

Owner:SUZHOU XINGRUI NOBLE METAL MATERIAL

Green plum and lycium fruit wine brewing technology

ActiveCN104987977AHas double health effectsImprove drinking tasteAlcoholic beverage preparationBiotechnologyPectinase

The invention relates to a green plum and lycium fruit wine brewing technology. The technology comprises the following steps that green plums and lycium are crushed after being mixed with water according to the proportion to obtain fruit mash; potassium metabisulfite, pectinase and a deacidification agent are added into the fruit mash, and the mixture is stirred uniformly and stands for enzymolysis; the mixture is fermented primarily and secondarily, clarified and sterilized to obtain finished fruit wine. The technology has the advantages that enzymolysis and two-time fermentation are carried out on the fruit mash obtained after the green plums and the lycium are mixed to manufacture the fruit wine, consideration is given to the suitable brewing characteristic and nutrition healthcare value of the two fruits, and by the adoption of the scientific fermentation environment and parameter control, the manufactured fruit wine has double healthcare effects and is good in drinking mouthfeel.

Owner:YIBIN UNIV

Polyurethane catalysts from sulfur based salts

ActiveUS20160229945A1Organic-compounds/hydrides/coordination-complexes catalystsAdhesiveFoam polyurethanes

Owner:EVONIK OPERATIONS GMBH

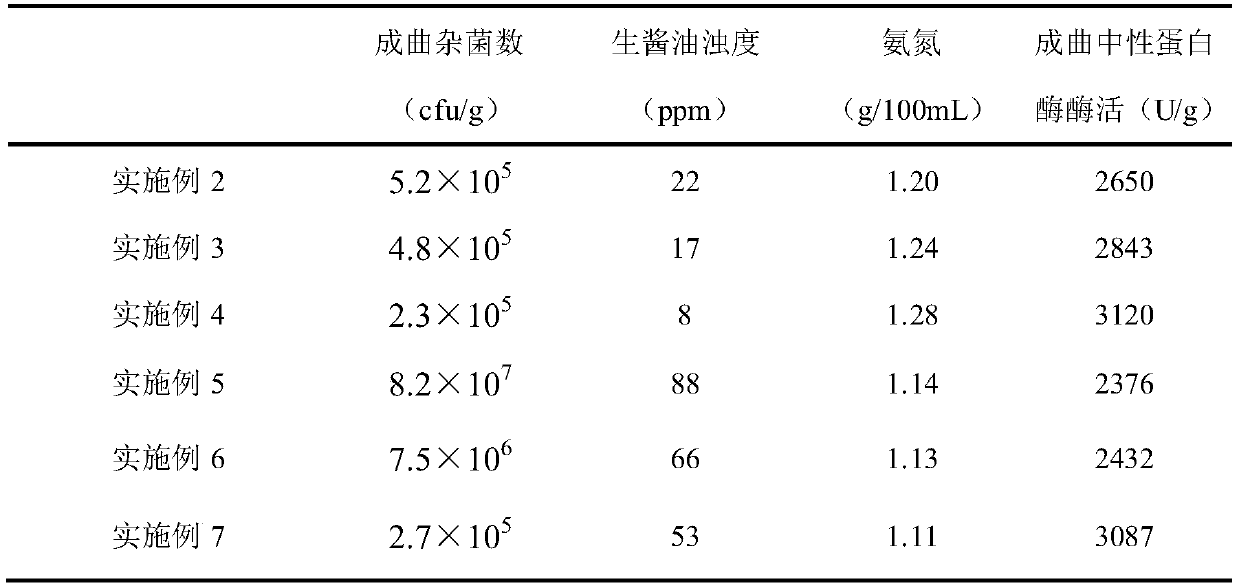

Preparing method of soy sauce free of plate-frame pressure filtration

The invention discloses a preparing method of soy sauce free of plate-frame pressure filtration. The method includes the following steps of firstly, preparing distiller's yeast, wherein heat-denaturedsoybeans and wheat are mixed and then inoculated with aspergillus oryzae, one or more of potassium sulfite, glycine and ammonium acetate are added to be mixed, and ventilating is conducted to preparethe distiller's yeast; secondly, conducting fermenting, wherein a saline solution and edible alcohol are added to the finished distiller's yeast obtained in the first step for fermentation and inoculated with torulopsis candida and zygosaccharomyces rouxii in the fermentation process for fermentation for 150-180 d in a high-salinity diluted state; thirdly, conducting pressure filtration to obtainraw soy sauce. Through the method, the turbidity of the raw soy sauce can be reduced, and the prepared soy sauce is convenient to filter, high in oil yield and more delicious in taste.

