Method for improving electrochemical properties of electrode material of lithium ion batteries

A lithium-ion battery and electrode material technology, which is applied in the field of improving the electrochemical performance of lithium-ion battery electrode materials, can solve the problems of large surface energy, difficult stable existence, and agglomeration of nanomaterials, so as to reduce large-scale industrialization, low cost, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

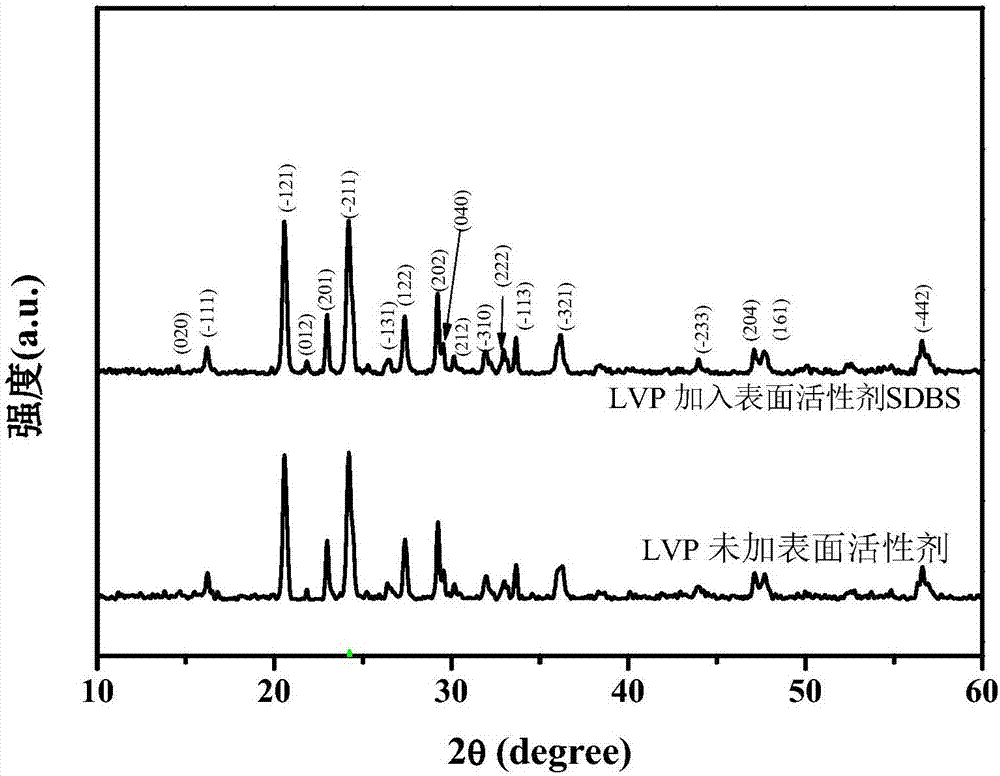

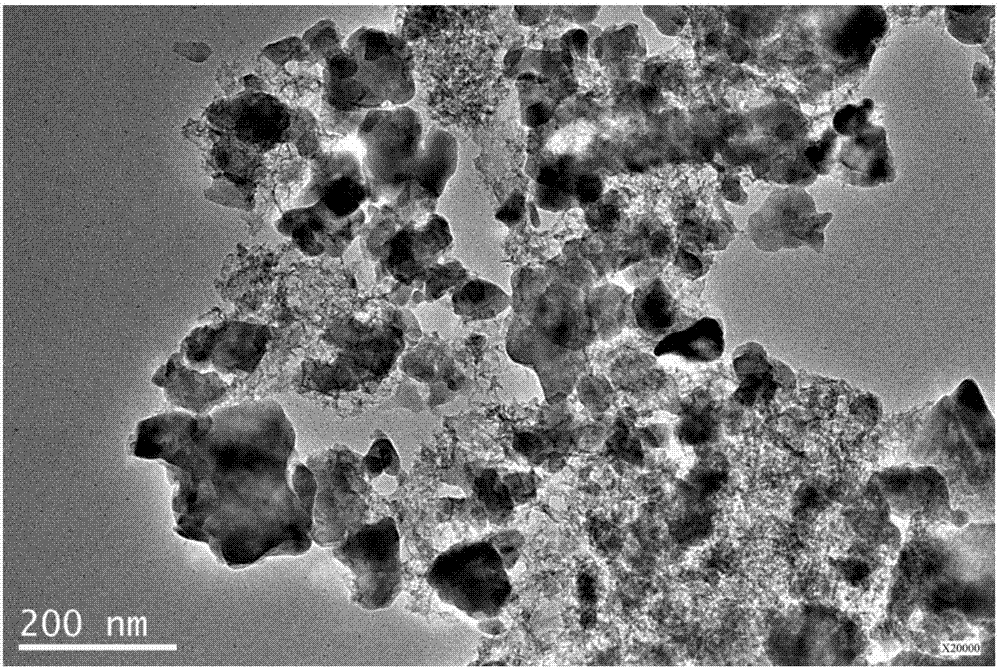

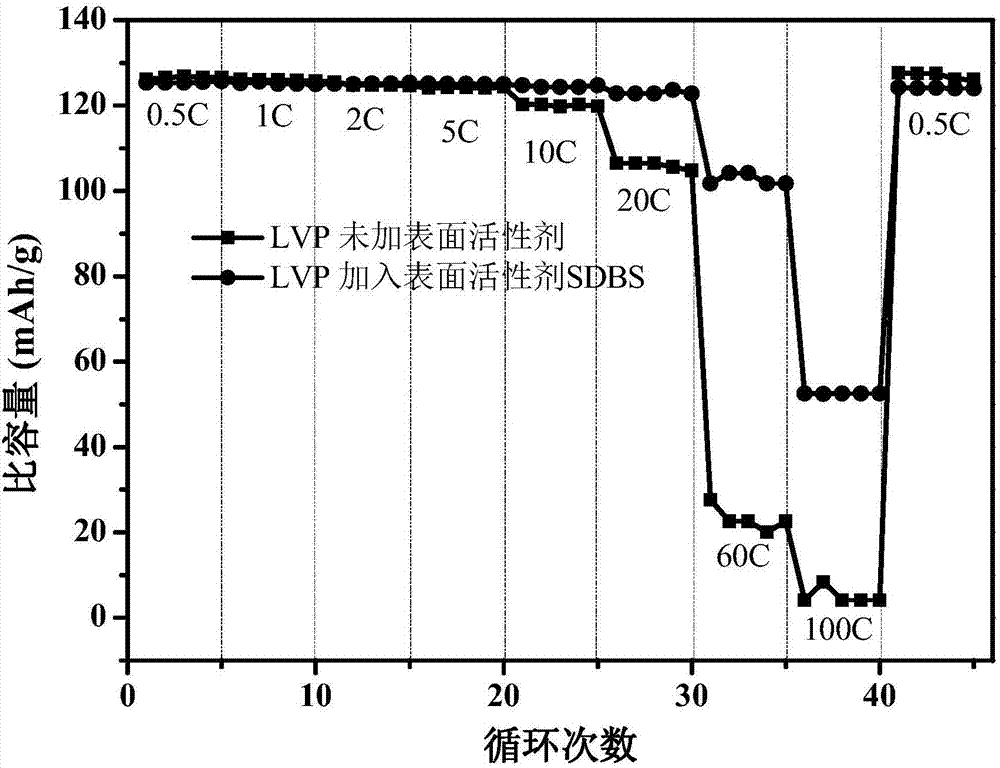

Embodiment 1

[0033] A kind of method of improving the electrochemical performance of lithium-ion battery electrode material of the present embodiment, comprises the steps:

[0034] (1) sodium dodecylbenzenesulfonate (SDBS) is dissolved in deionized water;

[0035] (2) The NH of the electrode material will be prepared 4 VO 3 、CH 3 COOLi·H 2 O, NH 4 h 2 PO 4 And complexing agent citric acid, maintain in the form of solid phase or aqueous solution under certain condition (pH, temperature, the drip rate of raw material and atmosphere protection) add in step (1) solution, form solution;

[0036](3) Heat and stir the solution in step (2) in a water bath at 60°C until it forms a sol, then transfer it to an oven at 120°C for drying to obtain a precursor;

[0037] (4) After grinding the precursor obtained in step (3) in 5% H 2 / N 2 After sintering at 350°C for 5 hours in an atmosphere tube furnace, cool to room temperature naturally;

[0038] (5) Grinding the sample processed in step (4);...

Embodiment 2

[0042] A kind of method of improving the electrochemical performance of lithium-ion battery electrode material of the present embodiment, comprises the steps:

