Preparation method of fatty alcohol polyethenoxy ether sulfonate

A technology of alcohol polyoxyethylene ether sulfonate and alcohol polyoxyethylene ether, which is applied in the field of preparation of surfactants, can solve problems such as unused, difficult, and yield reduction, and achieve increased yield, increased concentration, and system Viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

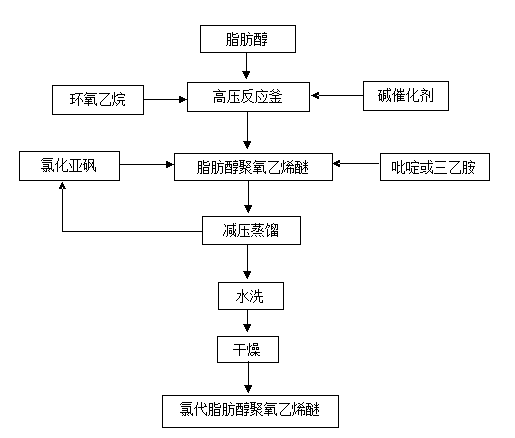

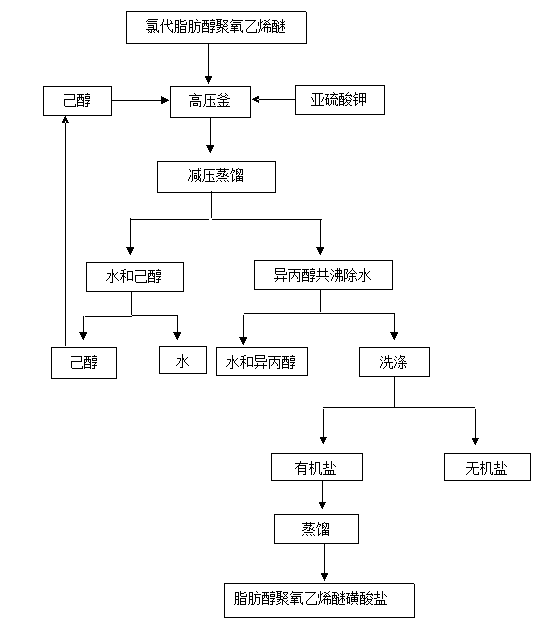

[0033] The steps of the preparation method of fatty alcohol polyoxyethylene ether sulfonate of the present invention are as follows:

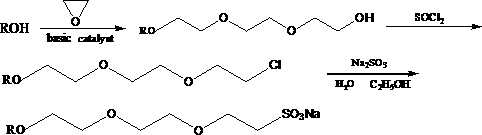

[0034] The first step: put fatty alcohol and alkali catalyst into the autoclave, and intermittently feed ethylene oxide into the reaction system to prepare fatty alcohol polyoxyethylene ether;

[0035] The second step: dissolve the fatty alcohol polyoxyethylene ether with an organic solvent, add thionyl chloride under the condition of stirring and nitrogen protection, and prepare the chlorinated fatty alcohol polyoxyethylene ether;

[0036] Step 3: Put an aqueous solution of potassium sulfite, a diluent, and chlorinated fatty alcohol polyoxyethylene ether into the autoclave, and stir rapidly under high pressure to prepare fatty alcohol polyoxyethylene ether sulfonate.

[0037] Wherein, the fatty alcohol described in the first step is dodecyl alcohol, myristyl alcohol or cetyl alcohol; the base catalyst is sodium hydroxide or potassium hydro...

Embodiment 1

[0043] Step 1: Add 90.00g (0.484mol) of dodecanol and 0.27g of sodium hydroxide into the autoclave, intermittently feed 63.87g (1.451mol) of ethylene oxide, control the reaction temperature to 125°C, and the pressure React for 3 hours at 0.3Mpa, and after the reaction is completed and cooled, polyoxyethylene lauryl ether can be obtained.

[0044] Step 2: Add 38.13g (0.100mol) dodecyl alcohol polyoxyethylene ether and 7mL pyridine into the four-neck flask, add thionyl chloride drop by drop under nitrogen protection and stirring conditions, and the molar ratio of the feed is dodecyl alcohol Polyoxyethylene ether: thionyl chloride = 1:1.4. After the dropwise addition, the temperature was raised to 80°C for 10 hours. After the reaction, it was subjected to rotary evaporation, washing with distilled water, liquid separation, and vacuum drying to obtain a light yellow oily liquid dodecachloride alcohol polyoxyethylene ether.

[0045] Step 3: Add 39.98g (0.100mol) chlorinated fatty ...

Embodiment 2

[0047] The reaction steps are exactly the same as in Example 1, except that for the first step, tetradecyl alcohol is used as a reactant, potassium hydroxide is used as an alkali catalyst, and the quality of potassium hydroxide is 2% of the quality of tetradecyl alcohol, and the reaction temperature is 130° C. , the reaction pressure was 0.2Mpa, and the reaction was carried out for 2.5h, finally obtaining amber liquid potassium tetradecyl alcohol polyoxyethylene ether sulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com