Potash fertilizer-loaded slow-release degradable porous material and preparation method thereof

A technology of porous materials and potash fertilizers, which is applied in the preparation/purification of carbon, potash fertilizers, inorganic fertilizers, etc. It can solve the problems of high preparation cost and short release time, and achieve the effect of low cost, long fertilizer effect time and ideal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

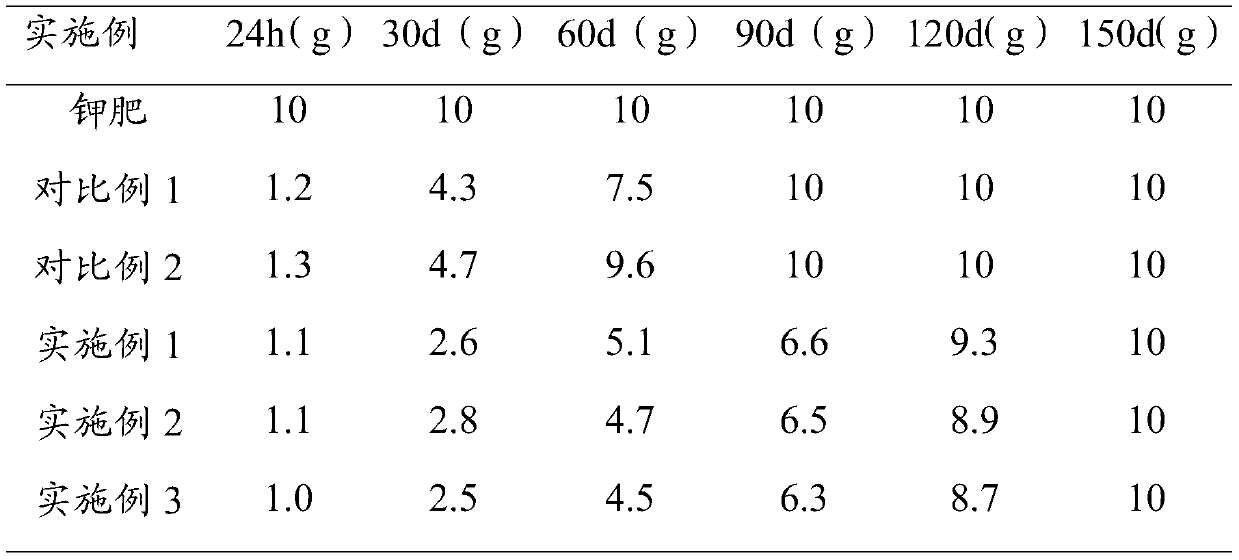

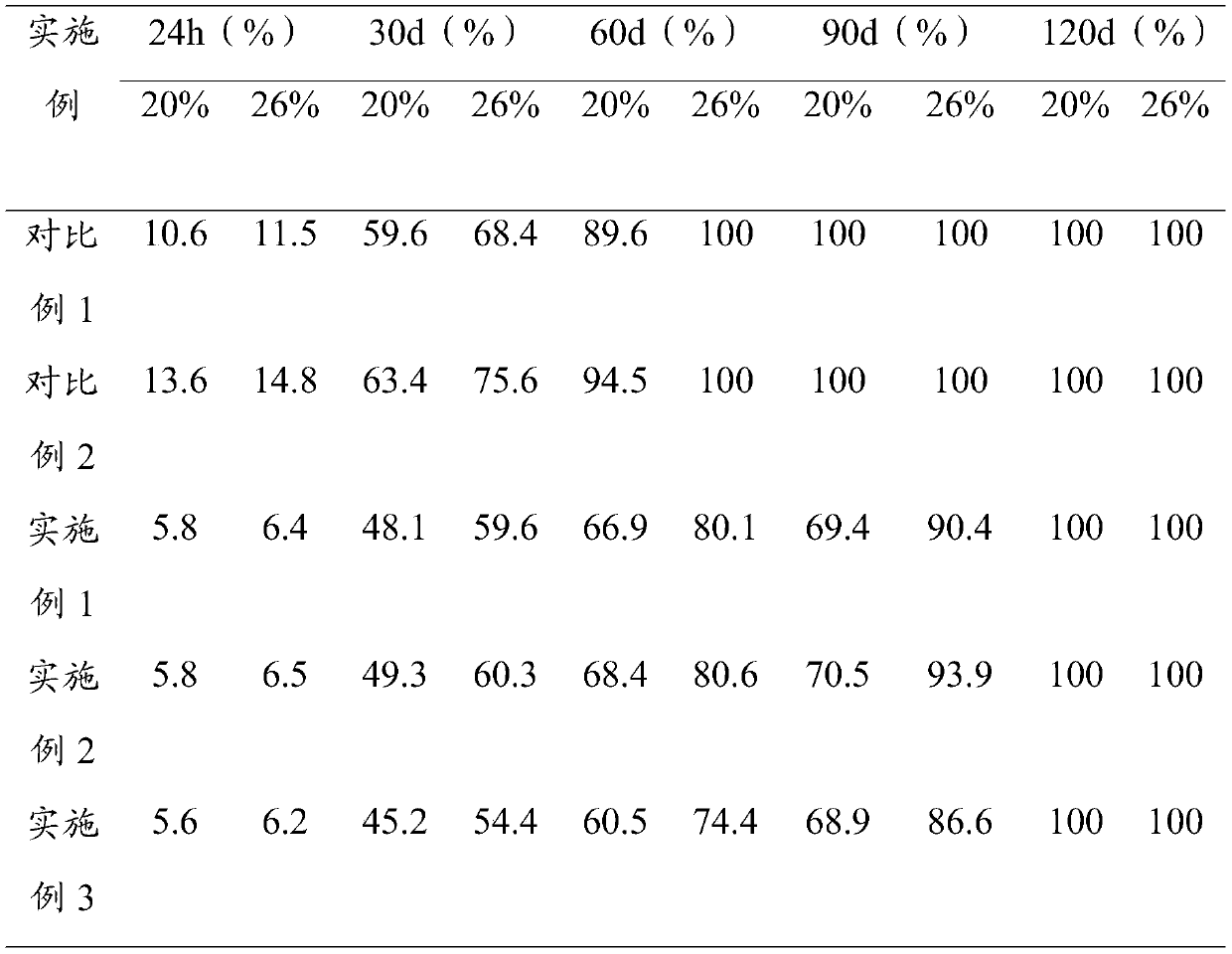

Embodiment 1

[0043] Embodiment 1: preparation load potassium fertilizer slow-release degradable porous material

[0044] 1. Preparation of biomass porous matrix materials

[0045]1) Pore-enhancing treatment of the powder: Dissolve the dry powder of Trichoderma konii in deionized water in a sterile environment, and culture it in a constant temperature incubator at 23°C for 5 days to obtain the bacterial liquid; then inoculate the bacterial liquid onto the culture medium Cultivate at 24°C for 6 days, wash with water, and filter to obtain a biomass pore-enhancing suspension; then put the crushed passion fruit vine powder and biomass pore-enhancing suspension in a co-cultivation device, seal and react at a constant temperature of 23°C for 6 days After filtering, washing and drying, porous powder is obtained; the weight ratio of the strain dry powder to deionized water is 1:50; the volume ratio of the bacterial liquid to the culture medium is 1:1000; the culture medium is potato dextrose agar ...

Embodiment 2

[0056] Embodiment 2: preparation load potassium fertilizer slow-release degradable porous material

[0057] 1. Preparation of biomass porous matrix materials

