Method for treating tail gas of acyl chlorination

A technology of acid chlorination and tail gas, applied in chemical instruments and methods, separation methods, chlorine/hydrogen chloride, etc., can solve the problems of ineffective recovery of by-products, etc., and achieve the effects of easy control, pollution reduction, and process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

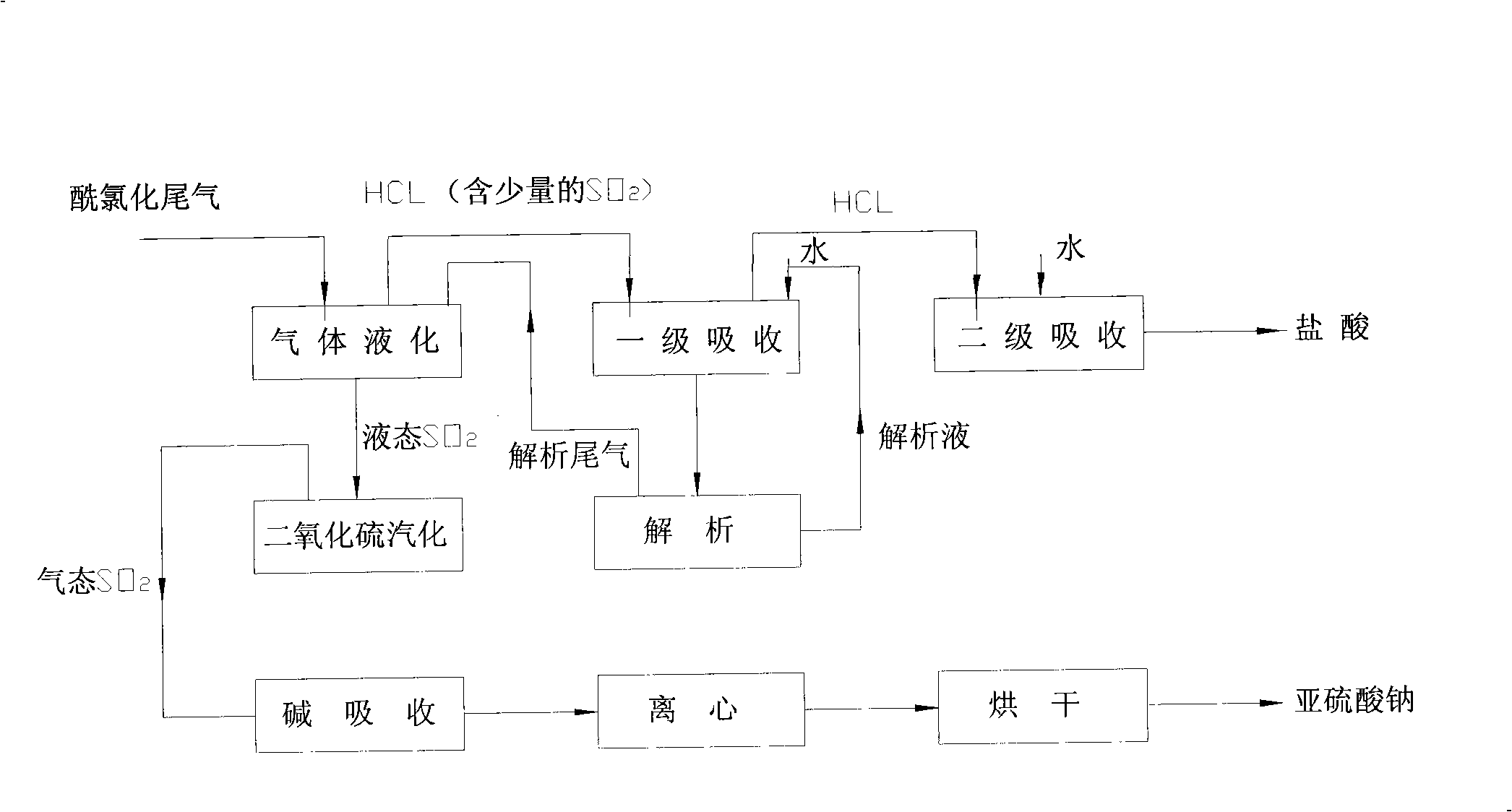

Image

Examples

Embodiment 1

[0017] The absorption separation of embodiment 1 hydrogen chloride gas

[0018] The permethrin acid chloride tail gas continuously enters the tail gas cooling system, the system temperature is controlled at -25°C, the tail gas is detected, the sulfur dioxide is 1.3%, the hydrogen chloride is 98.7%, and the liquid sulfur dioxide content is greater than 99%. Hydrogen chloride gas enters the first-stage falling film absorption system, and the absorption temperature is 20-23°C. The sulfur dioxide content in the primary absorption liquid increases gradually. When the sulfur dioxide content reaches 5%, sulfur dioxide gas begins to appear in the overflow tail gas, and the primary absorption liquid starts to be extracted, and water is added according to the output. The detection result of the sulfur dioxide content in the overflowing exhaust gas was 0. Hydrogen chloride gas enters the secondary absorption, the absorption temperature is 20-22°C, and 30-35% hydrochloric acid is obtaine...

Embodiment 2

[0019] The absorption separation of embodiment 2 hydrogen chloride gas

[0020] The tail gas of permethrin acid chloride enters the tail gas cooling system continuously, the system temperature is controlled at -30°C, and the tail gas of non-condensable gas is detected, the sulfur dioxide is 0.8%, the hydrogen chloride is 99.2%, and the liquid sulfur dioxide content is greater than 99%. Hydrogen chloride gas enters the first-stage falling film absorption system, and the absorption temperature is 20-23°C. The sulfur dioxide content in the primary absorption liquid increases gradually, and when the sulfur dioxide rises to 4%, the primary absorption liquid starts to be produced, and water is added according to the production amount. The detection result of the sulfur dioxide content in the overflowing exhaust gas was 0. Hydrogen chloride gas enters the secondary absorption, the absorption temperature is 20-22°C, and 30-35% hydrochloric acid is obtained.

Embodiment 3

[0021] Embodiment 3 sodium sulfite preparation

[0022] The temperature of liquid sulfur dioxide is raised to 0°C, and gas is gradually released, and the gas is passed into 30% sodium hydroxide solution, and the flow is continued until the pH value of the system is 6-7, and the obtained sodium sulfite aqueous solution enters the crystallization system, and the temperature is lowered to 2°C , keep warm for 30 minutes, centrifuge, dry in an oven until the water content is less than 0.2%, and the analysis content is 97.9%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com