Owner:QIANHE CONDIMENT & FOOD CO LTD

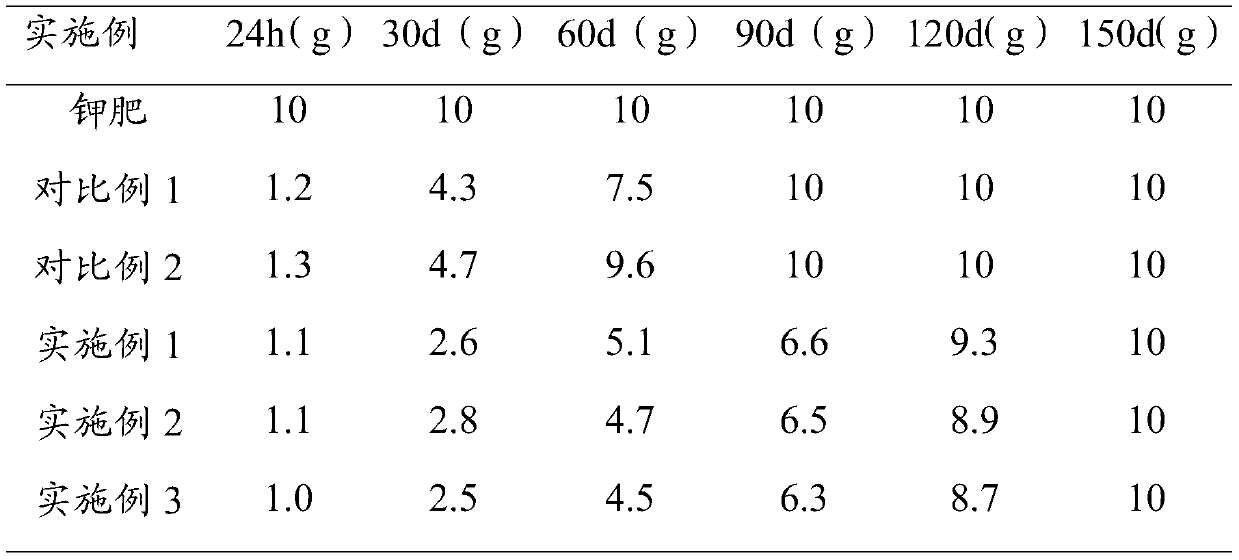

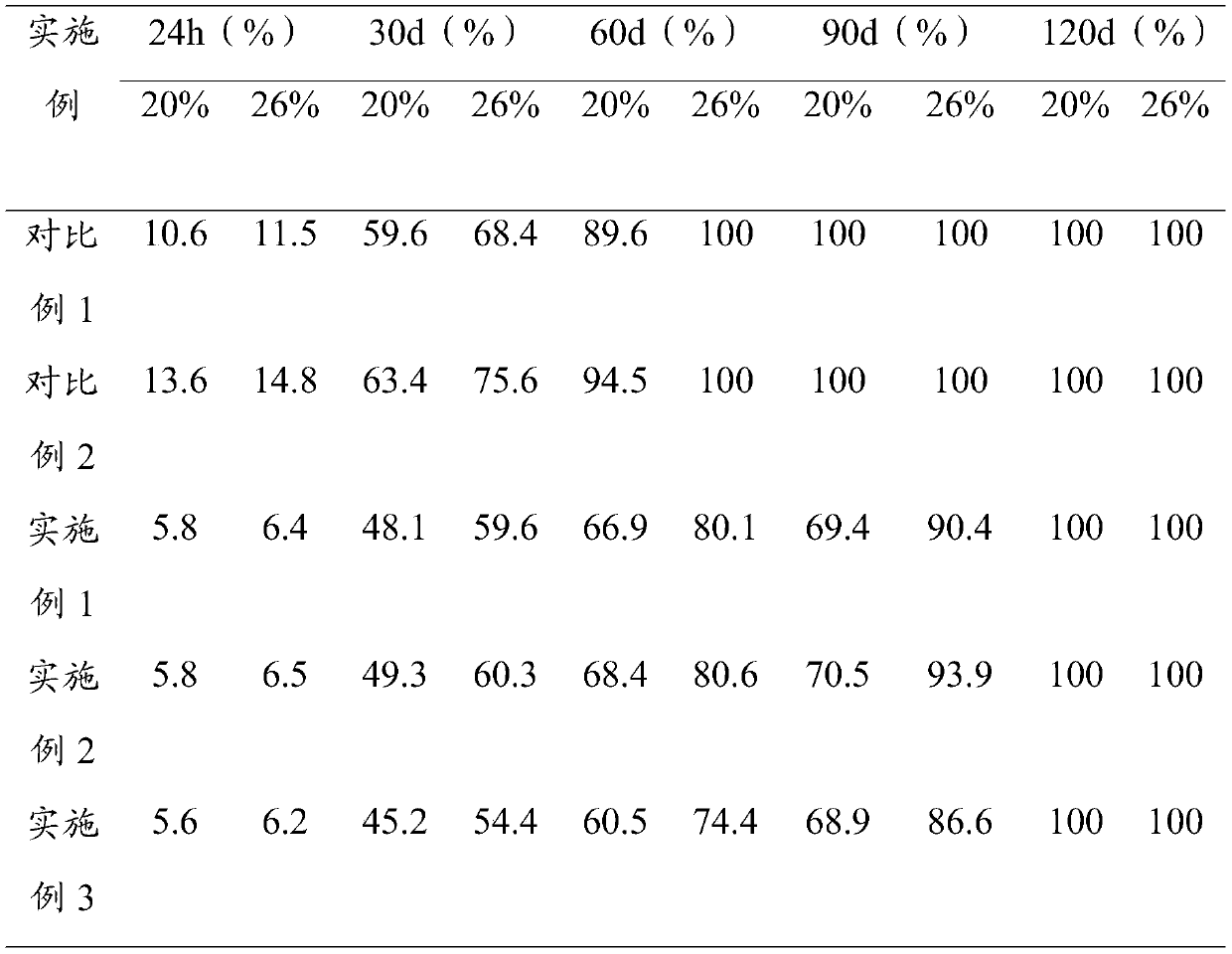

Potash fertilizer-loaded slow-release degradable porous material and preparation method thereof

InactiveCN110563510ASimple structureExtension of timeCarbon preparation/purificationPotassium fertilisersPolyvinyl alcoholPassion fruit

The invention discloses a potash fertilizer-loaded slow-release degradable porous material and a preparation method thereof. The preparation method comprises the following steps: carrying out pore-increasing treatment on crushed passion fruit vines, and then carrying out carbonizing to obtain a biomass porous matrix material; uniformly mixing starch, sugarcane water and potato peel under stirring,and sequentially adding an oxidant, a catalyst, potassium sulfite, polyvinyl alcohol, borax and sodium hydroxide to obtain a coating material; and mixing the prepared biomass porous matrix material with a potash fertilizer solution, carrying out uniform mixing under stirring, carrying out ultrasonic treatment, uniformly mixing the obtained mixture with a coating material, carrying out spray drying by using a spray dryer, and performing screening to obtain the potash fertilizer-loaded slow-release degradable porous material. The potash fertilizer-loaded slow-release degradable porous materialprepared in the invention is a slow-release potash fertilizer which uses a biomass porous material as a carrier and is low in preparation cost, friendly to environment, degradable and longer fertilizer efficiency duration.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD +1

