Porous nitrogen-doped carbon sphere material with ultralow cobalt atom content as well as preparation method and application of porous nitrogen-doped carbon sphere material

A nitrogen-doped carbon, ultra-low cobalt technology, applied in chemical instruments and methods, catalyst activation/preparation, electrical components, etc., can solve the problems of low cobalt atom content, high specific surface area and pore structure, etc., and achieve oxygen reduction performance. Excellent effect, improved electrochemical activity, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

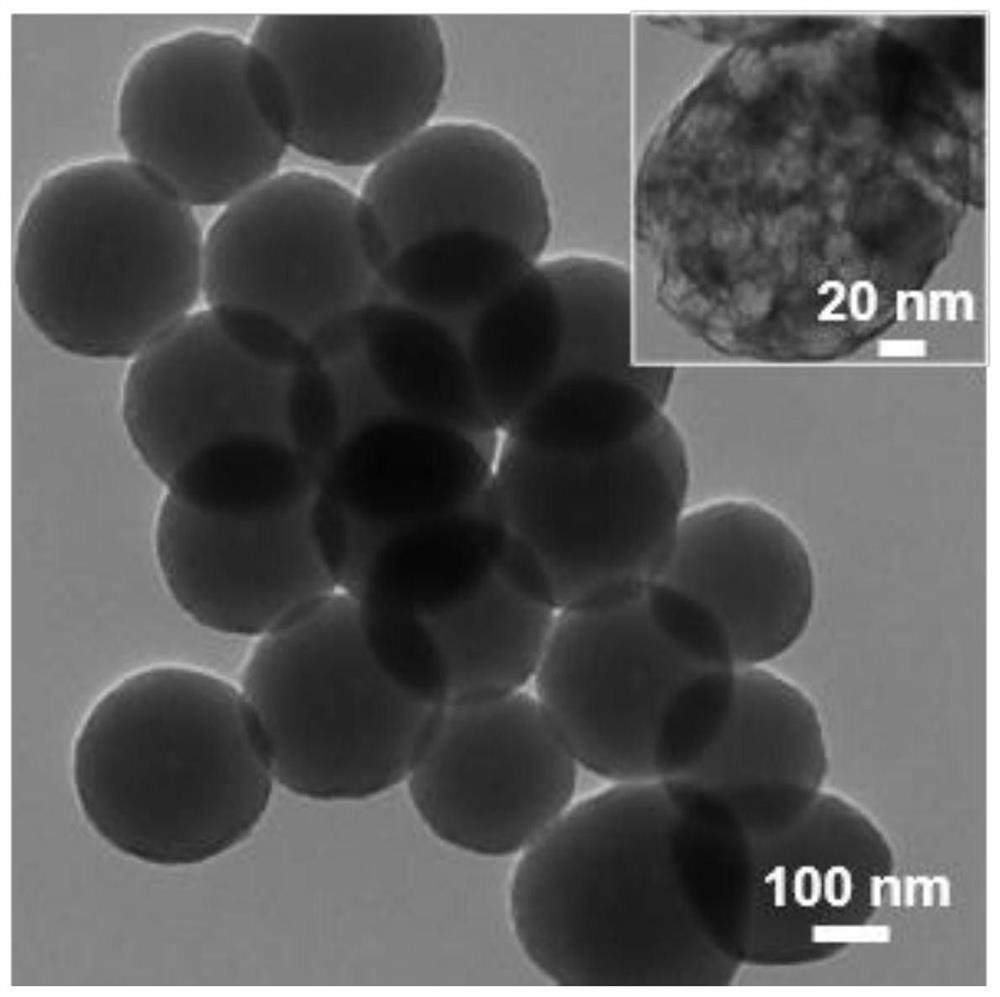

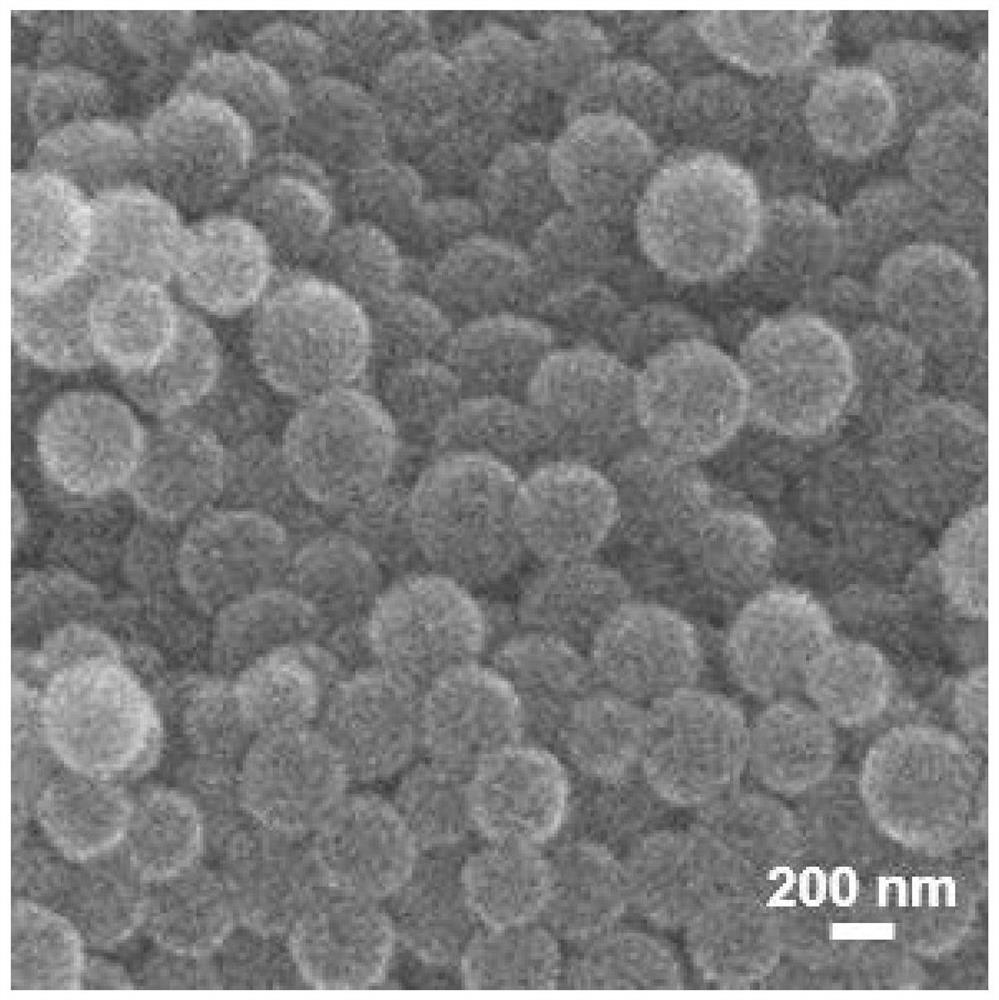

[0050] In this example, see Figure 8 , a porous nitrogen-doped carbon sphere material with ultra-low cobalt atom content, using EDTA disodium cobalt salt as the cobalt source, dopamine hydrochloride as the nitrogen source, in an alkaline environment, through polymer encapsulation and In the high-temperature pyrolysis process, dopamine is used to stir and polymerize to form polydopamine to wrap cobalt atoms, and to form porous carbon spheres after high-temperature pyrolysis, thereby forming a porous nitrogen-doped carbon sphere electrocatalyst with ultra-low cobalt atom content.

[0051] In this example, see Figure 8 , a method for preparing a porous nitrogen-doped carbon sphere material with an ultra-low cobalt atom content in this embodiment, comprising the following steps:

[0052] a. By volume, 2 parts of ammonia water, 36 parts of ethanol and 90 parts of deionized water are placed in a beaker, and fully stirred at a speed of 600 rpm for 30 minutes to obtain a uniform an...

Embodiment 2

[0066] This embodiment is basically the same as Embodiment 1, especially in that:

[0067] In this example, see Figure 8 , a porous nitrogen-doped carbon sphere material with ultra-low cobalt atom content, using EDTA disodium cobalt salt as the cobalt source, dopamine hydrochloride as the nitrogen source, in an alkaline environment, through polymer encapsulation and In the high-temperature pyrolysis process, dopamine is used to stir and polymerize to form polydopamine to wrap cobalt atoms, and to form porous carbon spheres after high-temperature pyrolysis, thereby forming a porous nitrogen-doped carbon sphere electrocatalyst with ultra-low cobalt atom content.

