Gas-liquid phase reactor for preparing sulfite

A sulfite and reactor technology, which is applied in the preparation of sulfite, the chemical method of reacting liquid and gas medium, and the chemical/physical/physical-chemical stationary reactor, etc., can solve the problem of high comprehensive cost per unit of product, The problems of low bubbling uniformity and high equipment investment can reduce the corrosion rate of the wall surface, uniform gas-liquid contact, and reduce the cleaning frequency.

Inactive Publication Date: 2019-10-25

NANJING GEKOF INST OF ENVIRONMENTAL PROTECTION TECH & EQUIP CO LTD +3

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Disadvantages are high equipment investment, high operating energy consumption, and high product unit comprehensive cost; at the same time, the uniformity of bubbling is small and the reaction efficiency is low

[0005] Patent CN201720300607.0 discloses a gas-liquid phase reactor equipped with two gas material inlets. When two gas materials participate in the reaction, the setting of the two gas material inlets can make the two gas materials enter separately. material, which is convenient for flow control, but it still does not avoid the inherent defects of the internal stirring method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

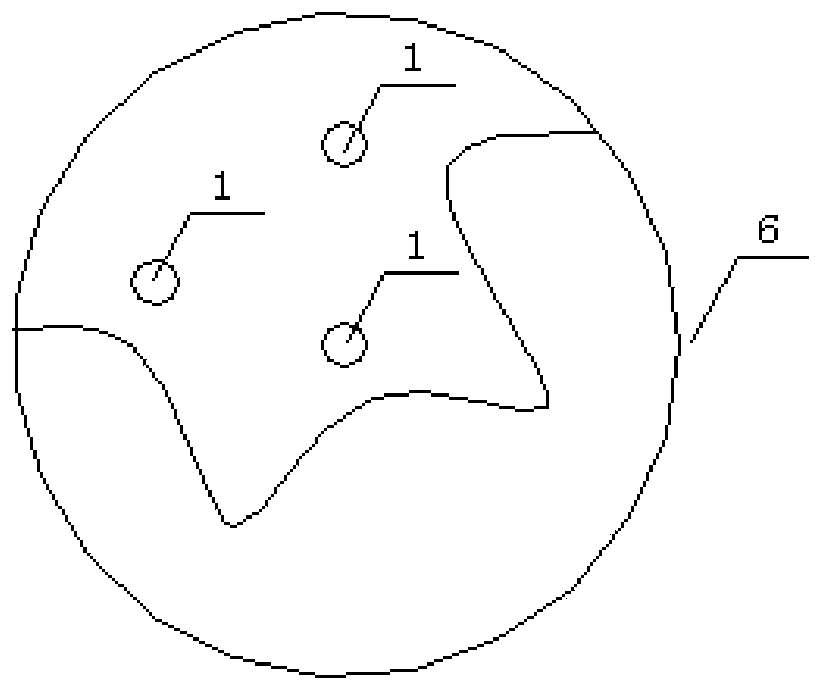

[0037] Such as Figure 4 As shown, the bubbler tube 1 is composed of several circular tubes of the same specification, and each bubbler tube 1 is connected to the gas collecting tube 12 by welding or flanges. Others are as described in Example 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