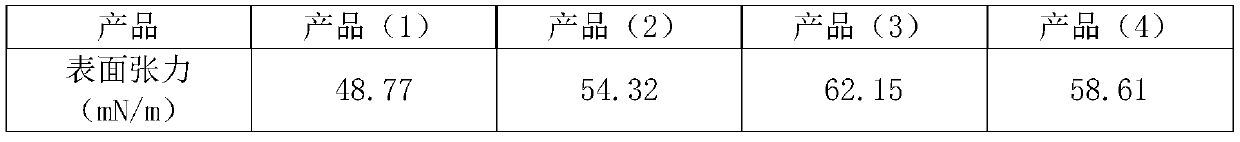

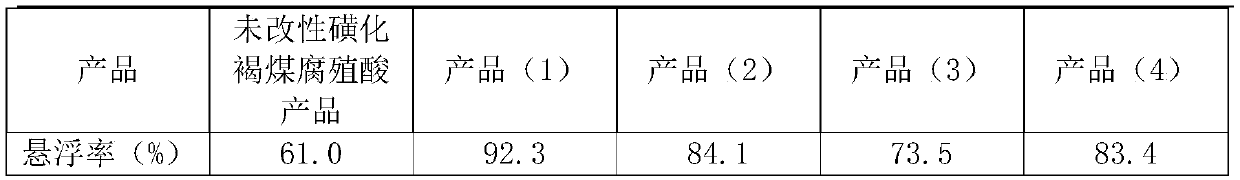

Humic acid-containing water-soluble fertilizer and preparation method thereof

The invention belongs to the field of fertilizers. The invention provides humic acid-containing water-soluble fertilizer which comprises sulfonated lignite humic acid, a wetting agent and a disintegrating agent, and the sulfonated lignite humic acid is prepared from sulfuric acid and potassium sulfite sulfonated humic acid.

Owner:ZHEJIANG FENGYU ECOLOGICAL TECH CO LTD

Neutral cyanide-free brush electroplating silver plating solution and preparation process and use method thereof

The invention provides a neutral cyanide-free brush electroplating silver plating solution. The neutral cyanide-free brush electroplating silver plating solution is prepared from, by mass concentration, 20 g / L to 30 g / L of silver salt, 40 g / L to 60 g / L of a coordination agent sodium thiosulfate, 70 g / L to 90 g / L of thiourea and homolog thereof, 20 g / L to 30 g / L of a protective agent methanesulfonic acid derivative, 20 g / L to 120 g / L of an additive polyethyleneimine, 5 g / L to 20 g / L of potassium metabisulfite, 35 g / L to 110 g / L of ammonium hydroxide and 0.1 g / L to 0.6 g / L of a stabilizer sodium citrate, the pH value of the solution is adjusted to range from 6.8 to 7.2 with dilute nitric acid or dilute sodium hydroxide, and the solution is a neutral plating solution. The invention further provides a preparation process and use method of the neutral cyanide-free brush electroplating silver plating solution. The neutral cyanide-free brush electroplating silver plating solution is prepared by mixing the harmfulless silver salt, coordination agent, protective agent and the like, the raw materials are easy to obtain, and the preparation process is simple. The neutral cyanide-free brush electroplating silver plating solution is applied to the surface of copper or a copper alloy for brush electroplating, the method is simple and practicable, and plating is stable.

