Method for synthesizing thionyl chloride with crude product thionyl chloride as raw material

A technology for thionyl chloride and crude products, which is applied in the field of raw material synthesis, and can solve problems such as difficult separation, complicated process, and difficulty in obtaining high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

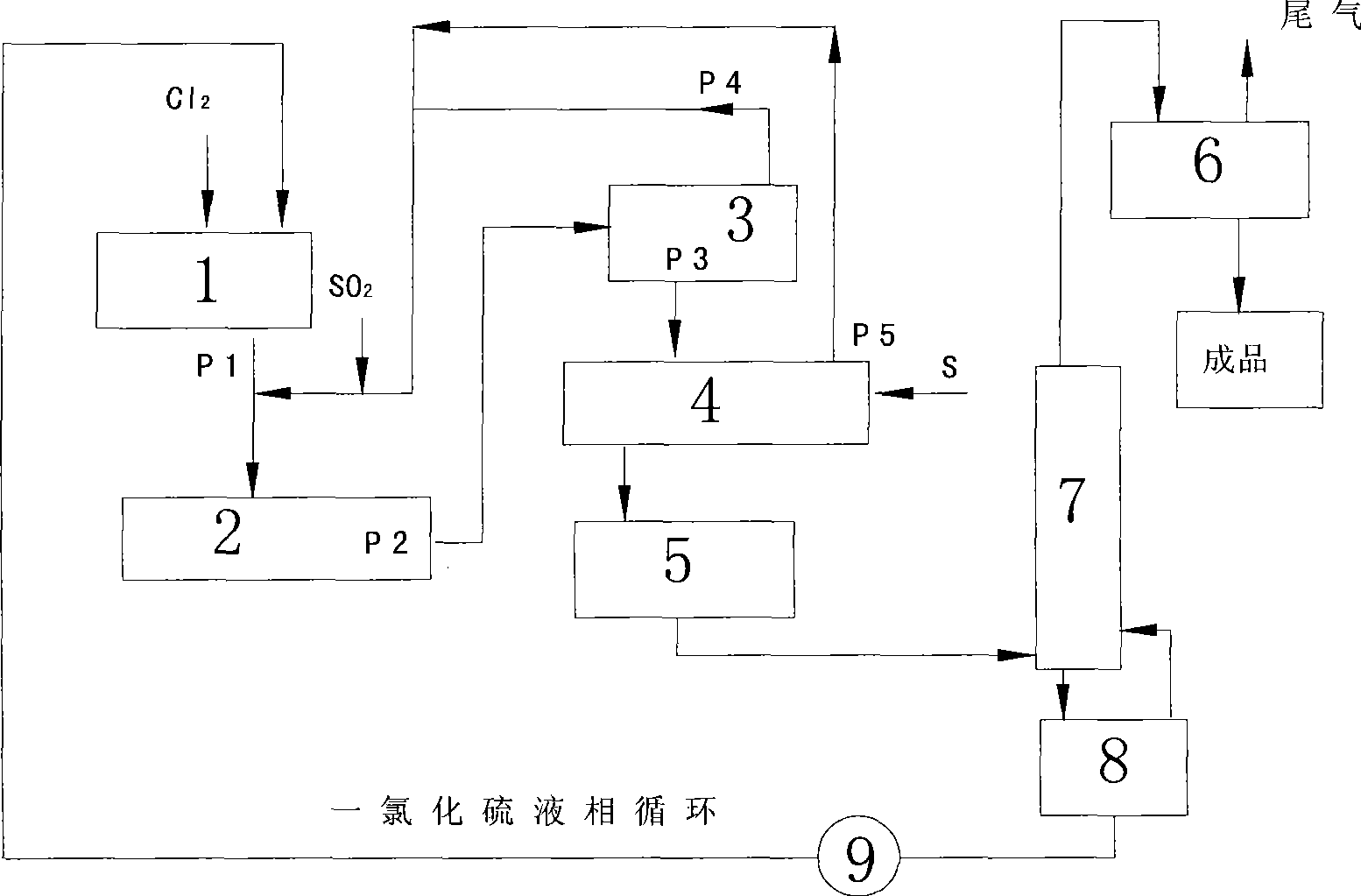

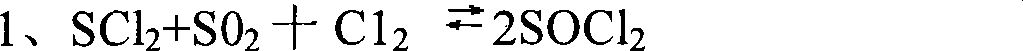

Method used

Image

Examples

Embodiment 1

[0094] A method for synthesizing thionyl chloride with crude product thionyl chloride as raw material, comprising:

[0095] (1) The crude product sulfur oxychloride whose content of sulfur oxychloride accounts for 60% of the crude product sulfur oxychloride is vulcanized in a vulcanization kettle, and the crude product sulfur oxychloride also contains 18% of sulfur dichloride , Sulfur monochloride 20%. The temperature in the vulcanization kettle is that the residual temperature of the crude product thionyl chloride is 65° C., and the pressure is normal pressure. To the crude product thionyl chloride, add sulfur that is not excessive relative to the sulfur dichloride therein. The amount of sulfur added is For 80% of the amount of sulfur required for the complete reaction with the sulfur dichloride in the crude product sulfur oxychloride, so that other substances in the crude product sulfur oxychloride are converted into sulfur monochloride except for the sulfur oxychloride, obt...

Embodiment 2

[0105] A method for synthesizing thionyl chloride with crude product thionyl chloride as raw material, comprising:

[0106] (1) The crude product sulfur oxychloride whose content of sulfur oxychloride accounts for 65% of the crude product sulfur oxychloride is vulcanized in a vulcanization kettle, and the crude product sulfur oxychloride also contains 20% of sulfur dichloride , the temperature in the vulcanization kettle is that the residual temperature of the crude product thionyl chloride is ≤ 80°C, and the pressure is 0.12MPa. Add sulfur that is not excessive relative to the sulfur dichloride therein in the crude product thionyl chloride, and the amount of sulfur The amount added is 88% of the amount of sulfur required for the complete reaction of sulfur dichloride in the crude product thionyl chloride, so that other substances in the crude product thionyl chloride except thionyl chloride are converted into sulfur monochloride , to obtain the crude sulfur oxychloride after su...

Embodiment 3

[0116] A method for synthesizing thionyl chloride with crude product thionyl chloride as raw material, comprising:

[0117] (1) The crude product sulfur oxychloride whose content of sulfur oxychloride accounts for 68% of the crude product sulfur oxychloride total amount is vulcanized in a vulcanization kettle, and also contains 15% sulfur dichloride in the crude product sulfur oxychloride , the temperature in the vulcanization kettle is that the residual temperature of the crude product thionyl chloride is ≤ 80°C, and the pressure is normal pressure, and the sulfur that is not excessive relative to the sulfur dichloride therein is added to the crude product thionyl chloride, and the amount of sulfur is The amount added is 80-98% of the amount of sulfur required for the complete reaction of sulfur dichloride in the crude product thionyl chloride, so that other substances in the crude product thionyl chloride except thionyl chloride are converted into monochlorine sulfur sulfide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com