Neutral cyanide-free brush electroplating silver plating solution and preparation process and use method thereof

A brush-plating, neutral technology, applied in the field of electrochemistry, can solve the problems of affecting the concentration of silver ions, poor bonding force of the coating, easy foaming of the coating, etc., and achieve the effects of avoiding discoloration of the coating, good stability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a kind of neutral cyanide-free electric brush plating silver-plating liquid, comprises following component and mass concentration thereof: nitrate silver salt 30g / L, complexing agent sodium thiosulfate 40g / L and thiourea and its homologue 90g / L, protective agent methylsulfonic acid derivative 30g / L, additive polyethyleneimine 60g / L, potassium metabisulfite 10g / L, ammonia water (density 0.91g / cm 3 , 25°C) 70g / L, stabilizer sodium citrate 0.6g / L.

[0036] The invention provides a kind of preparation technology of neutral cyanide-free electric brush plating silver-plating liquid, comprises the steps:

[0037] (1) Prepare a mixed solution of complexing agent, protective agent and stabilizer, and fully stir to make the dispersion uniform;

[0038] (2) under stirring, potassium metabisulfite is added in the mixed solution of step (1);

[0039] (3) under stirring, silver salt is added in the mixed solution of step (2);

[0040] (4) under stirring, po...

Embodiment 2

[0050] The invention provides a kind of neutral cyanide-free electric brush plating silver-plating liquid, comprises following component and mass concentration thereof: nitrate silver salt 30g / L, complexing agent sodium thiosulfate 45g / L and thiourea and its homologue 80g / L, protective agent methylsulfonic acid derivative 25g / L, additive polyethyleneimine 35g / L, potassium pyrosulfite 8g / L, ammonia water (density 0.91g / cm 3 , 25°C) 40g / L, stabilizer sodium citrate 0.4g / L.

[0051] The preparation process and application method of this embodiment are the same as that of Embodiment 1.