Owner:STATE GRID CORP OF CHINA +1

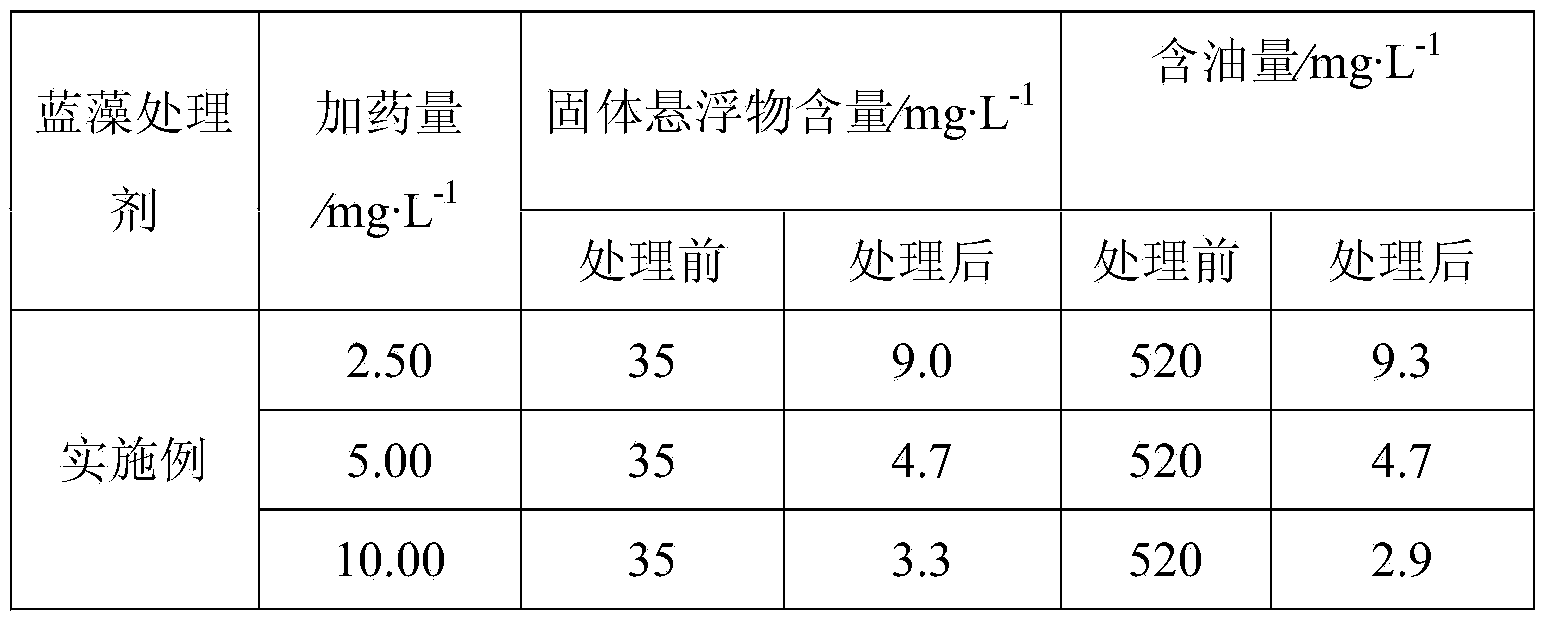

Deodorizing powdery blue algae treating agent and production method thereof

ActiveCN103936122AGood deodorizing effectStrong flocculation and purificationWater/sewage treatment by flocculation/precipitationPotassium bisulfiteBiology

The invention discloses a deodorizing powdery blue algae treating agent. The deodorizing powdery blue algae treating agent is characterized by being prepared from the following raw materials in parts by weight: 26-29 parts of TiO2 pillared montmorillonite, 18-22 parts of pumice, 17-19 parts of urea, 19-20 parts of potassium bisulfite, 20-22 parts of potassium sulfite, 16-18 parts of manganese sulfate, 1-3 parts of garden burnet, 2-4 parts of honeysuckle, 2-5 parts of red paeony root and 4-7 parts of trigone. The deodorizing powdery blue algae treating agent is good in deodorization effect, high in flocculation and purification capacity, convenient to use, low in cost and strong in adaptability, can take effect quickly and has smaller erosion and corrosion effects of alkalisation on equipment than other aluminum salts and ferric salts, and thus can be widely applied to various blue algae polluted water areas.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com