A kind of preparation method of magnesium alloy surface micro-arc electrophoresis containing ha biocomposite film layer

A bio-composite film and bio-film layer technology is applied in the field of preparing bio-film layers on the surface of magnesium alloys to achieve the effects of reducing defects, uniform and dense appearance, and increasing bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of magnesium alloy surface micro-arc electrophoresis containing HA biocomposite membrane layer is carried out according to the following steps:

[0028] (1) Surface pretreatment of the magnesium alloy sample: the magnesium alloy is processed into a 20mm×20mm×5mm pattern by wire cutting, the surface of the sample is ground with 600#, 1000# and 1500# sandpaper in sequence, and then acetone, alcohol and desiccant are used in sequence. Ultrasonic cleaning of the samples with ionized water, and then drying for later use;

[0029] (2) Micro-arc oxidation treatment: the magnesium alloy sample in step (1) is placed in the bioelectrolyte, the magnesium alloy sample is used as the anode, the stainless steel tank is used as the cathode, the temperature of the electrolyte is 35-40°C, and the current density is 10A / dm 2 1. Under the condition of working frequency of 500Hz and duty cycle of 40%, micro-arc oxidation was performed for 13 minutes to obtain ...

Embodiment 2

[0039] The difference between this embodiment and embodiment 1 is:

[0040] The micro-arc oxidation current density in step (2) is 20A / dm 2 , the frequency is 700Hz, the duty cycle is 20%, and the micro-arc oxidation time is 20min. Other parameters are the same as in Example 1.

