Platinum-cobalt alloy carbon catalyst for proton exchange membrane fuel cell and preparation method of platinum-cobalt alloy carbon catalyst

A proton exchange membrane, platinum-cobalt alloy technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve problems such as insufficient description of catalyst application, and achieve strong preparation process operability, cost reduction, and high power density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

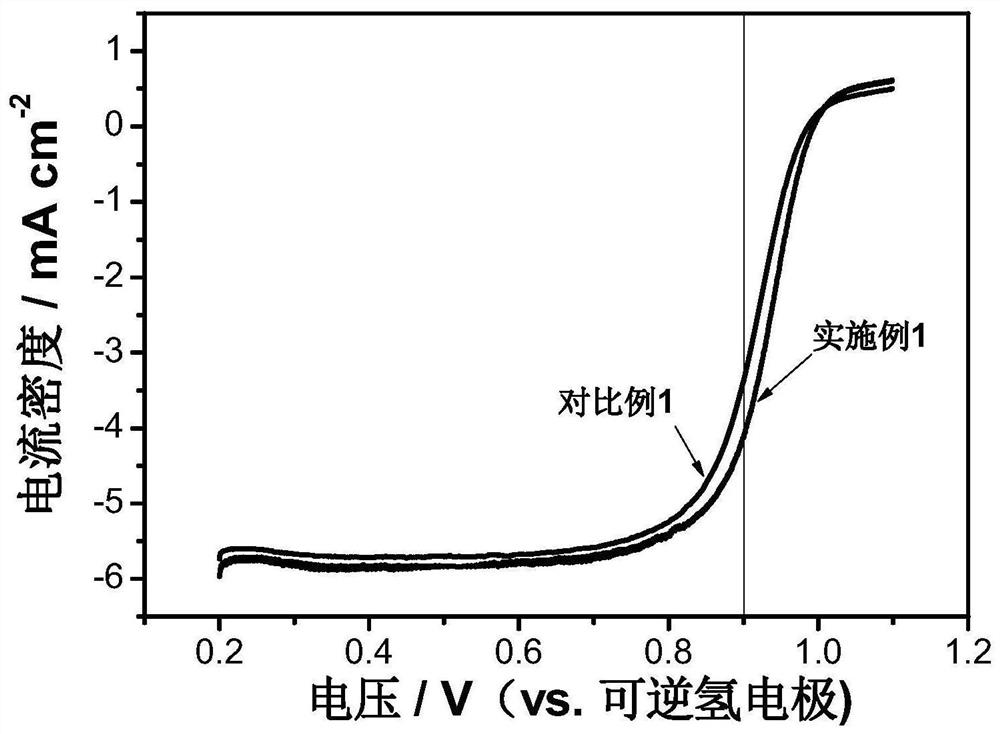

Embodiment 1

[0029] A preparation method of a platinum-cobalt alloy carbon catalyst for a proton exchange membrane fuel cell, comprising the following steps:

