Patents

Literature

68results about How to "Facilitate mixed reactions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength and high-ductility magnesium alloy capable of being dissolved rapidly and preparation method thereof

ActiveCN110184518AHigh strength and high elongation mechanical strength propertiesIncrease speedFluid removalSealing/packingDuctilityWater soluble

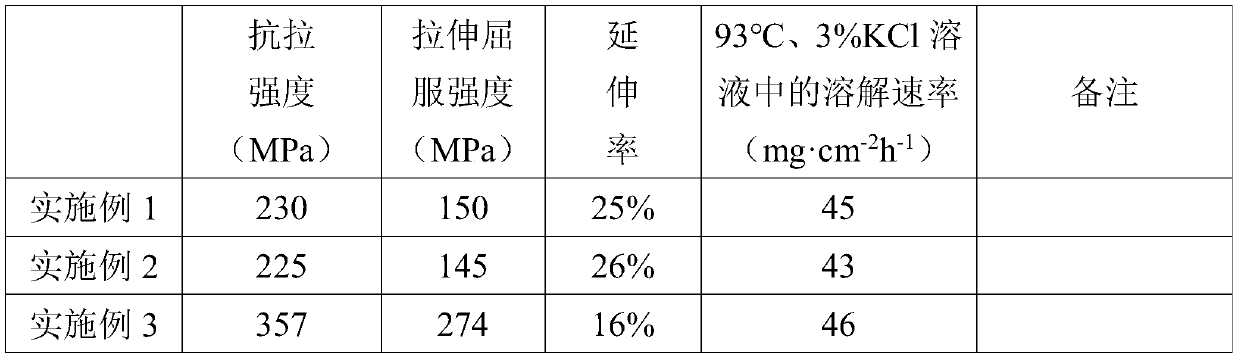

The invention provides a high-strength and high-ductility magnesium alloy capable of being dissolved rapidly and a preparation method thereof. The high-strength and high-ductility magnesium alloy capable of being dissolved rapidly comprises, by mass, 1.0%-22.0% of Gd, 0.001%-5.0% of Y, 0.001%-10% of Al, 0.001%-5.0% of Zn, 0.01%-1.0% of Zr, 0.0001%-1.0% of Sc, 0.01%-10.0% of Cu, 0.01%-3.0% of Li, 0.01%-3.0% of Ni, 0.01%-3.0% of Ga, 0.01%-3.0% of In, and the balance Mg and impurities, wherein the total content of Li, Ga and In is 0.1%-6.0%. The high-strength and high-ductility magnesium alloy capable of being dissolved rapidly can react with a water-soluble medium rapidly so as to be dissolved, has the mechanical strength properties of high strength and high ductility, and can meet the application requirements in various industrial fields.

Owner:FIVE STAR DOWNHOLE SERVICE INC

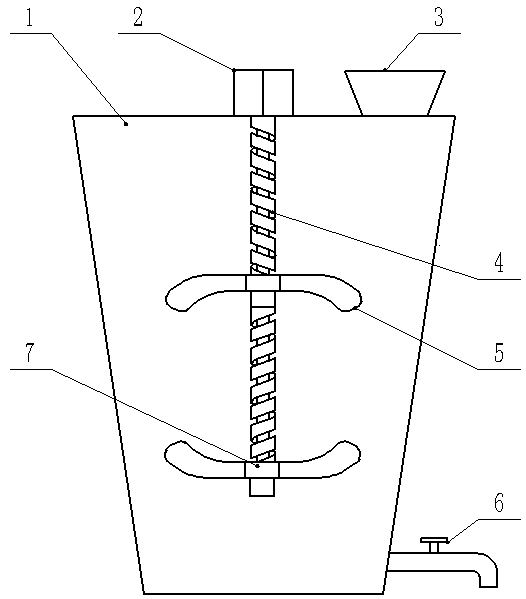

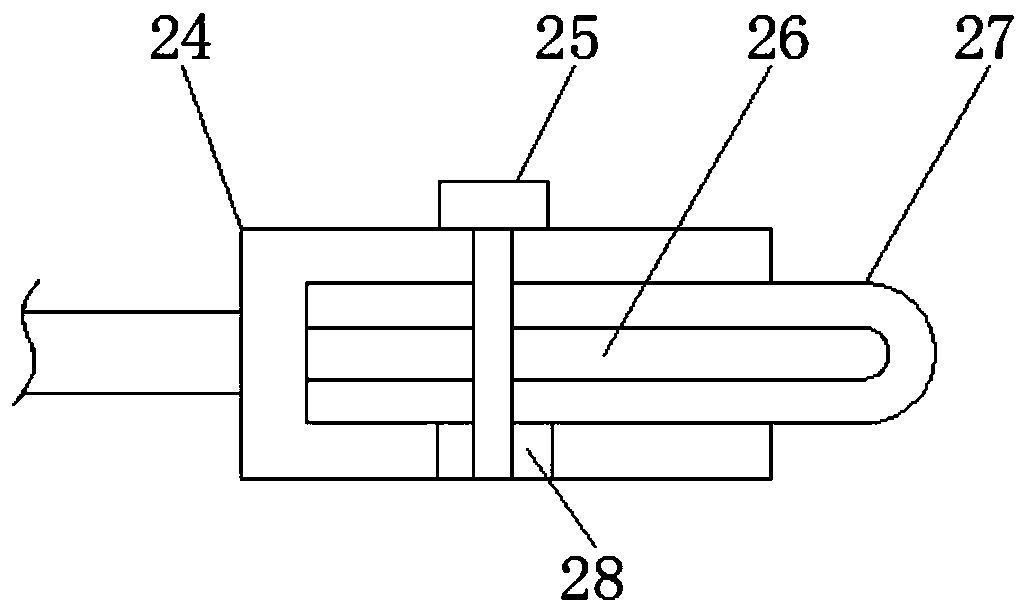

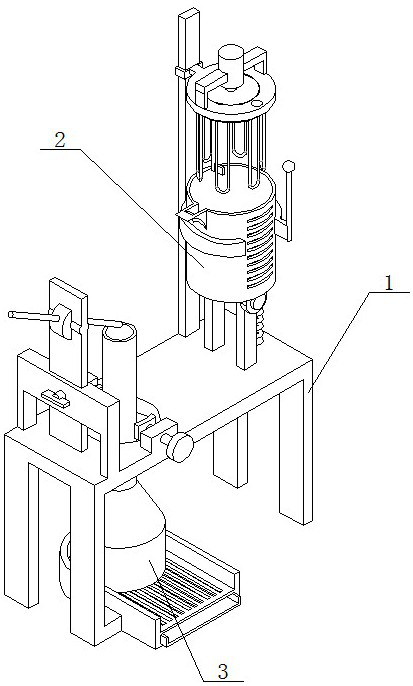

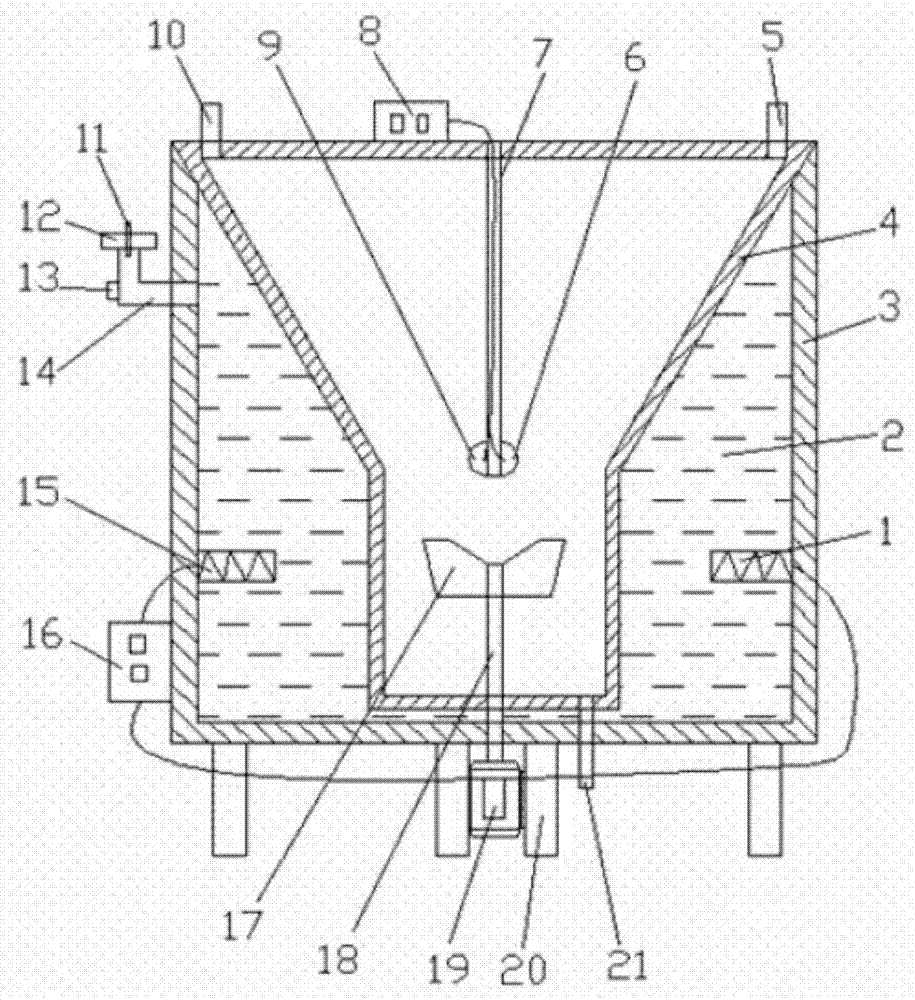

Chemical reaction stirring device with solid-liquid separation feeding way

InactiveCN107551955AResidue reductionImprove feeding efficiencyWithdrawing sample devicesChemical/physical/physico-chemical stationary reactorsChemical reactionEngineering

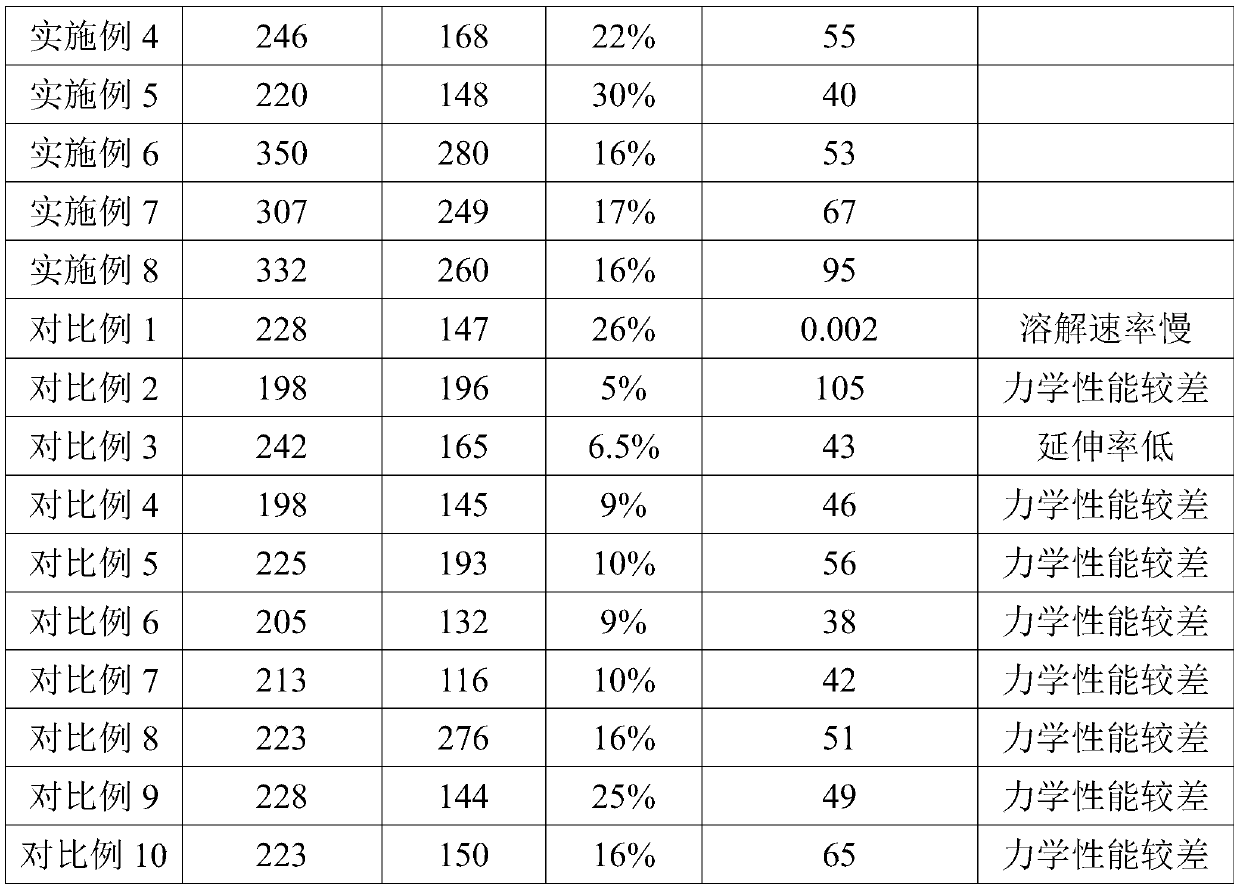

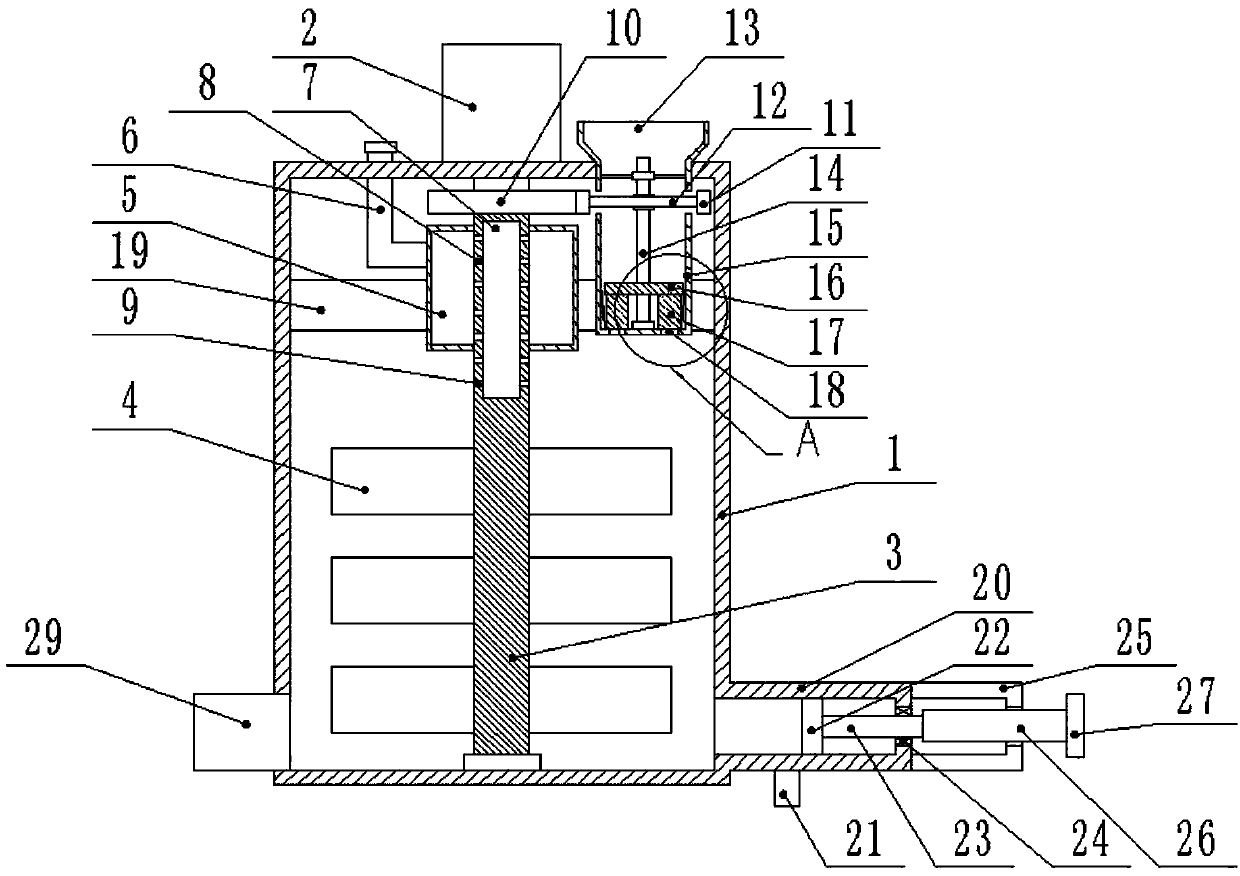

The invention discloses a chemical reaction stirring device for solid-liquid separation and feeding, which comprises a shell, a motor, a stirring shaft and a stirring blade; one, uniformly and fixedly installed on the side wall of the stirring shaft; the upper end of the stirring shaft is provided with a communication chamber, and the outer side of the stirring shaft corresponding to the communication chamber is provided with a liquid inlet tank; the top of the housing is also equipped with a solid The feeding structure is connected with a sampling device at the bottom of the shell. The invention feeds the liquid and the solid separately, so that the solid and the liquid can be mixed inside at the same time, which improves the feeding efficiency, shortens the reaction production time, and does not react at the feed port, and also reduces the material at the feed port. Residue, the device is convenient for sampling and easy to operate; the device is safe and stable, fully mixed, the mixing effect is good, and the production efficiency is improved.

