New process for preparing chlorosulfonic acid and equipment thereof

A chlorosulfonic acid and a new process technology, applied in the field of chlorosulfonic acid preparation technology, can solve problems such as potential safety hazards, large equipment footprint, cost reduction and stable production, and achieve simple post-treatment process and reduced device volume. , to promote the full effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

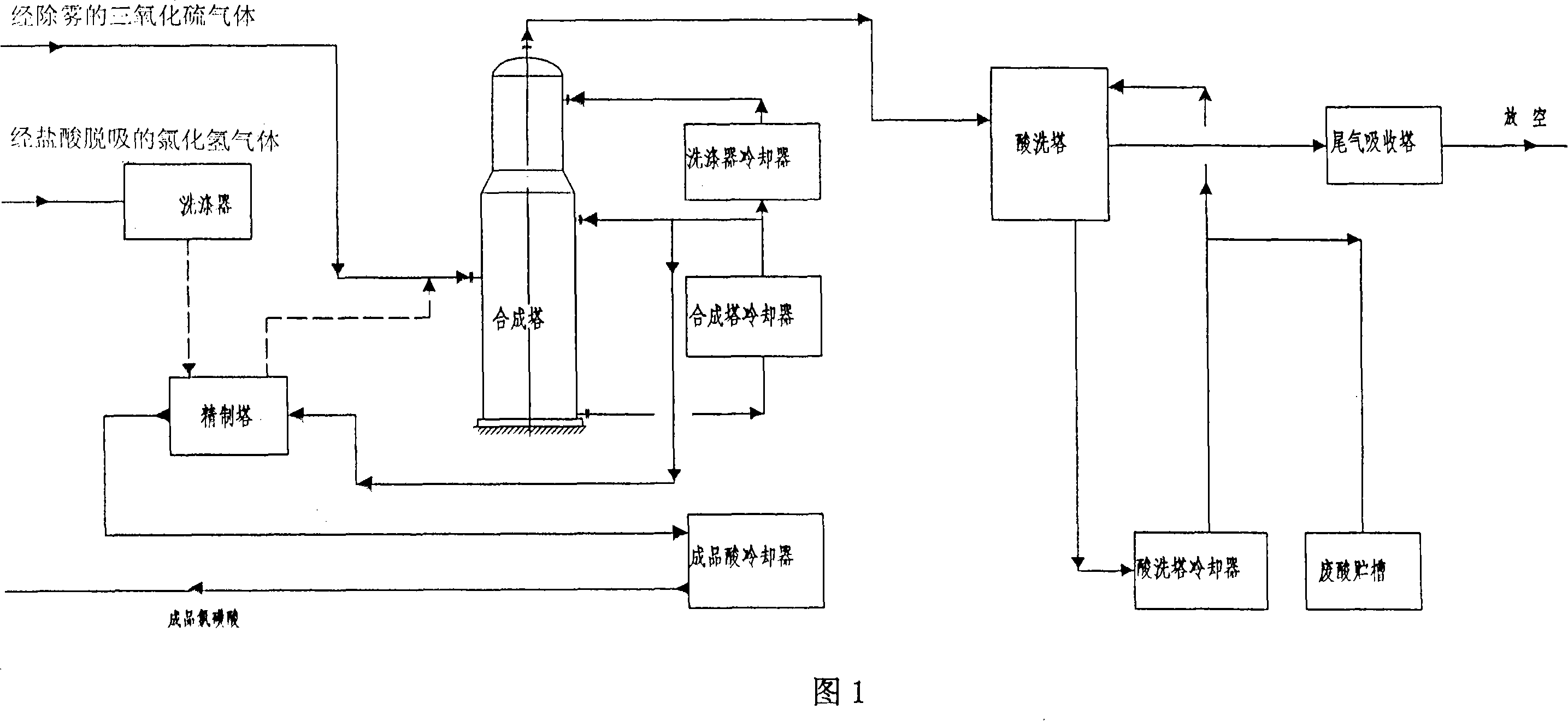

[0040] A new process for preparing chlorosulfonic acid, using high-purity hydrogen chloride gas and high-purity sulfur trioxide gas as raw materials, comprises the following steps:

