Deodorizing powdery blue algae treating agent and production method thereof

A cyanobacterial treatment agent and a technology for the preparation method, which are applied in the field of water treatment, can solve the problems of being difficult to obtain extensive and effective application, failing to solve pollution from the root cause, and single treatment technology, achieving good deodorization effect, easy recycling, Strong flocculation purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

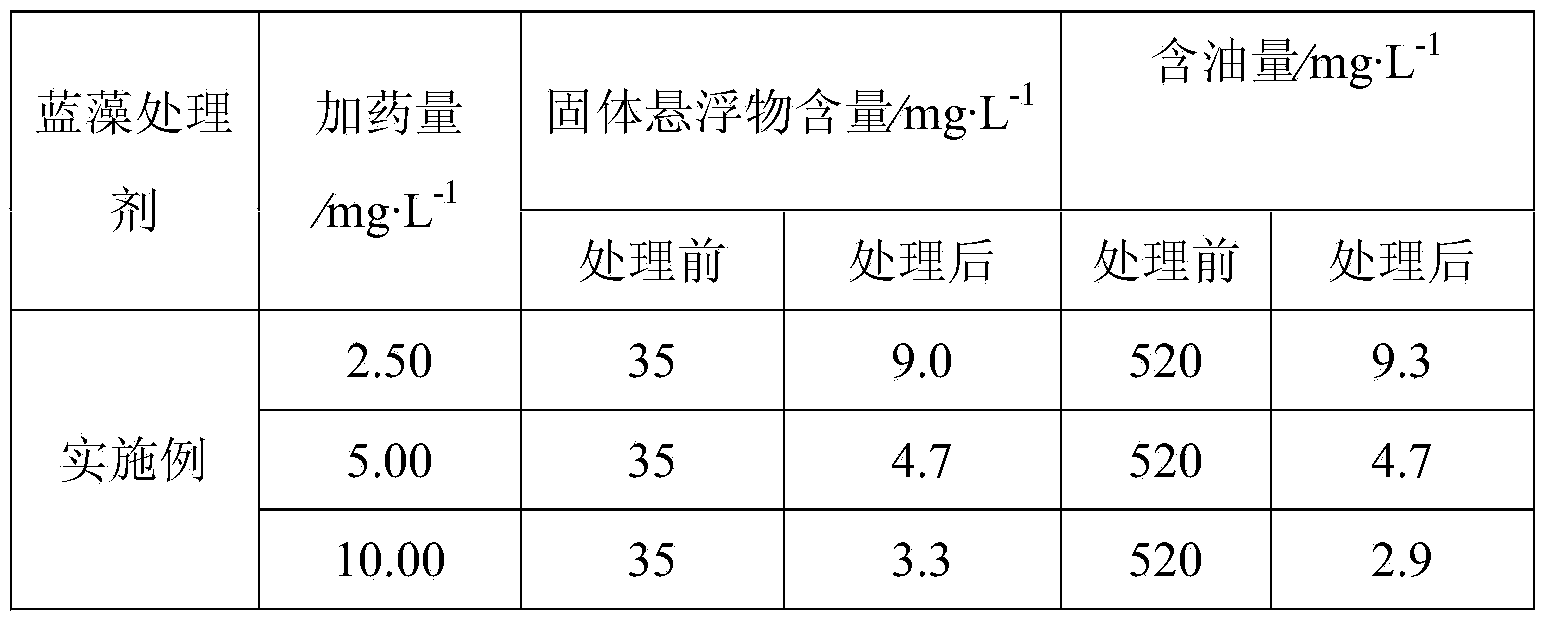

Examples

Embodiment Construction

[0013] Described a kind of deodorizing powdery cyanobacteria treatment agent is characterized in that, is made of the raw material of following weight part: TiO2 pillared montmorillonite photocatalyst 27, pumice stone 18, urea 17, potassium bisulfite 20, potassium sulfite 22. Manganese sulfate 16, Burnet 1, honeysuckle 2, red peony 5, trigonum 4.

[0014] The preparation method comprises the following steps:

[0015] (1) Boil Burnet, honeysuckle, Radix Paeoniae Rubra, and Sanleng in water for 2-3 hours and filter, take the filtrate and pumice and soak it for 30 minutes, dry it, and crush it into powder;

[0016] (2) Send the filter residue of step (1) into a carbonization furnace, calcinate at 535-645°C for 3-4 hours, take it out and dry it, and crush it into powder;

[0017] (3) Mix potassium bisulfite and potassium sulfite for 30-40 minutes, add manganese sulfate and mix for 45-50 minutes, then add urea and mix for 50-60 minutes;

[0018] (4) Mix the reaction materials of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com