All-steel load radial tire tread base rubber material and preparation method thereof

A radial tire and tread base technology, which is applied in the field of all-steel radial tire tread base compound and its preparation, can solve the problems of tire crown delamination and poor rubber processing performance, and achieve the improvement of crown delamination, Improve processability, improve dispersibility and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

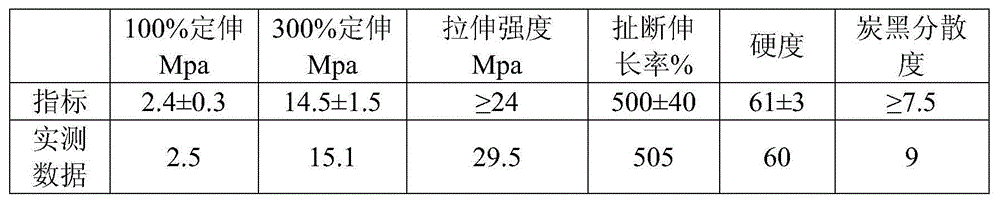

Examples

Embodiment 1

[0030] A rubber compound for the base of an all-steel radial truck tire. The raw materials include, in parts by weight, 100 parts of No. 5 standard rubber, 0.1 part of peptizer A86, 40 parts of carbon black N234, 15 parts of white carbon black, and a silane coupling agent. 3 parts of Si-69, 5 parts of zinc oxide, 2 parts of stearic acid, 1.35 parts of phenolic tackifying resin T6000, 1.5 parts of petroleum resin A100, antioxidant 6PPD (N-(1,3-dimethylbutyl)-N '-Phenyl-p-phenylenediamine) 1.3 parts, anti-aging agent RD (2,2,4-trimethyl-1,2-dihydroquinoline polymer) 0.6 parts, sulfur 1.0 parts, accelerator TBBS (N- 1.9 parts of tert-butyl-2-benzothiazole sulfenamide) and 0.11 parts of anti-scorch agent CTP (N-cyclohexylthiophthalimide).

[0031] The preparation method of the above-mentioned all-steel radial truck tire tread base compound comprises the following steps:

[0032] 1) Preparation of a section of carbon black masterbatch:

[0033] According to the parts by weight, a...

Embodiment 2

[0044] A kind of all-steel radial truck tire base compound, its raw material includes by weight: 100 parts of natural rubber SMR20, 0.3 parts of peptizer SJ-103, 30 parts of carbon black N234, 18 parts of white carbon black, silane coupling 3.5 parts of agent Si-69, 3 parts of zinc oxide, 1.5 parts of stearic acid, 1 part of phenolic tackifying resin SL1402, 2 parts of petroleum resin E1102, 1 part of anti-aging agent 6PPD, 0.5 parts of anti-aging agent RD, 2 parts of sulfur, accelerator 1 part of TBBS and 0.3 part of anti-scorch agent CTP.

[0045] The preparation method of the above-mentioned all-steel radial truck tire tread base compound comprises the following steps:

[0046] 1) Preparation of a section of carbon black masterbatch:

[0047]At a temperature > 35°C, add natural rubber SMR20 and peptizer SJ-103 into the internal mixer, and knead for 20 seconds at a speed of 50 rpm and a pressure of 14 MPa; then white carbon black, one third of carbon Add black and silane c...

Embodiment 3

[0053] A rubber compound for the base of an all-steel radial truck tire. The raw materials include, in parts by weight, 100 parts of smoked sheet rubber and TSR10 rubber, 0.2 parts of peptizer WP-10, 45 parts of carbon black N234, and 10 parts of white carbon black. , 2.5 parts of silane coupling agent Si-69, 4 parts of zinc oxide, 1 part of stearic acid, 2 parts of phenolic tackifying resin T6000, 3 parts of petroleum resin A100, 0.5 parts of antioxidant 6PPD, 1.5 parts of antioxidant RD, 2.5 parts of sulfur Part, accelerator TBBS 0.8 part.

[0054] The preparation method of the above-mentioned all-steel radial truck tire tread base compound comprises the following steps:

[0055] 1) Preparation of a section of carbon black masterbatch:

[0056] (1) Add smoked sheet glue, TSR10 glue and peptizer WP-10 into the internal mixer at a temperature of 40°C, and mix for 40 seconds at a speed of 50rpm and a pressure of 14MPa; then white carbon Black, one-third of carbon black, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com