Owner:李云

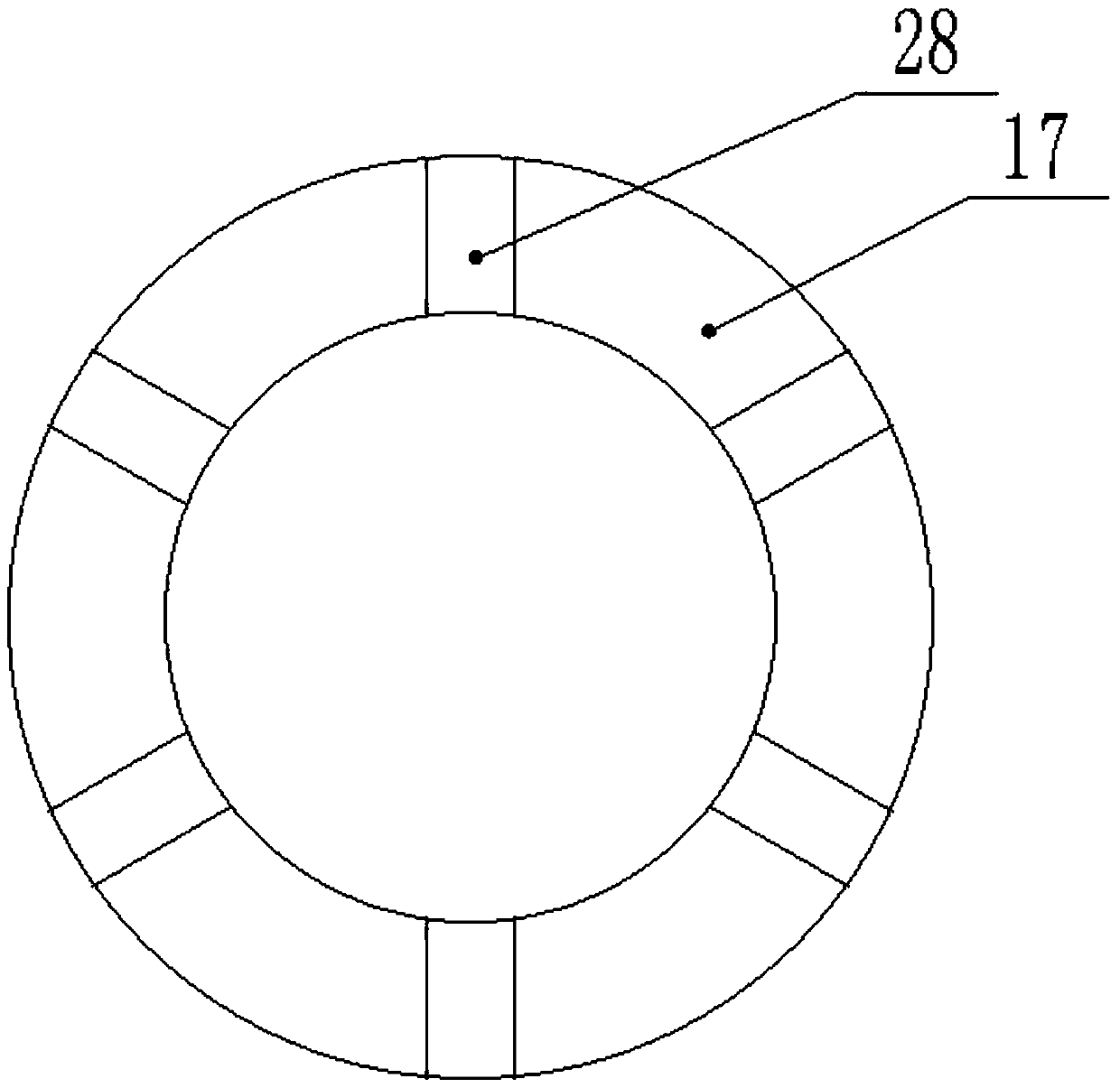

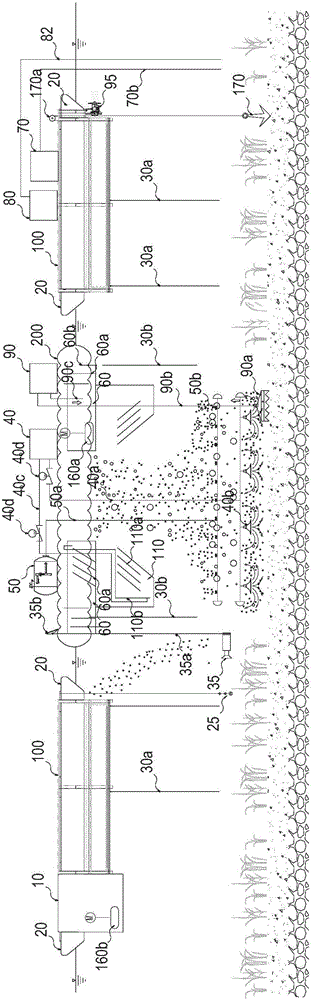

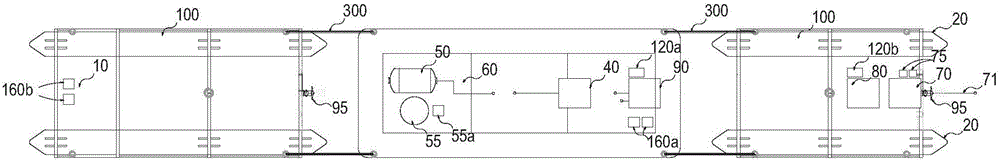

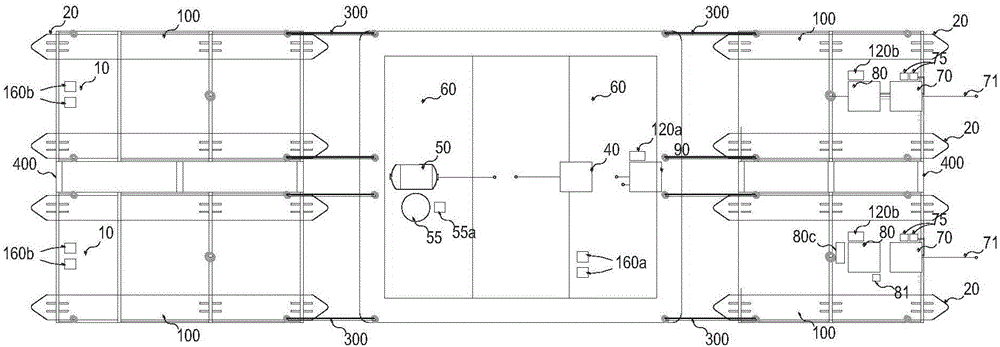

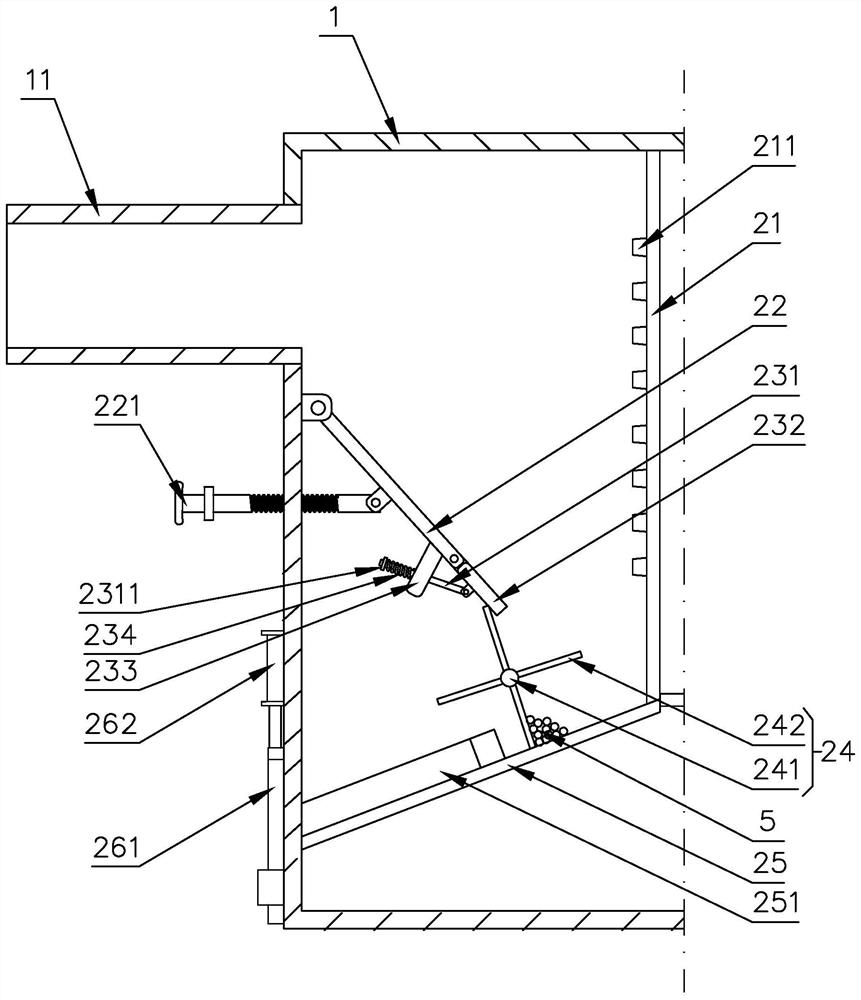

Floating type device riverway bottom pollutant removing and purifying device and method

ActiveCN105948390AAvoid redissolutionFacilitate mixed reactionsWater treatment parameter controlMultistage water/sewage treatmentHigh concentrationEnvironmental engineering

The invention relates to a floating type device riverway bottom pollutant removing and purifying device and method. The device comprises one or more front end devices provided with a microorganism carrier module, a settling pond, a pollution isolating film and a sensor, one or more rear end devices provided with a microorganism carrier module cover, a pollution isolation film, a microorganism culture supply device, a high-concentration oxygen dissolving device and a floater, and a middle device comprising a primary sediment collecting device, a secondary sediment collecting device, a pressurized air spraying device, a small bubble generating device, an underwater camera, a pollution isolation film and a floater. The device can float on the surface of different water bodies such as rivers, lakes, river water and oceans to remove suspended solids, sediment and pollutant bottom mud in water, and the water ecological restoration problem is fundamentally solved.

Owner:上海中韩术环境科技有限公司 +2

Efficient oil removal device for rare earth material liquid

ActiveCN107164645AGood degreasingHigh oil removal efficiencyProcess efficiency improvementRare earthBilateral symmetry

The invention relates to an oil removal device, in particular to an efficient oil removal device for rare earth material liquid. The efficient oil removal device for the rare earth material liquid comprises large L-shaped supports, a material liquid conveying device, a rotating device, a top pipe, a connecting pipe and the like, wherein the material liquid conveying device is arranged on one large L-shaped support, the rotating device is arranged between the large L-shaped supports in bilateral symmetry, the top pipe is arranged above the rotating device, the left end of the connecting pipe is connected with the right side wall of the top pipe in a welding mode, and the connecting pipe communicates with the top pipe. According to the efficient oil removal device for the rare earth material liquid, by combining the material liquid conveying device and the rotating device, high-efficiency oil removal can be carried out on the rare-earth material liquid, and the oil removal work efficiency is high.

Owner:XUZHOU NANFANG YONGCI MATERIAL

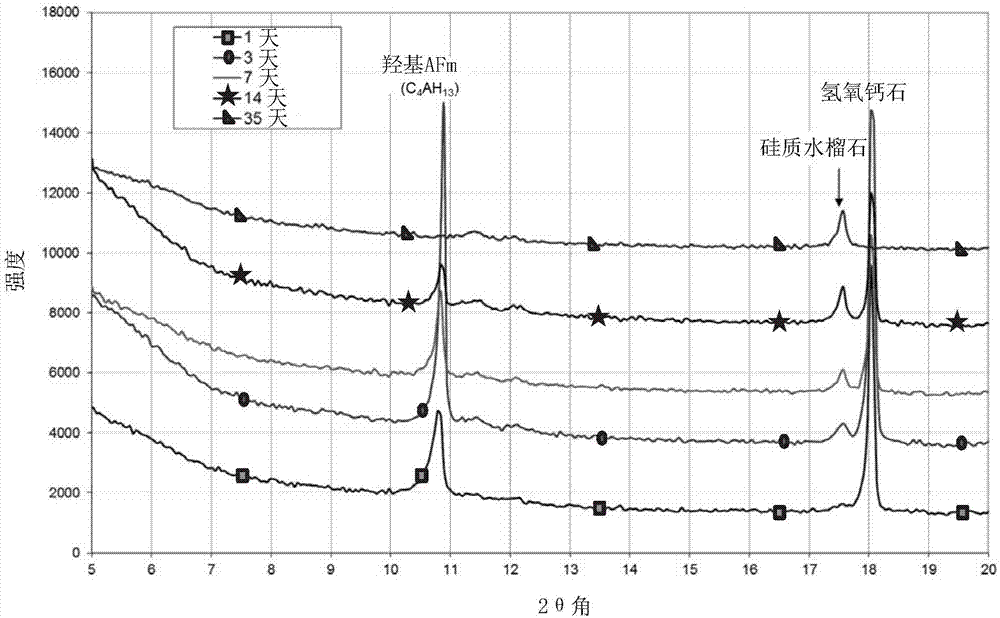

Low density cementitious compositions for use at low and high temperatures

InactiveCN107531570AReduce churnReduce free waterSolid waste managementDrilling compositionLow densitySilicon dioxide

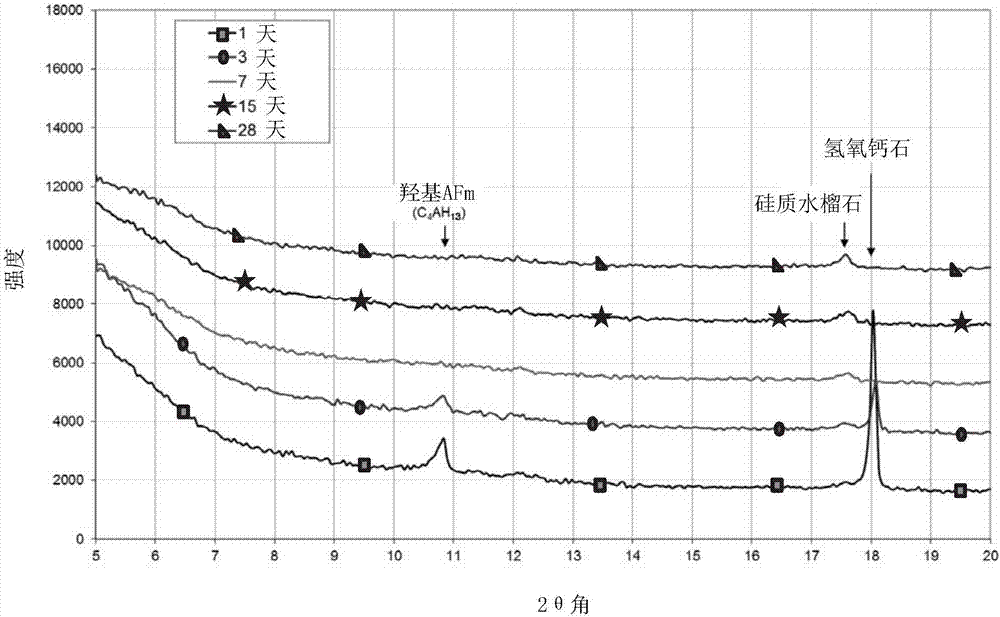

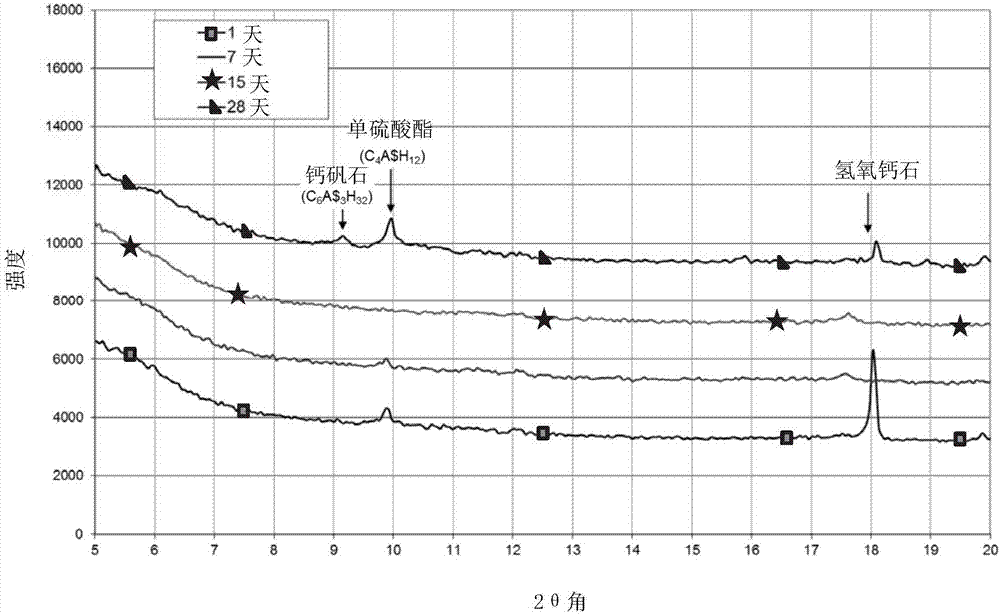

A cementitious binder, includes a hydraulic binder in an amount in the range from 50 to 80% by weight of the cementitious binder; a first siliceous based material in an amount in the range from 0.5 to35% by weight of the cementitious binder, the first siliceous based material having a (SiO2) / (AI2O3) ratio by weight greater than 2.5; a second siliceous based material in an amount in the range from10 to 25% by weight of the cementitious binder, the second siliceous based material being different from the first siliceous based material and having (a) a (SiO2) / (AI2O3) ratio by weight greater than 10 and (b) a BET specific surface area greater than 5m2 / g; and an aluminum based material in the range from 0 to 10% by weight of the cementitious binder and having a (SiO2) / (AI2O3) ratio by weightlower than 2.5, wherein 0.09 < AIEFF / ( AIEFF+SiEFF) < 0.28, where AIEFF = molar content of alumina in the hydraulic binder, and SiEFF = molar content of silica in the first siliceous based material for particles having a size lower than 3 mu m + molar content of silica in the second siliceous based material.

Owner:HOLCIM

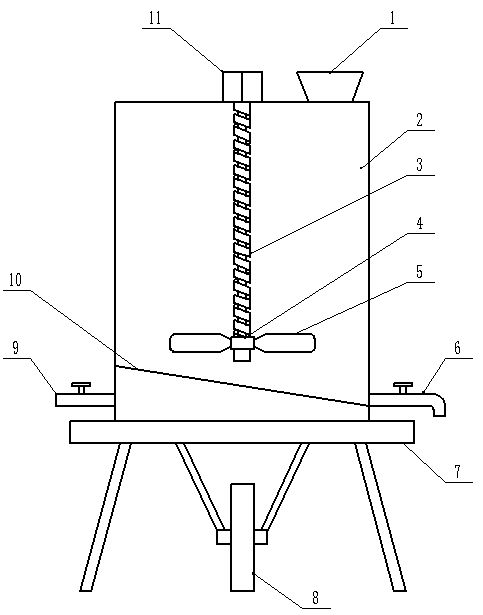

Spiral-flow type water-soluble fertilizer fertilization tank

InactiveCN107750561AWell mixedStir wellManure treatmentSludge spreadersAgricultural engineeringWater soluble

The invention discloses a swirl type water-soluble fertilizer fertilization tank, which comprises a tank body, a feed inlet, a discharge outlet and a stirring device; the feed inlet is arranged above the tank body; the discharge outlet is arranged Below the tank body; the stirring device is located inside the tank body; the stirring device includes a stirring shaft and a stirring blade; the outer wall of the stirring shaft is provided with a threaded groove; the stirring blade Arranged in the upper and lower layers along the axis of the stirring shaft; the stirring paddles are all connected to the stirring shaft through connectors; a motor is arranged above the tank body, and the motor is connected to the stirring shaft. The invention does not need manual mixing, and under the action of the stirring device, the fertilizer can be fully mixed and stirred, and the utilization rate of the fertilizer is improved.

Owner:广西北贸农牧有限公司

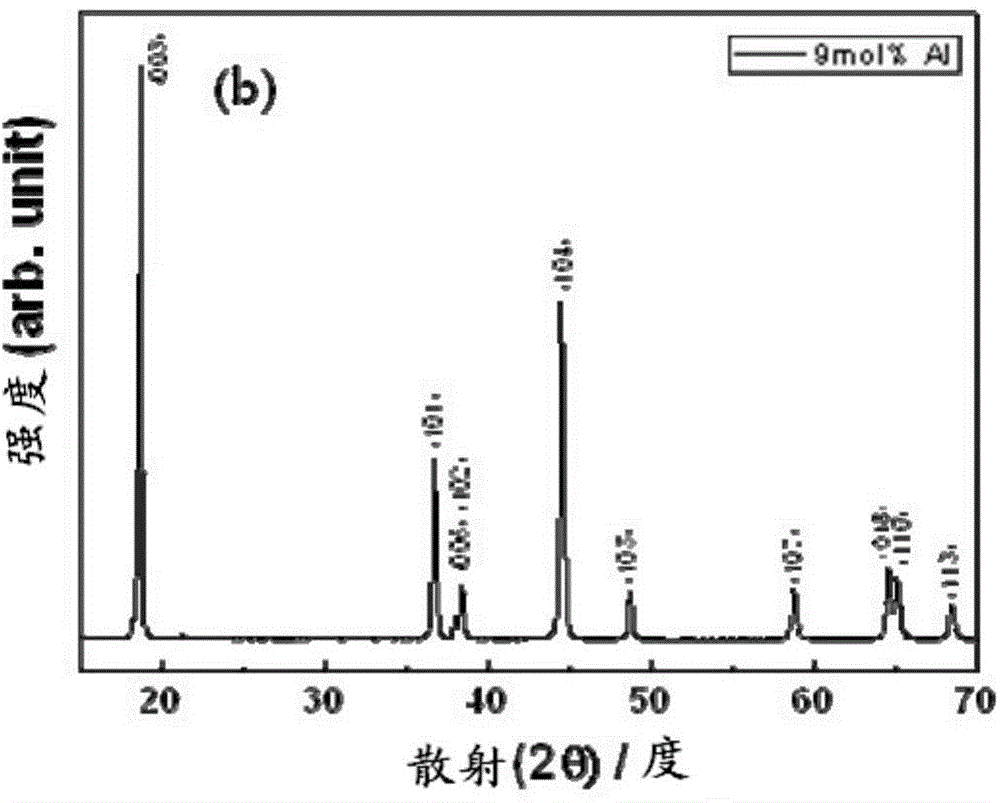

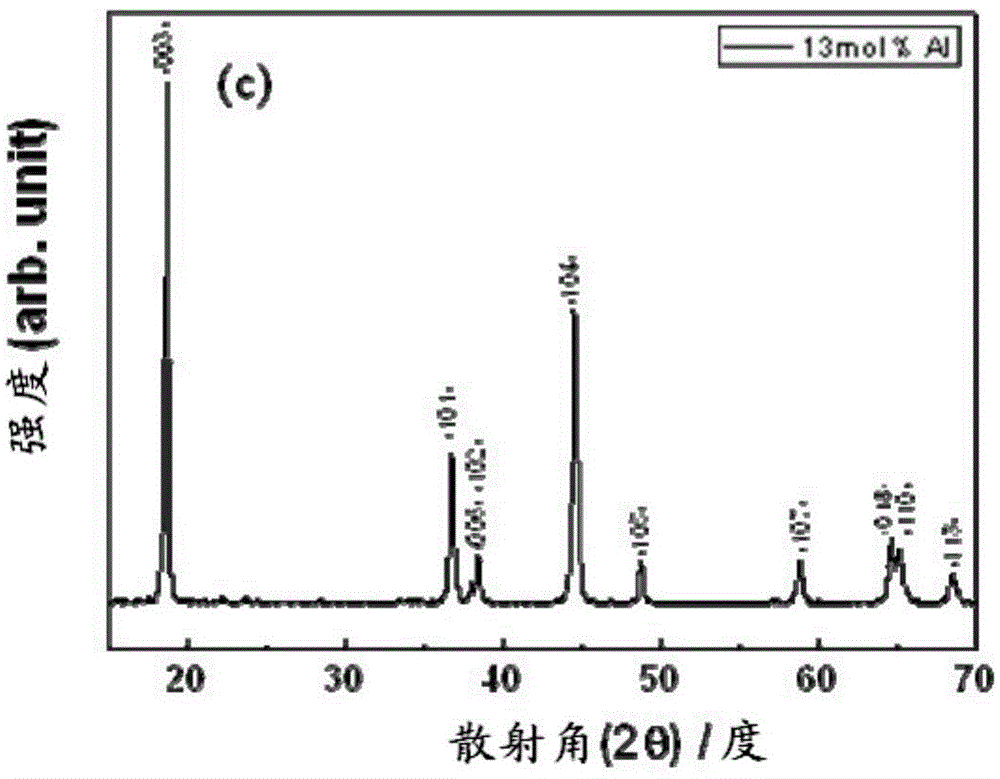

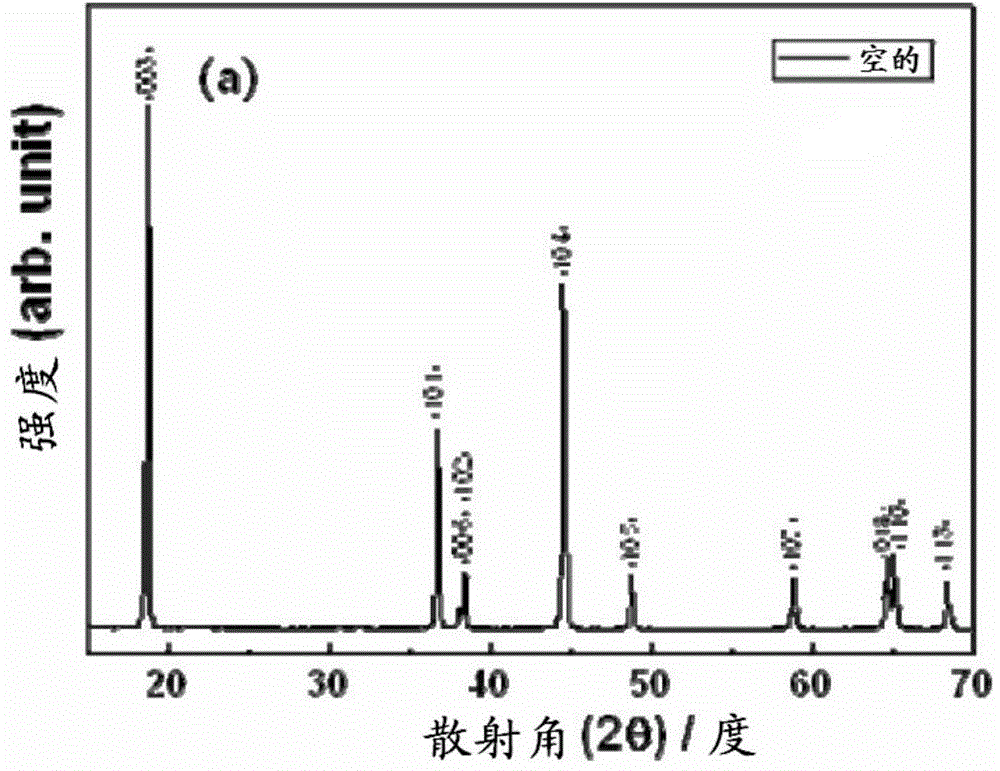

Process for producing layered lithium nickel oxide, and lithium secondary cell employing it

ActiveCN104103826AReduce capacitySolution to short lifeOxide/hydroxide preparationElectrode thermal treatmentIndiumStructural stability

The invention relates to a process for producing a layered lithium nickel oxide, and a lithium secondary cell employing it. The metal oxide for a cathode active material of a lithium secondary battery is capable of having improved structural and thermal stability, high efficiency, high capacity, and excellent cycle property and life span property, the metal oxide represented by the following Chemical Formula 1: [Chemical Formula 1] Li a Ni x Co y M z O 2 (in Chemical Formula 1, M is any one selected from aluminum, magnesium, titanium, gallium and indium, and a, x, y and z satisfy 1.01<=a<=1.05, 0.7<=x<=0.9, 0<=y<=0.17, 0.02<=z<=0.16, and x+y+z=1, respectively).

