Fume purification system with tower box

A flue gas purification system and flue gas technology, applied in the direction of inorganic chemistry, nitrogen compounds, air quality improvement, etc., can solve the problems of low value of by-products, high value of by-products, high operating costs, etc., to achieve low resource and energy consumption, flow Smooth, stable and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

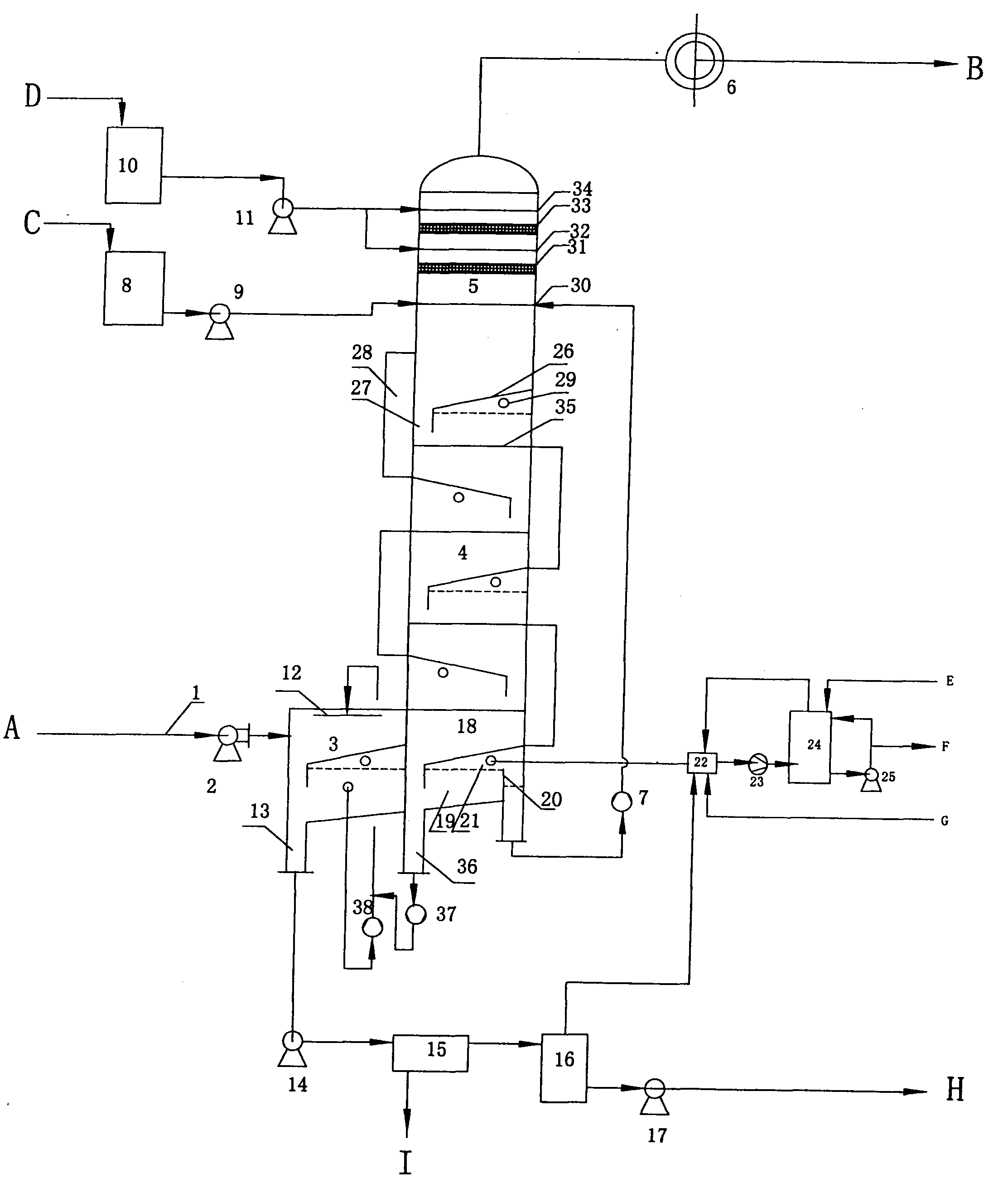

[0061] Such as figure 1 As shown, a tower box flue gas purification system is a tower box structure formed by arranging absorption boxes vertically, constructing an analytical gas space separated from the flue gas channel, and using an alkaline absorbent to absorb flue gas in the absorption box Medium SO 2 and NOx, according to the principle of dynamic absorption and analysis of NOx by alkaline absorbents, then the analyzed NOx is sent to the NOx recovery system for recovery, and the liquid phase in the absorption box absorbs SO 2 The final product is mainly sulfite, which is directly sent out of the absorption system and leaves a large space for flue gas purification; including interconnected flue gas input system, flue gas dust removal and concentration system, flue gas absorption system, flue gas removal The mist system and the purified flue gas output system also include the absorbent adding system connected to the flue gas absorption system, the absorption slurry spray s...

Embodiment 2

[0105] Such as figure 1 As shown, a box-type flue gas purification system, its equipment settings and implementation steps are the same as in Example 1, except for the following settings and steps:

[0106] Take the combination of five absorption boxes, the lye adopts sodium carbonate, and the concentration is 20%.

[0107] Applying the box-type flue gas purification system of this application, the desulfurization efficiency is 99.6%, the denitrification efficiency is 93.5%, and the NOx recovery rate is 93.0%.

Embodiment 3

[0109] Such as figure 1 As shown, a box-type flue gas purification system, its equipment settings and implementation steps are the same as in Example 1, except for the following settings and steps:

[0110] Four absorption boxes are combined in series; the lye is sodium hydroxide with a concentration of 20%.

[0111] Applying the box-type flue gas purification system of this application, the desulfurization efficiency is 99.5%, the denitrification efficiency is 92.7%, and the NOx recovery rate is 92.2%.

[0112] The beneficial effects of the present invention are: (1) the absorption box is vertically combined to form a tower box structure, the combination is convenient, and the equipment is easy to manufacture, transport and install; (2) most of the dust in the flue gas is removed before entering the tower box, Make the absorption slurry pump suitable for the liquid phase pump, so that the flow of the liquid phase is smooth, so as to ensure the desulfurization and denitrifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com