[0058] 1) Pore-enhancing treatment of the powder: Dissolve the dry powder of Trichoderma konii in deionized water in a sterile environment, and cultivate it in a constant temperature incubator at 30°C for 3 days to obtain the bacterial liquid; then inoculate the bacterial liquid onto the culture medium Cultivate at 30°C for 4 days, wash with water, and filter to obtain a biomass pore-enhancing suspension; then put the crushed passion fruit vine powder and biomass pore-enhancing suspension in a co-cultivation device, seal and shake at a constant temperature of 30°C for 4 days After filtering, washing and drying, porous powder is obtained; the weight ratio of the bacterial classification dry powder to deionized water is 1:1000; the volume ratio of the bacterial liquid to the culture medium is 1:100; the culture medium is ...

Embodiment 3

[0069] Embodiment 3: preparation load potassium fertilizer slow-release degradable porous material

[0070] 1. Preparation of biomass porous matrix materials

[0071] 1) Pore-enhancing treatment of the powder: Dissolve the dry powder of Trichoderma konii in deionized water in a sterile environment, and culture it in a constant temperature incubator at 28°C for 4 days to obtain the bacterial liquid; then inoculate the bacterial liquid onto the culture medium Cultivate at 28°C for 5 days, wash with water, and filter to obtain a biomass pore-increasing suspension; then put the crushed passion fruit vine powder and biomass pore-enhancing suspension in a co-cultivation device, seal and react at a constant temperature of 28°C for 5 days After filtering, washing and drying, porous powder is obtained; the weight ratio of the bacterial classification dry powder to deionized water is 1:500; the volume ratio of the bacterial liquid to the culture medium is 1:500; the culture medium is po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com