Method for preparing SiO2-poly(dimethylaminoethyl methacrylate) (PDMAEMA) nanoparticles having core-shell structure

A nanoparticle and shell structure technology, applied in the field of nanometers, can solve the problem of uncontrollable molecular weight of shell polymers, and achieve the effects of short preparation cycle, mild reaction conditions and controllable molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

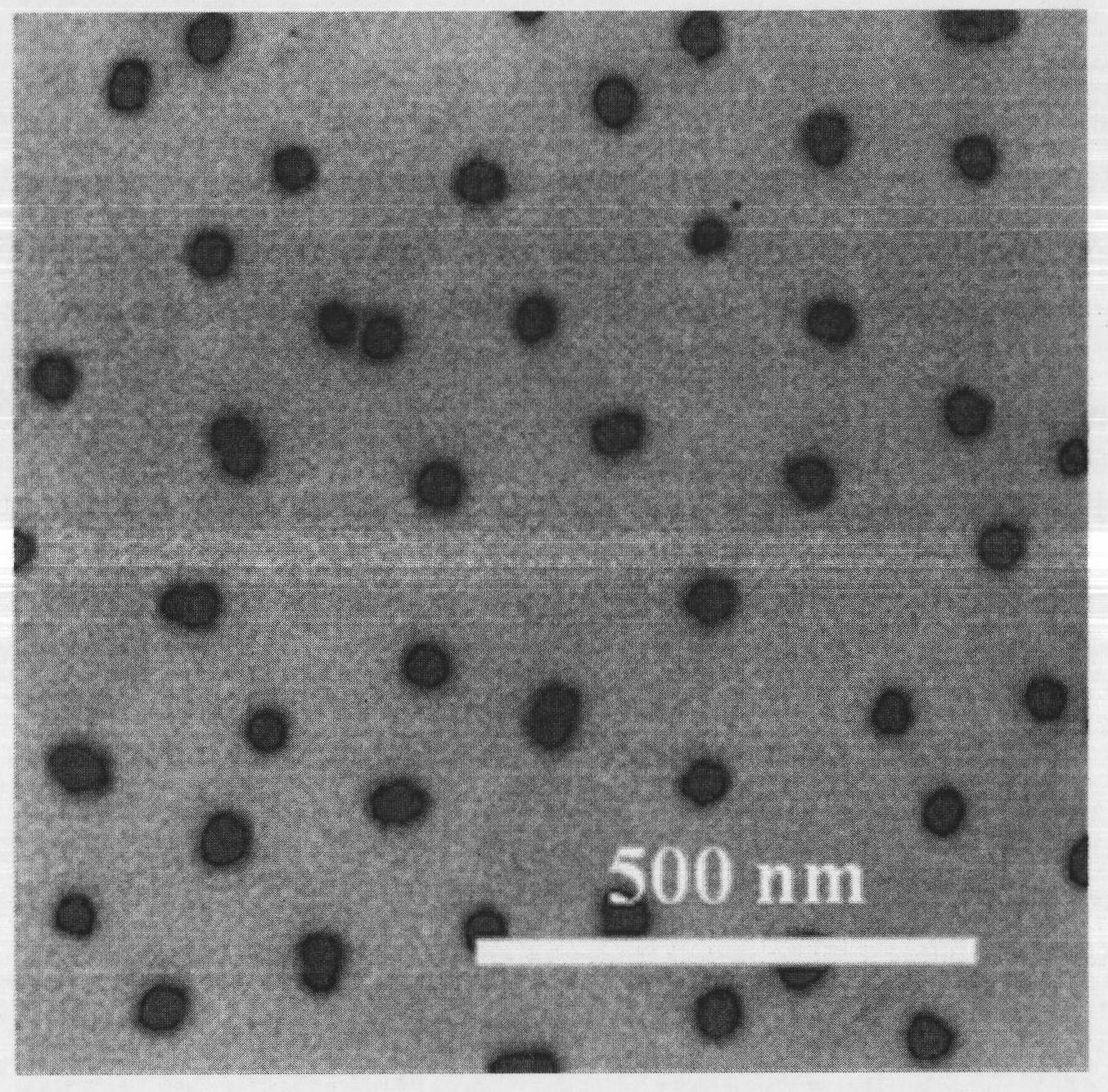

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a core-shell structure of SiO 2 The preparation method of @PDMAEMA nanoparticles is characterized in that it includes:

[0033] CuX 2 , ligand, initiator modified SiO 2The nanoparticles, the solvent and N,N-dimethylaminoethyl methacrylate are mixed to obtain the first mixed liquid, and the ligands are pentamethyldiethylenetriamine, 2,2-bipyridine, 4, 4-Dinonyl-2,2-bipyridine, tetramethylethylenediamine, hexamethyltriethylenetetramine, tris[2-(dimethylamino)ethyl]amine or tris[(2-pyridine base) methyl] amine, the SiO modified by the initiator 2 The initiator in the nanoparticles is 2-bromoisobutyryl bromide or a compound shown in (I),

[0034]

[0035] Wherein, n≥3, R is an ethoxy group or a chlorine atom;

[0036] The first mixed solution is subjected to deoxidation treatment, and CuX is added to obtain a reaction raw material solution, and the CuX 2 and X in CuX is Cl or Br;

[0037] Deoxidize the reaction raw ...