[0043] (1) cetyltrimethylammonium bromide (CTAB) is dissolved in deionized water;

[0044] (2) The CH of the electrode material will be prepared 3 COOLi·H 2 O, (CH 3 COO) 2 Mn 4H 2 O, (CH 3 COO) 2 Ni·4H 2 O and auxiliary raw material ammonia water are maintained in the form of solid phase or aqueous solution under certain conditions (pH, temperature, drip rate and atmosphere protection of raw materials) and added in the solution of step (1) to form a solution;

[0045] (3) Transfer the solution of step (2) into a hydrothermal reaction kettle, react at 180°C for 24 hours to obtain a sol, then evaporate in a water bath at 70°C, and then transfer to an oven for drying at 120°C to obtain a precursor;

[0046] (4) Grinding the precursor obtained in step (3) and sintering it in a muffle furnace at 250°C for 1 hour; ...

Embodiment 3

[0051] A kind of method of improving the electrochemical performance of lithium-ion battery electrode material of the present embodiment, comprises the steps:

[0052] (1) polyvinyl alcohol (PVA) and cetyltrimethylammonium bromide (CTAB) are dissolved in deionized water;

[0053] (2) The CH of the electrode material will be prepared 3 COOLi·H 2 O, (CH 3 COO) 2 Co 6H 2 O and Precipitant Na 2 CO 3 Each was dissolved in deionized water, and each solution was added dropwise to the solution of step (1) under continuous stirring, adjusted with ammonia water to maintain pH = 10, continued to stir for 10 h after the addition, filtered, and washed with deionized water , get the precipitate;

[0054] (3) transferring the precipitate obtained in step (2) to a vacuum oven for vacuum drying to obtain a precursor;

[0055] (4) After grinding the precursor obtained in step (3) in 10% H 2 / N 2 Sintering at 600°C for 8 hours in an atmosphere tube furnace;

[0056] (5) Grinding the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com