Bright tin plating solution and preparation method thereof and method for electrobrush tin plating on copper-based material surface

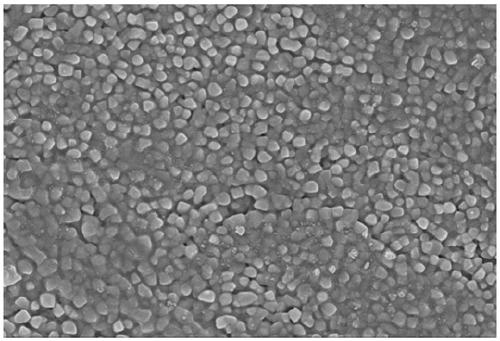

A technology of tin plating solution and electric brush plating, which is applied in the field of electrochemistry, can solve the problems of easy turbidity of the plating solution, gray spots, pinholes, pitting, and crystal polarization reduction in the appearance of the coating layer, and achieves uniform and dense appearance. Avoid the effect of coating discoloration and tin plating process specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] A kind of preparation method of described bright tin plating liquid, comprises the following steps:

[0053] In the aqueous solution of thiourea and methanol, sequentially add stannous sulfate, trisodium phosphate and compound additives, and mix well to obtain the bright tin plating solution.

[0054] Preferably, the preparation method of the compound additive specifically comprises the following steps:

[0055] Mix fatty alcohol polyoxyethylene ether, polyethylene glycol 400, N,N-dimethylformamide and 2-mercaptobenzothiazole, then add anhydrous methanol, stir until dissolved, then add catechol and ascorbic acid , stirring and mixing to obtain the compound additive.

[0056] The ingredients in the compound additive combination are difficult to dissolve in the aqueous solution. First, the organic additive is gradually dissolved to prepare the compound additive combination. Adding it to the aqueous solution system avoids the phenomenon of long dissolution period and prec...

Embodiment 1

[0072] Take a certain amount of fatty alcohol polyoxyethylene ether, polyethylene glycol 400, N,N-dimethylformamide and 2-mercapto-thiazole in a beaker, add a small amount of anhydrous methanol, stir to dissolve, and then add a certain amount of Amount of catechol and ascorbic acid stirring, in which fatty alcohol polyoxyethylene ether, polyethylene glycol 400, N, N-dimethylformamide, 2-mercapto-thiazole, anhydrous methanol, catechol and The dosage ratio of ascorbic acid is: 4g: 9.5ml: 0.115g: 0.08g: 13.5ml: 2g: 1.2g.

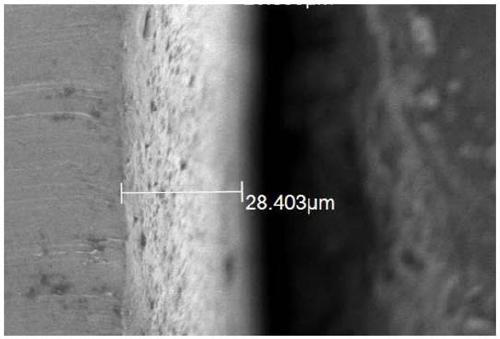

[0073] A certain amount of thiourea and methanesulfonic acid are dissolved in deionized water to obtain a mixed solution of thiourea and 35g / L methanesulfonic acid with a concentration of 60g / L to obtain the first mixed solution; Tin joins in above-mentioned mixed solution, and gained stannous sulfate concentration is 30g / L, obtains the second mixed solution; Add a certain amount of trisodium phosphate in the second mixed solution described above, stir, obtain ...

Embodiment 2

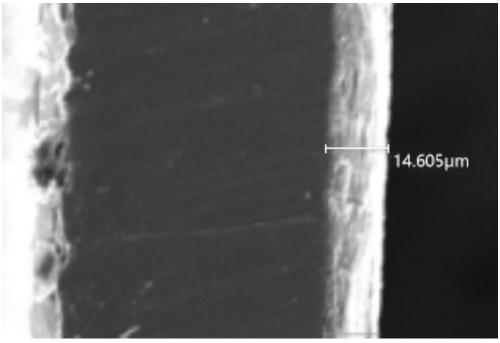

[0076] The formula and usage method of this embodiment are the same as those of Embodiment 1, the difference being that the number of times of brush plating is 5 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com