Owner:SK ON CO LTD

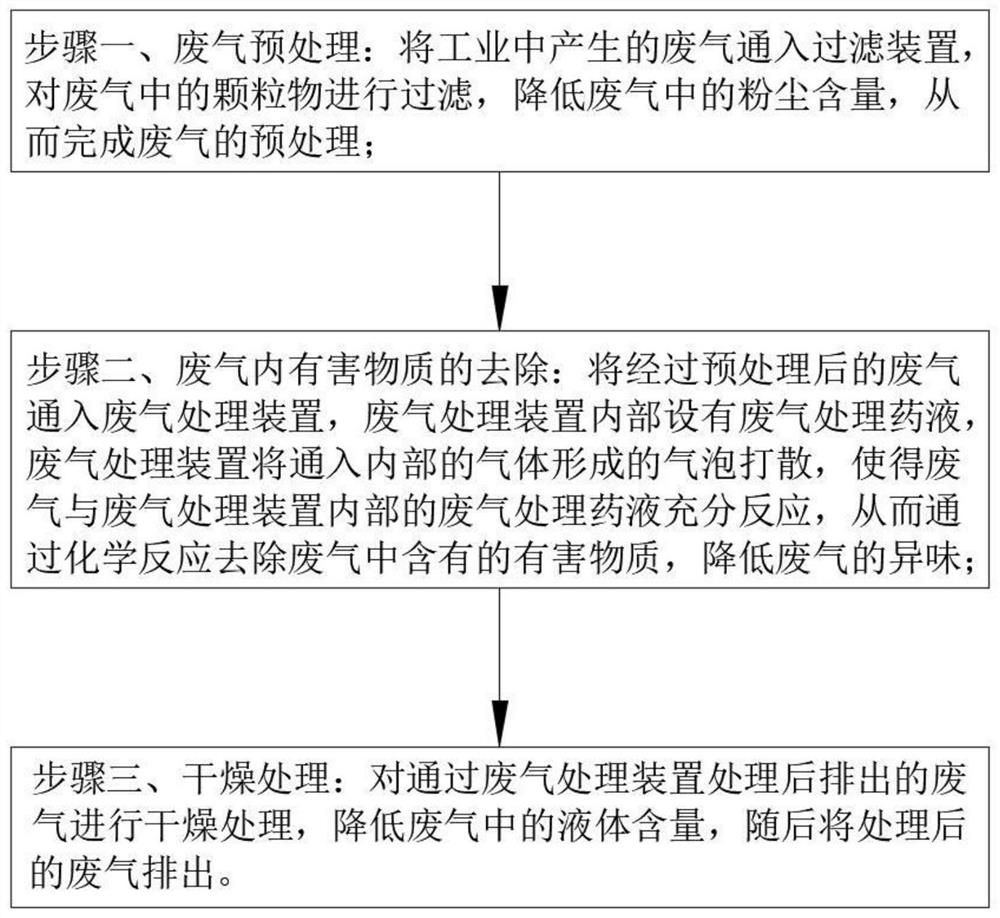

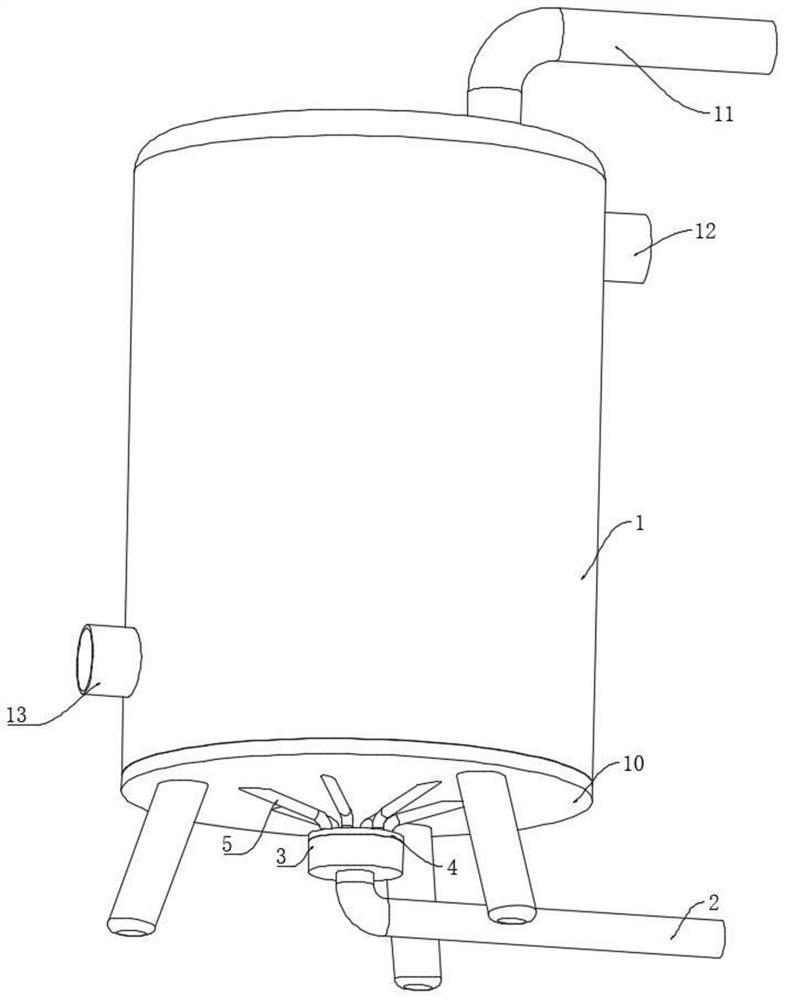

Environment-friendly industrial waste gas treatment process

PendingCN113477064AQuality improvementPromote adequate responseDispersed particle filtrationIndustrial wasteExhaust fumes

The invention relates to the technical field of waste gas treatment, in particular to an environment-friendly industrial waste gas treatment process. A treatment barrel is involved. The treatment process comprises the following step of: 1, waste gas pretreatment: introducing generated industrial waste gas into a filter device, filtering particulate matters in the waste gas, reducing the dust content of the waste gas, and therefore, completing pretreatment of the waste gas. A water inlet pipe can feed waste gas treatment liquid medicine into the treatment barrel to achieve a flow dividing effect, bubbles are more dispersed, the used waste gas treatment liquid medicine is discharged through a drainage pipe, a bubble separation device can spirally separate waste gas input in a concentrated mode, and meanwhile, the waste gas is separated into a large number of dispersed bubbles. Therefore, difficult full contact between the waste gas and the waste gas treatment liquid medicine due to large bubbles formed after the waste gas is introduced is avoided, full reaction between the waste gas and the waste gas treatment liquid through fine bubbles is facilitated, and the waste gas treatment quality is improved.

Owner:马云燕

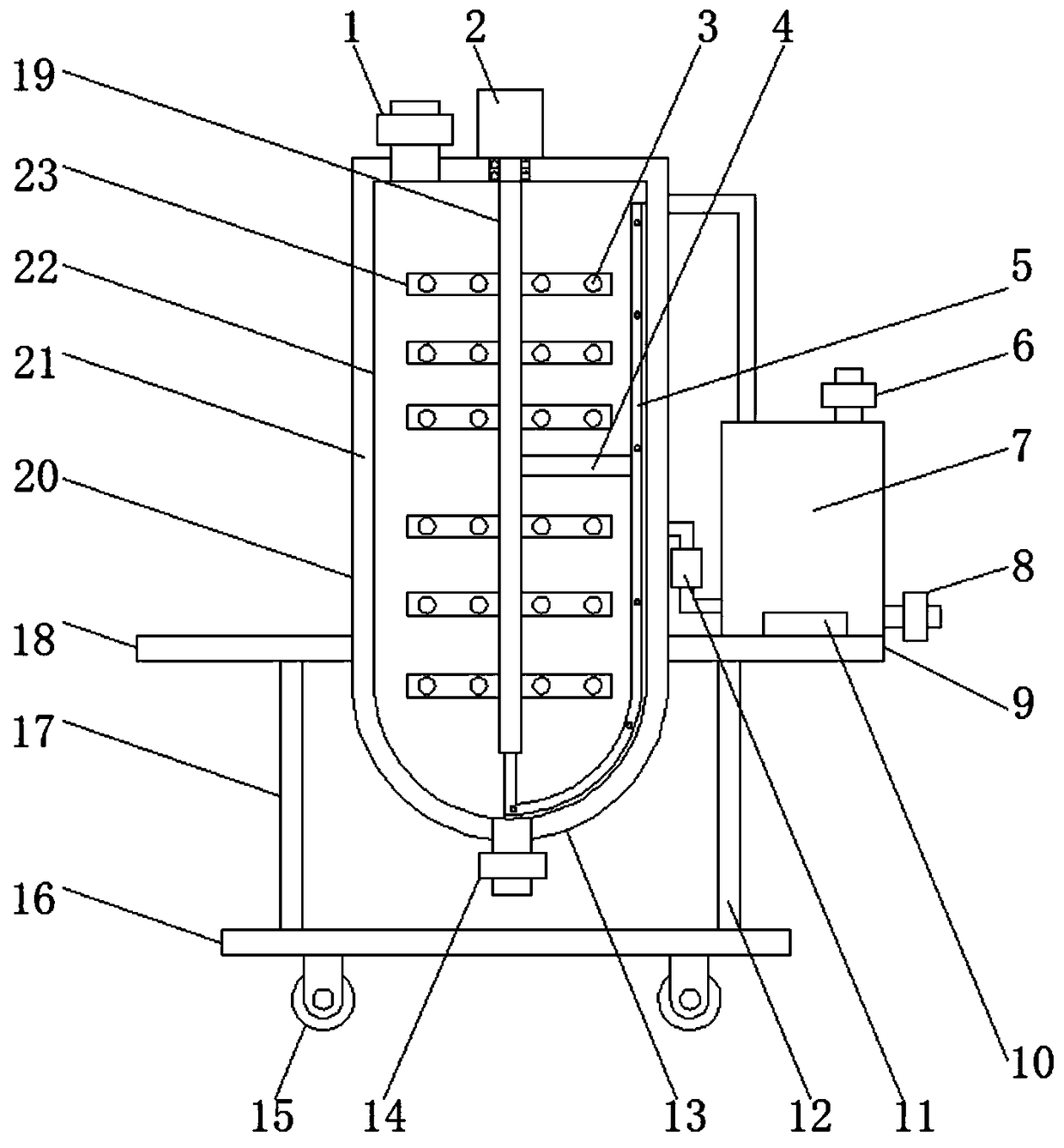

High-viscosity traditional Chinese medicine extract liquid separation device

PendingCN108686603AReduce resistanceReduce loadLiquid degasificationTransportation and packagingWater storage tankEngineering

The invention discloses a high-viscosity traditional Chinese medicine extract liquid separation device. The separation device comprises a first valve, a motor, a connecting rod, a scraping plate, a second valve, a water storage tank, a third valve, a first transverse plate, an electric heating block, a water pump, a first supporting rod, a reaction vessel, a bottom plate, a second supporting rod,a second transverse plate, a stirring rotating shaft and stirring blades. The reaction vessel comprises an outer reaction vessel and an inner reaction vessel, and the outer reaction vessel fixedly sleeves the outer side of the inner reaction vessel. The blades are provided with through holes to reduce resistance in contact of the stirring blades and materials in the reaction vessel, and accordingly operating load of the motor is further reduced, and practicality of the device is improved. The internal scraping plate is driven to rotate to scrape materials adhered on the inner wall of the reaction vessel, difficulty in cleaning due to accumulation is avoided, and practicality of the device is improved. Internal temperature regulation is realized through the water storage tank, and mixed reaction is benefited.

