Preparing method of soy sauce free of plate-frame pressure filtration

A technology of plate and frame filter press and manufacturing method, which is applied in the direction of food science, etc., can solve the problems of increased turbidity of soy sauce, which cannot be solved, and affects protein degradation, etc., and achieves the effects of reducing filtration costs, high oil yield, and strengthening vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

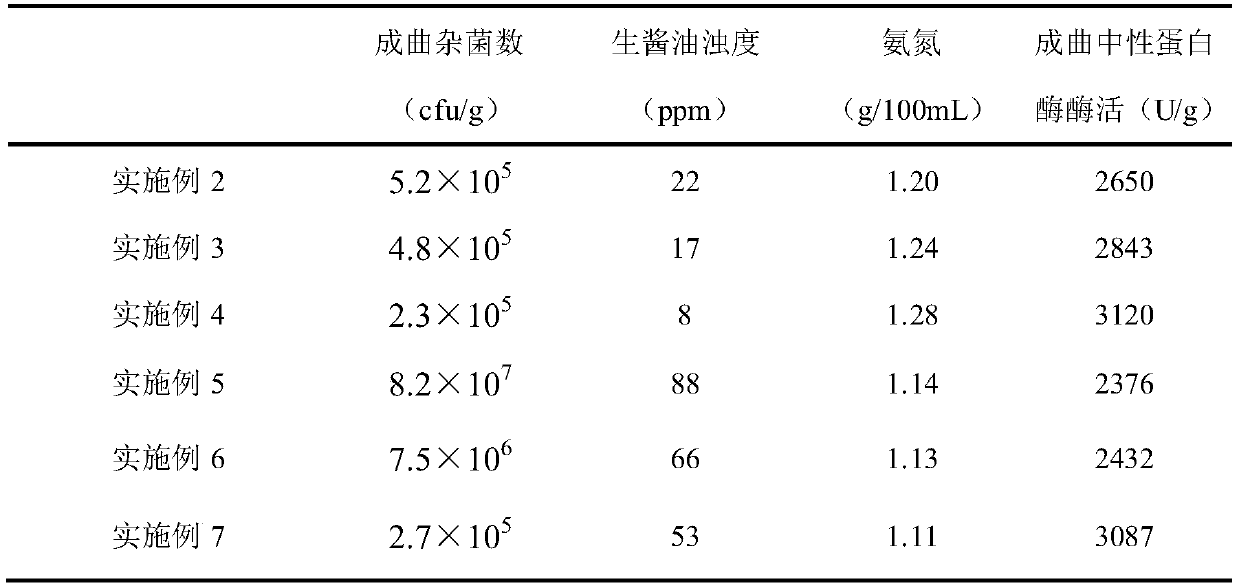

Examples

Embodiment 1

[0025] A kind of low turbidity soy sauce of the present invention is obtained through the following steps;

[0026] 1) Pretreatment: Stir-fried wheat, steamed soybeans, baked at 120-160°C for 5-20s to remove surface moisture, and then cooled to room temperature in a cooler;

[0027] 2) Preparation of koji: Heat-denatured soybeans and wheat are mixed according to the weight ratio of 5:5-7:3, then inoculated with Aspergillus oryzae, and 0.01-0.1% potassium sulfite or 0.005-0.1% glycine or 0.05-0.5% ammonium acetate, or two or three of the above three substances, the water content of the koji material is maintained at 35-45%, and the soy sauce is obtained by ventilating and culturing at 33°C for 3 days;

[0028] 3) Fermentation: a mixture of koji and 22-23wt% salt water, the amount of salt water added is 1.2-1.6 times the mass of the koji, 2-3% edible alcohol is added immediately after entering the tank, and it is added on the 1st to 4th day of fermentation 0.1-0.5% of Torulopsi...

Embodiment 2

[0033] A kind of low turbidity soy sauce of the present invention is obtained through the following steps;

[0034] 1) Pretreatment: Stir-fry wheat, steam soybeans, bake at 160°C for 5 seconds to remove surface moisture, and then cool to room temperature with a cooler;

[0035] 2) Preparation of finished koji: heat-denatured soybeans and wheat were mixed according to the weight ratio of 7:3, then inoculated with Aspergillus oryzae, and 0.05% potassium sulfite was added, the water content of the koji was maintained at 45%, and the soy sauce was obtained by ventilating and culturing at 33°C for 3 days. song;

[0036] 3) Fermentation: a mixture of koji and 23wt% salt water, the amount of salt water added is 1.2 times the quality of the koji, 2% edible alcohol is added immediately after entering the tank, and 0.1% Torulopsis globosa CICC1019 is added on the first day of fermentation, On the 20th day of fermentation, 1.6% combined yeast CGMCC NO.16313 was added and fermented for 1...

Embodiment 3

[0041] A kind of low turbidity soy sauce of the present invention is obtained through the following steps;

[0042] 1) Pretreatment: Wheat is fried, soybeans are steamed and then baked at 140°C for 20s to remove surface moisture, and then cooled to room temperature by a cooler;

[0043] 2) Preparation of finished koji: heat-denatured soybeans and wheat are mixed according to the weight ratio of 5:5, then inoculated with Aspergillus oryzae, and 0.2% ammonium acetate is added, the water content of the koji material is maintained at 35%, and the soy sauce koji is obtained by ventilating and culturing at 33°C for 3 days ;

[0044] 3) Fermentation: a mixture of koji and 23wt% salt water, the amount of salt water added is 1.4 times the quality of the koji, 2% edible alcohol is added immediately after entering the tank, and 0.5% Torulopsis globosa CICC1019 is added on the 4th day of fermentation, On the 30th day of fermentation, add 0.5% combined yeast CGMCC NO.16313, and ferment fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com