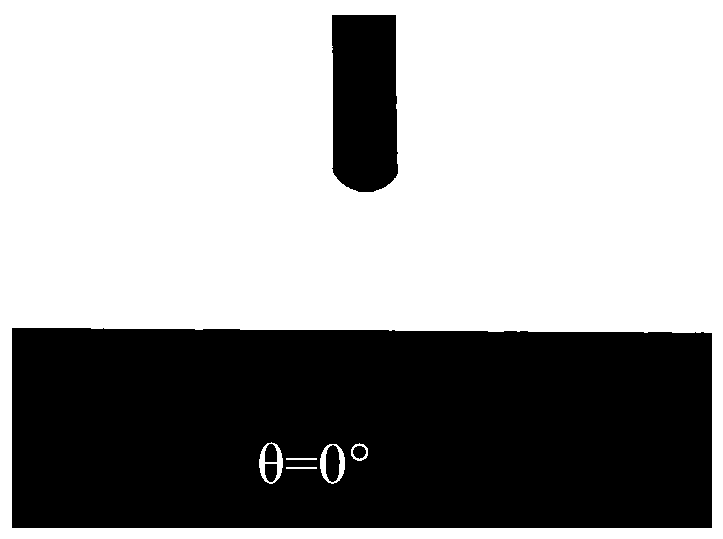

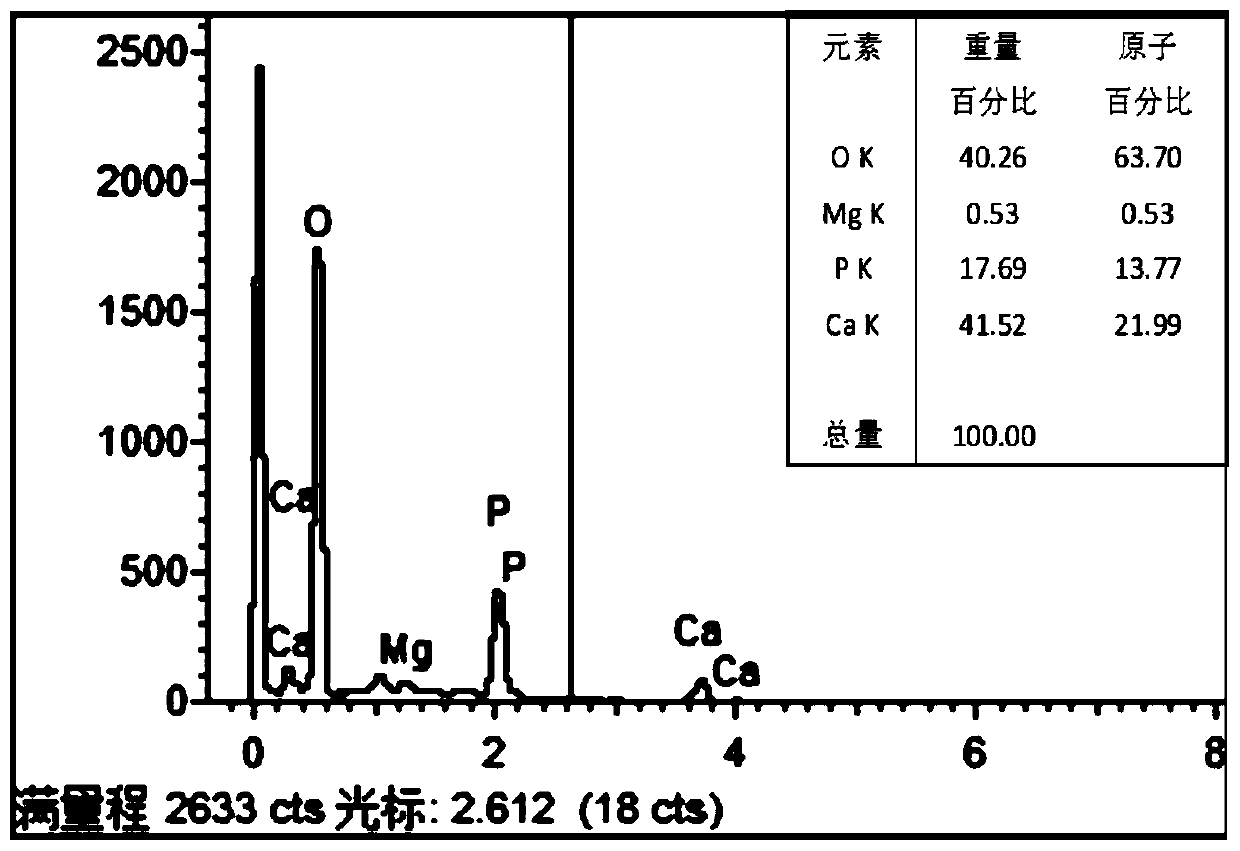

[0041] The appearance of the composite film obtained in this example is uniform and dense, with a thickness of about 51 μm, of which the micro-arc oxidation layer is about 41 μm, and the deposited layer is about 10 μm; the porosity of the film layer is 0.21, the roughness is 1.19 μm, and the contact angle is 0° ,like image 3 As shown, compared with the substrate, the corrosion potential increased from -1.57V to -0.21V in 3.5wt% NaCl solution, and the corrosion current density was 3.28×10 -7 A / cm 2 The Ca / P of the surface film layer is about 1.60, such as Figure 4 As shown, the film layer has α-TCP(Ca 9 HPO 4 (PO 4 ) 5 OH) products, later decomposed into HA, such as Figure 5 As shown, the ...

Embodiment 3

[0043] The difference between this embodiment and embodiment 1 is:

[0044] The HA concentration in step (4) is 20g / L, the electrophoresis voltage is 60V, and the electrophoresis time is 5min. Other parameters are the same as in Example 1.

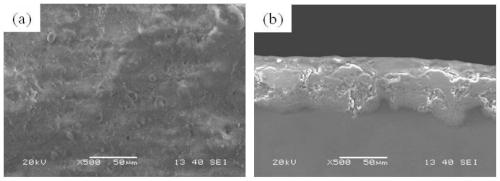

[0045] The appearance of the composite film obtained in this example is uniform and dense, with a thickness of about 52 μm, in which the micro-arc oxidation layer is about 40 μm, the deposited layer is about 12 μm, and the porosity of the film layer is 0.2, such as figure 2 As shown; the roughness is 1.18μm, the contact angle is 1°, compared with the substrate, the corrosion potential increases from -1.57V to -0.20V in 3.5wt% NaCl solution, and the corrosion current density is 3.27×10 -7 A / cm 2 The Ca / P of the surface film layer is about 1.62, and the film layer has α-TCP(Ca 9 HPO 4 (PO 4 ) 5 OH) product, which is decomposed and converted into HA in the later stage, so the corrosion resistance, biological activity and osteoinductivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com