Owner:洛阳伊尹实业有限公司

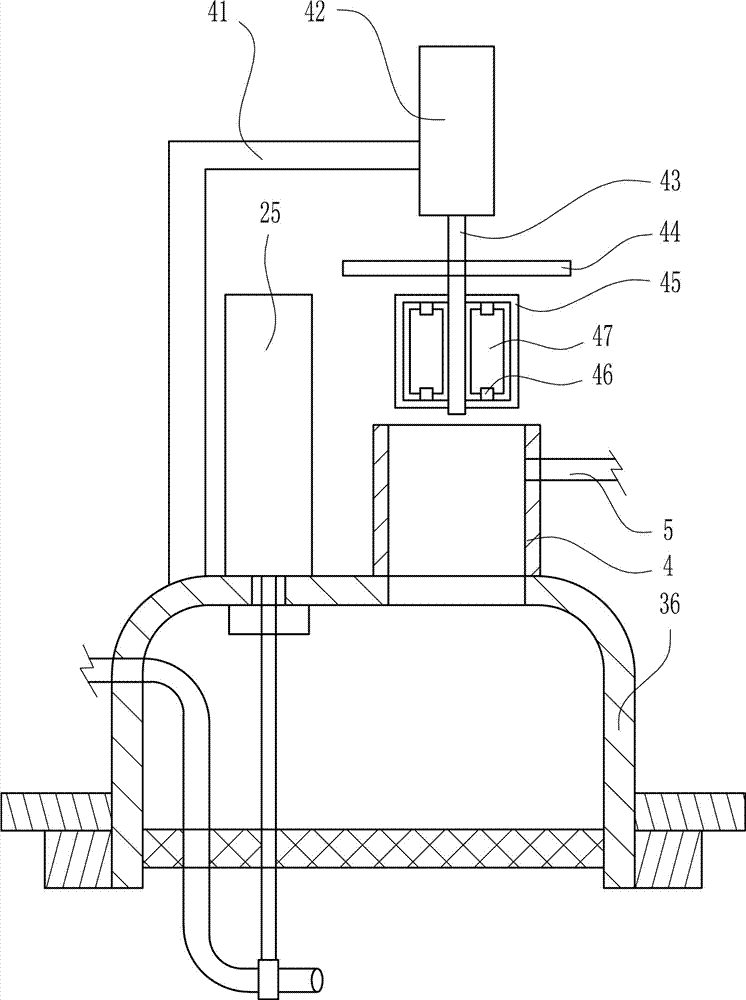

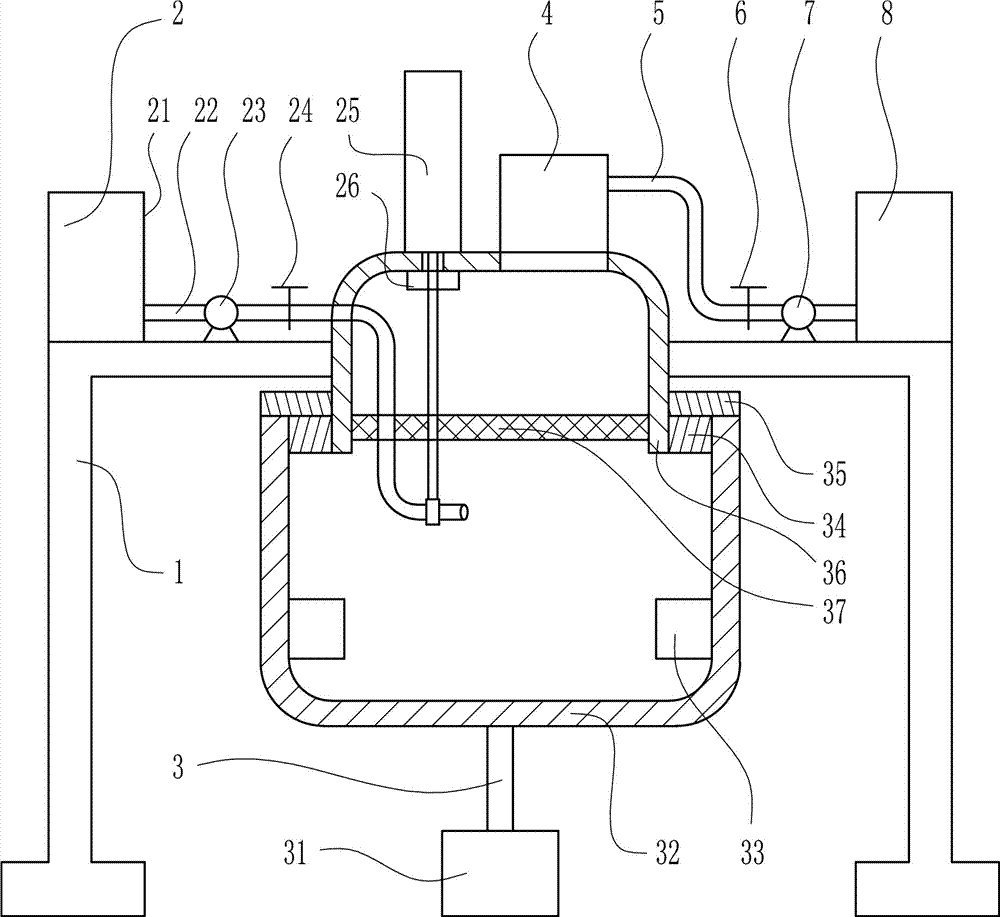

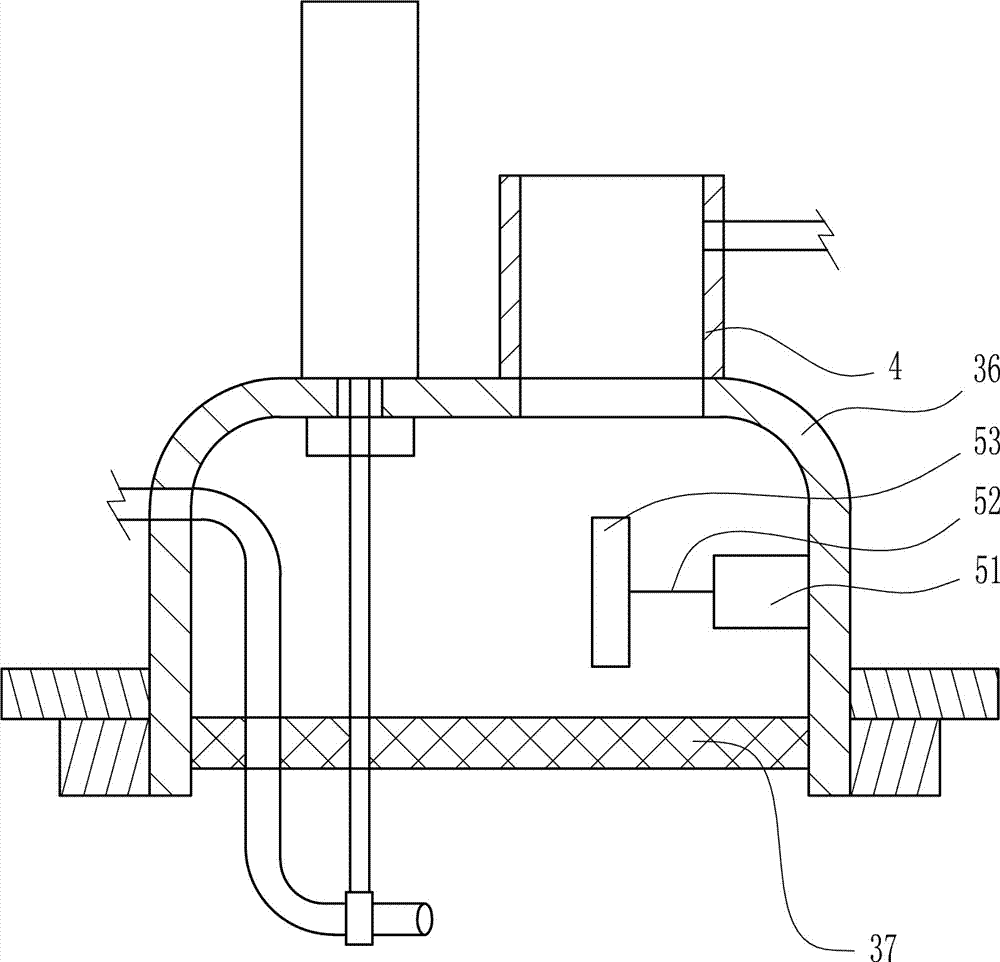

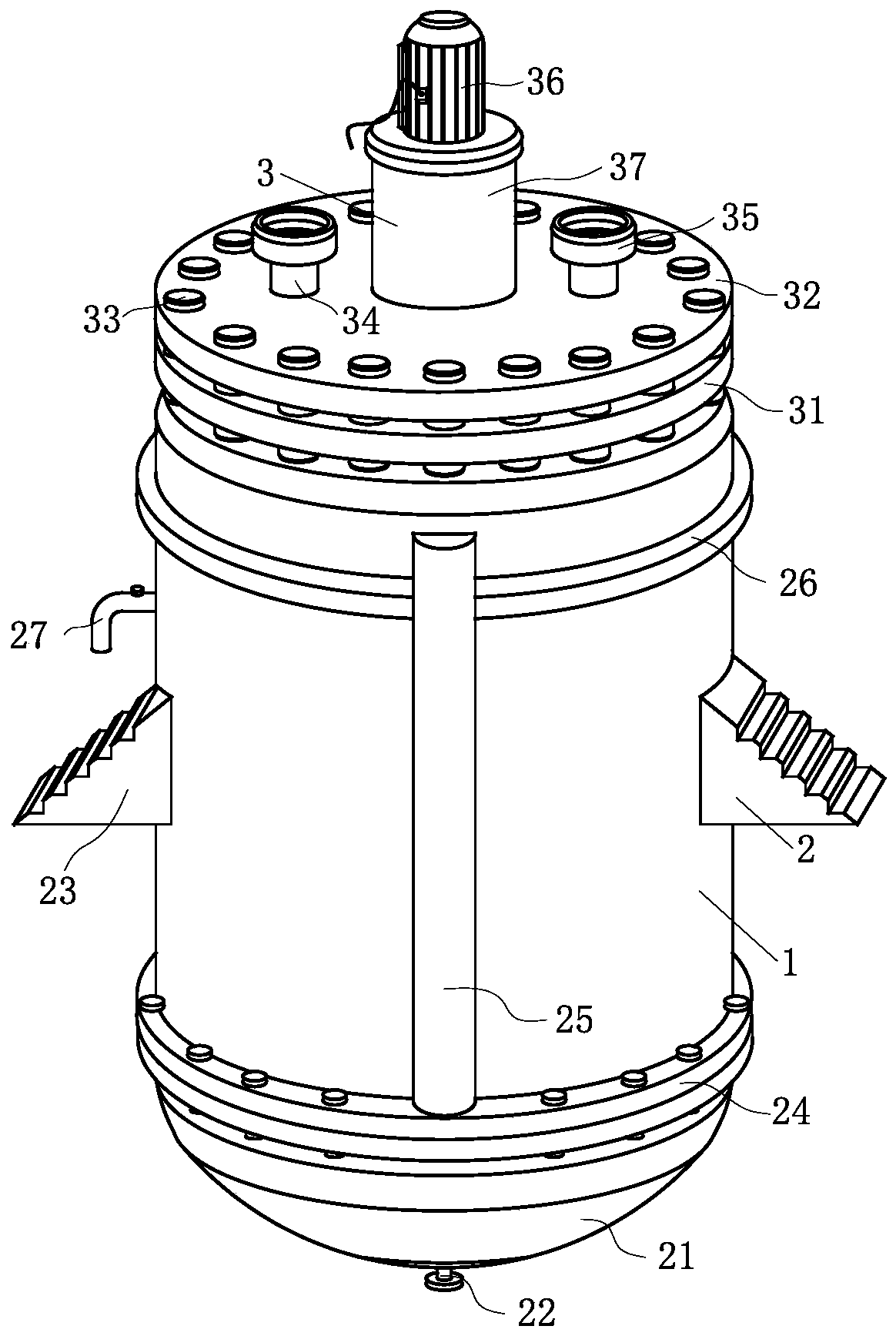

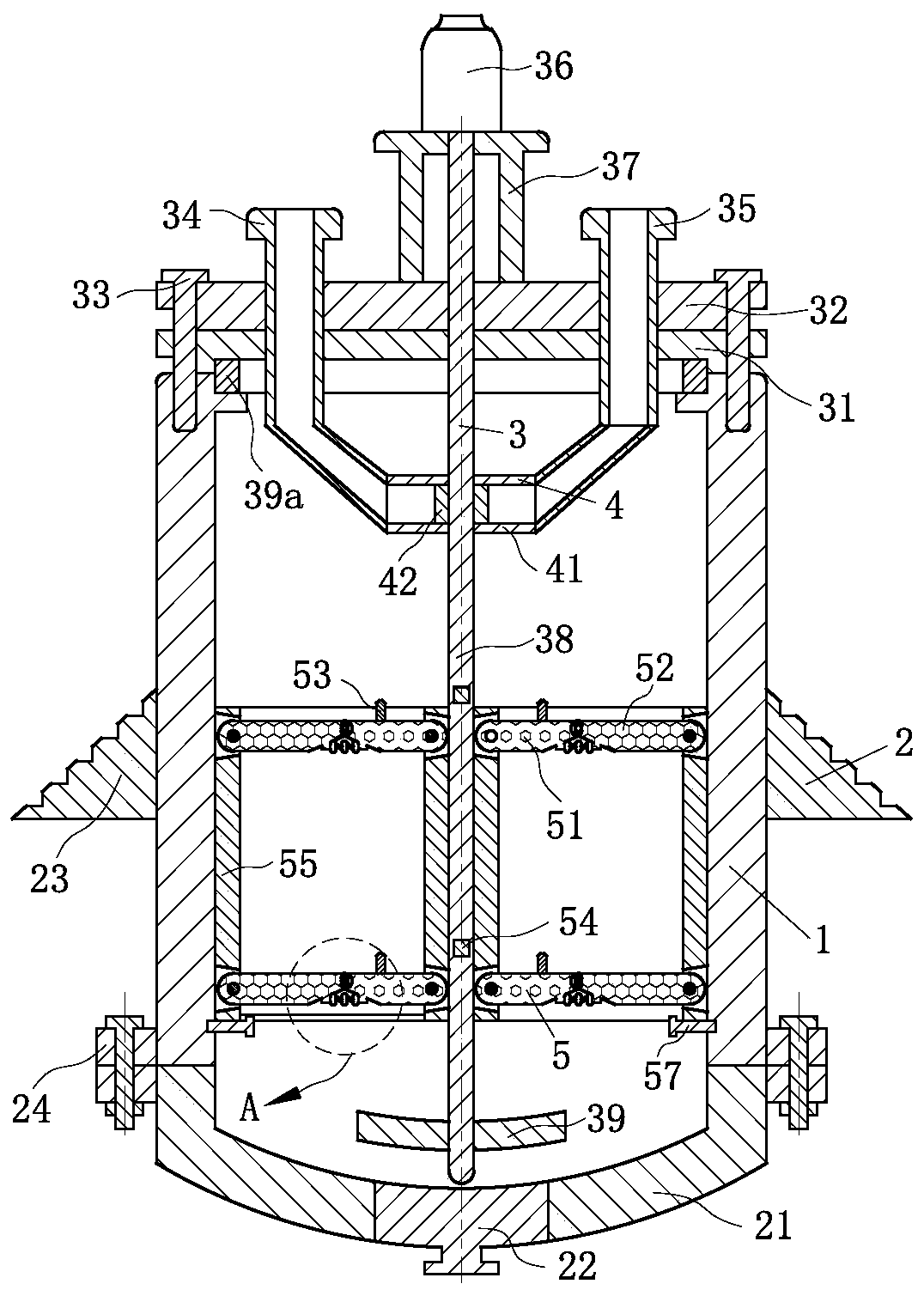

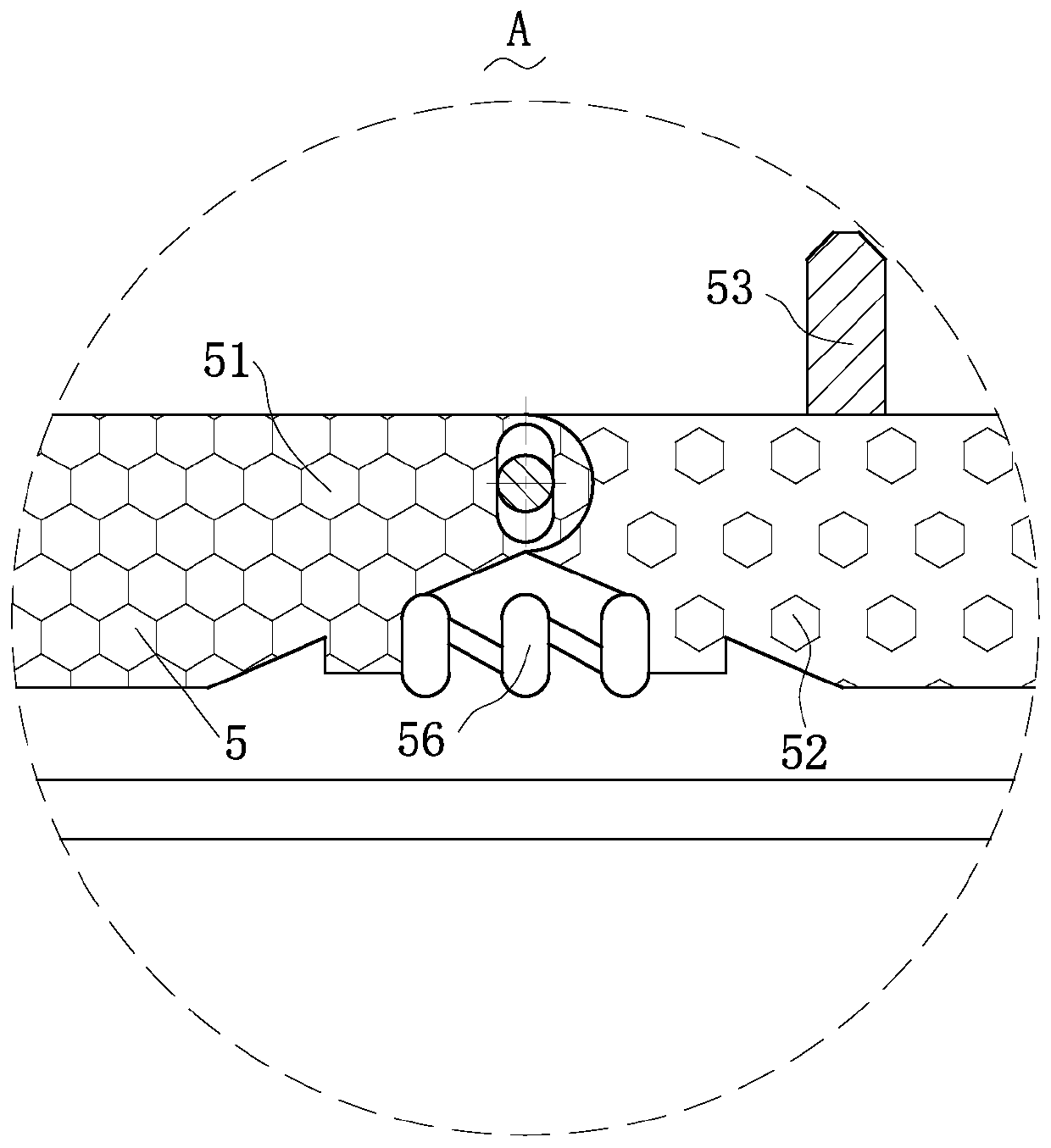

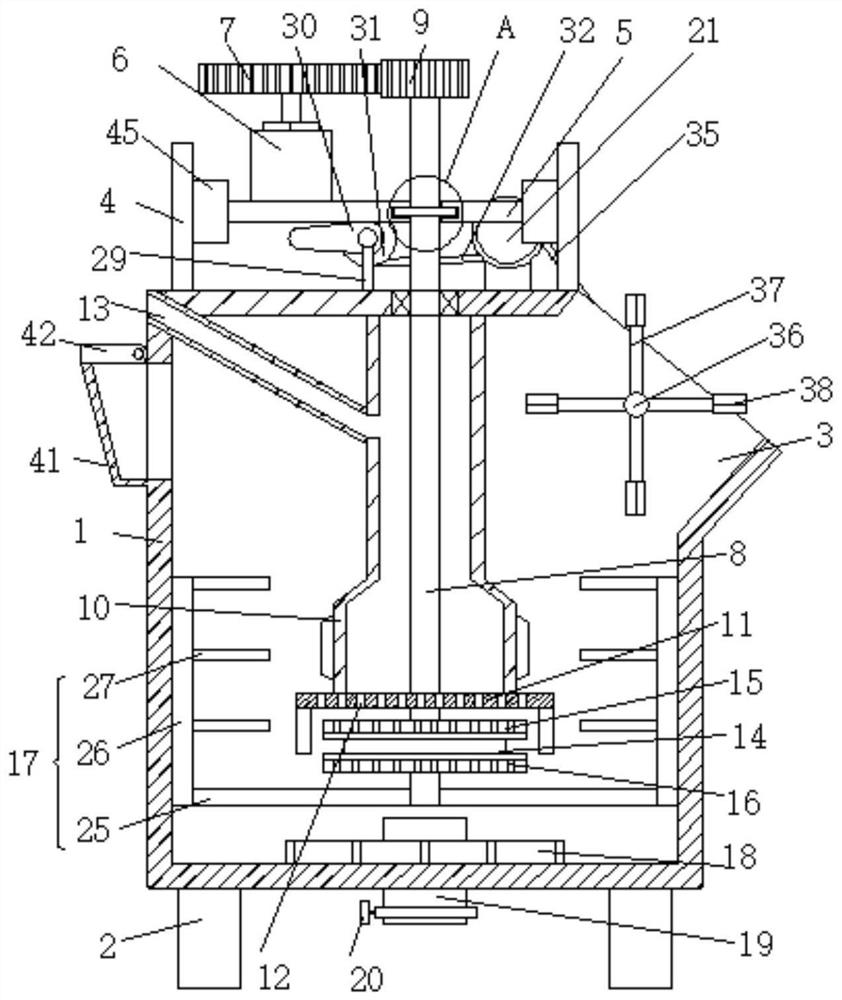

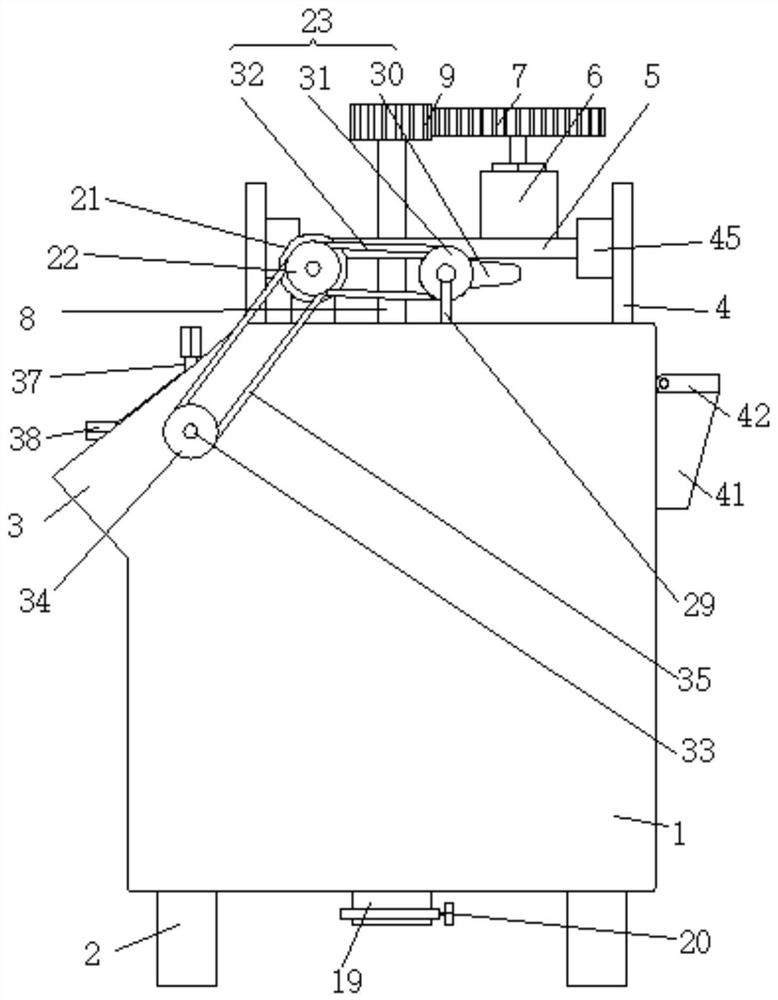

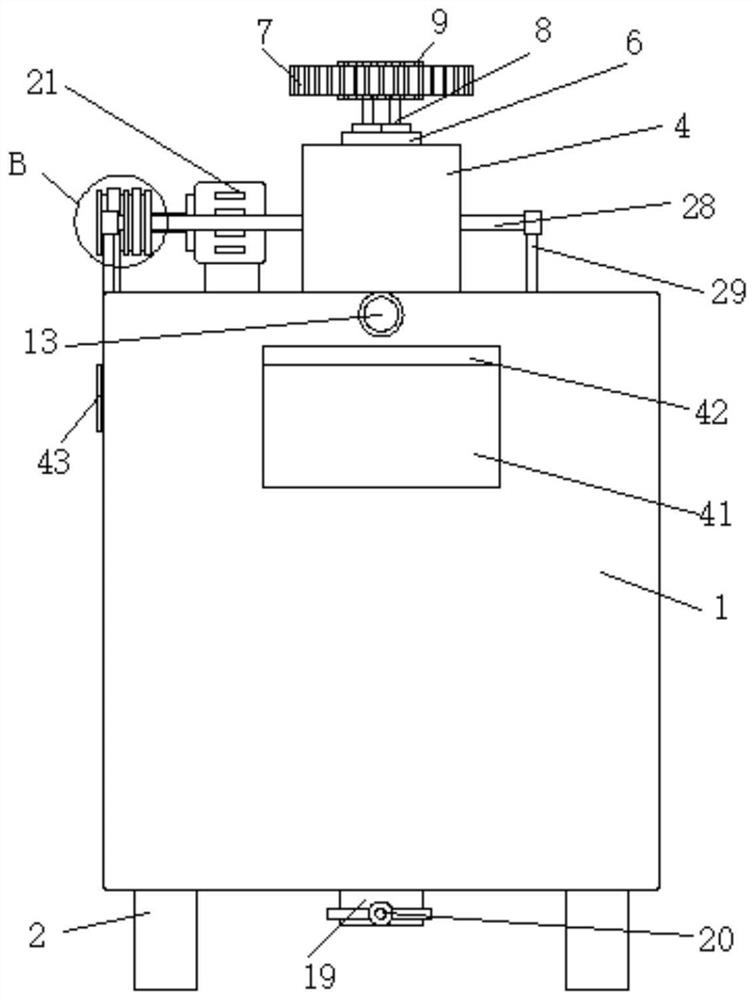

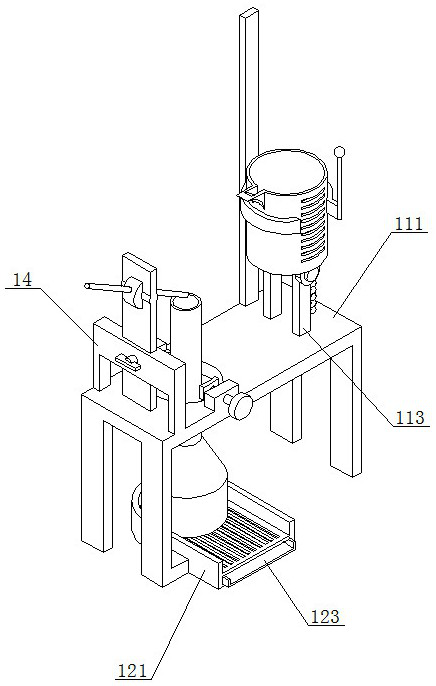

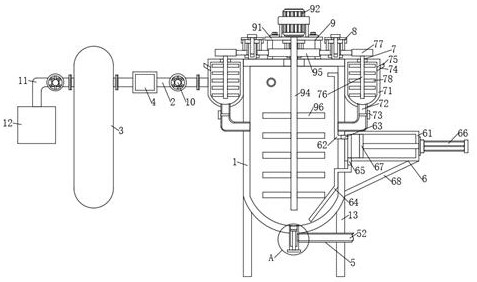

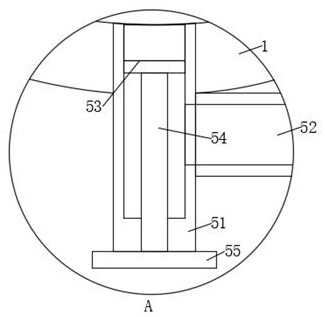

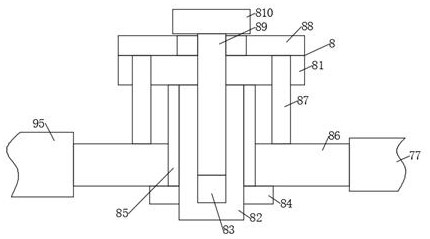

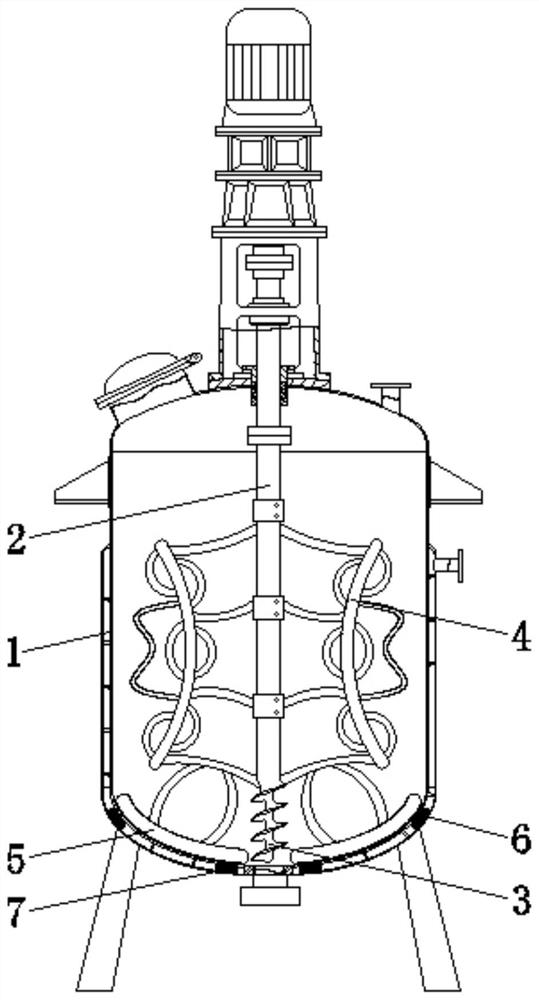

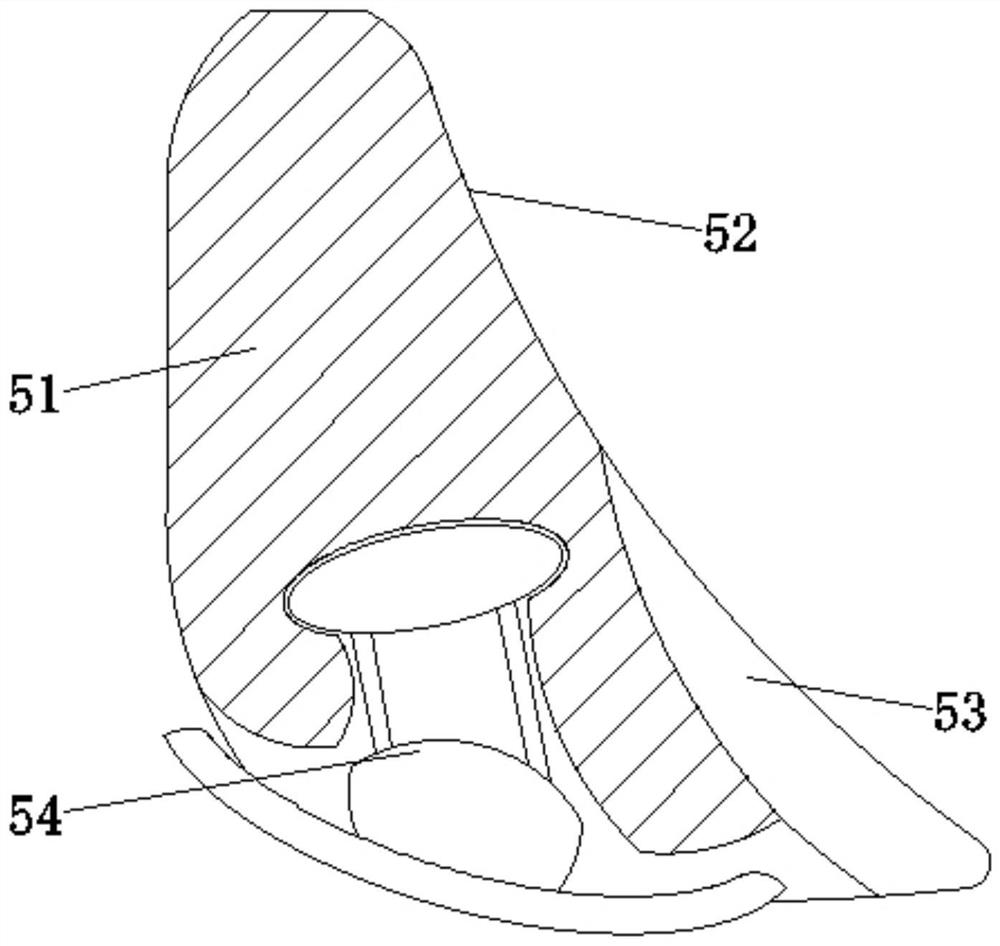

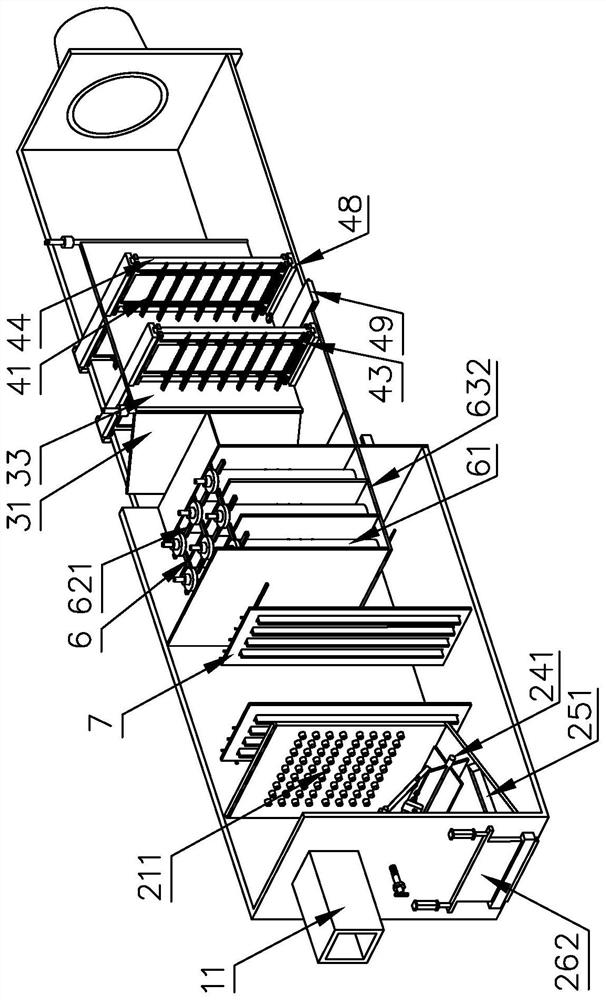

Reaction kettle convenient for layered disassembling of filter screens

InactiveCN110813215AFacilitate mixed reactionsAvoid direct contactProcess control/regulationChemical/physical/physico-chemical stationary reactorsPolymer sciencePolyol

The invention relates to the field of reaction kettles, and concretely relates to a reaction kettle convenient for layered disassembling of filter screens. The reaction kettle comprises a reaction kettle body, an auxiliary structure, a stirring structure, a mixing structure and a filtering structure. The mixing structure runs while polymer polyol raw material and a catalyst are stirred through thestirring structure, so the polymer polyol raw material and the catalyst are uniformly mixed gradually, and fall into the reaction kettle body from the mixing structure, thereby the stirring structureruns easily; gradual stirring of the polymer polyol raw material and the catalyst facilitates a mixing reaction of the polymer polyol raw material and the catalyst; the filtering structure is pushedwhile the polymer polyol raw material and the catalyst are stirred through the stirring structure, so the polymer polyol raw material and the catalyst are fully reacted in a layering manner; and blockage is avoided in the shaking process of the filtering structure, and a gas can penetrate through the filtering structure and is discharged, so decompression of the internal of the reaction kettle body prevents the reaction kettle body from being damaged.

Owner:金博

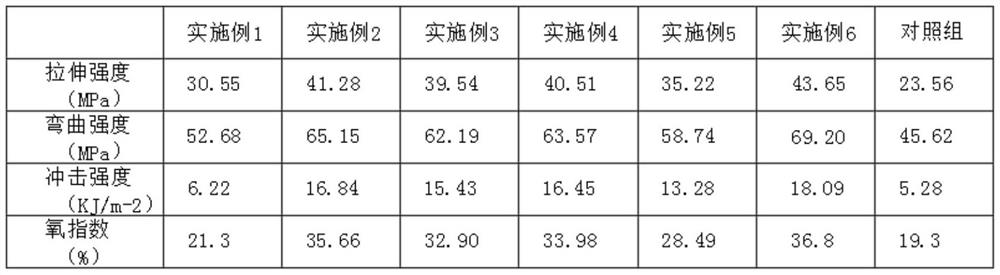

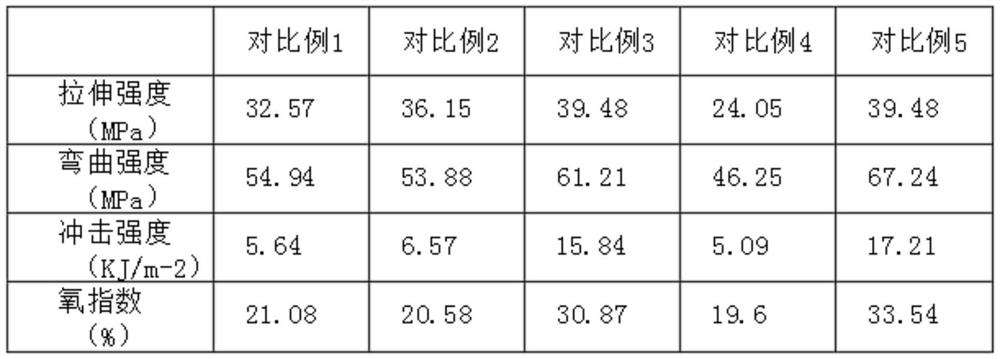

Degradable flame-retardant polylactic acid elastic fiber and preparation method thereof

PendingCN112813528AHigh cell affinityGood biocompatibilityFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberPolymer science

The invention discloses the technical field of fibers, and provides degradable flame-retardant polylactic acid elastic fiber and a preparation method thereof. The degradable flame-retardant polylactic acid elastic fiber is composed of the following components of polylactic acid, a modifier, a flame retardant, a plasticizer and enzymolysis corn starch; and the modifier is formed by mixing collagen, active peptide, chitosan and hydroxyapatite. The modifier used in the invention has relatively high biomimetic property, can significantly improve the biocompatibility, bioactivity and mechanical properties of a polylactic acid material, and improves the cell affinity of the polylactic acid, so that the prepared fiber has better physical properties and flame retardant effect; and the elasticity of the prepared fiber is improved, so that the fiber has better tensile strength and bending strength.

Owner:LANGSHA KNITTING

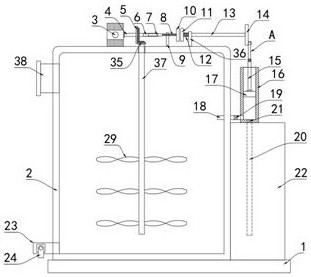

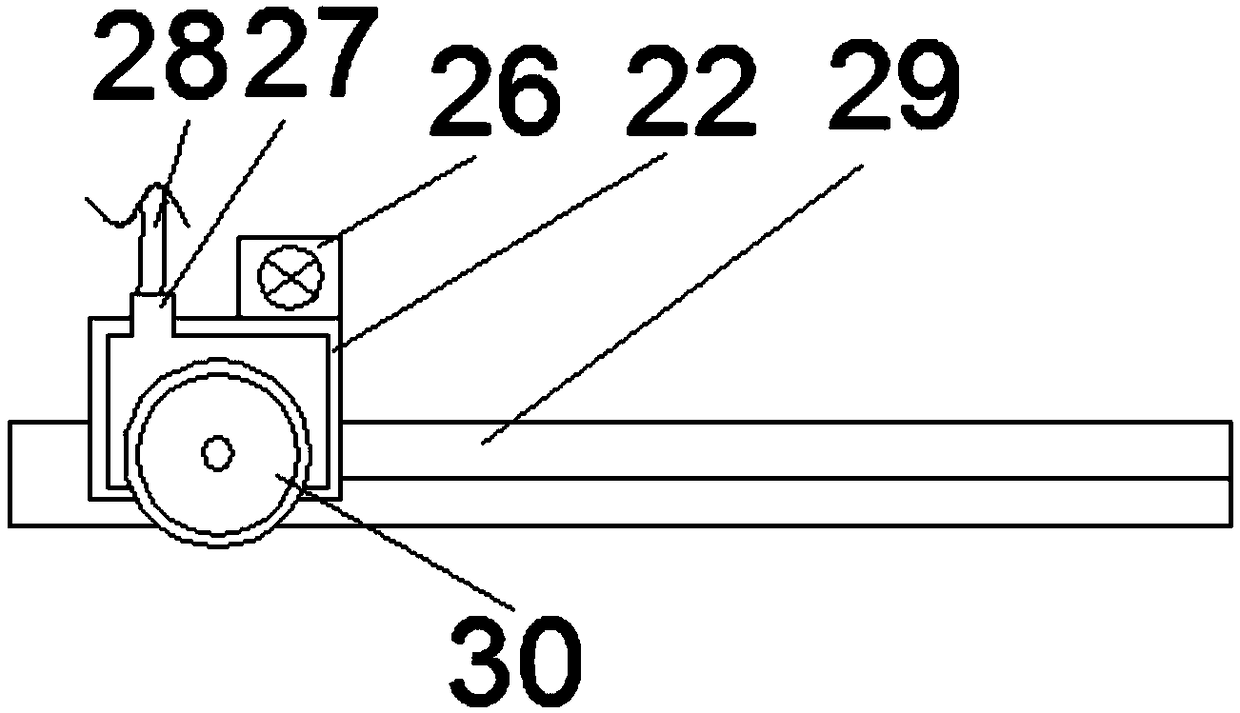

Movable type water-soluble fertilizer fertilization vehicle

InactiveCN107715746AWell mixedStir wellRotary stirring mixersTransportation and packagingAgricultural engineeringMovable type

