Graphene/hard nanometer particle synergistic modified phenolic resin wear-resistant material

A nanoparticle and phenolic resin technology, which is applied in the field of graphene/hard nanoparticle synergistically modified phenolic resin wear-resistant materials and its preparation, can solve the problems that limit the development of high-performance friction materials, pure phenolic resin has high brittleness and heat resistance Insufficient and other problems, the preparation method is simple and efficient, the cost is low, and the effect of inhibiting damage is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

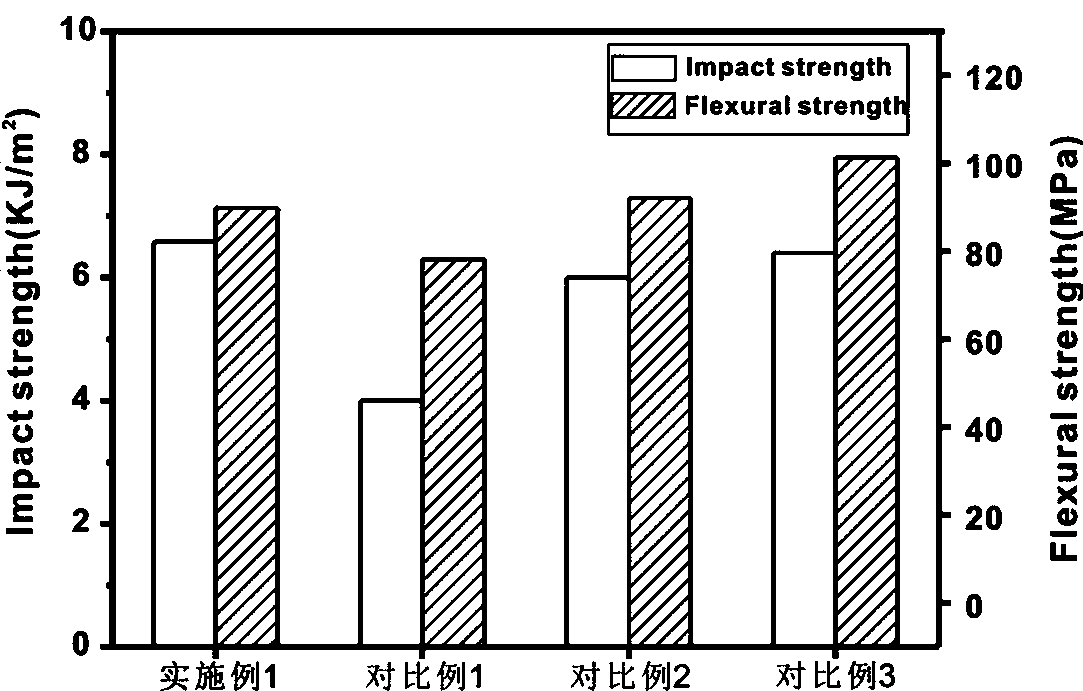

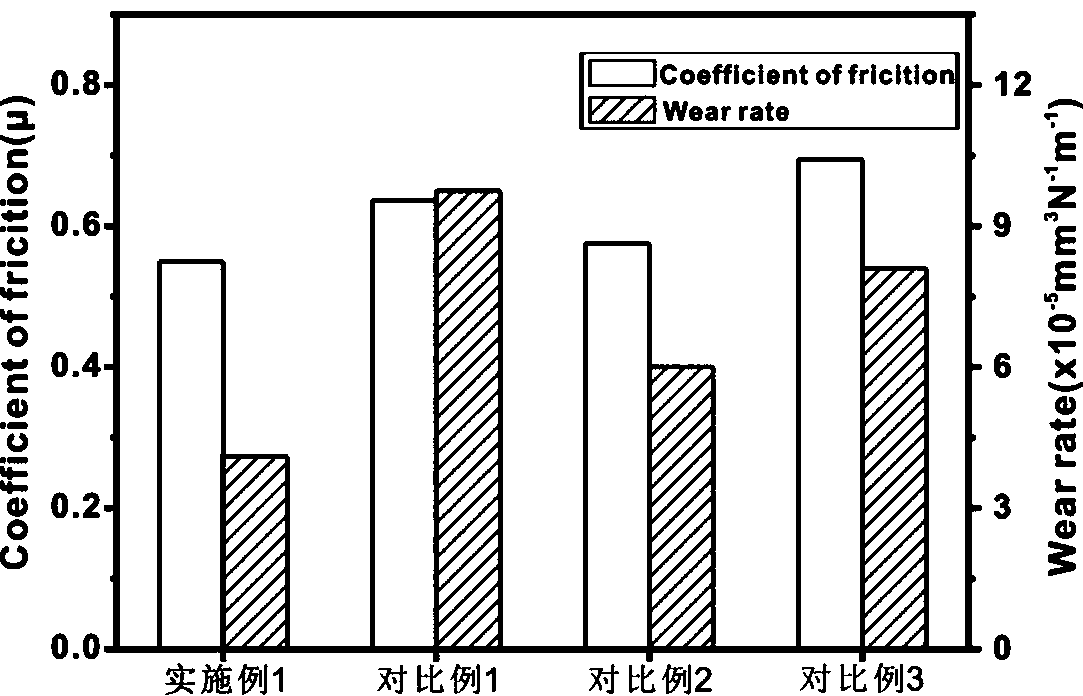

[0030] In the present invention, the functionalized hard nanoparticles and graphene can have a synergistic effect to prepare a wear-resistant material with better wear resistance. In order to prove the synergistic effect of functionalized hard nanoparticles and graphene, the present invention further provides a method for preparing graphene / hard nanoparticles synergistically modified phenolic resin wear-resistant material, comprising the following steps:

