Method for recycling iron waste for fenton technology and water treating device of method

A technology of waste and Fenton, which is applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of high cost of ultraviolet photocatalytic Fenton technology, secondary pollution of water bodies, and difficulty in large-scale application, so as to achieve resource utilization and realize The effect of zero emission and easy promotion and popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

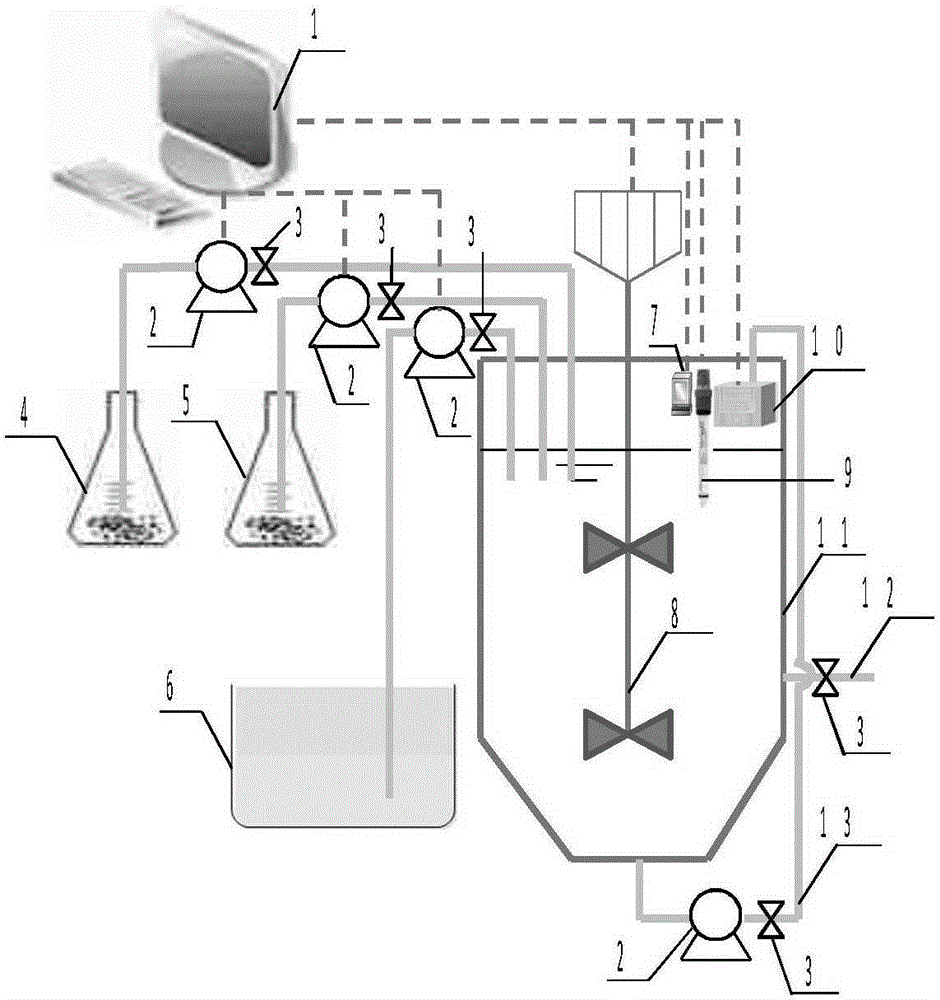

Method used

Image

Examples

Embodiment 1

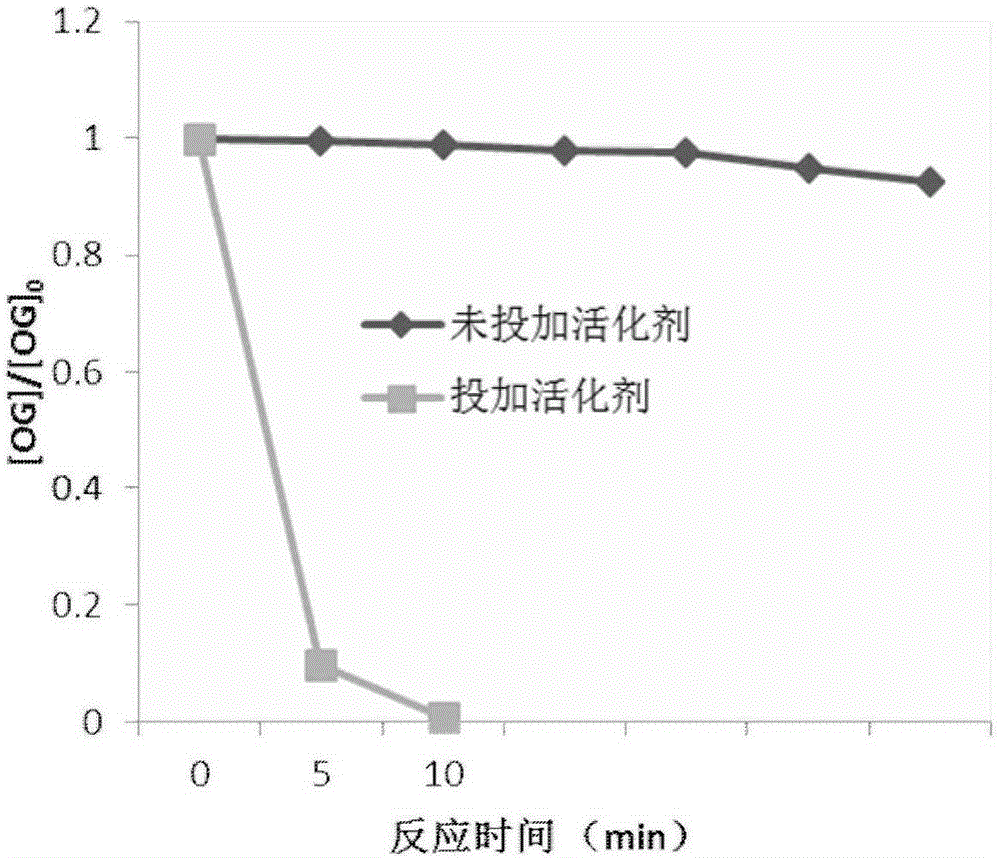

[0035] Take 500mL of untreated water samples containing printing and dyeing wastewater, orange G (OG) for refractory organic matter, and the pH value of the system is 3.0. Add 10mmol / L of hydrogen peroxide, 0.5g / L of ferric oxide, and 1mmol / L of hydroxylamine hydrochloride to the water sample, and stir the water sample for 10min at a rate of 300r / min. Ratio, the removal rate increased from 1% to 99%.

[0036] figure 1 It is the effect diagram of the removal of refractory organic matter in printing and dyeing wastewater in this example. The refractory organic matter is orange G (OG). The removal rate curve of degradation of organic wastewater without adding active agent.

Embodiment 2

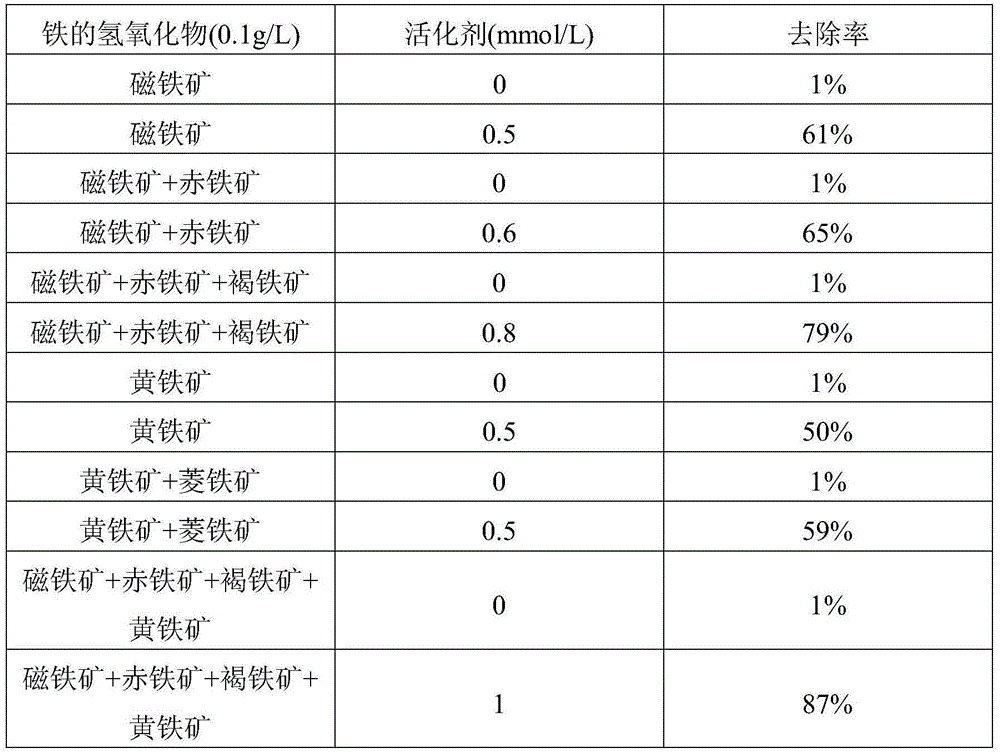