The invention discloses a movable type water-soluble fertilizer fertilization vehicle. The movable type water-soluble fertilizer fertilization vehicle comprises a mixing box, a feeding opening, a water inlet, a discharging opening, a stirring device and a frame, wherein wheels are arranged below the frame; the mixing box is fixed on the frame; the feeding opening is formed above the mixing box; the water inlet and the discharging opening are formed below the mixing box; the stirring device is arranged in the mixing box; the stirring device comprises a stirring shaft and stirring paddles; a thread groove is formed in an outer wall of the stirring shaft; the stirring paddles are connected with the stirring shaft through a connecting part; a motor is arranged above the mixing box and the motor is connected with the stirring shaft. The movable type water-soluble fertilizer fertilization vehicle disclosed by the invention can be used while being assembled in a fertilization process and wastes are prevented; manual mixing is not needed so that the fertilizer can be sufficiently mixed and stirred under the action of the stirring device and the utilization rate of fertilizer is improved.

Owner:广西北贸农牧有限公司

Surface enhanced treatment process for metal bearing of numerically-controlled machine tool

InactiveCN108251786AImprove bindingLow wear and tear rateMolten spray coatingSolid state diffusion coatingPlasma beamMachine tool

The invention relates to a surface enhanced treatment process for a metal bearing of a numerically-controlled machine tool. The process comprises the following steps: surface cleaning and activating:putting the metal bearing in a phosphoric acid buffer solution to be soaked for 20-30 min, then adding a cleaning activator thereinto, and carrying out ultrasonic treatment for 5-10 min; nitrocarburizing: putting the metal bearing in a nitrifying furnace, introducing nitrogen, and treating the metal bearing for 2.2-2.4 h at 565+ / -2 DEG C; and compound metal paint spraying: coating compound metal powder to the outer layer of the metal bearing by means of plasma beam fusion covering. By means of multi-time enhanced treatment on the surface layer of the metal bearing, the process has an excellentmechanical property, and the toughness and the wear resistance are enhanced remarkably. By selecting a proper raw material proportion, the bonding forces between the coatings and a matrix and betweenthe coatings are great, the wear delamination rate is low, and the service life is prolonged by more than two folds.

Owner:MAANSHAN XINQIAO IND DESIGN CO LTD

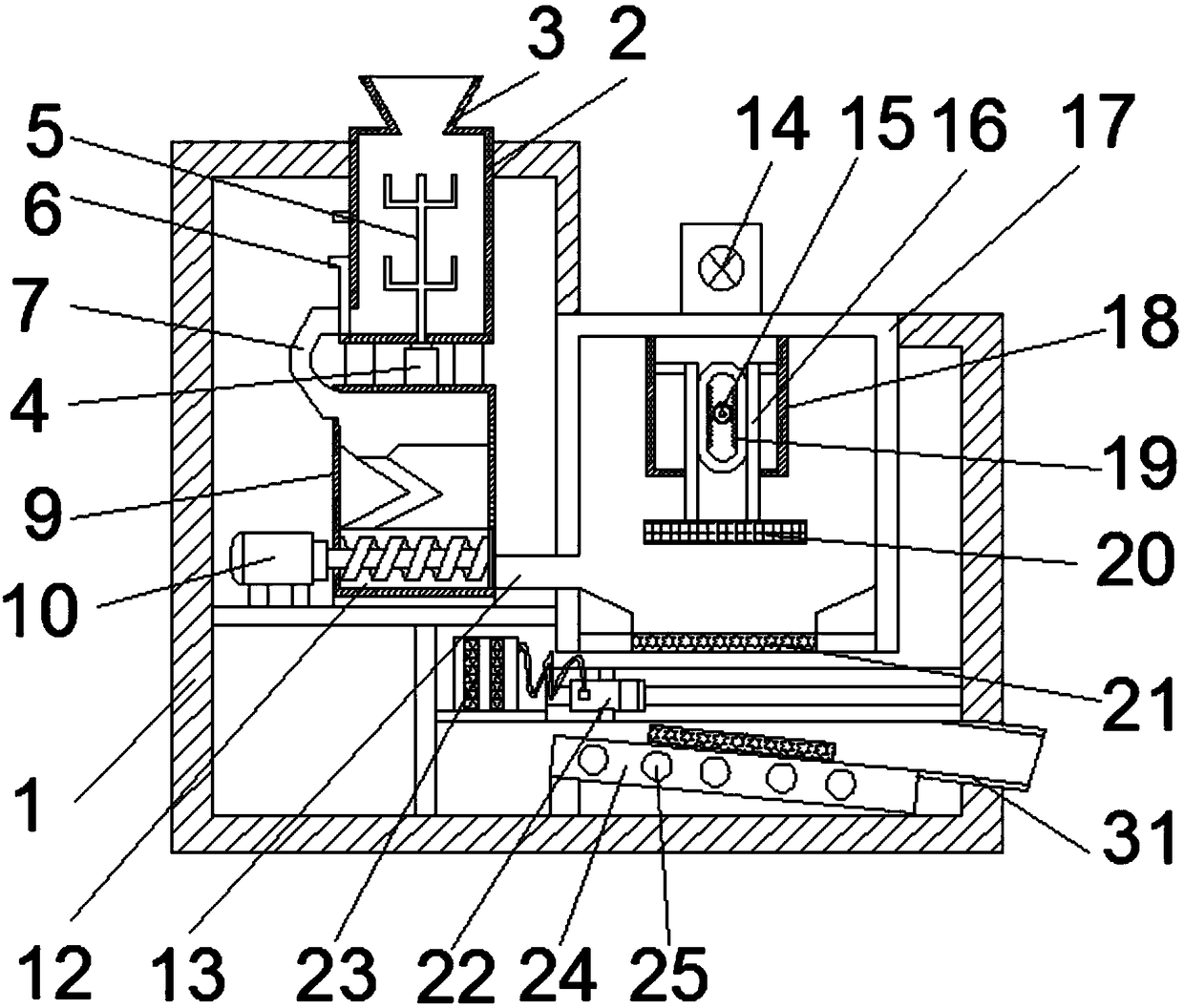

Normal and low temperature suspension reactor for resin processing

InactiveCN113457610AEasy to processReduce production and processing costsChemical/physical/physico-chemical stationary reactorsFeed devicesElectric machineControl engineering

The invention discloses a normal and low temperature suspension reactor for resin processing, the reactor comprises a base, a reaction box is installed on the base, a driving motor is installed at the upper end of the reaction box, the output end of the driving motor is fixedly connected with a rotating rod, a stirring mechanism connected with the rotating rod is installed on the reaction box, and a material box is installed on the base. A material supply mechanism is installed at the upper end of the material box, a feeding pipe is installed at the upper end of one side of the reaction box, a discharging pipe is installed at the lower end of one side of the reaction box, a valve is installed on the discharging pipe, the stirring mechanism comprises a rotating shaft penetrating through the side wall of the upper end of the reaction box, and a plurality of spiral stirrers are fixedly connected to the outer wall of the rotating shaft. With arrangement of the driving motor, the material stirring can be achieved, the mixed material can be intermittently injected into the reaction box, and the addition is almost quantitative each time so as to achieve the good mixing reaction, no manual addition is needed, the manpower resource is saved, and the safety is provided.