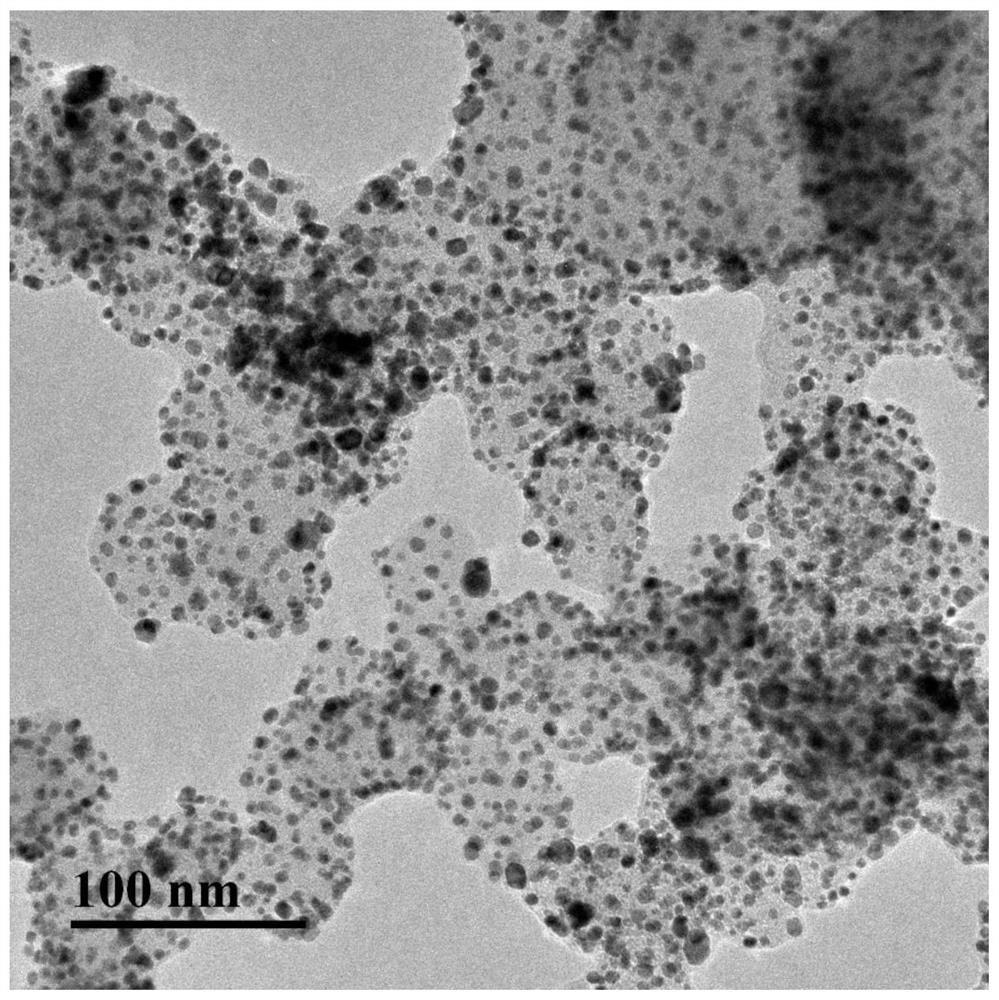

[0030] (1) Pretreatment: Weigh 1g of platinum-carbon material (self-made platinum-carbon catalyst with a platinum content of 50%, the preparation method is as follows: disperse 0.5g of carbon carrier, platinum-containing compound containing 0.5g of platinum in ethylene glycol, and disperse Obtain a suspension evenly, stir and add a precipitant with a molar mass ratio of 4 to platinum, and an additive with a molar mass ratio to platinum of 1, then heat to boiling in a microwave oven, cool down to room temperature and let stand; The platinum-carbon catalyst can be obtained by drying under low temperature, and the specific carbon carrier, platinum-containing compound, precipitating agent, additive, etc. refer to the Chinese patent with the publication number CN111584884A), measure 80mL of water, 1mL of the concentration of 1mol / L cobalt...

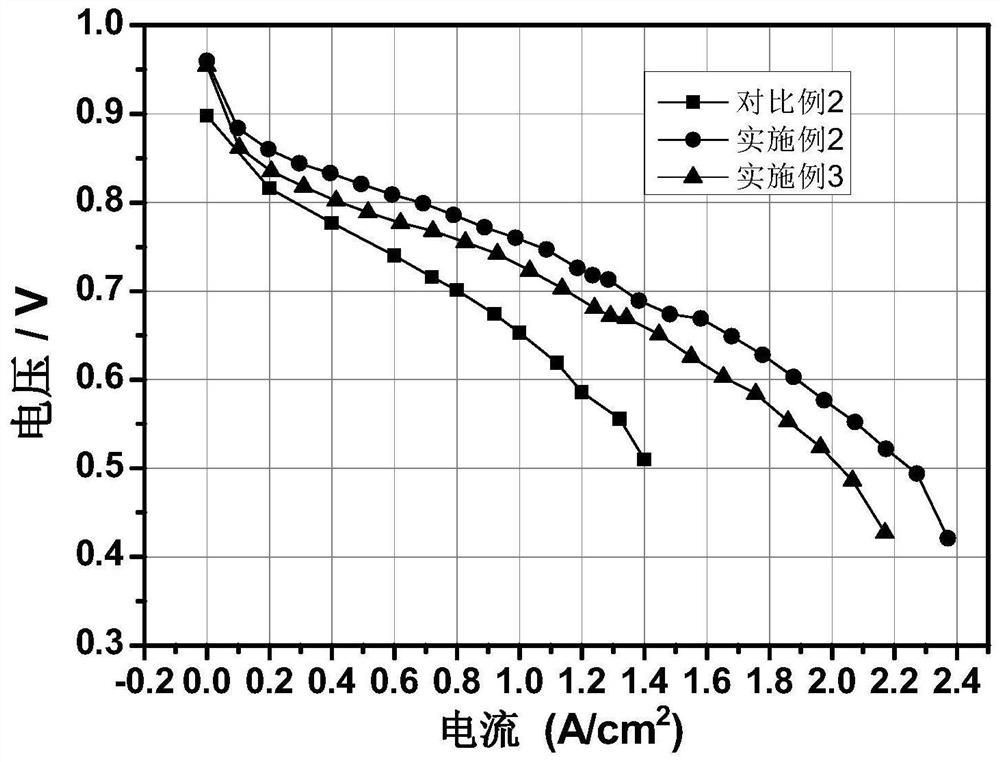

Embodiment 2

[0036] A method for preparing a platinum-cobalt alloy carbon catalyst for a proton exchange membrane fuel cell, the difference from Example 1 is that 5g of platinum-carbon material is weighed (a self-made platinum-carbon catalyst with a platinum content of 40%, the preparation method is the same as in Example 1), and other The conditions are the same as those in Example 1; the manufacturing and testing conditions of a single cell using the platinum-cobalt alloy carbon catalyst prepared in this example are the same as those in Example 1.

Embodiment 3

[0038] A method for preparing a platinum-cobalt alloy carbon catalyst for a proton exchange membrane fuel cell, the difference from Example 1 is that 5g of platinum-carbon material (commercially available 40% Johnson Matthey platinum-carbon catalyst) is taken, and other conditions are the same as in Example 2 The proportions in the same; the single cell production and test conditions using the platinum-cobalt alloy carbon catalyst prepared in this embodiment are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com