Closure Liner Composition With Improved Oxygen Reduction

a technology of oxygen reduction and liner composition, which is applied in the field of liner composition with improved oxygen reduction, can solve the problems of high manufacturing cost and complicated multi-layer devices such as these, and achieve the effect of improving shelf life and superior oxygen reduction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

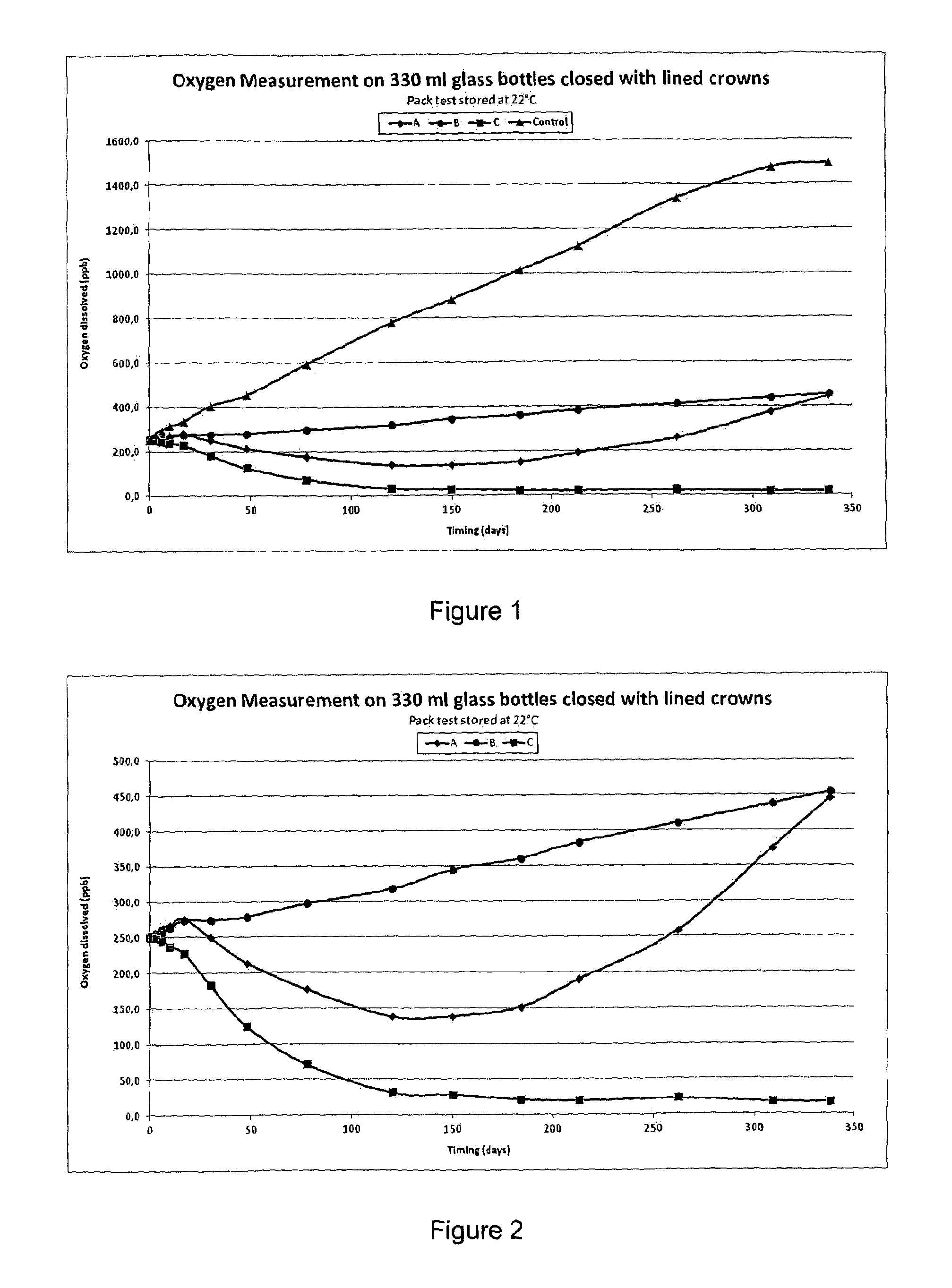

[0018]Closure liners are prepared from the closure liner compositions shown in Table 1 below. Compositions A and B are prior art compositions for comparison, while composition C is a composition of the present invention. Composition A includes an oxygen scavenging material (sodium sulfite), but does not include an oxygen barrier polymer. Composition B includes an oxygen barrier polymer (polyisobutylene), but does not include an oxygen scavenging material. Composition C includes both an oxygen scavenging material (sodium sulfite) and an oxygen barrier polymer (polyisobutylene).

TABLE 1Amount (parts by weight)IngredientABCControlLDPE13037HDPE26058Ethylene Butylene Copolymer318101018Polyisobutylene43025Styrene-Butadiene-Styrene Copolymer53030White Mineral Oil61515Polydimethyl Siloxane70.50.5Sodium Sulfite (anhydrous; 771LDPE 1070 MN 18C (Total Petrochemicals)2Stamylan HD7108 (Sabic)3Flexirene CL10 (Polimeri) for A; Clearflex MQB0 (Polymeri) for B&C4Butyl 101-3 (Lanxess)5Kraton D1153 ES ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com