Owner:青岛伊森新材料股份有限公司

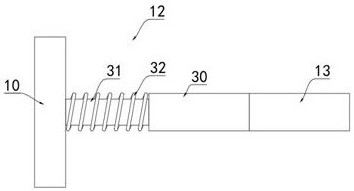

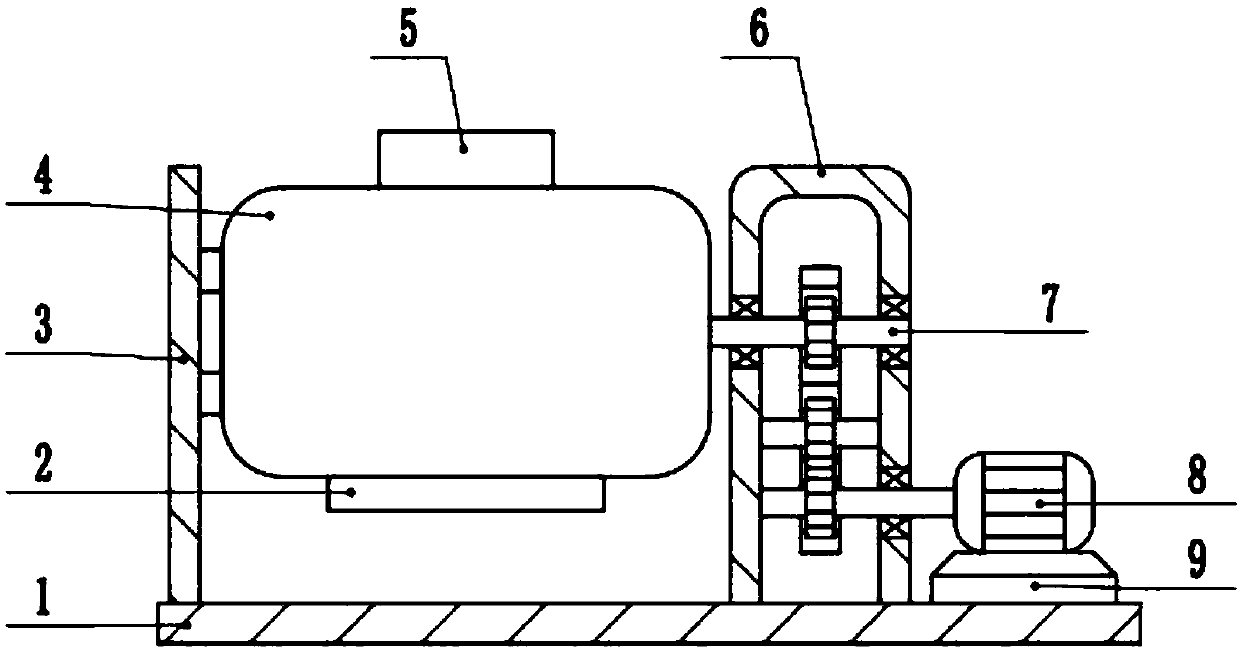

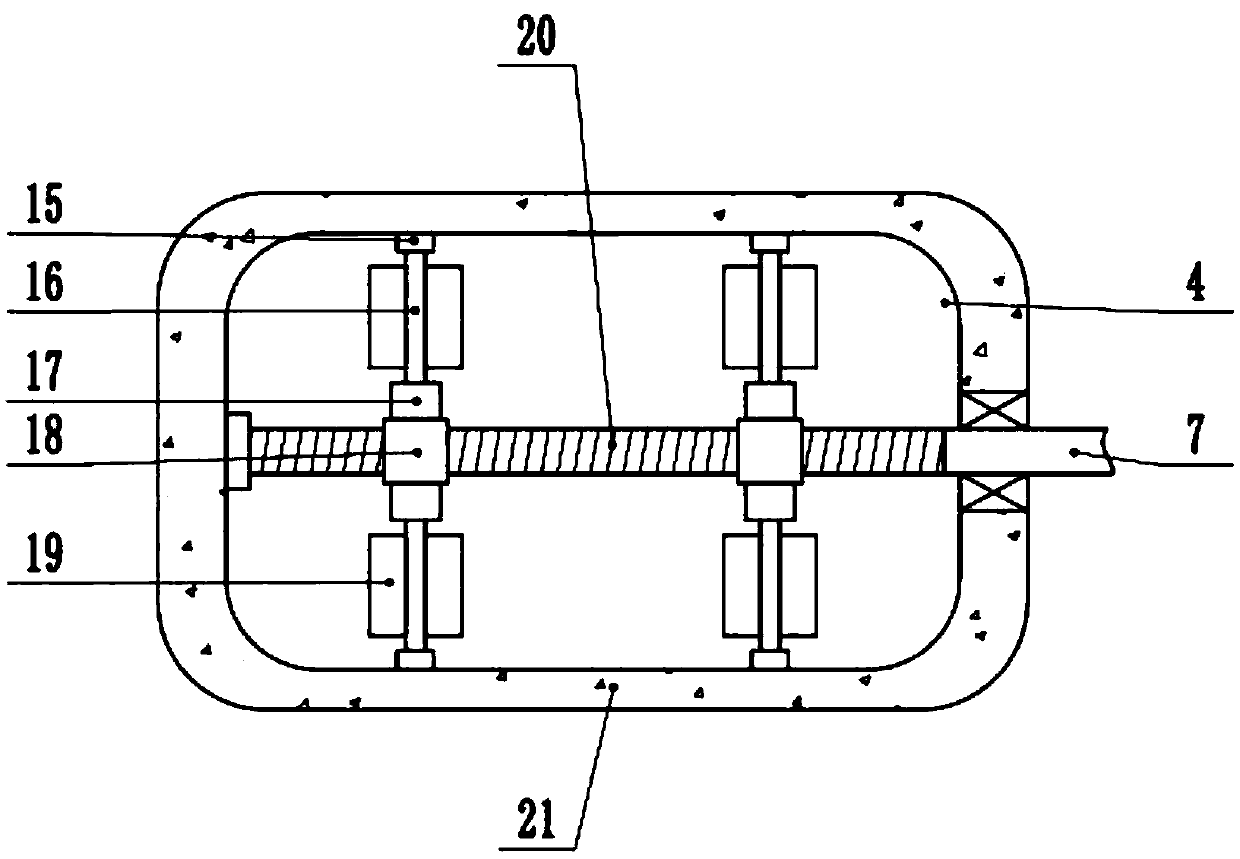

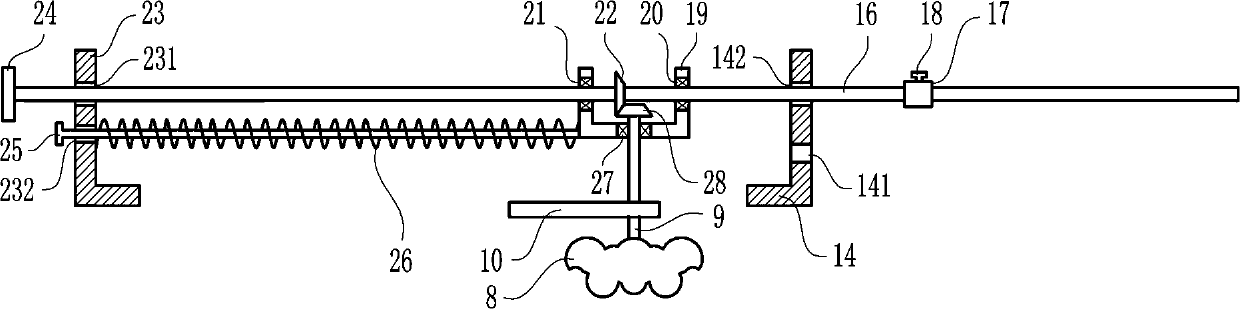

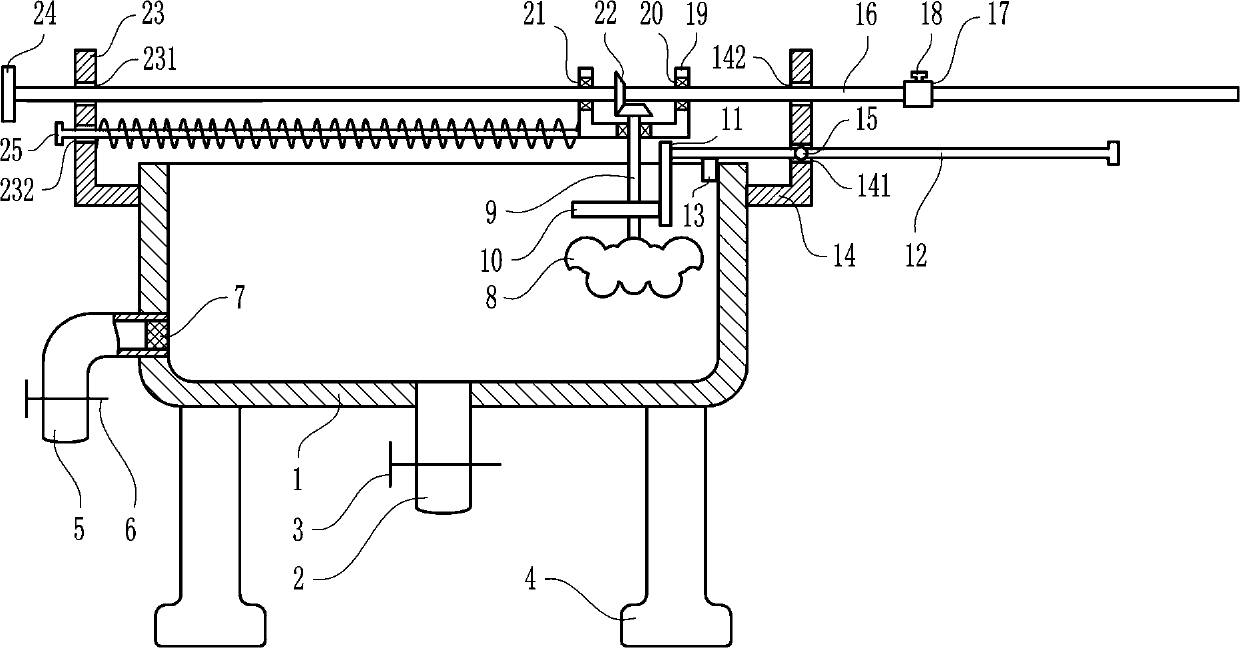

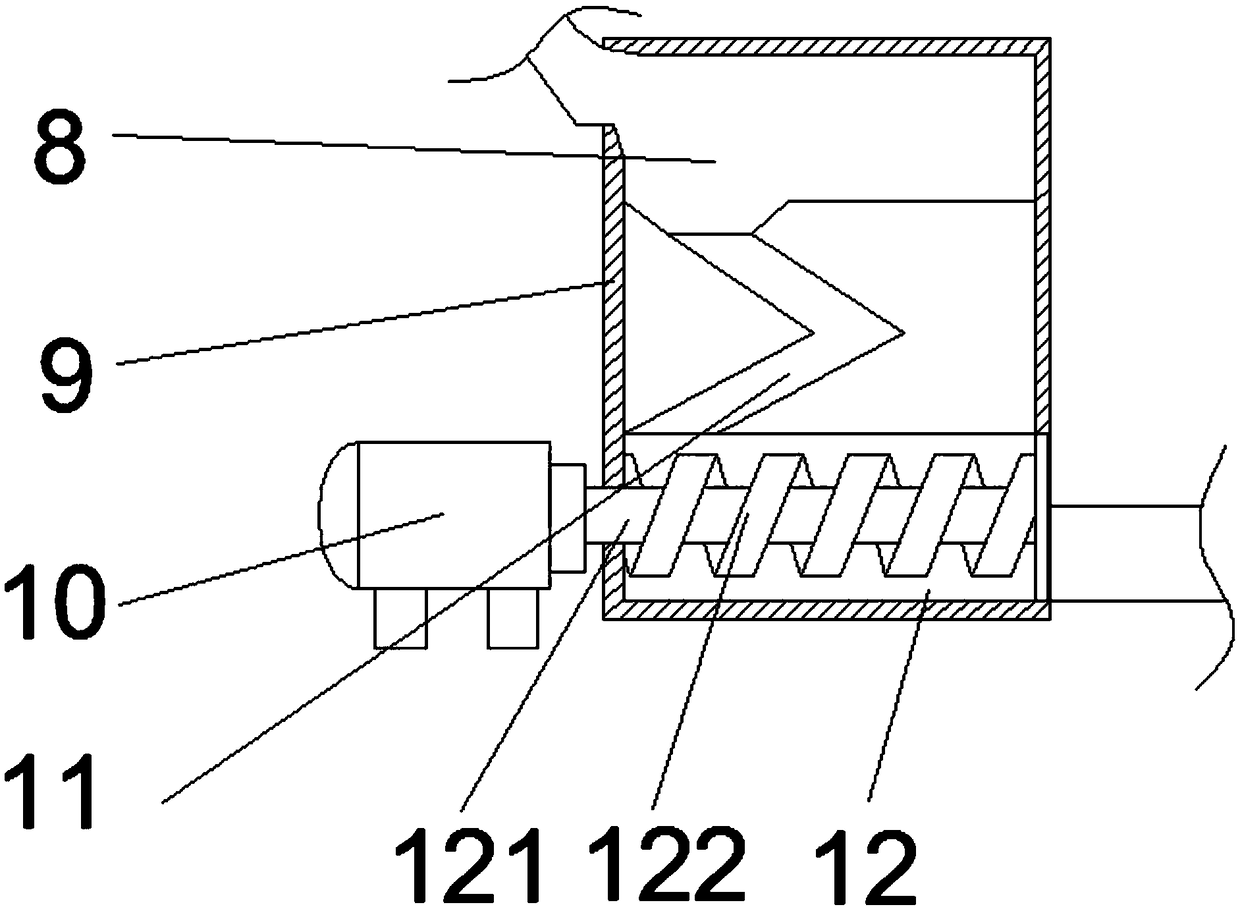

Efficient horizontal reaction kettle for chemical industry production

InactiveCN107583584AImprove responseFacilitate mixed reactionsChemical/physical/physico-chemical stationary reactorsGrain treatmentsChemical industryElectric machinery

The invention discloses an efficient horizontal reaction kettle for chemical industry production. The efficient horizontal reaction kettle comprises a base, a reaction kettle, a driving box, a drivingmotor and a rack, wherein a feeding device is fixedly mounted on the upper side of the reaction kettle; a rotating shaft is rotatably mounted on the upper side of the driving box; outer threads are formed in one side, positioned in the reaction kettle, of the rotating shaft; two thread sleeves are in thread connection with the rotating shaft; two motor hoods are symmetrically mounted at the frontsides and the rear sides of the thread sleeves; rotating motors are fixedly mounted in the motor hoods; output ends of the rotating motors are fixedly connected with stirring shafts; stirring bladesare fixed to the stirring shafts. According to the efficient horizontal reaction kettle for the chemical industry production, two crushing rollers are arranged in the feeding device to crush fed materials, and block shaped raw materials can be crushed into granules which facilitate the reaction, and thus the reaction speed of the reaction kettle is increased; in addition, the movable stirring shafts provided with stirring blades are arranged, so that the raw material mixing reaction is accelerated, and as a result, the reaction efficiency is improved.

Owner:NINGBO ZHENHAI XIUYANG ADVERTISEMENT DECORATION

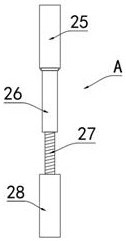

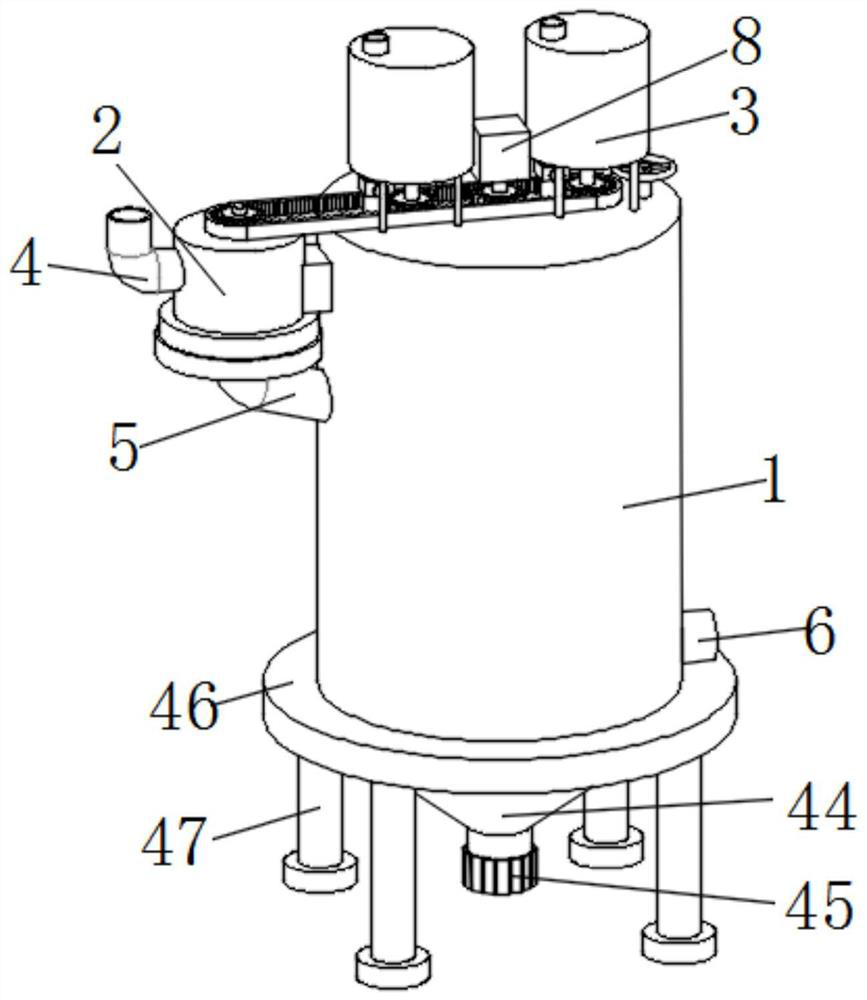

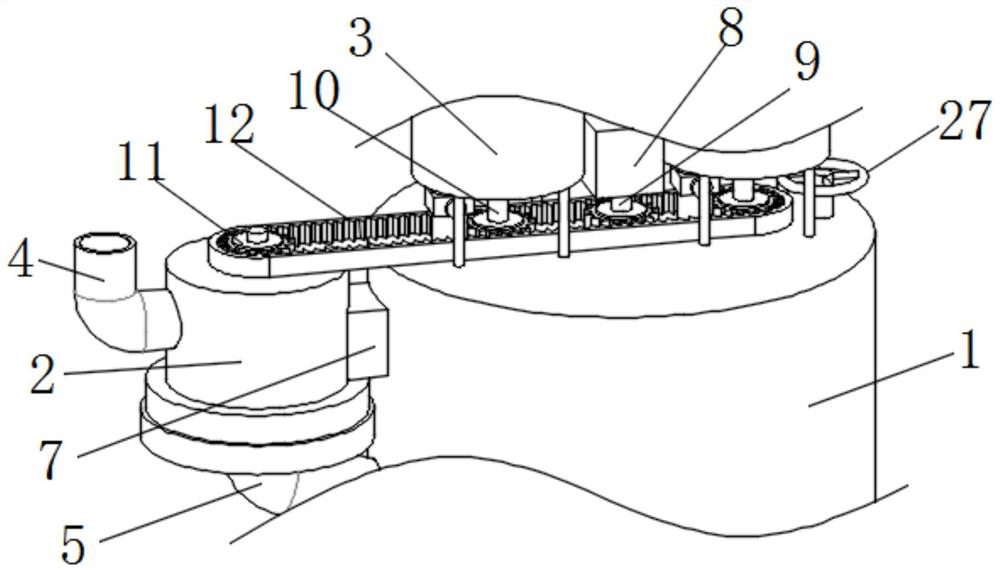

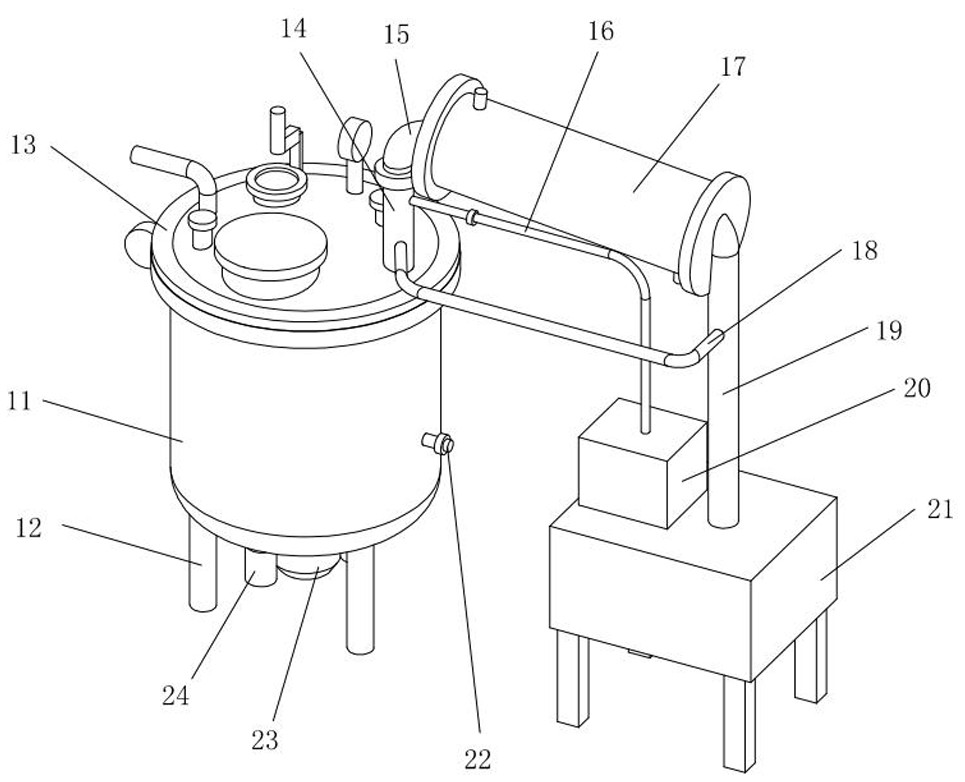

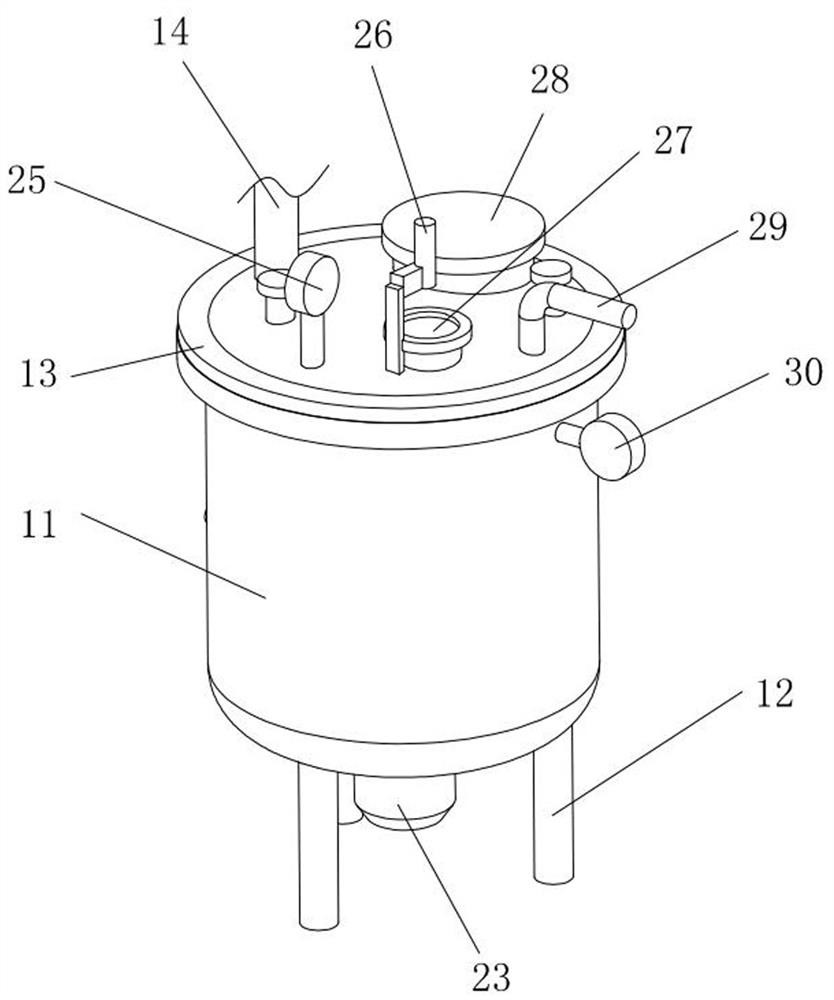

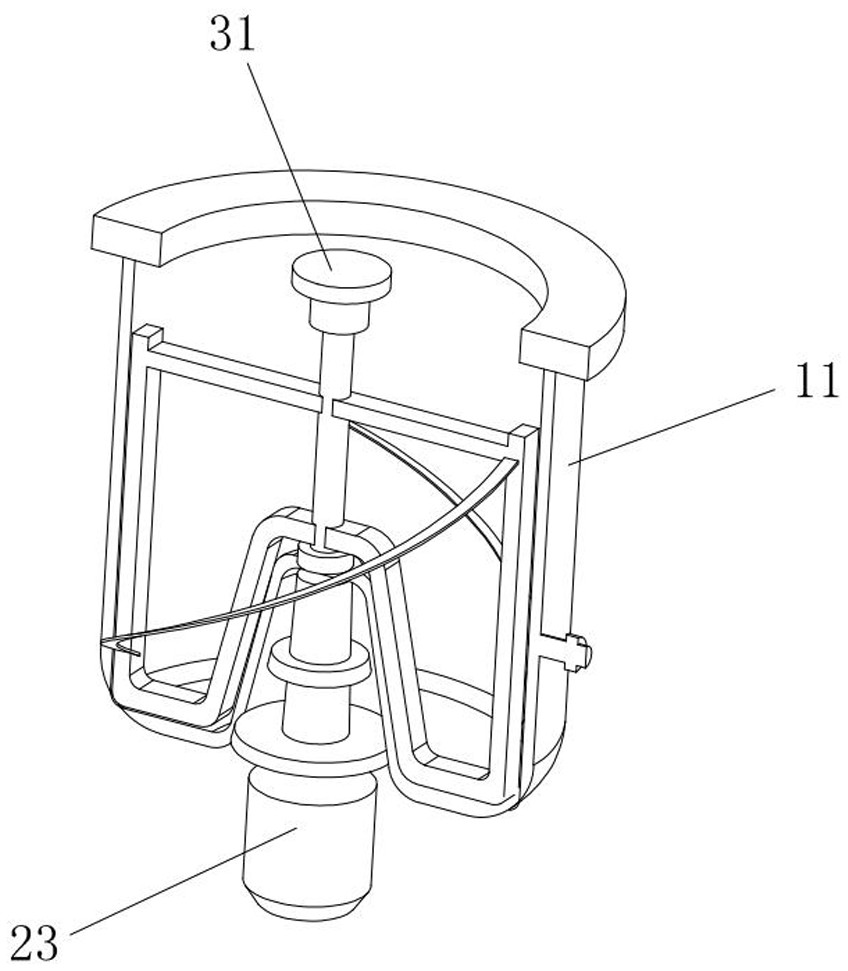

Movable stirring-type coprecipitation device for rare earth

ActiveCN109097607AUniform responseLarge mixing rangeProcess efficiency improvementRare earthCoprecipitation