[0038] Take 500mL of untreated water samples containing printing and dyeing wastewater, orange G (OG) for refractory organic matter, and the pH value of the system is 1.0. Add hydrogen peroxide 1mmol / L in this water sample, adopt the composition 0.1g / L of the hydroxide of different iron, wherein, the hydroxide of iron is selected from Fe(OH) 2 , Fe(OH) 3 , α-FeOOH, β-FeOOH, γ-FeOOH, or a mixture of several of them, sodium sulfite 0.1-0.4mmol / L, stirring the water sample at a rate of 300r / min for 5min, and adding no active agent Compared with the treatment, the results are shown in Table 1:

[0039] Table 1 Effects of different iron hydroxides on the removal rate of orange G under the action of activators

[0040] Iron hydroxide (0.1g / L)

[0041] It can be seen from Table 1 that by adding activator, the removal rate increased from 5% to 70%-90%. The removal rate of orange G is positively correlated with the dosage of activator, and also related to the valence state...

Embodiment 3

[0043] Take 500mL of untreated water sample containing coal chemical wastewater, in which the refractory organic matter is phenol, and the pH value of the system is 4.0. Add hydrogen peroxide 5mmol / L to this water sample, zero valent iron (Fe 0 ) 1g / L, potassium sulfite 1mmol / L, stirring the water sample at a speed of 300r / min for 20min, compared with the treatment without adding active agent, the removal rate increased from 1% to 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com