High-purity polymetallic-element solid mixed salt and preparation method and application thereof

A technology of solid mixing and metal elements, applied in the direction of sulfite preparation, chloride preparation, electrical components, etc., can solve the problems of high cost, large space demand, low efficiency, etc., achieve good economic and social benefits, and high production efficiency , highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

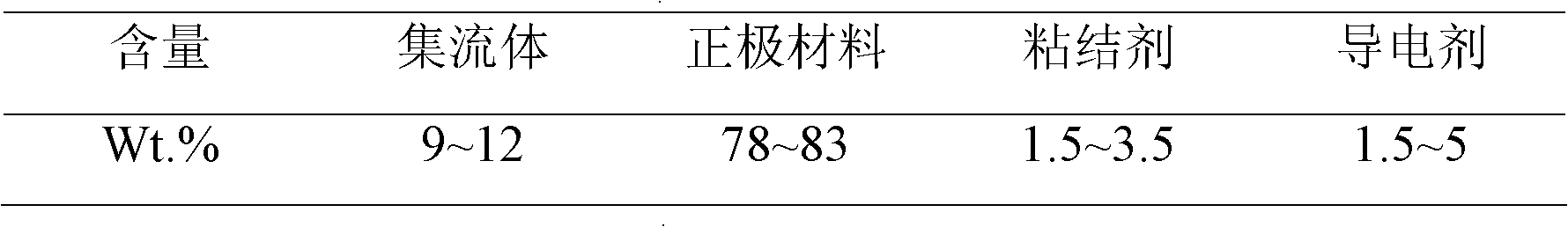

[0028] Take the lithium-ion batteries used in mobile phones or notebook computers whose positive electrode materials contain nickel, cobalt and manganese, disassemble them with tools, select 500 grams of positive electrode pieces, and crush them with a high-speed rotary grinder for 10 minutes. The materials can all pass 100 mesh , then put the material into a muffle furnace at 550°C for calcination for 4 hours, put the fired powder into a 1000 ml beaker containing 2 moles of sodium hydroxide one by one, put the beaker in a water bath in advance, and control the inside of the beaker The temperature of the solution is 50°C. After the powder is fed, the reaction is continued for 1.5 hours, filtered, washed 2-3 times with hot water, the aluminum content is 0.008% from the filter cake, and the sodium hydroxide concentration of the filtrate is 0.23 mol / liter. Put the filter cake into a beaker containing 390 ml of sulfuric acid with a concentration of 2.3 mol / L one by one. Put the bea...

Embodiment 2

[0032] Take the lithium-ion batteries used in mobile phones or notebook computers whose positive electrode materials contain nickel, cobalt and manganese, disassemble them with tools, select 500 grams of positive electrode pieces, and crush them with a high-speed rotary grinder for 10 minutes. The materials can all pass 100 mesh , then put the material into a muffle furnace at 550°C for calcination for 4 hours, put the burned powder into a 1000 ml beaker with 2 moles of sodium hydroxide one by one, put the beaker in a water bath in advance, and control the inner solution of the beaker The temperature is 50°C. After the powder is fed, continue to react for 1.5 hours, filter, wash with hot water 2-3 times, take a sample from the filter cake and analyze the aluminum content. The concentration of sodium hydroxide in the filtrate is 0.23 mol / liter. Put the filter cake into a beaker containing 390 ml of sulfuric acid with a content of 2.3 mol / L one by one. Put the beaker in a water b...

Embodiment 3

[0037] Get the lithium-ion battery used for waste mobile phones or notebook computers whose positive electrode material contains cobalt and manganese, and the pulverization step is the same as that of Example 1. The powder that has been burned is dropped into a 1000 ml beaker containing 2 moles of sodium hydroxide successively, and the beaker is placed in advance. In the water bath, control the temperature of the solution in the beaker to 50°C. After the powder is poured, continue to react for 1.5 hours, filter, wash with hot water 2-3 times, and analyze the aluminum content from the filter cake. The concentration of sodium hydroxide in the filtrate is is 0.28 mol / L. Put the filter cake into a beaker containing 400 ml of hydrochloric acid with a content of 4 mol / L one by one. Put the beaker in a water bath in advance, keep the temperature at 90°C, and add sodium sulfite to the beaker one by one. After the addition of sodium sulfite, the reaction is not obvious. , stop adding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com