The invention relates to a coprecipitation device for rare earth, in particular to a movable stirring-type coprecipitation device for rare earth. The movable stirring-type coprecipitation device for the rare earth can be adjusted and can stir rare earth mixture liquid in a moving mode. According to the technical scheme, the movable stirring-type coprecipitation device for the rare earth comprisesa precipitation cylinder, a discharging pipe, a first valve, supporting legs, a liquid discharging pipe, a second valve, a filtering net, a large stirring plate, a first connecting shaft, a small cam,a contact plate and the like; and the discharging pipe is located on the lower portion of the precipitation cylinder and connected with the precipitation cylinder. The movable stirring-type coprecipitation device for the rare earth can be adjusted, can stir the rare earth mixture liquid in the moving mode, and can enable a mixing reaction of the rare earth mixture liquid to be even, the quality of a prepared product is improved advantageously, the production and development of enterprises are facilitated, and operation is convenient.

Owner:江苏鑫环球建设工程有限公司

Anti-blocking sewage treatment device

InactiveCN112678988AInjection impactFlexible and convenient controlMultistage water/sewage treatmentElectric machinerySewage treatment

The invention discloses an anti-blocking sewage treatment device, and relates to the technical field of sewage treatment equipment, the anti-blocking sewage treatment device comprises a treatment box, a filter box is arranged on one side of the treatment box, a connecting pipe and a connecting block are arranged between the treatment box and the filter box, two ends of the connecting pipe and two sides of the connecting block are fixedly connected with the treatment box and the filter box respectively; and two ends of the connecting pipe are respectively communicated with the treatment box and the filter box. According to the invention, a cleaning part is arranged, sewage is injected into the filter box from the water inlet pipe, the sewage is filtered by a filter screen, large impurities, garbage and the like in the sewage are filtered and remained on the filter screen, and a motor is started to drive a transmission shaft to rotate, so that a driven shaft in the filter box is driven to rotate through gear and rack belt transmission, and a scraper is driven to rotate through a fixed clamping seat; impurities, garbage and the like are thrown into a storage box below by utilizing centrifugal force, so that the impurities and the like are prevented from accumulating on the filter screen to block the connecting pipe and influence the injection of sewage.

Owner:佛山市馨乐环保科技有限公司

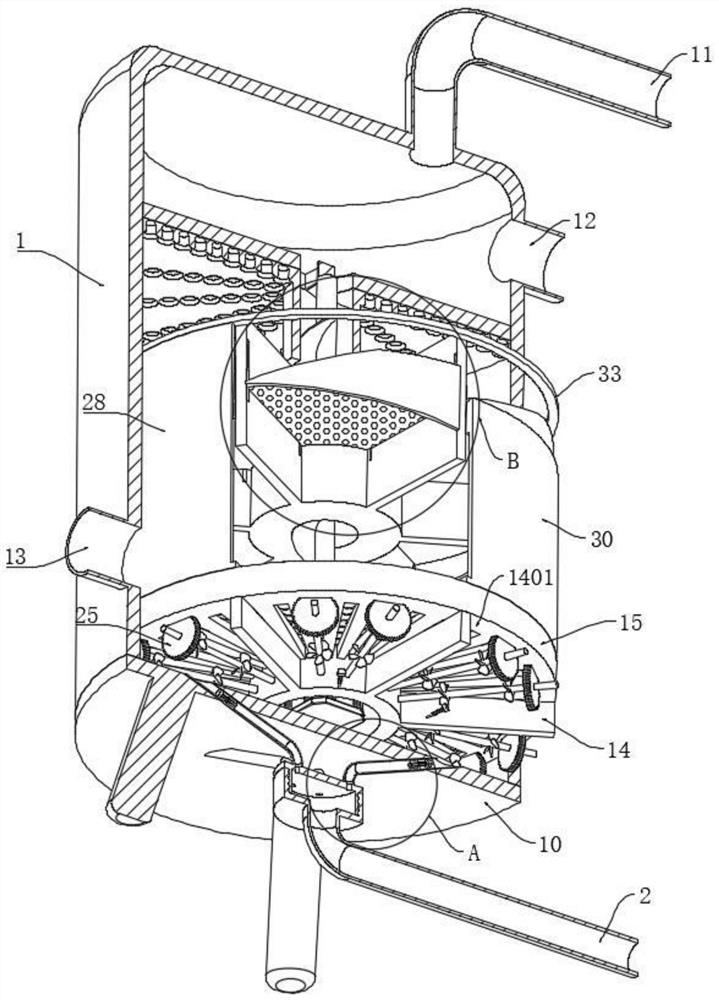

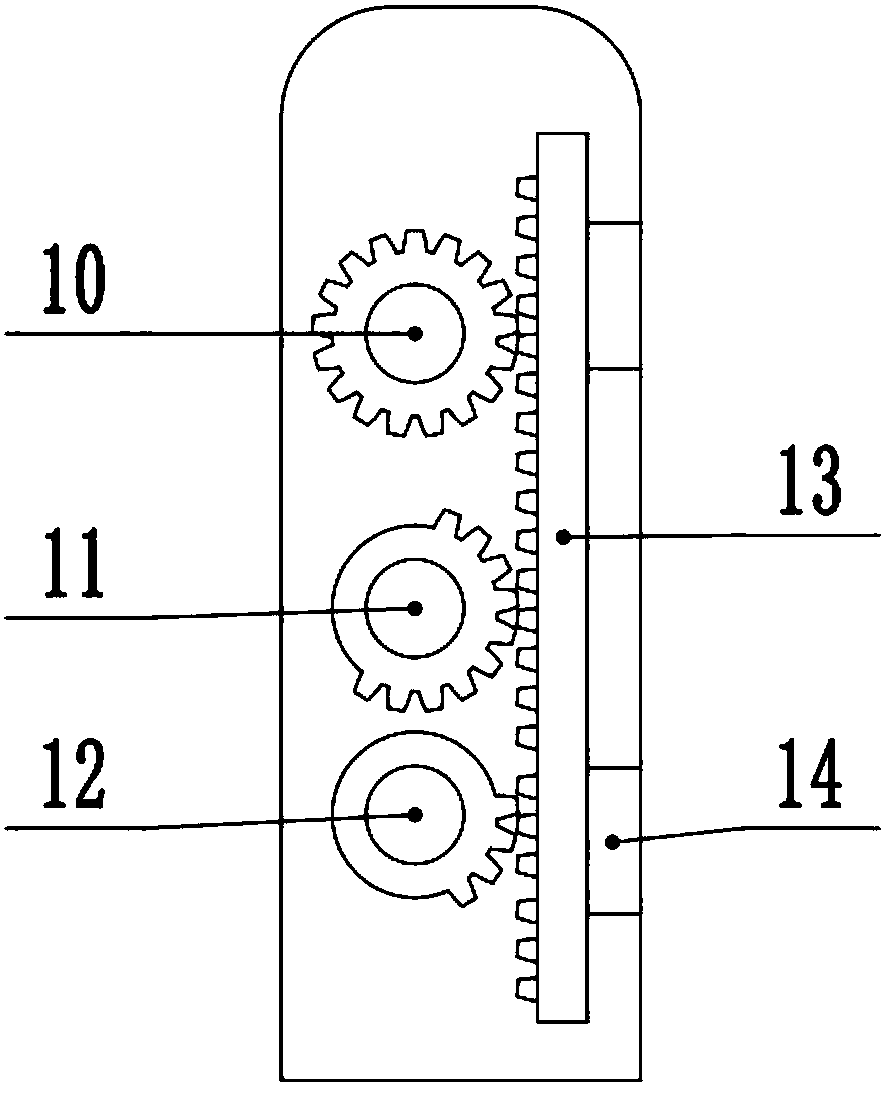

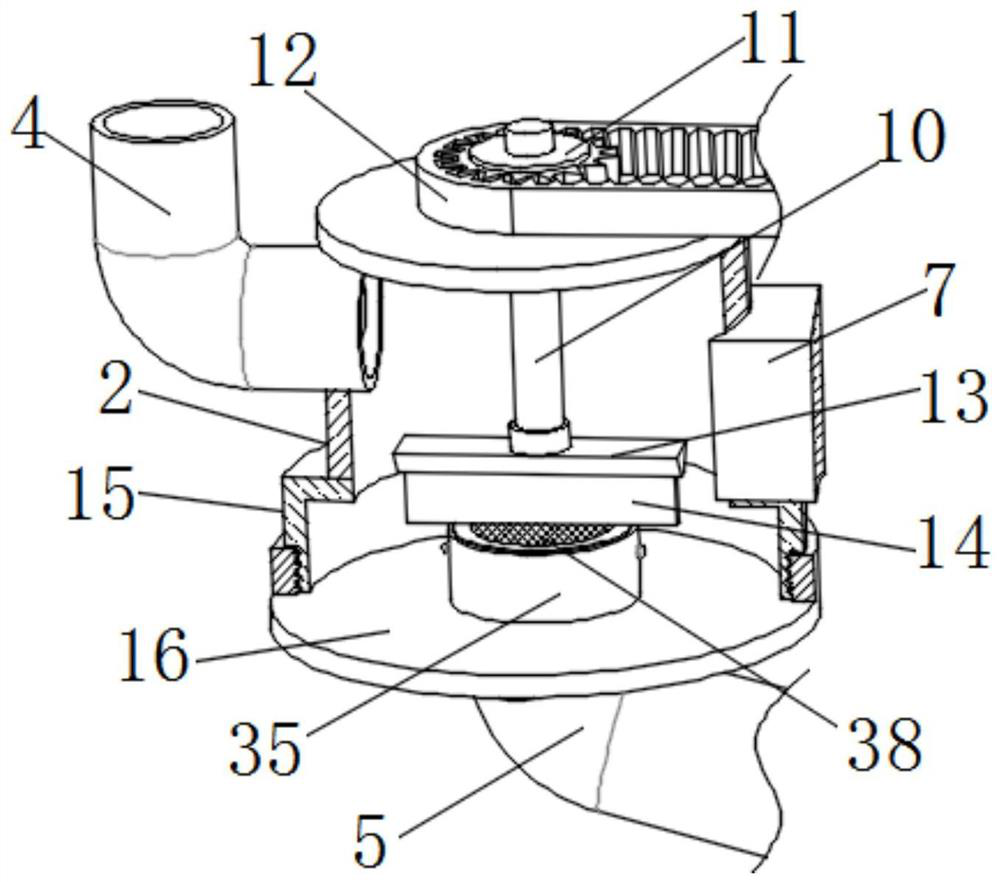

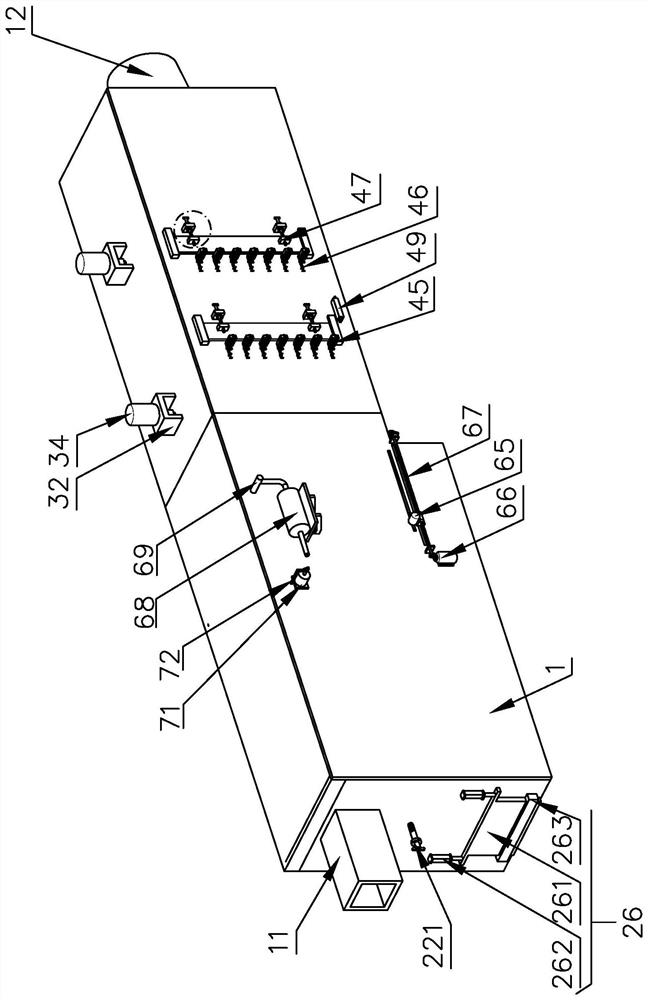

Lifting flotation machine for graphite production

InactiveCN112246447AFacilitate mixed reactionsPromote generationFlotationGear wheelElectric machinery

The lifting type flotation machine for graphite production comprises a tank body, the tank body is cylindrical, a plurality of vertically-arranged supporting columns are fixedly connected to the outerbottom face of the tank body, an opening is formed in the upper end of one side of the tank body, and two vertically-arranged supporting plates are fixedly connected to the upper surface of the upperwall of the tank body; a bottom plate is horizontally arranged between the two supporting plates; the bottom plate is slidably connected with the two supporting plates; a first motor is fixedly connected to the upper surface of the bottom plate; and a horizontally-arranged first gear is fixedly connected to a shaft of the first motor. a first connecting rod, a second connecting rod and a stirringrod are arranged, the mixing reaction of materials in the device is promoted; the stirring and mixing effect is enhanced through rotation and lifting motion, so that the reaction rate of the device is increased, foam generation is accelerated; meanwhile, bubbles attached to the inner wall of the tank body are removed through the stirring rod, and foam generation is promoted; the foam generation effect of the device is optimized, and the practicability of the device is higher.

