Water-borne polyurethane synthetic leather foaming slurry

A technology of water-based polyurethane and water-based polyurethane, applied in the field of synthetic leather materials, can solve the problems of thin coating, poor plumpness and air permeability, and affect the performance of finished polyurethane synthetic leather products, so as to improve dispersion and uniformity and ensure plumpness The effect of sex and breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

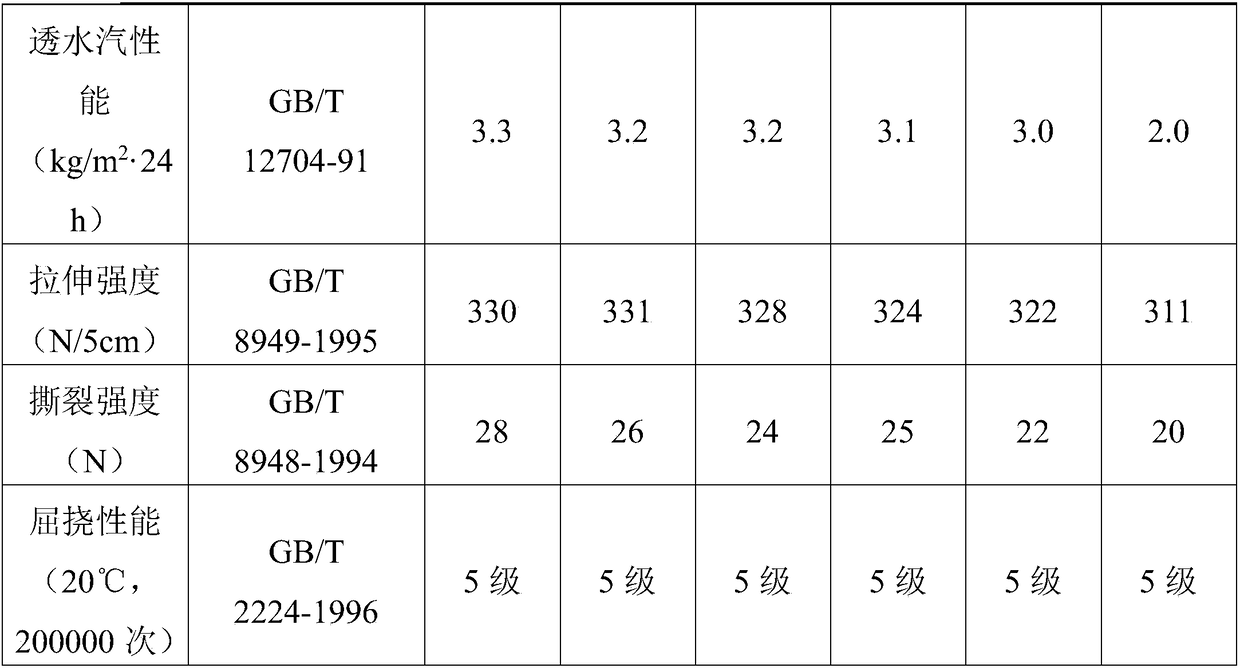

Examples

Embodiment 1

[0043] A water-based polyurethane synthetic leather foaming slurry, comprising the following components by weight: 100 parts of water-based polyurethane emulsion, 12 parts of silica nano whiskers (30-40 nm in diameter, 2-5 μm in length), modified hair 0.3 parts of foaming agent, 0.6 parts of water-based crosslinking agent carbodiimide, 0.11 parts of leveling agent (Silok Leveling8255, purchased from Guangzhou Silok Chemical Co., Ltd.), defoamer (Foamex 800, purchased from German Tego Company) ) 0.12 parts, thickener (COSIE FT-835, Lanya Trading Co., Ltd.) 0.3 parts;

[0044] The preparation process of the modified foaming agent is as follows: grind the sepiolite and pass through a 700-mesh sieve, then mix the azodicarbonamide foaming agent with the ground sepiolite powder, ultrasonically treat for 30 minutes, and then add silane Coupling agent KH-602, continue ultrasonic treatment for 10 minutes.

[0045] The above water-based polyurethane emulsion consists of the following r...

Embodiment 2

[0051] A water-based polyurethane synthetic leather foaming slurry, comprising the following components by weight: 100 parts of water-based polyurethane emulsion, 11 parts of silica nano whiskers (30-40 nm in diameter, 2-5 μm in length), modified hair 0.2 parts of foaming agent, 0.4 parts of water-based cross-linking agent carbodiimide, 0.1 part of leveling agent (Silok Leveling8255, purchased from Guangzhou Silok Chemical Co., Ltd.), defoamer (Foamex 800, purchased from German Tego Company) ) 0.1 part, thickener (COSIE FT-835, Lanya Trading Co., Ltd.) 0.2 part;

[0052] The preparation process of the modified foaming agent is as follows: grind the sepiolite and pass through a 700-mesh sieve, then mix the azodicarbonamide foaming agent with the ground sepiolite powder, ultrasonically treat for 30 minutes, and then add silane Coupling agent KH-602, continue ultrasonic treatment for 10 minutes.

[0053] The above water-based polyurethane emulsion consists of the following raw m...

Embodiment 3

[0059] A water-based polyurethane synthetic leather foaming slurry, comprising the following components by weight: 100 parts of water-based polyurethane emulsion, 14 parts of silica nano whiskers (30-40 nm in diameter, 2-5 μm in length), modified hair 0.4 parts of foaming agent, 0.7 parts of water-based cross-linking agent carbodiimide, 0.18 parts of leveling agent (Silok Leveling8255, purchased from Guangzhou Silok Chemical Co., Ltd.), defoamer (Foamex 800, purchased from Germany Tego Company) ) 0.15 parts, thickener (COSIE FT-835, Lanya Trading Co., Ltd.) 0.4 parts;

[0060] The preparation process of the modified foaming agent is as follows: grind the sepiolite and pass through a 700-mesh sieve, then mix the azodicarbonamide foaming agent with the ground sepiolite powder, ultrasonically treat for 40 minutes, and then add silane Coupling agent KH-602, continue ultrasonic treatment for 20min.

[0061] The above water-based polyurethane emulsion consists of the following raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com