Embodiment 1

[0060] When the initiator modified SiO 2 Preparation of initiator-modified SiO2 when the initiator in the nanoparticles is 2-bromoisobutyryl bromide 2 Nanoparticles:

[0061] Mix 100ml of absolute ethanol, ammonia water and tetraethyl orthosilicate (TEOS) (NH 3 , H 2 (0, TEOS concentration is respectively 0.6mol / L, 1.7mol / L, 0.1mol / L), stirred at room temperature for 24h, obtained white transparent sol, centrifuged, washed with absolute ethanol, obtained the first product;

[0062] Disperse the first product in absolute ethanol, mix it with the silane coupling agent 3-aminopropyltrimethoxysilane under the catalysis of ammonia water, stir at 60°C for 12 hours, centrifuge and wash with toluene to obtain the first product Second product;

[0063] Disperse the second product in anhydrous toluene, add triethylamine, add 2-bromoisobutyryl bromide dropwise while stirring in an ice-water bath, stir at room temperature for 12 hours after 0.5h, centrifuge and wash with toluene, and ...

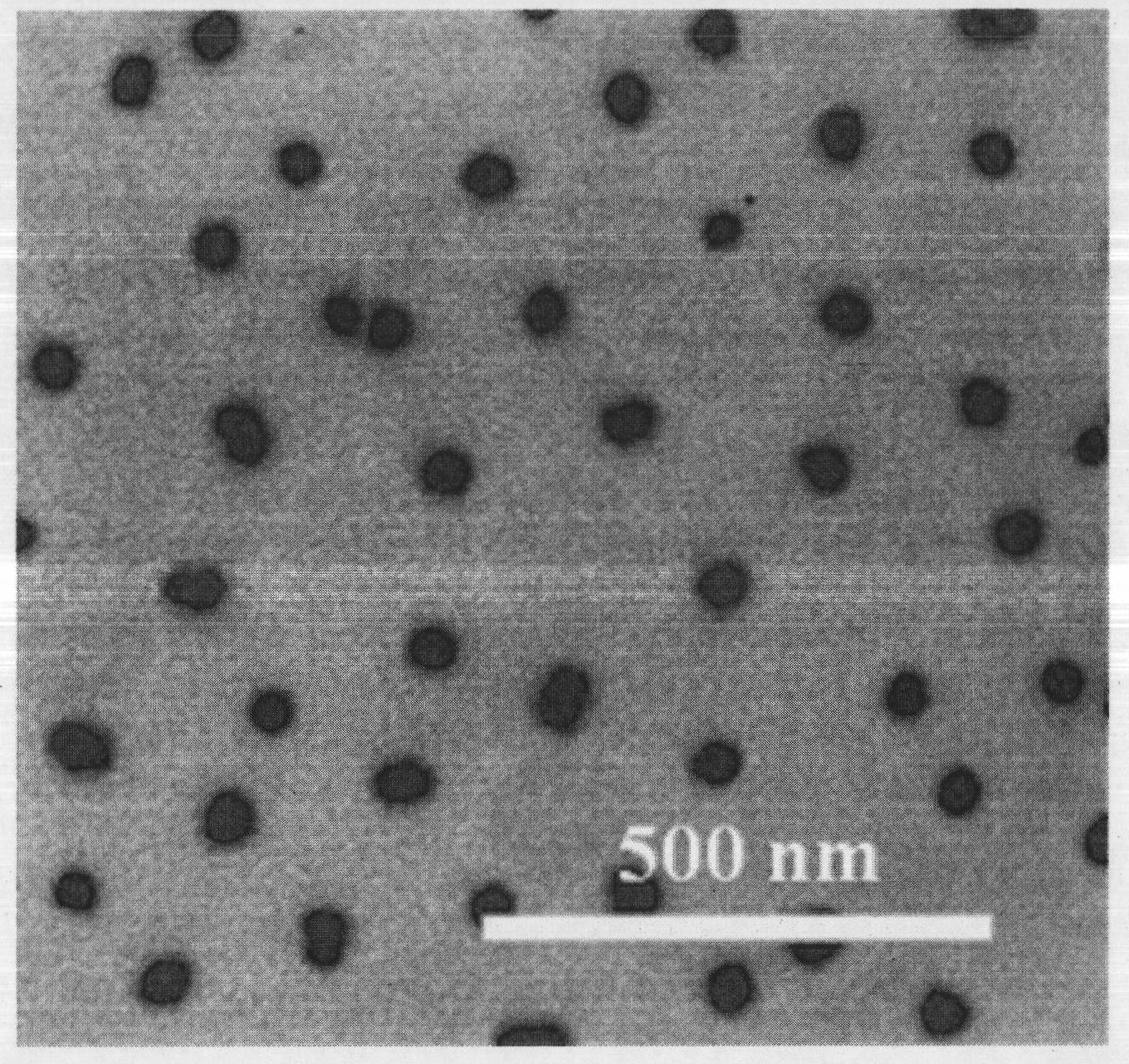

Embodiment 2

[0065] When the initiator modified SiO 2 Preparation of initiator-modified SiO2 when the initiator in the nanoparticles is 2-bromodimethylhexylpropionate triethoxysilane2 Nanoparticles:

[0066] At 0°C, 2-bromoisobutyryl bromide (63mL, 510mmol) was added dropwise to 5-hexenyl-1-ol (43g, 430mmol), triethylamine (71mL, 510mmol) and anhydrous tetrahydrofuran (1L) In the mixed solution, after stirring for 3 hours, stir at room temperature for 10 hours, filter the reaction solution with suction, distill the filtrate under reduced pressure, dilute the residue with chloroform (500 mL), and wash twice with 1 mol / L hydrochloric acid, saturated sodium bicarbonate, and deionized water , dry and suction filter over anhydrous sodium sulfate, and finally pass through a silica gel column (n-hexane / ethyl acetate with a volume ratio of 15 / 1 as eluent) to obtain transparent liquid 2-bromodimethylpropionate 5-hexenyl ;

[0067] Add 5-hexenyl 2-bromodimethylpropionate (40g, 160mmol) into a two-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com