Keratin heavy metal adsorbent and preparation method thereof

A keratin and heavy metal technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of inconvenient use, difficult to degrade, low adsorption capacity, etc., and achieve high adsorption strength and easy amplification. , the effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

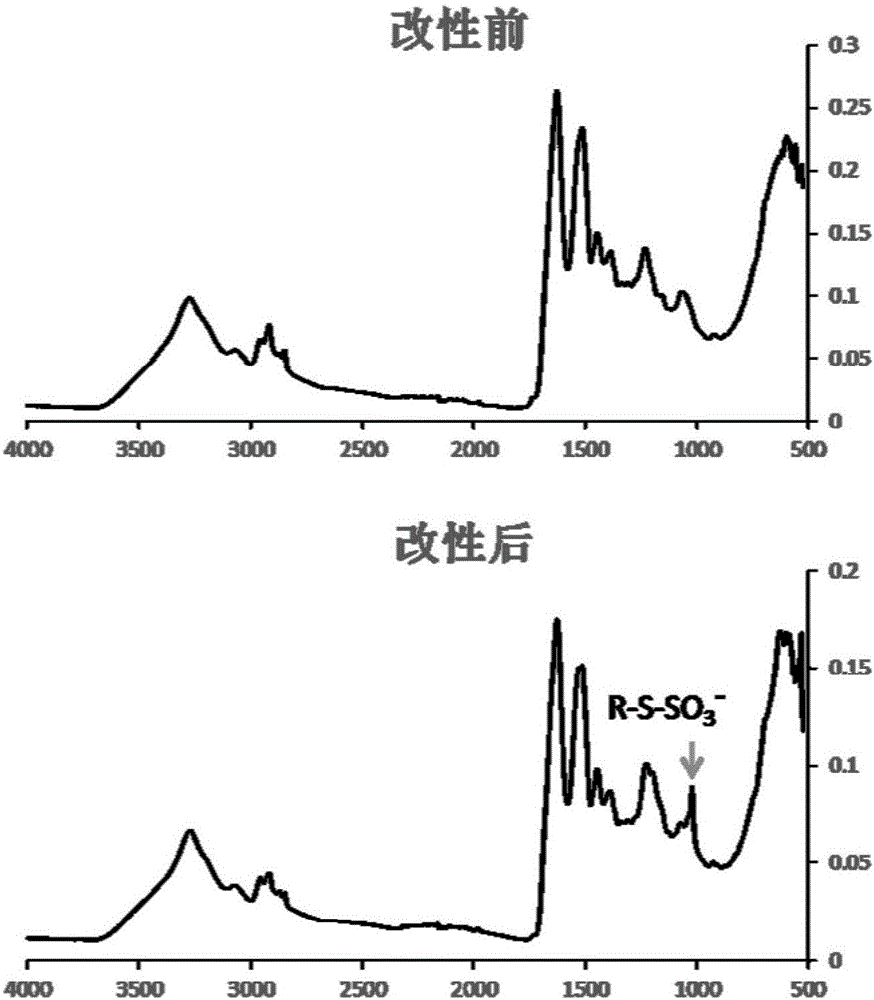

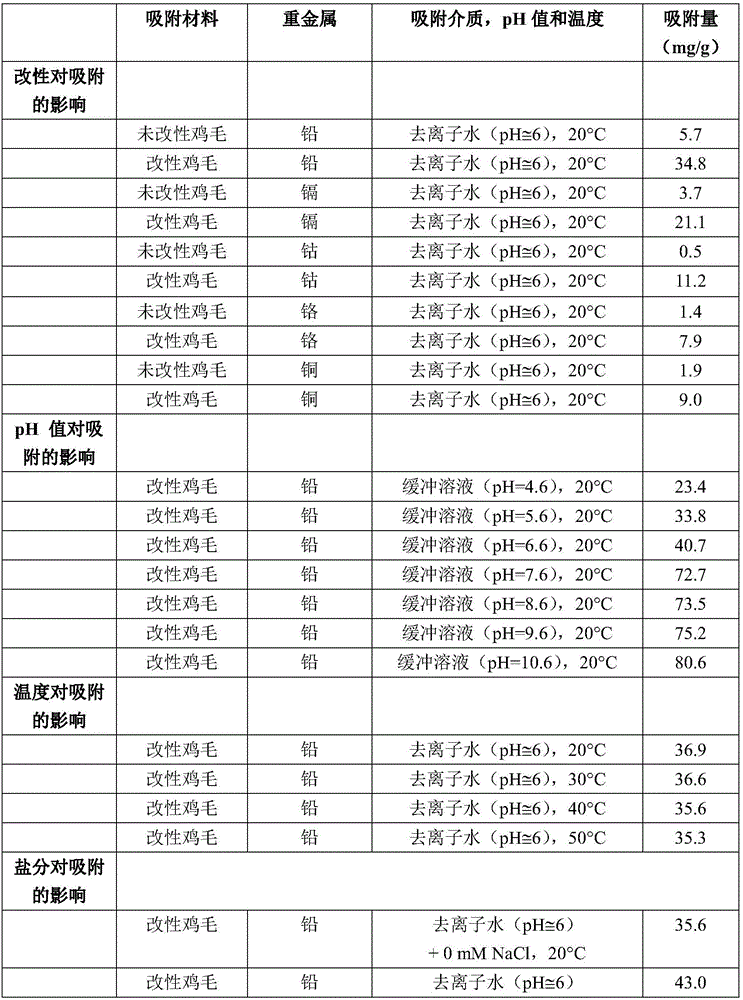

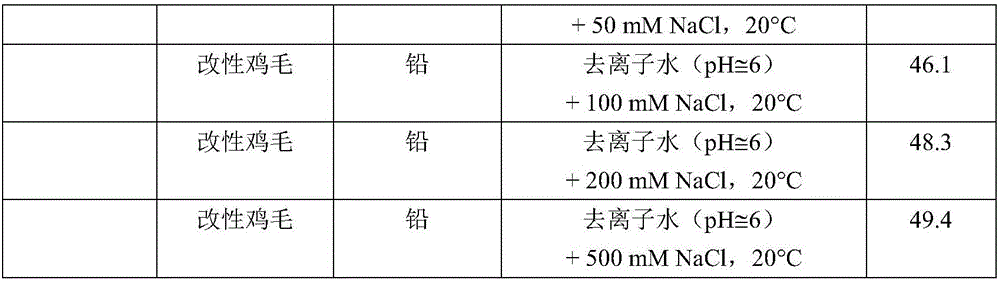

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a keratin heavy metal adsorbent, comprising the following steps:

[0026] 1. Clean the chicken feathers, dry them at 80°C, break them up, and set aside.

[0027] Two, (carry out oxidation reaction to prepared chicken feather) get 10g chicken feather, be placed in the aqueous solution of 500mL potassium hydrogen persulfate compound salt (0.2%, w / v). The solution contained 0.1% (v / v) of non-ionic surfactant Triton X-100. Shaking or agitation was applied during the reaction. The temperature is 25°C and the time is 30 minutes. After the reaction, the chicken feathers were washed briefly with water, and then squeezed to remove excess water.

[0028] Three, (reducing the oxidized chicken feathers) get the oxidized chicken feathers and put them in 500mL sodium sulfite (Na 2 SO 3 ) in an aqueous solution (1.0%, w / v, adjusted to pH 8.2 with dilute sulfuric acid in advance). Shaking or agitation was applied during the reaction. The temperature is 25...

Embodiment 2

[0031] A preparation method of a keratin heavy metal adsorbent, comprising the following steps:

[0032] 1. Clean the waste wool, dry it at 80°C, and smash it. spare.

