Dendritic three-dimensional graphene and preparation method thereof

A graphene and dendritic technology, applied in the field of dendritic three-dimensional graphene and its preparation, can solve the problem that graphene has no oxygen reduction performance, etc., and achieve the effects of good oxygen reduction performance, excellent catalytic performance, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of dendritic three-dimensional graphene comprises the steps:

[0022] 1) In CuSO 4 、NiSO 4 、H 2 SO 4 In the mixed solution with additives, the Cu sheet is used as the working electrode to deposit nano-Cu or CuNi clusters in the mixed solution to obtain a deposited product;

[0023] 2) After washing the deposition product in ultrapure water several times, the product was filtered out and freeze-dried to obtain a freeze-dried sample;

[0024] 3) Place the freeze-dried sample in a vacuum furnace, first perform reduction treatment in a hydrogen atmosphere at 800-1000 degrees Celsius, and then conduct graphene deposition treatment in a mixed atmosphere of 800-1000 degrees Celsius hydrogen and methane, and then use persulfuric acid Ammonium solution or ferric chloride solution removes the alloy substrate to obtain dendritic graphene.

[0025] Step 1), the CuSO 4 The concentration is 0.1-0.3mol / L, NiSO 4 Concentration 0-2mol / L, H 2 SO 4 The conc...

Embodiment 1

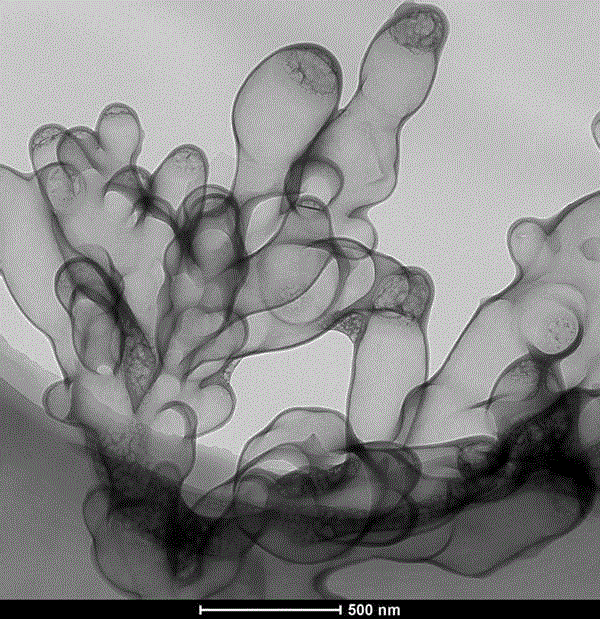

[0029] At 0.1mol / LCuSO 4 +0.5mol / LH 2 SO 4 In the mixed solution, the Cu sheet was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode, at 0.25A / cm 2 Cu nano-clusters were deposited under constant current conditions for 20 s. The deposited product was washed several times in ultrapure water and then freeze-dried. The freeze-dried samples were placed in a vacuum oven under Ar:H 2 (Flow ratio)=6:1, heat at 800 degrees Celsius for 20 minutes for reduction treatment, and then heat at 800 degrees Celsius Ar:H 2 :CH 4 (Flow ratio) = 8:1:1 for graphene deposition. After 20 minutes of deposition, use ammonium persulfate solution or ferric chloride solution to remove the metal substrate to obtain dendritic graphene. The dendritic graphite has a diameter of 200-400nm and a length of 200-1000nm primary tubular graphene, on which a large number of secondary tubular graphenes ...

Embodiment 2

[0032] At 0.2mol / LCuSO 4 +1.0mol / LH 2 SO 4 +0.8mol / LNiSO 4 (Addition of Ni ions can change the substrate composition, thermal stability and morphology of metal nanoclusters) In the mixed solution, the Cu sheet was used as the working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. 2 Nano-CuNi clusters were deposited under constant current conditions for 30 s. The deposited product was washed several times in ultrapure water and then freeze-dried. The freeze-dried samples were placed in a vacuum oven under Ar:H 2 (Flow ratio)=6:1, heat at 900 degrees Celsius for 20 minutes for reduction treatment, and then heat at 900 degrees Celsius Ar:H 2 :CH 4(Flow ratio) = 6:1:1 for graphene deposition, and dendritic graphene can be obtained after 20 minutes of deposition. The dendritic graphite has a diameter of 150-200nm and a length of 200-500nm primary tubular graphene, on which a large ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com