Preparation method of high-content thiodicarb

A technology with high content of thiodicarb, applied in botany equipment and methods, insecticides, animal repellents, etc., can solve the problems of difficult source of raw materials, long production cycle, low production efficiency, etc., and achieve the reduction of occupational safety The effect of health hazard risk, reducing environmental pressure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

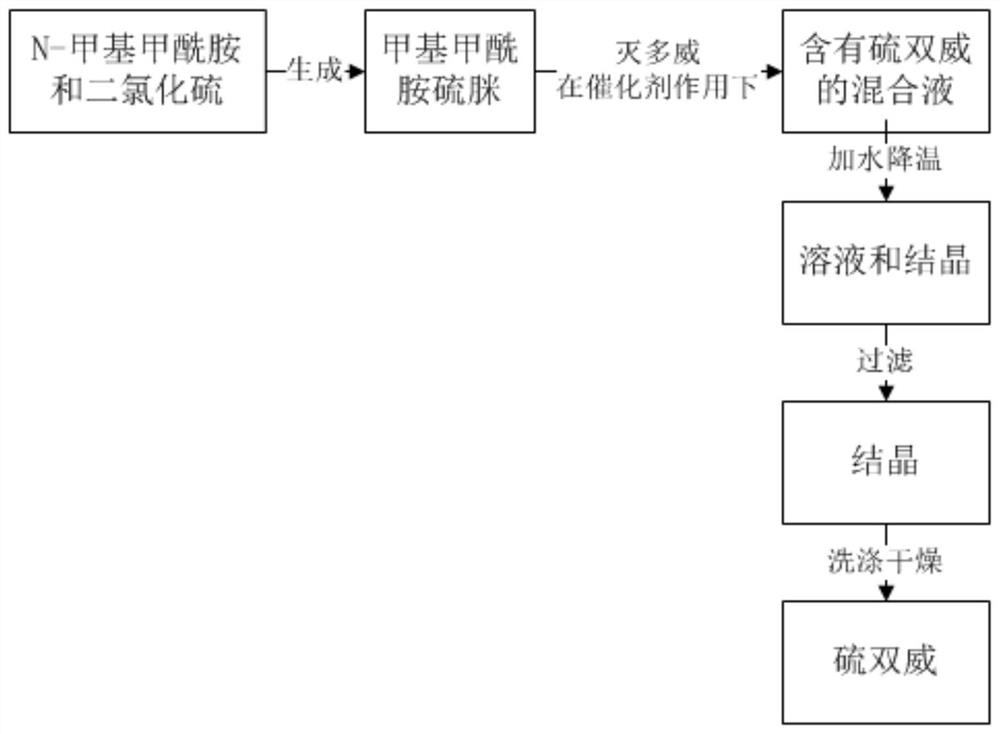

[0028] The invention provides a method for preparing high-content thiodicarb, using N-methylformamide and sulfur dichloride as raw materials to generate methylformamide thiamidine,

[0029] Using the methylformamide thiamidine and methomyl as raw materials under the action of a catalyst, carry out condensation reaction in a high shear emulsifier to generate a mixed solution containing thiodicarb, add water to the mixed solution to cool down, and obtain solutions and crystals, filtering solutions and crystals,

[0030] washing the filtered crystals, centrifugally filtering the crystals and detergent, and drying the centrifugally filtered crystals to obtain thiodicarb.

[0031] On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com