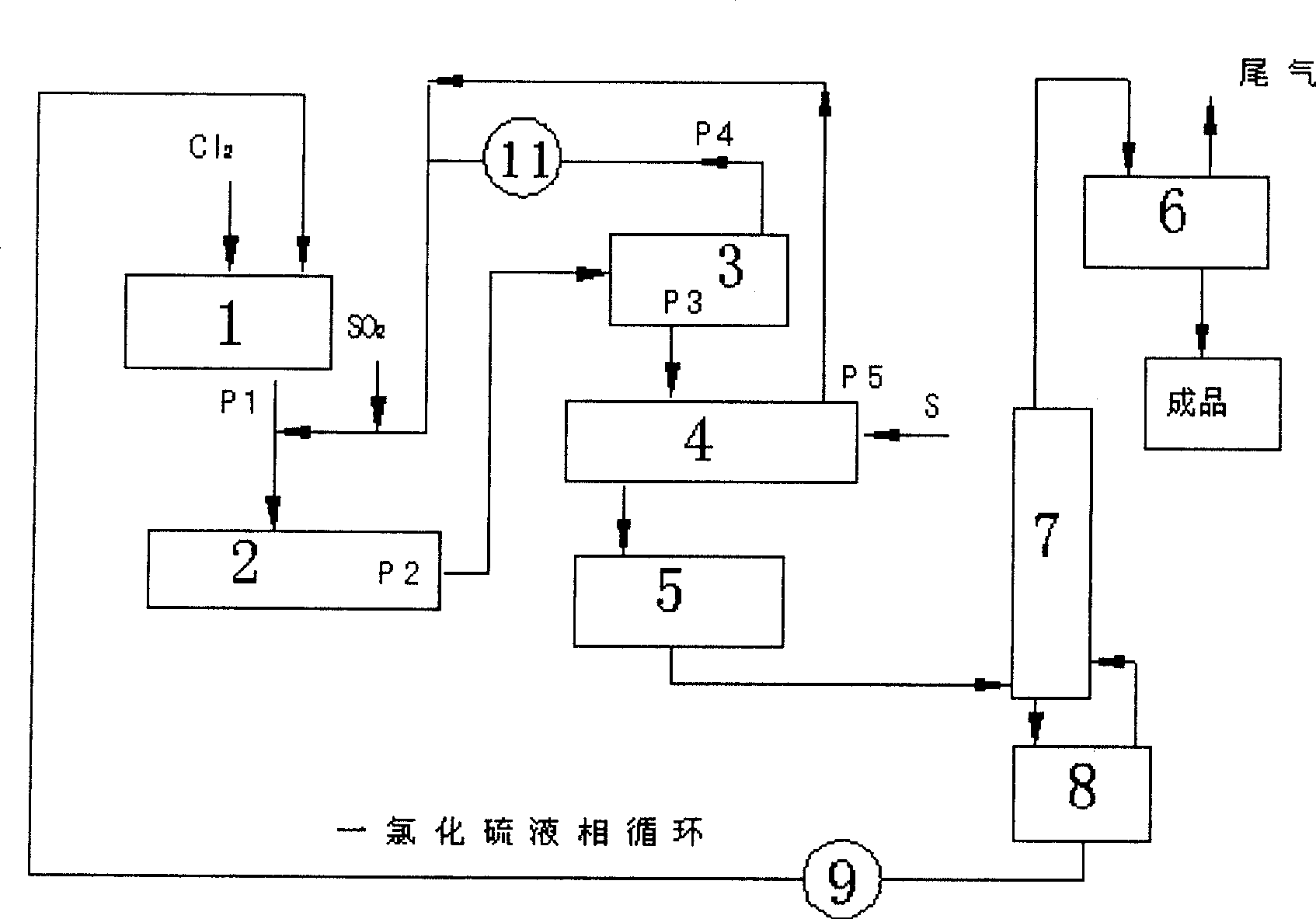

Gas phase circulation method in synthesis of thionyl chloride

A technology of thionyl chloride and gas phase circulation, which is applied in the direction of sulfur and halogen compounds, and can solve problems such as difficult separation, complicated process, and difficult to obtain high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