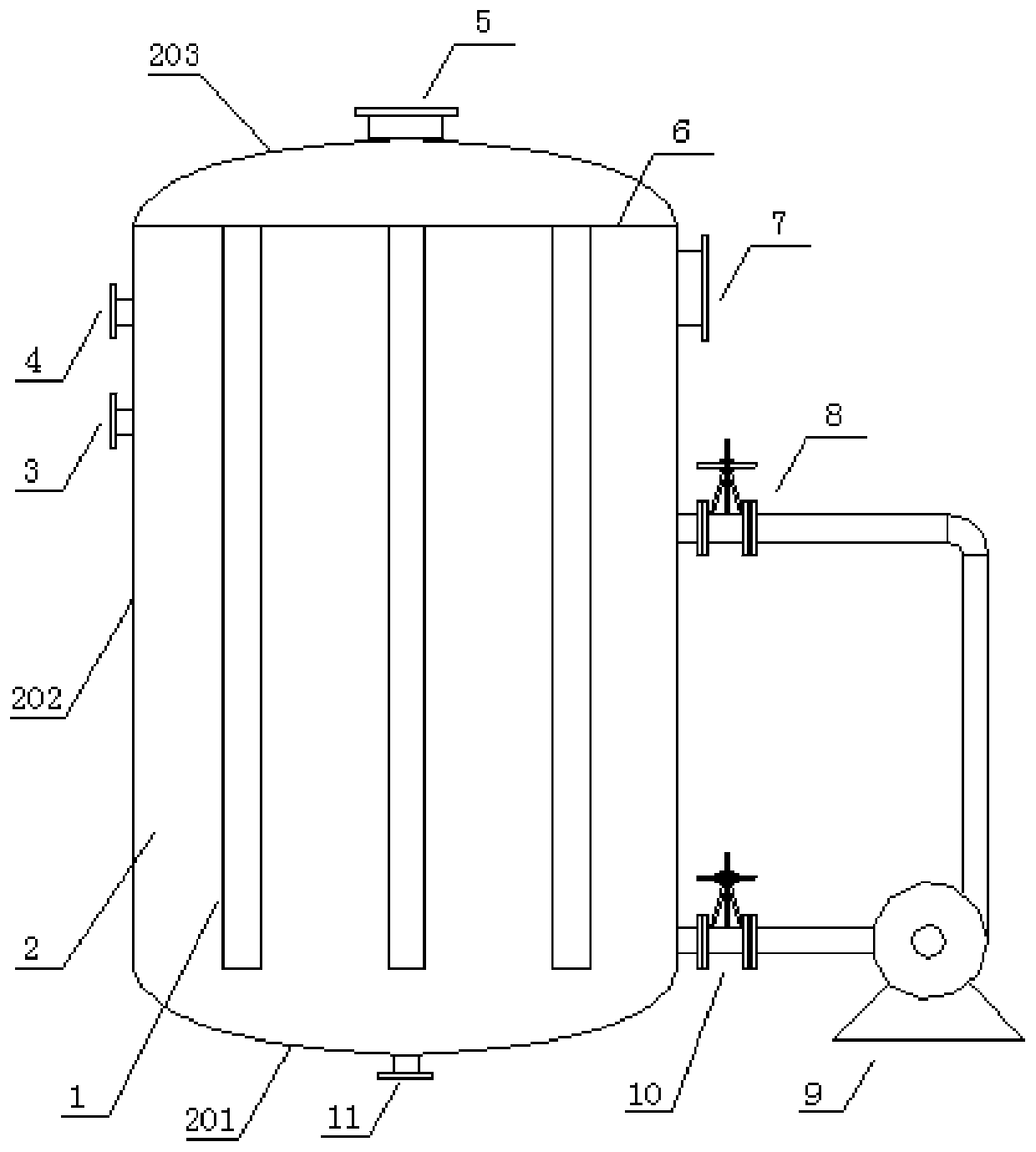

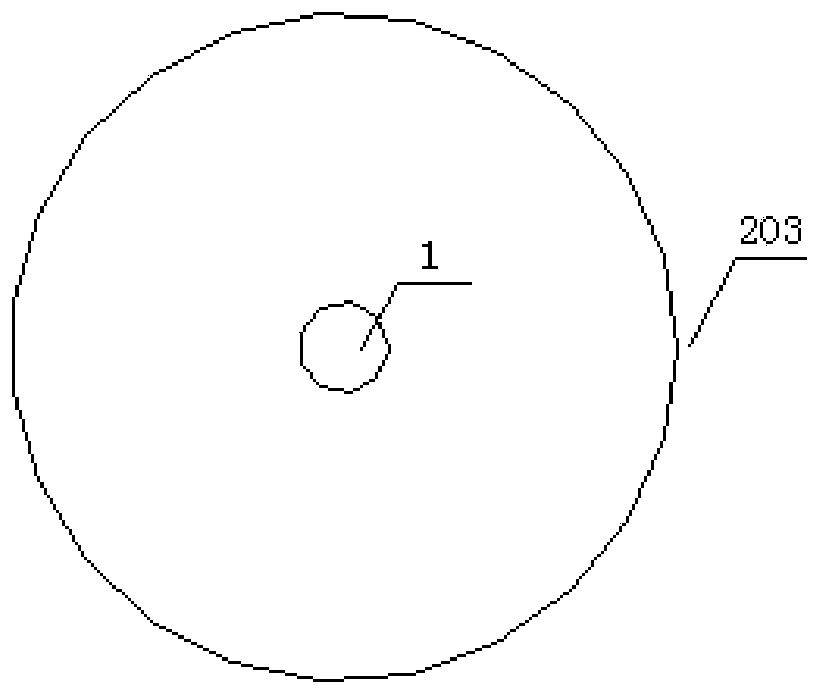

Login to View More Abstract

The invention provides a gas-liquid phase reactor for preparing a sulfite, and belongs to a chemical device. The gas-liquid phase reactor comprises a reactor tank body and a stirring pump, a certain number of bubbling tubes are inserted in the reactor tank body, the bubbling tubes are inserted from the upper part of the reactor tank body into the lower part of the reactor tank body, the reactor isnot internally provided with mechanical rotating equipment, the problems of required sealing and high energy consumption of an existing gas-liquid phase reactor stirring device are effectively avoided, the gas-liquid reactor realizes efficient mass transfer and heat transfer of a gas-liquid phase through gas bubbling and the stirring pump, and the system runs more smoothly.

Description

technical field [0001] The invention relates to the field of chemical industry, in particular to a gas-liquid phase reactor for preparing sulfite. Background technique [0002] In the chemical industry, environmental protection industry and other fields, gas-liquid reactions are often carried out in reactors / kettles. For example, in the production of wet-process sodium metabisulfite and potassium metabisulfite, in order to increase the reaction rate, most of the reactors are mainly stirred inside, but the sealing cost of mechanical stirring is high, and the energy consumption of the system is large; The gas velocity is high, the contact area between the gas material and the liquid material is small, the mixing is uneven, and the reaction yield is low. [0003] Patent CN201220732323.6 discloses a reactor, through the addition of a gas distributor, the gas material coming out of the central tube can be divided into several streams or bubbles, which increases the contact area ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J10/00B01J19/24B01J4/00C01B17/62

CPCB01J10/002B01J19/2465B01J4/004C01B17/62B01J2204/002

Inventor 徐海涛徐延忠陈任远李明波刘大华李军民吴振山宋静

Owner NANJING GEKOF INST OF ENVIRONMENTAL PROTECTION TECH & EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com