Method for preparing thionyl chloride

A technology of thionyl chloride and chlorine gas, applied in the direction of thionyl chloride, sulfur and halogen compounds, etc., can solve problems such as complicated process, and achieve the effects of improving product yield, strong system safety and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

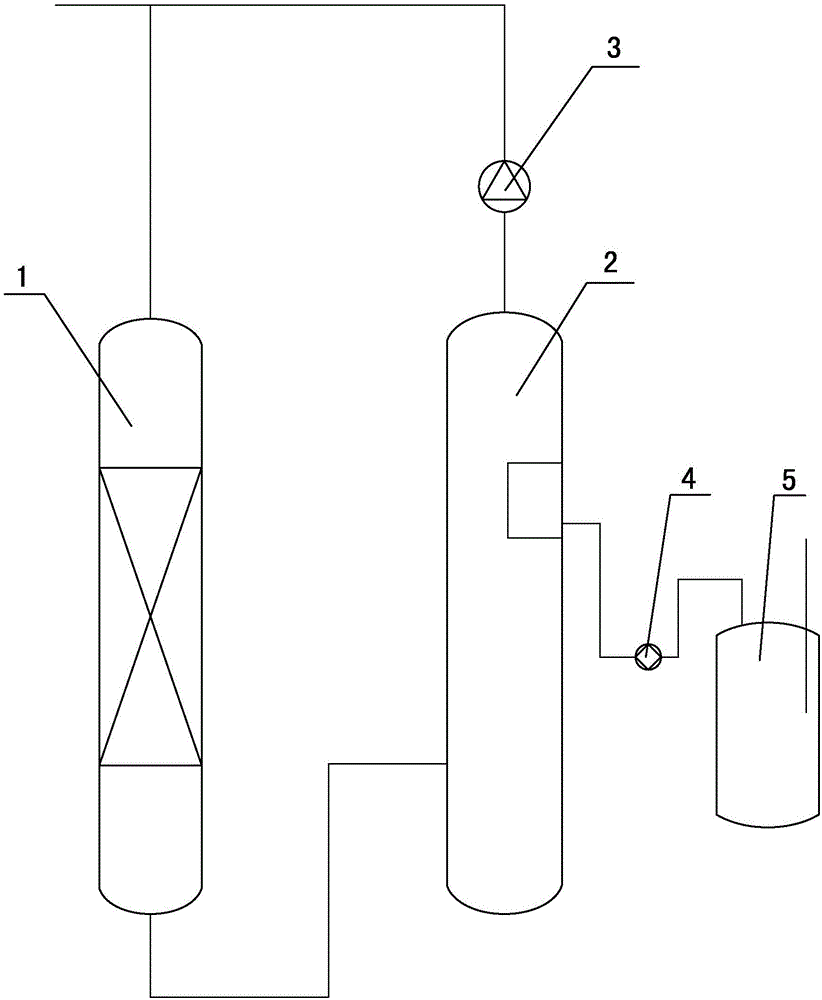

Image

Examples

Embodiment 1

[0016] The raw material mixture gas composed of sulfur dioxide, chlorine and sulfur dichloride enters from the upper part of the reactor, the gas phase of the crude thionyl chloride directly enters the rectification tower from the lower part of the reactor, and the gas phase at the top of the rectification tower is circulated back to the reactor, and the rectification tower The product is extracted from the middle part, and the product enters the blowing tank to blow off the light component with nitrogen to obtain a qualified product; the pressure of the reactor and the rectification tower are both normal pressure, the temperature of the reactor is 101 °C, and the temperature of the rectification tower top is The gas phase is circulated by fan control, and a liquid accumulator is installed in the middle of the rectification tower. The temperature of the liquid accumulator is controlled at 77°C, and the temperature of the rectification tower is 135°C. The product yield is 99.97%...

Embodiment 2

[0018] The raw material mixture gas composed of sulfur dioxide, chlorine and sulfur dichloride enters from the upper part of the reactor, the gas phase of the crude thionyl chloride directly enters the rectification tower from the lower part of the reactor, and the gas phase at the top of the rectification tower is circulated back to the reactor, and the rectification tower The product is taken out in the middle, and the product enters the blowing tank to blow off the light components with nitrogen to obtain qualified products; the pressure of the reactor and the rectifying tower are both normal pressure, the temperature of the reactor is 200 °C, and the temperature of the rectifying tower top is The gas phase is circulated by fan control, and a liquid accumulator is installed in the middle of the rectification tower. The temperature of the liquid accumulator is controlled at 76°C, and the temperature of the rectification tower tank is 110°C. The product yield is 99.96%.

Embodiment 3

[0020] The raw material mixture gas composed of sulfur dioxide, chlorine and sulfur dichloride enters from the upper part of the reactor, the gas phase of the crude thionyl chloride directly enters the rectification tower from the lower part of the reactor, and the gas phase at the top of the rectification tower is circulated back to the reactor, and the rectification tower The product is taken out in the middle, and the product enters the blowing tank to blow off the light components with nitrogen to obtain qualified products; the pressure of the reactor and the rectification tower are both normal pressure, the temperature of the reactor is 395 °C, and the temperature of the top of the rectification tower The gas phase is circulated by fan control, and a liquid accumulator is installed in the middle of the rectification tower. The temperature of the liquid accumulator is controlled at 78°C, and the temperature of the rectification tower is 130°C. The product yield is 99.96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com