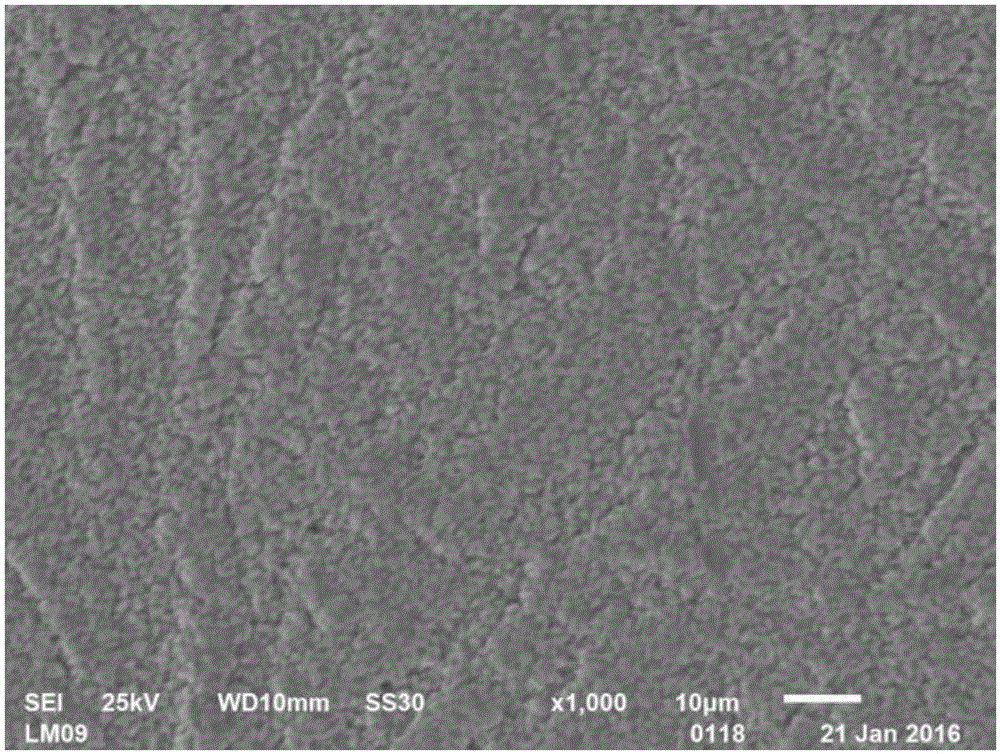

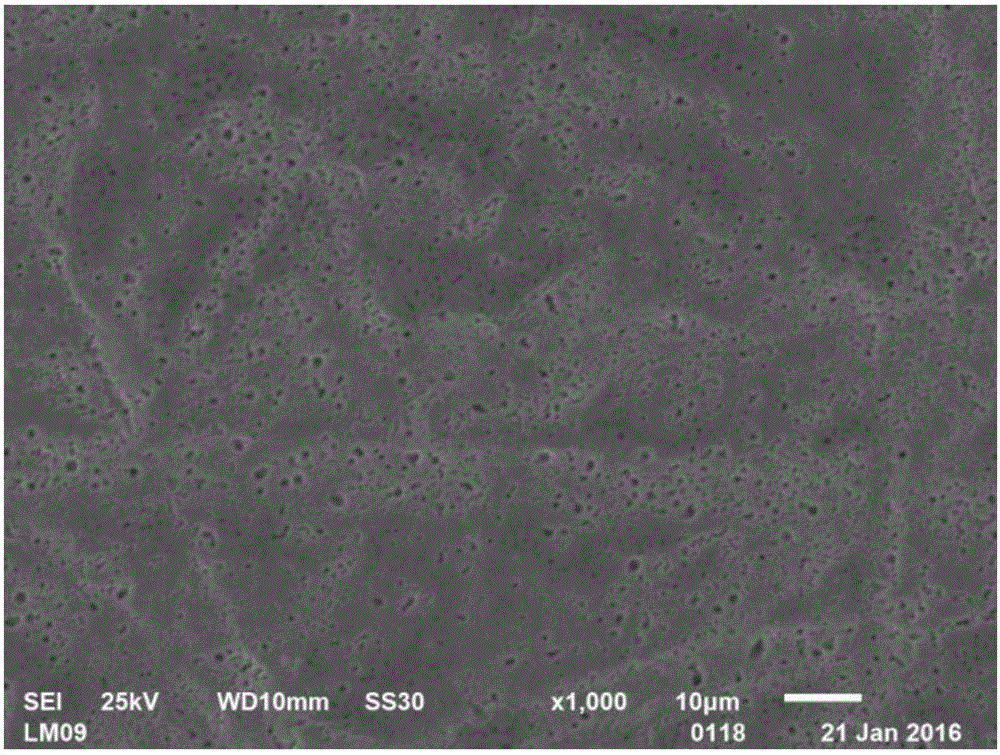

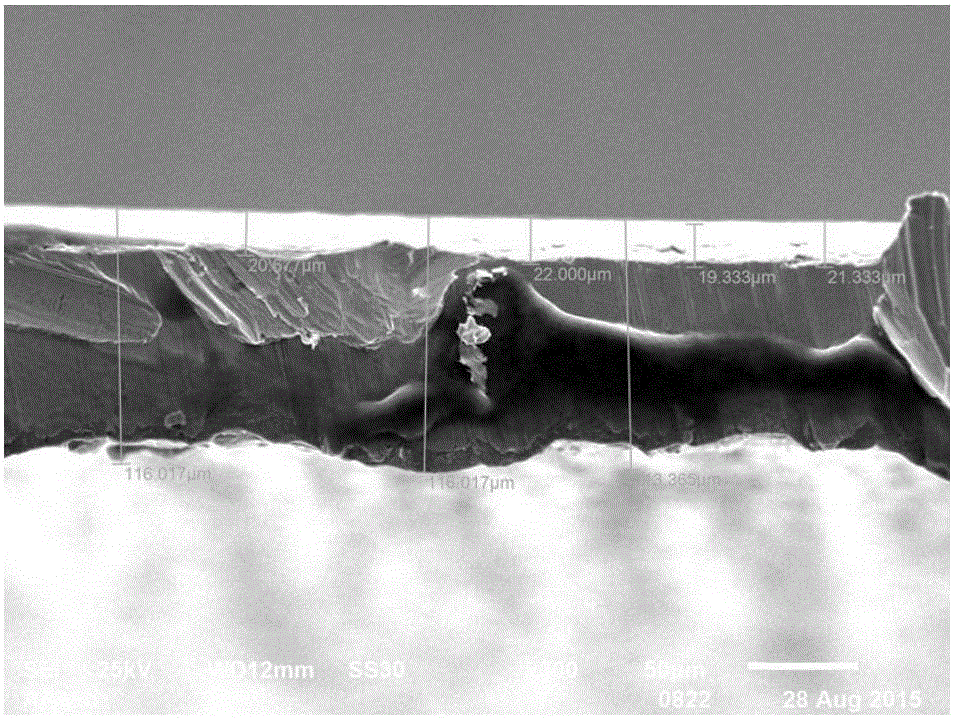

[0052] After a long time of sealing and standing (temperature 20-30°C), the coating properties obtained after electroplating of the silver plating solution of this embodiment were tested respectively during the storage period of 0 months, 5 months, and 10 months. The coating number is 1 -number 3. The thickness of the coating is tested by the Japanese JSM-6510 scanning electron microscope; the ...

Embodiment 3

[0056] The invention provides a kind of neutral cyanide-free electric brush plating silver-plating liquid, comprises following component and its mass concentration: nitrate silver salt 25g / L, complexing agent sodium thiosulfate 50g / L and thiourea and its homologue 80g / L, protective agent methylsulfonic acid derivative 26g / L, additive polyethyleneimine 50g / L, potassium metabisulfite 16g / L, ammonia water (density 0.91g / cm 3 , 25°C) 50g / L, stabilizer sodium citrate 0.5g / L.

[0057] The preparation process of this embodiment is the same as that of Example 1.

[0058] The usage method of this embodiment is the same as that of embodiment 1, the difference is that the current density is 15A / m during brush plating 2 , the pH value of the plating solution is 6.9, and the brush plating time is 20s, 60s, and 200s respectively.

[0059] The DL / T486-2010 standard stipulates that the contact surface of the isolating switch and the grounding switch must be silver-plated, and the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com