A method for preparing cobalt blue/phyllosilicate clay mineral hybrid pigments by solid phase method

A layered silicate and clay mineral technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problem of low yield, high cost, and influence on the crystal form of cobalt blue hybrid pigments And the problem of color matching, to achieve the effect of strong operability of the preparation process, low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

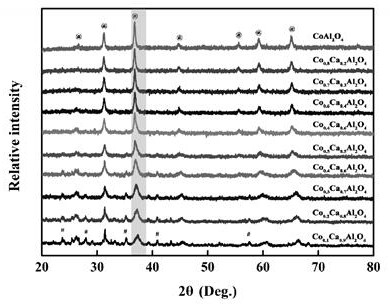

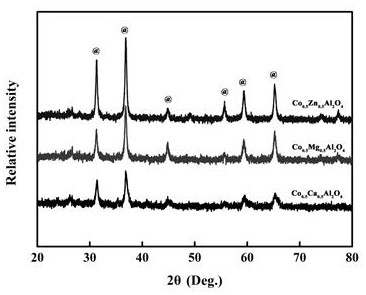

[0027] Preparation of cobalt blue hybrid pigment: Accurately weigh 14.58 g of kaolinite, 72.42 g of dicobalt oxide, 102 g of aluminum oxide and 7.242 g of zinc oxide and mix them evenly. After crystallization for 2 h, the cobalt blue hybrid pigment was obtained, the sample number was S0, and the yield was 96.44%.

Embodiment 2

[0029] Preparation of cobalt blue hybrid pigment: Accurately weigh 46.5 g of halloysite, 46.5 g of cobalt hydroxide, 204 g of aluminum oxide and 20 g of magnesium oxide and mix evenly. The resulting mixture is placed in a calciner and crystallized at a high temperature of 1300 °C 2 h, the cobalt blue hybrid pigment was obtained, the sample number was S1, and the yield was 97.16%.

Embodiment 3

[0031] Preparation of cobalt blue hybrid pigment: Accurately weigh 16.2 g of kaolinite, 16.32 g of dicobalt oxide, 102 g of aluminum oxide and 44.8 g of calcium oxide and mix them evenly. After crystallization for 2 h, the cobalt blue hybrid pigment was obtained, the sample number was S2, and the yield was 98.97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com