Preparation method for glyphosate

A technology of glyphosate and glyphosate, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as side reactions, unfavorable industrial production, and poor effect of activated carbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

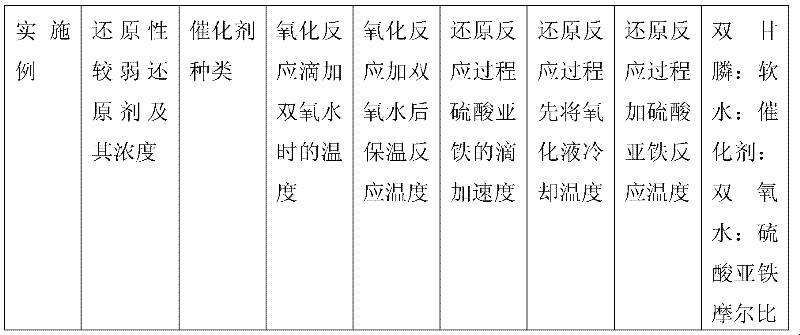

Image

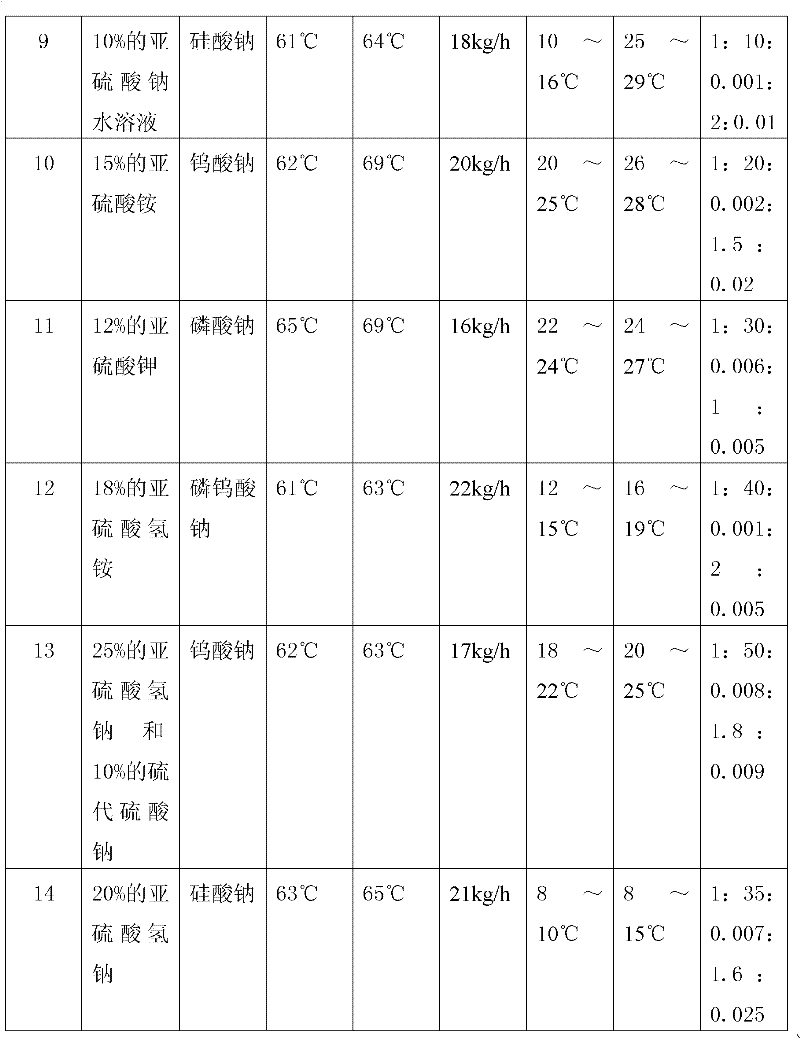

Examples

Embodiment 1

[0050] A kind of preparation method of glyphosate, carries out according to the following steps:

[0051] Add 350g of bisglyphosate, 350g of deionized water or tap water and 1.1g of sodium tungstate into a 1000ml four-necked bottle, measure the pH after stirring, it is generally about 1.5-2, raise the temperature to T=64-65°C, and start to drop the content of 228g of 27.5% hydrogen peroxide, the temperature of hydrogen peroxide dripping is controlled at 66±1°C, and the dropping time is generally 40-50min. Impurity activated carbon obtains oxidized liquid.

[0052] Cool the oxidizing solution with ice-salt water until T<25°C, use KI starch test paper to test that the test paper turns blue, add 76g of 20% sodium sulfite aqueous solution to consume excess hydrogen peroxide, and test with KI starch test paper, when the test paper is white or colorless When, stop adding sodium sulfite aqueous solution.

[0053]Cool the oxidizing solution to 10°C, start to drop 33.5g of ferrous su...

Embodiment 2

[0055] A kind of preparation method of glyphosate, carries out according to the following steps:

[0056] Add 250Kg of bisglyphosate, 240Kg of deionized water or tap water and 0.9Kg of sodium tungstate into a 1000l enamel kettle, measure the pH after stirring, generally around 1.5-2, raise the temperature to T=64-65°C, and start to drop the content of 171Kg of 28.1% hydrogen peroxide, the temperature of hydrogen peroxide is controlled at 66±1°C, the time of dropping is generally 40-50min, the mixture becomes clear after about 40min after the addition, keep warm for 30min, add a small amount of activated carbon to decolorize, filter to remove mechanical Impurities and activated carbon get oxidized liquid.

[0057] Cool the oxidizing solution with ice-salt water to T<25°C, use KI starch test paper to detect that the test paper turns blue, add 26.5Kg of 20% sodium sulfite aqueous solution, consume excess hydrogen peroxide, and test with KI starch test paper, when the test paper i...

Embodiment 3

[0060] A kind of preparation method of glyphosate, carry out as follows:

[0061] Add bisglyphosate, soft water and sodium phosphotungstate into the reaction kettle, then add hydrogen peroxide to react to obtain an oxidation solution, consume excess hydrogen peroxide with a sodium sulfite aqueous solution with a concentration of 10-30% by mass, and use KI starch test paper to detect the concentration of the oxidation solution. Whether the excess hydrogen peroxide is consumed, the temperature in the process of consuming excess hydrogen peroxide is 10-50°C; then add ferrous sulfate for reduction reaction, crystallization, and drying to obtain glyphosate raw powder, bisglyphosate: soft water: phosphotungsten The molar ratio of sodium acid: hydrogen peroxide: ferrous sulfate is 1: 20: 0.005: 1.5: 0.02, and the HPLC purity and yield of glyphosate finally obtained can reach the beneficial effects described in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com