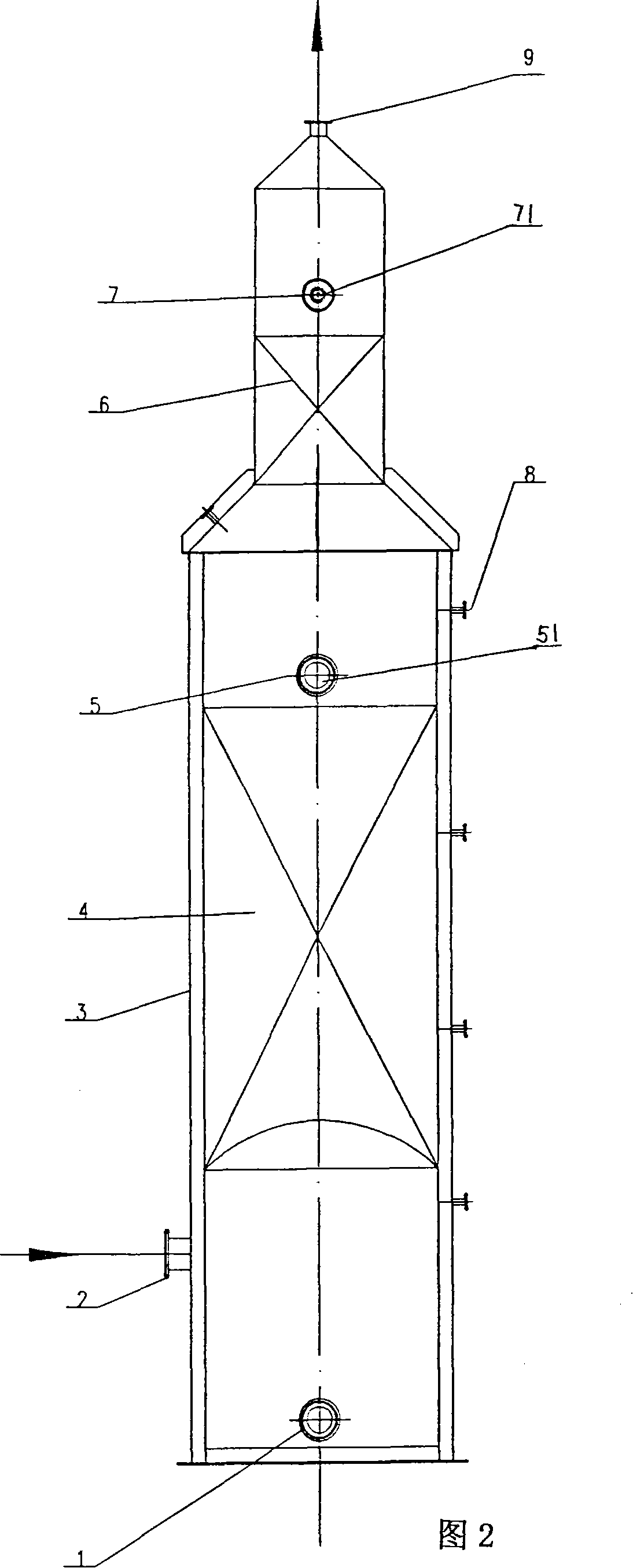

[0041] (1) High-purity (above 99%) hydrogen chloride is deabsorbed with hydrochloric acid, removed water and defogging with concentrated sulfuric acid in a scrubber, enters a refining tower, and enters a synthesis tower at a temperature controlled at 80-90°C; high-purity (99% % or more) sulfur trioxide gas is demisted to remove water, the temperature is controlled at 90-100°C and enters the synthesis tower, hydrogen chloride gas and sulfur trioxide gas are synthesized at a volume ratio of 1:1.1, and the reaction temperature is 95-110°C;

[0042] (2) Synthesize in the liquid phase through the circulation of spraying and absorbing the gas phase reactant in the synthesis tower with the liquid phase product obtained by synthesis; and absorb the small droplets generated by the gas phase reactant reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com