Preparation method for auric potassium citrate for gold plating

A technology of gold potassium citrate and potassium citrate, applied in the field of preparation of gold potassium citrate for gold plating, can solve problems such as difficult control of chemical process, and achieve the effects of low cost, good quality and simple preparation equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

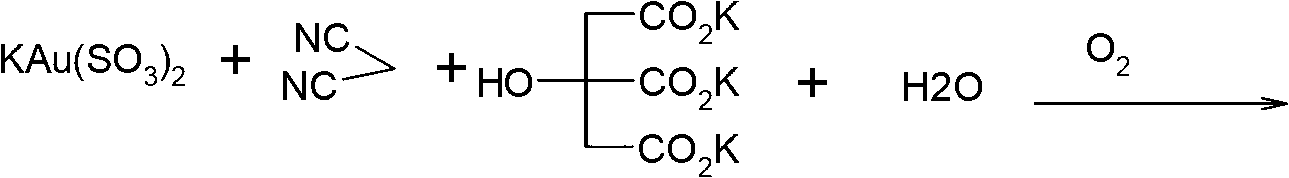

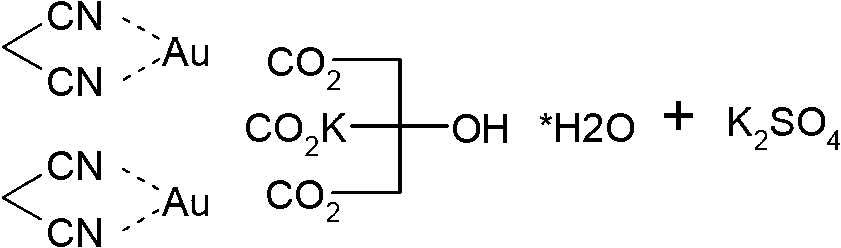

Method used

Image

Examples

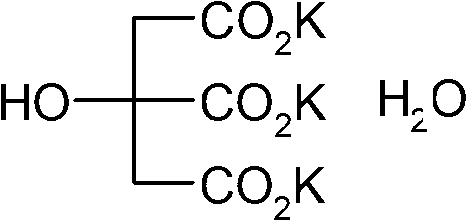

Embodiment 1

[0024] Take 100ml of gold potassium sulfite solution with a gold content of 50g / L and add it to a 250ml three-necked flask, add 12g of potassium citrate, heat to 60°C under stirring, add 3g of malononitrile, and after all of the solution is dissolved, feed high-purity oxygen. Flow rate 0.5M 3 After 24 hours, no sulfite was detected, concentrated under reduced pressure, cooled to obtain a white solid, suction filtered, washed 2 times with pure water, each 20ml of water, and dried at 105 degrees to obtain 9.1g of potassium gold citrate, The gold content is 51.1%, and the clarity of the aqueous solution is qualified.

Embodiment 2

[0026] Take 1000ml gold potassium sulfite solution with a gold content of 5g / L and add it to a 2000ml three-necked flask, add 6g potassium citrate, heat it in a water bath to a temperature of 60 degrees under stirring, add 3g malononitrile, and after it is completely dissolved, pass it into a high-purity Oxygen, flow rate 0.5M 3 / hour, concentrated under reduced pressure after 24 hours, cooled to obtain a white solid, suction filtered, washed twice with pure water, 20ml of water each time, and dried at 105 degrees to obtain 8.9g of gold potassium citrate, gold content 51.1%, aqueous solution Clarity is acceptable.

Embodiment 3

[0028] Take 100ml of gold potassium sulfite solution with a gold content of 50g / L and add it to a 250ml three-necked flask, add 6g of potassium citrate, heat it in a water bath to 60 degrees under stirring, add 3g of malononitrile, and after it is completely dissolved, let it flow into the air. 0.5M 3 After 72 hours, no sulfite was detected, concentrated under reduced pressure, cooled to obtain a white solid, suction filtered, washed 2 times with pure water, each 20ml of water, and dried at 105 degrees to obtain 9.1g of potassium gold citrate, The gold content is 51.1%, and the clarity of the aqueous solution is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com