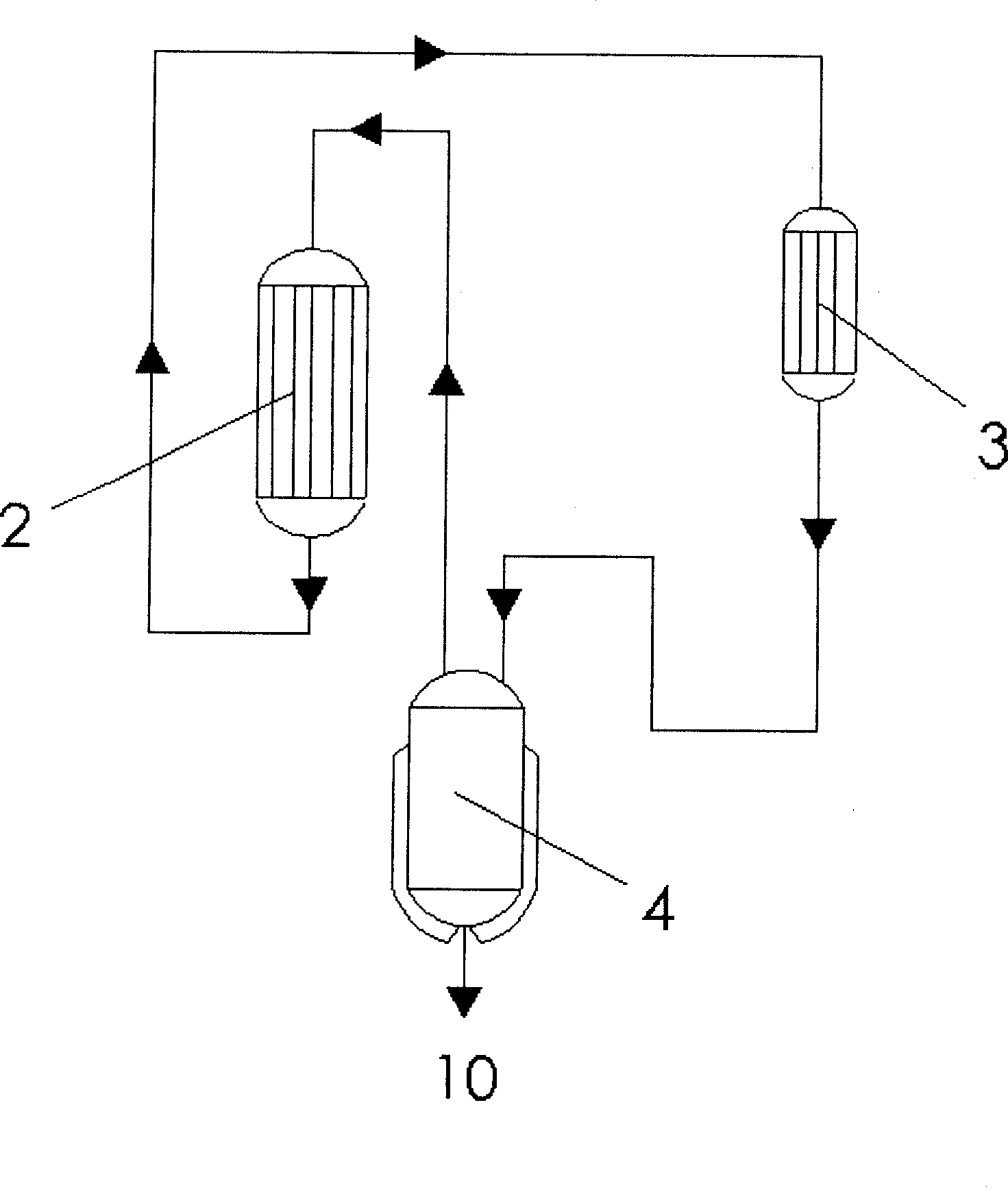

[0084] This embodiment is to describe the method of using the gas released from the crude product condenser as a part of the source of synthesis gas for thionyl chloride in the present invention, and then enter the thionyl chloride synthesis reactor for recycling, thereby completing the gas phase cycle. The method includes :

[0085] (1) The crude product sulfur oxychloride whose content of sulfur oxychloride accounts for 68% of the crude product sulfur oxychloride total amount is vulcanized in a vulcanization kettle, and also contains 15% sulfur dichloride in the crude product sulfur oxychloride , the temperature in the vulcanization kettle is 78°C of the residual temperature of the crude product thionyl chloride, and the pressure is normal pressure. To the crude product thionyl chloride, no excess sulfur is added relative to the sulfur dichloride therein, and the amount of sulfur added is For 80% of the amount of sulfur required for the complete reaction with sulfur dichlori...

Embodiment 2

[0095] This embodiment is to describe the method of using the gas extracted from the crude product degassing and purification kettle as a part of the raw material source of the thionyl chloride synthesis gas in the present invention, and re-entering the thionyl chloride synthesis kettle 2 for recycling, thereby completing the gas phase cycle. . The method is as follows:

[0096] As described in step (5) of Example 1, the mixed gas of thionyl chloride is condensed in the crude product condenser at 38°C, and the content of thionyl chloride in the obtained condensed product is 65%. The sulfur content is 25%, and the chlorine gas is 10%. The condensed product is degassed and purified in the crude product degassing purification kettle at a temperature of 90°C and a pressure of 0.02Mpa to obtain the crude product sulfur oxychloride, the crude product sulfur oxychloride Then proceed to the next cycle. And the SO released from the degassing purification kettle 2 content of 25%, chl...

Embodiment 3

[0098] This embodiment is to describe the method of using the gas discharged from the rectification tower as a part of the source of synthesis gas for thionyl chloride in the present invention, and then enter the thionyl chloride synthesis tank for recycling, thereby completing the gas phase cycle. The method is as follows:

[0099] As described in embodiment 1 step (2), the crude product sulfur oxychloride after sulfidation carries out rectification in rectification tower, obtains sulfur oxychloride and mixed high boiler and tail gas, and the gas contained in this tail gas has Sulfur dioxide (about 45%), thionyl chloride (about 45%), chlorine (about 2%), and other non-condensable gases (about 8%). The mixed high boilers are discharged from the tower directly to the kettle, and then the mixed high boilers are sent to the sulfur dichloride synthesis kettle through a pump to complete the liquid phase circulation. The tail gas is mainly sulfur dioxide and chlorine, which are sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com