[0068] In this example, see Figure 8 , a method for preparing a porous nitrogen-doped carbon sphere material with an ultra-low cobalt atom content in this embodiment, comprising the following steps:

[0069] a. By volume, 4 parts of ammonia water, 50 parts of ethanol and 150 parts of deionized water are placed in a...

Embodiment 3

[0079] This embodiment is basically the same as Embodiment 1, especially in that:

[0080] In this example, see Figure 8 , a porous nitrogen-doped carbon sphere material with ultra-low cobalt atom content, using EDTA disodium cobalt salt as the cobalt source, dopamine hydrochloride as the nitrogen source, in an alkaline environment, through polymer encapsulation and In the high-temperature pyrolysis process, dopamine is used to stir and polymerize to form polydopamine to wrap cobalt atoms, and to form porous carbon spheres after high-temperature pyrolysis, thereby forming a porous nitrogen-doped carbon sphere electrocatalyst with ultra-low cobalt atom content.

[0081] In this example, see Figure 8 , a method for preparing a porous nitrogen-doped carbon sphere material with an ultra-low cobalt atom content in this embodiment, comprising the following steps:

[0082] a. By volume, 2 parts of ammonia water, 36 parts of ethanol and 90 parts of deionized water are placed in a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

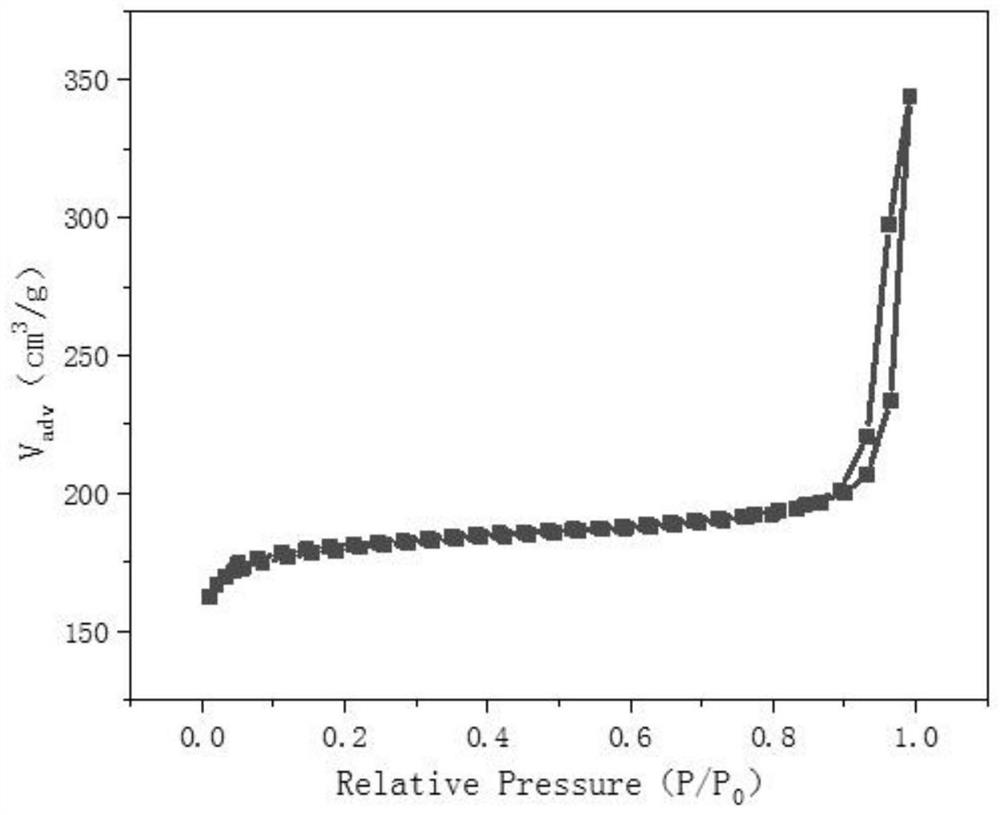

| specific surface area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com