[0033] Two, (oxidize the prepared wool) take 10g of wool and put it in 500mL aqueous solution of sodium persulfate complex salt (0.2%, w / v). The solution contained 0.1% (v / v) of non-ionic surfactant Triton X-100. Shaking or agitation was applied during the reaction. The temperature is 25°C and the time is 30 minutes. After the reaction, the wool is washed briefly with water and then squeezed to remove excess water.

[0034] Three, (reduce the oxidized wool) take the oxidized wool and put it in 500mL sodium sulfite (Na 2 SO 3 ) in aqueous solution (1.0%, w / v, adjusted to pH 8.2 with dilute sulfuric acid in advance). Shaking or agitation was applied during the reaction. The temperature is 25°C and the time is 30 minutes. After the reaction, the wool was washed briefly with water, then squeezed to remove ...

Embodiment 3

[0036] A preparation method of a keratin heavy metal adsorbent, comprising the following steps:

[0037] 1. Clean the chicken feathers, dry them at 80°C, and smash them into pieces. spare.

[0038] Two, (oxidation reaction is carried out to prepared chicken feather) get 10g chicken feather, be placed in the aqueous solution of 500mL sodium persulfate compound salt (0.2%, w / v). The solution contained 0.1% (v / v) of non-ionic surfactant Triton X-100. Shaking or agitation was applied during the reaction. The temperature is 25°C and the time is 30 minutes. After the reaction, the chicken feathers were washed briefly with water, and then squeezed to remove excess water.

[0039] Three, (reducing the oxidized chicken feathers) get the oxidized chicken feathers and put them in 500mL sodium metabisulfite (Na 2 S 2 o 5 ) in an aqueous solution (1.0%, w / v, adjusted to pH 8.2 with dilute sulfuric acid in advance). Shaking or agitation was applied during the reaction. The temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com