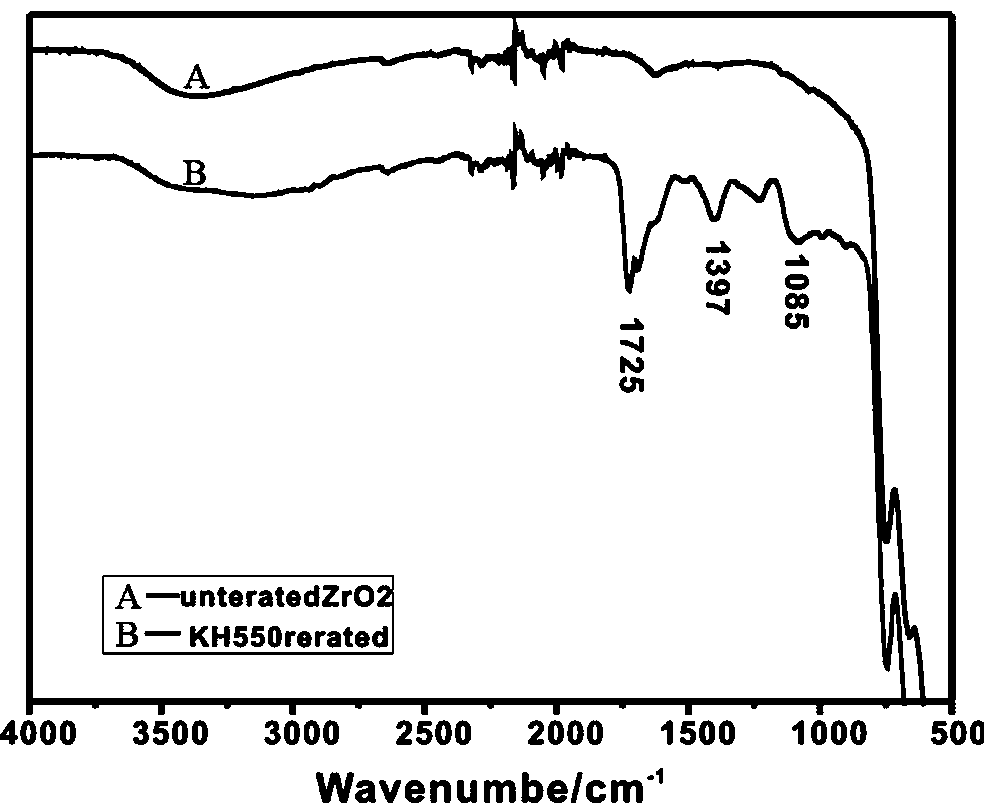

[0031] 1) Functionalization of hard nanoparticles: add hard nanoparticles to the dispersant, ultrasonically disperse to form a hard nanoparticle dispersion with a concentration of 10-100 mg / mL, add a silane coupling agent dropwise to it, and stir for 1-24 hours Finally, centrifuge, wash, and then dry for subsequent use to obtain functionalized hard nanoparticles;

[0032] 2) Wet-mechanical combined mixing: add functionalized hard nanoparticles, graphene, and phenolic resin to the dispersant and stir for 0.5-2 hours before dr...

Embodiment 1

[0042] A preparation method for synergistically modified phenolic resin wear-resistant material of graphene / hard nanoparticles, which comprises the following steps: 1) Functionalization of hard nanoparticles: adding nanometer zirconium dioxide to absolute ethanol, and ultrasonically dispersing to form a concentration It is 50 mg / mL hard nano-zirconia dispersion liquid, add 5 mg / mL γ-aminopropyltriethoxysilane (KH550) dropwise to it, stir in a water bath at 75°C for 4 hours, centrifuge, wash, and then dry Standby; 2) mixing materials: put the above-mentioned modified nano zirconium dioxide (10wt%), graphene (0.2wt%), phenolic resin (89.8wt%) into deionized water and stir for 1h and then dry it. Put the dry mixed raw materials into a high-speed mixer and stir for 10 minutes to make them fully and uniformly dispersed; 3) Composite material hot-press molding: put the mixed raw materials into a mold, and press at a pressure of 45MPa and a temperature of 160°C for 30 minutes. Then p...

Embodiment 2

[0050] A kind of preparation method of graphene / hard nano particle synergistically modified phenolic resin wear-resistant material, it comprises the following steps: 1) hard nano particle functionalization: adding hard nano silicon dioxide in dehydrated alcohol, ultrasonic dispersion Form a hard nano-silica dispersion with a concentration of 10 mg / mL, add 0.3 mg / mL of γ-aminopropyltriethoxysilane (KH550) dropwise to it, stir for 24 hours, centrifuge, wash, and then dry Standby; 2) Wet-mechanical joint mixing: add the above-mentioned modified hard nano-silica (3wt%), graphene (0.5wt%), phenolic resin into acetone and stir for 0.5h and then dry, then Put the dried mixed raw materials into a high-speed mixer and stir for 5 minutes to make them fully and uniformly dispersed; 3) Composite material hot-press molding: put the mixed raw materials into a mold, and press for 30 minutes at a pressure of 20 MPa and a temperature of 160 °C , and then put the molded sample into an oven, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com