Non-cyanogen type electrolytic gold plating bath for bump forming

A technology of electrolytic gold and electroplating solution, which is applied in the direction of circuits, printed circuits, electrical components, etc., and can solve the problems that conductive particles cannot be thermocompressed, conductive particles cannot be bonded, and poor bonding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] According to the combination shown in Tables 1 to 5, prepare non-cyanide electrolytic gold plating solution. The unit of the compounding concentration of each raw material is g / L unless otherwise specified. However, Na3Au(SO3)2 and gold ammonium sulfite are concentrations indicating the amount of Au.

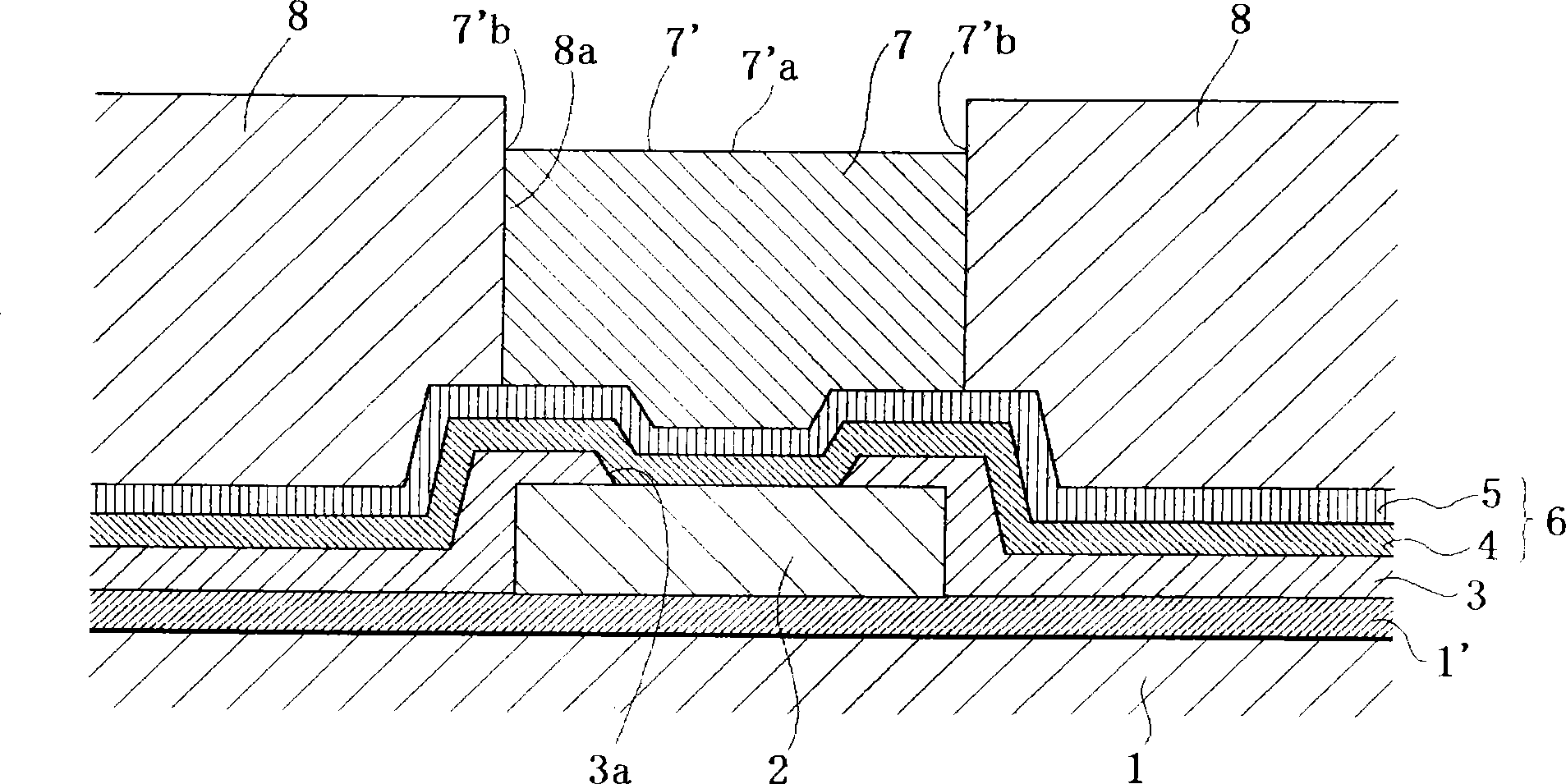

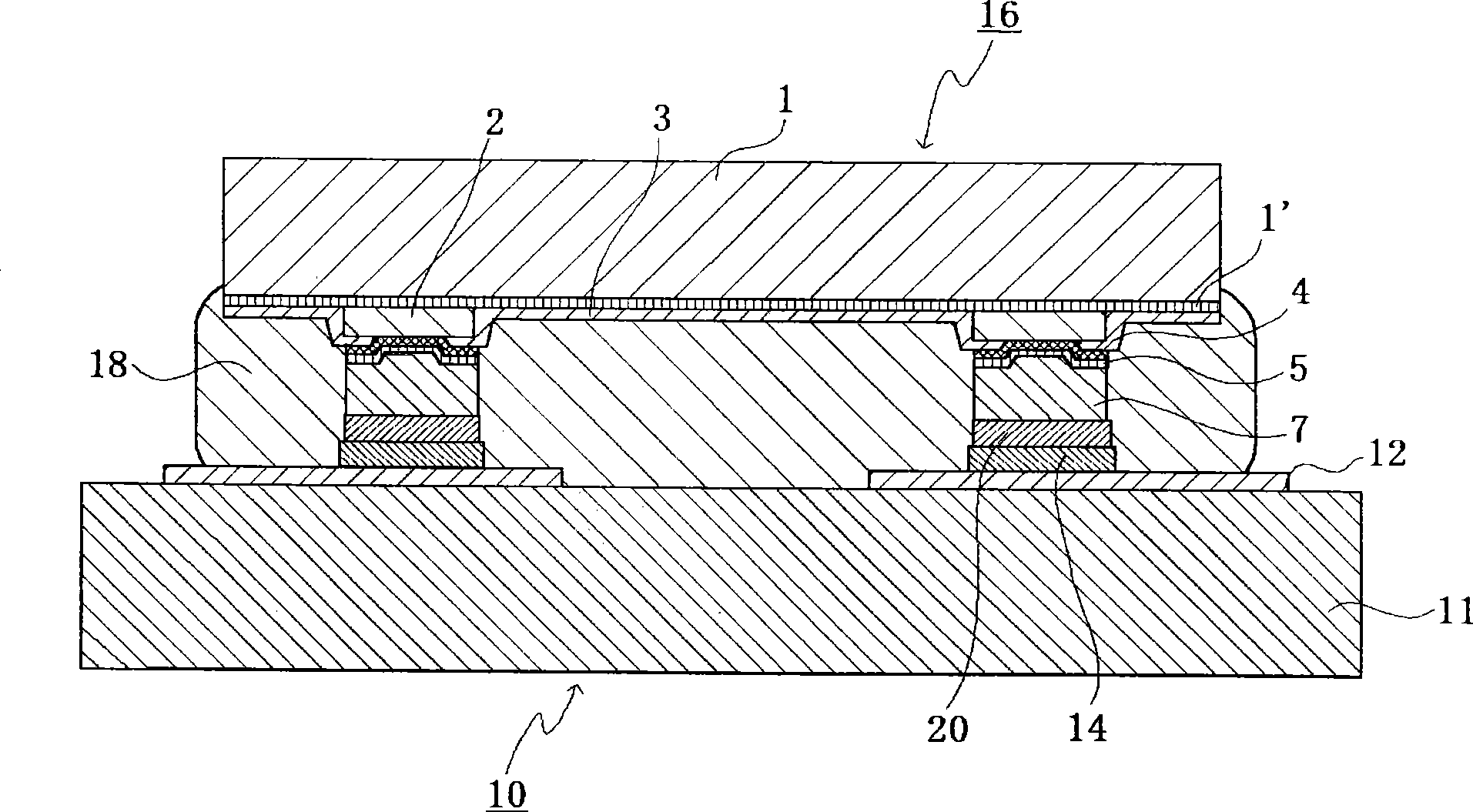

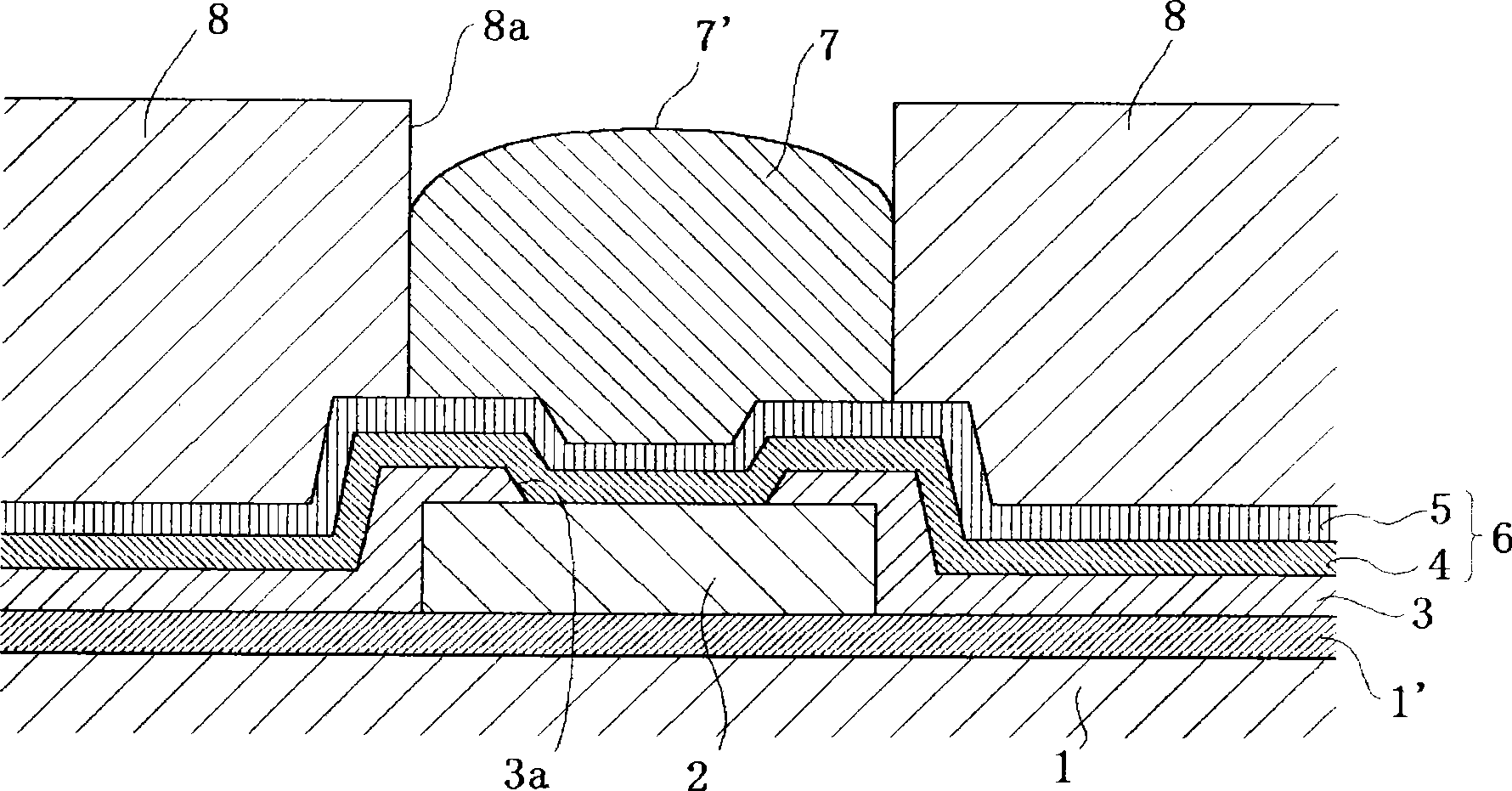

[0080] As the object to be plated, a silicon wafer having protrusion openings patterned with a phenolic positive photoresist film (substrate cross-sectional composition: gold sputtered film / TiW / SiO2) was used. The object to be plated was dipped in 1 L of the prepared non-cyanide electrolytic gold plating solution, and energized to form a gold plating film having a film thickness of 15 μm. In addition, the current efficiency of non-cyanide electrolytic gold plating solutions is usually 100% under constant plating operating conditions.

[0081] After forming a film with a predetermined film thickness, remove the mask material, the shape of the formed protrusions, the stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com