Owner:马丹丹

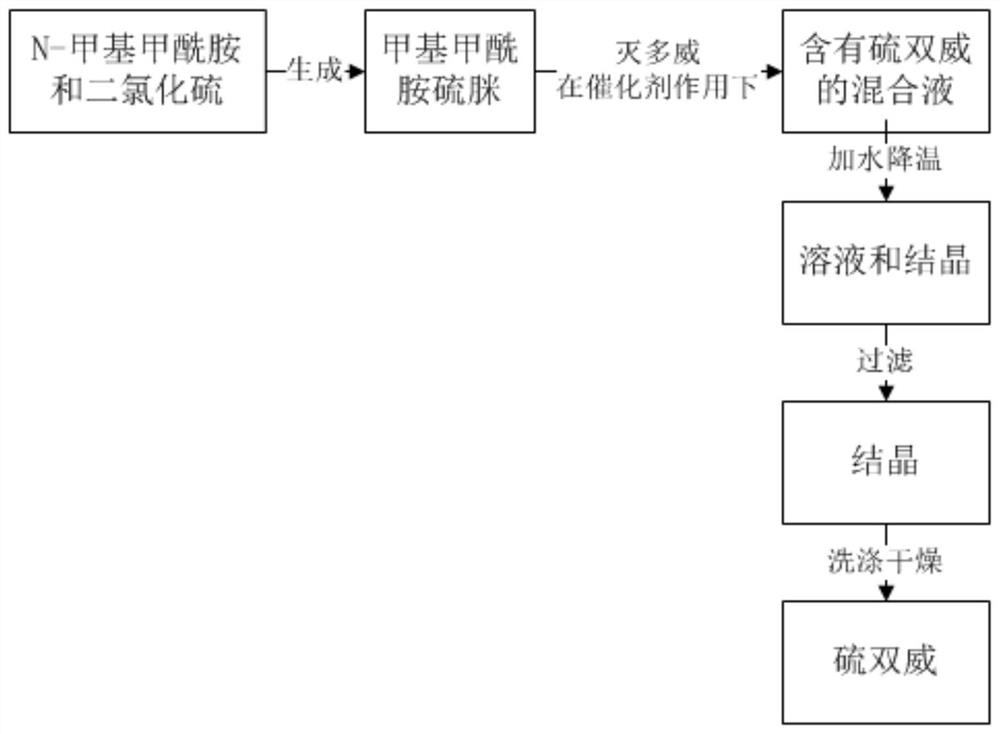

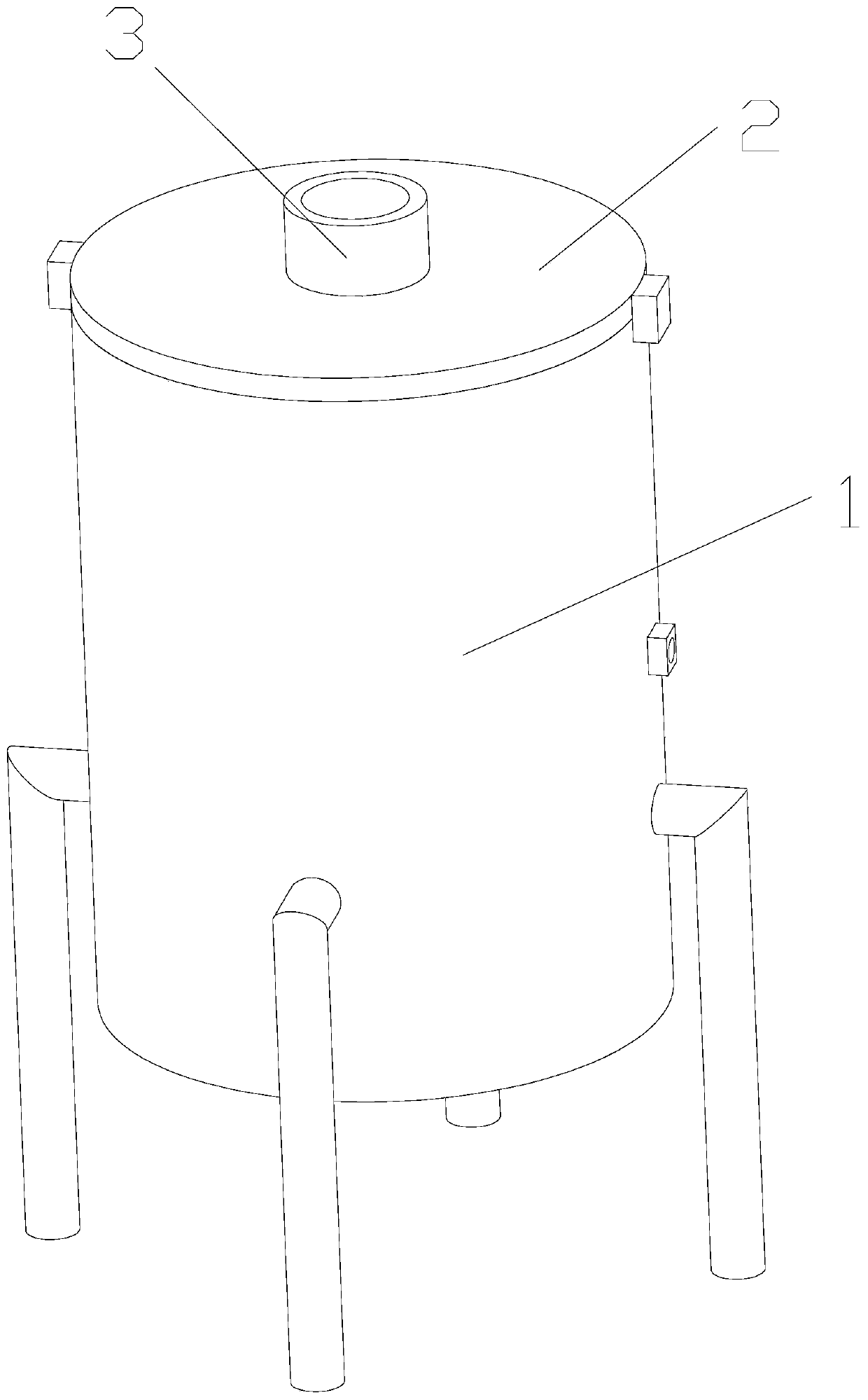

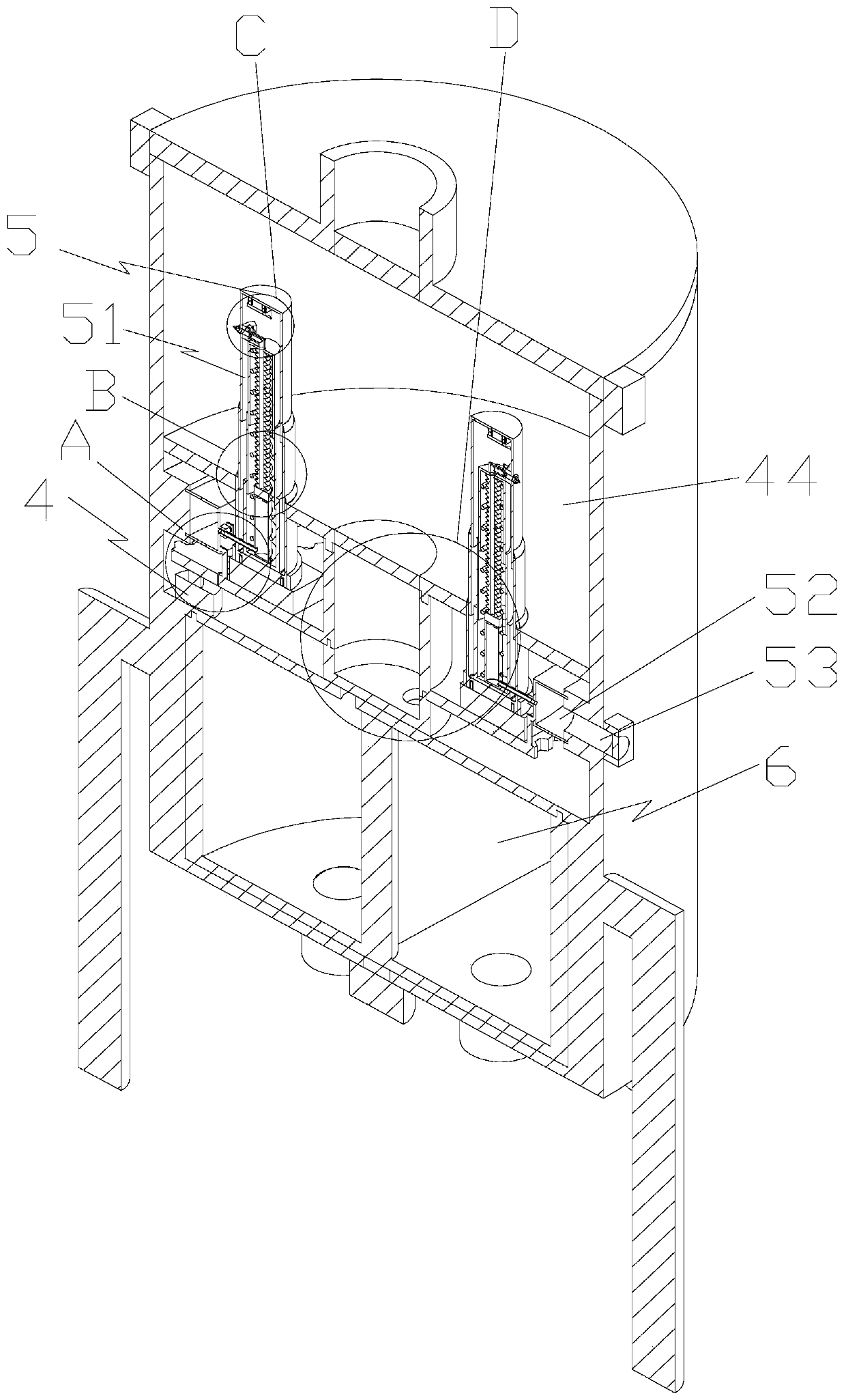

Preparation method of high-content thiodicarb

PendingCN114031533AIncreased toxicityReduce the risk of safety occupational health hazardsBiocideOrganic chemistryChemical synthesisPtru catalyst

The invention discloses a preparation method of high-content thiodicarb, and relates to the technical field of chemical synthesis. The method comprises the following steps: generating methylformamide thiamidine by taking N-methylformamide and sulfur dichloride as raw materials, carrying out condensation reaction on the methylformamide thiamidine and methomyl as raw materials under the action of a catalyst to generate a mixed solution containing thiodicarb, adding water into the mixed solution, conducting cooling to obtain a solution and crystals, filtering the solution and crystals, washing the filtered crystals, centrifugally filtering the crystal and a detergent, and drying the centrifugally filtered crystal to obtain thiodicarb with the content of greater than or equal to 98.0% and the total yield of greater than or equal to 95.0% in terms of methomyl. According to the method provided by the invention, the safety occupational health hazard risk is reduced, the process is safer, the operation is convenient, the use of pyridine is avoided, the foul odor on the production site is avoided, the environmental protection pressure is relieved, the production cost is reduced, the product quality and yield of thiodicarb are remarkably improved, and the thiodicarb reaches the export standard.

Owner:山东华阳农药化工集团有限公司

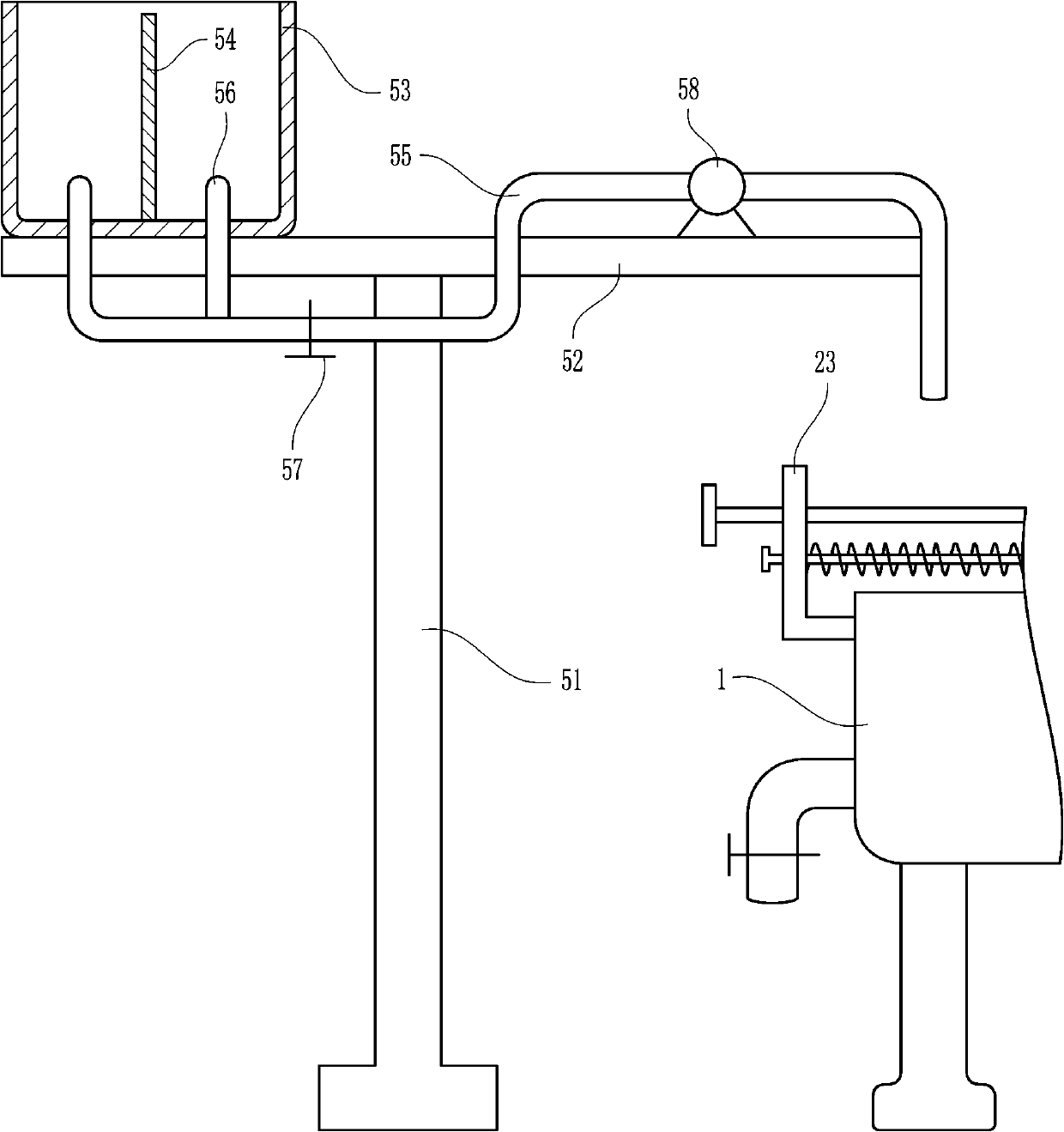

Sewage treatment equipment

InactiveCN111470600AProcessing speedFacilitate mixed reactionsRotary stirring mixersTransportation and packagingGear wheelSewage

The invention discloses sewage treatment equipment. The sewage treatment equipment comprises a tank body, a cover body, a water inlet hole, a driving device, a stirring device and a material distribution device; the driving device comprises a first driving piece, a first gear, a second gear and a rotating disc; and the stirring device comprises a plurality of stirring assemblies, and each stirringassembly comprises a second driving part, a first telescopic rod, a second telescopic rod, a storage tank, a third driving part, a discharging port, a telescopic pipe and a first elastic part. The reaction effect and efficiency of the water purifying agent and sewage are improved, and the sewage treatment speed is increased.

Owner:陆驰英

Preparation method of sericite-containing composite with high water absorption and retention performance

InactiveCN105524303AHigh moisture absorption and water retentionUnique aspect ratio structureCarboxymethyl celluloseParticulates

The invention discloses a preparation method of a sericite-containing composite with high water absorption and retention performance. The preparation method comprises steps as follows: S1, grinding of sericite: a sericite ore raw material is collected and is roughly broken, the roughly broken sericite ore raw material is ground through a wheel mill, and particles A are obtained after 2-6 times of repeated grinding; S2, processing of the sericite: the particles A are put in a grinder and sufficiently and finely ground for 1-2 h, and a ground substance B is obtained; S3, mixing: carboxymethyl cellulose, cationic starch and polyoxyethylene are added to the ground substance B and sufficiently mixed and stirred for 2-3 h, a sodium sulfate initiator is added for a reaction for 20-40 min at the temperature of 100-120 DEG C, the reaction continues for 30-50 min after the temperature is increased to 120-140 DEG C, and a mixture C is obtained; S4, ultrasonic treatment: the mixture C is ultrasonically dispersed through ultrasonic waves. The preparation process is simple, and the prepared composite has high water absorption and retention performance, has wide application in the aspect of agriculture and chemical engineering and is suitable for popularization.

Owner:ANHUI HENGHAO SCI & TECH

Low-fragrance low-organosilicon glass fiber reinforced PBT material and preparation technology thereof

InactiveCN109762311AImprove the lubrication effectImprove thermal stabilityDecabromodiphenyl etherAntibacterial property

The invention discloses a low-fragrance low-organosilicon glass fiber reinforced PBT material and a preparation technology thereof. The low-fragrance low-organosilicon glass fiber reinforced PBT material is prepared from the following raw materials in parts by weight: 40-50 parts of PBT resin, 4-8 parts of glass fiber, 3-5 parts of antistatic agents, 2-6 parts of coupling agents, 4-8 parts of silicon oil, 2-6 parts of antioxygen, 1-5 parts of fire retardants, 4-8 parts of dispersing agents, 3-6 parts of toughening agents, 4-8 parts of lead caprylate, 2-6 parts of disodium hydrogen phosphate, 1-3 parts of sodium dehydroacetate and 2-4 parts of dimethyl fumarate. The preparation technology comprises the following steps that S1, a set of weighing equipment is selected, stearamide and higher alcohol raw materials are weighed by weight, and the weighted stearamide and higher alcohol raw materials are placed into an anti-corrosion container. According to the low-fragrance low-organosilicon glass fiber reinforced PBT material and the preparation technology thereof, the design is reasonable, decabromodiphenyl ether, titanate and other addition agents are added into the raw materials, the heat stability, antibacterial property, oxidation resistance and flame retardant property for preparing the low-fragrance low-organosilicon glass fiber reinforced PBT material are effectively improved,and the safety of the PBT material is enhanced.

Owner:林建民

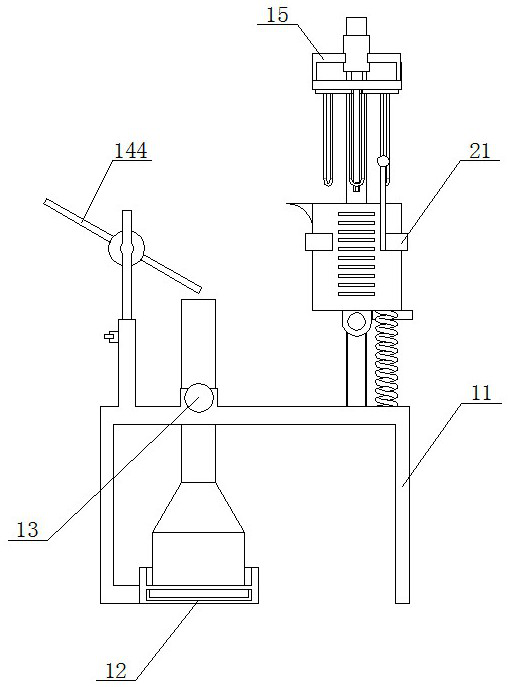

Detection equipment for fluorite titration analysis

PendingCN112697960AFacilitate mixed reactionsStable stirringChemical analysis using titrationWorkbenchTitration

The invention discloses a detection equipment for fluorite titration analysis. The detection equipment comprises a workbench, a measuring cup and a collecting mechanism; the workbench comprises an experiment table and a placing table; the placing table is arranged at the lower end of the experiment table and fixedly connected with the experiment table; the measuring cup is mounted on the upper end face of the experiment table, and the measuring cup is rotatably connected with the experiment table; the collecting mechanism is placed at the upper end of the placing table, the collecting mechanism is detachably and fixedly connected with the experiment table, and it is guaranteed that a user can stably place the experiment table on a corresponding table top for use when needing to use the experiment table; and meanwhile the measuring cup and the collecting mechanism are stably mounted through the experiment table for experiment use, when the detection equipment is used, a user can stably put raw materials needing to be mixed into the measuring cup through the measuring cup to carry out a reaction experiment, and the user can control a stirring mechanism to ascend and descend on a rear end plate in the using process.

Owner:XILIN STEEL GROUP ACHENG IRON & STEEL

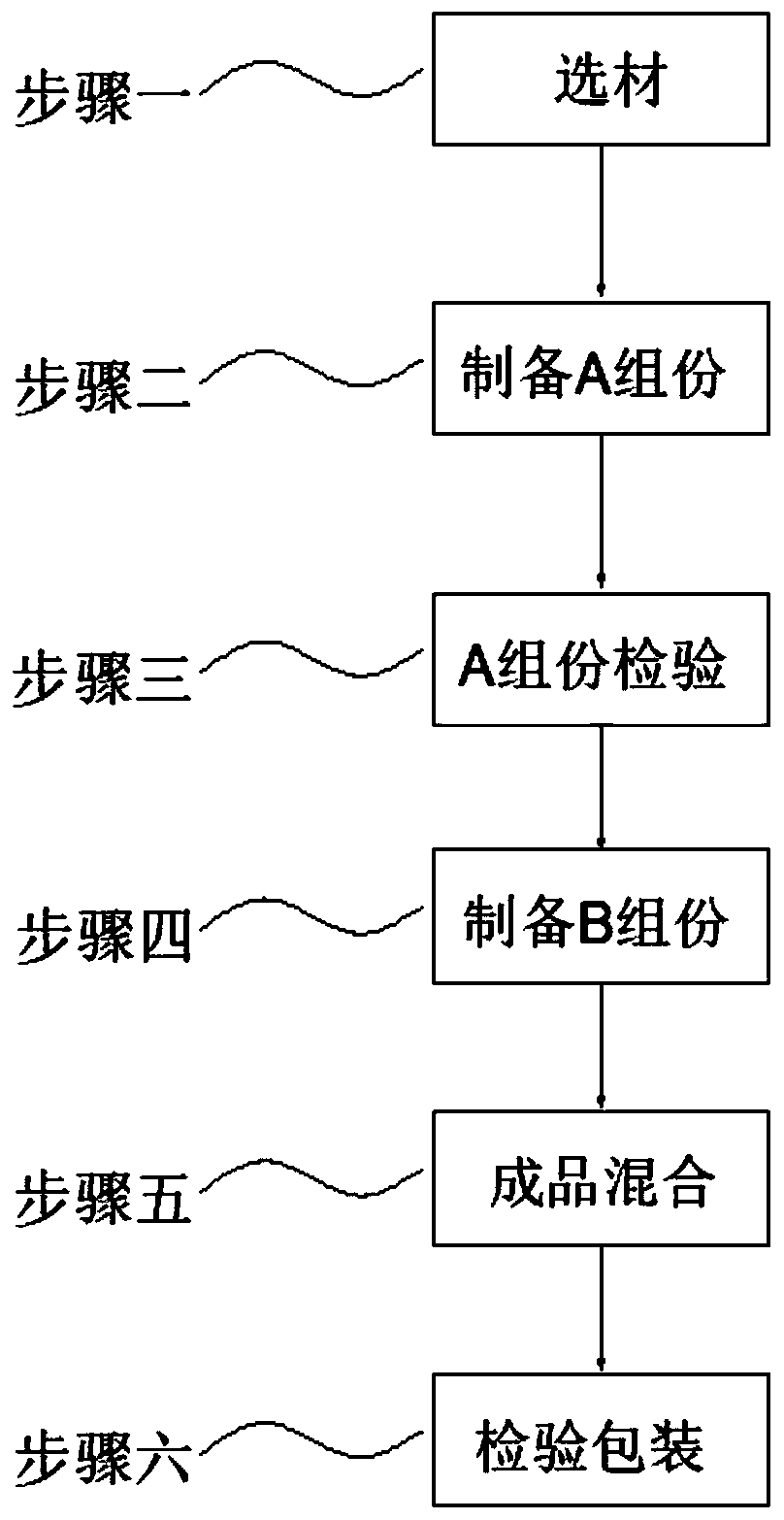

Concrete gel for enhancing hardness and processing method thereof

The invention discloses a concrete gel for enhancing hardness and a processing method thereof. A formula of the concrete gel comprises a component A and a component B, wherein the component A comprises sulphoaluminate, sulfonate and a water-retaining and tackifying agent; the component B comprises ammonium sulfate, sodium sulfate, magnesium chloride, potassium sulfate, sodium silicate, polymeric ferric sulfate, calcium sulfate, sodium gluconate and water; the component A comprises the following components in proportions by weight: 50% of the sulphoaluminate, 30% of the sulfonate and 20% of thewater-retaining and tackifying agent. The concrete gel uses the water-retaining and tackifying agent for replacing originally used cellulose ether, so that the production cost is greatly reduced andthe strength and the hardness of concrete can be improved; the concrete gel accelerates a mixing reaction of cement and water, so that the strength and the hardness of the concrete are greatly enhanced; especially, the sulphoaluminate and the sulfonate are added into the water-retaining and tackifying agent, so that the water permeability and the strength of a product can be further enhanced; through addition of the sodium silicate, the hardness of the concrete is improved; in addition, the preparation method of the gel is simple, short in cycle and low in cost, and is suitable for industrialbatch production.

Owner:福建嘉瑞宝海绵城市环保科技有限公司

Temperature adjusting equipment for chemical mixing

InactiveCN107441988AUniform and stable temperature changesTimely supplementRotary stirring mixersTransportation and packagingHeater RodMixing chamber

The invention discloses temperature adjusting equipment for chemical mixing. The temperature adjusting equipment for chemical mixing comprises a body, a mixing chamber, an alarm, a liquid supplementing pipe, a heating rod controller, a stirrer and a motor, wherein the mixing chamber is formed in the body, a connecting rod is arranged in the middle of the mixing chamber, a pressure detector and a temperature detector are arranged at the bottom end of the connecting rod, the alarm is located above the mixing chamber, a stirring shaft is arranged in the middle of the bottom of the mixing chamber, a stirrer is arranged above the stirring shaft, the lower part of the stirring shaft is connected to the motor, heat conductive oil is accommodated between the body and the mixing chamber, a heating rod II and a heating rod I are arranged on the left side and the right side of the body respectively, the heating rod controller is located on the left side of the body, the liquid supplementing pipe is arranged above the left side of the body, and a sealing cover and a liquid level monitor are arranged on the liquid supplementing pipe. The temperature adjusting equipment is applicable to production and mixing of chemical preparations, is high in safety coefficient and has notably improved mixing efficiency.

Owner:WUHAN CHUANGXINTE TECH CO LTD

Chemical reaction kettle with air pressure stabilizing structure

InactiveCN112619584AAvoid clogging the catheterShorten the timeTransportation and packagingMixersPhysicsEngineering

The invention relates to the field of chemical reaction kettles, and in particular, relates to a chemical reaction kettle with an air pressure stabilizing structure, wherein the chemical reaction kettle comprises a reaction kettle main body, a first fixing pipe is fixedly connected to the side wall of the back face of one side of the reaction kettle main body, and a gas storage tank is fixedly connected to one end, away from the reaction kettle main body, of the first fixing pipe; the gas storage tank is fixedly connected with an air compressor through a second fixing pipe; a gas pressure stabilizer and a pneumatic valve are fixedly connected to the first fixing pipe; a liquid outlet mechanism is mounted in the middle of the lower end of the reaction kettle main body; supporting columns are fixedly connected to the outer walls of the four corners of the lower end of the reaction kettle main body, and a mixing mechanism is mounted in the middle of the upper end of the reaction kettle main body. The liquid outlet mechanism is arranged at the lower end of the reaction kettle, and the upper end of a first piston of the liquid outlet mechanism is flush with the lower end in the reaction kettle main body, so that granular chemical raw materials in the reaction kettle are difficult to enter a liquid guide pipe, and the liquid guide pipe is prevented from being blocked by the granular chemical raw materials; and the mixing reaction between the granular chemical raw materials and the liquid chemical raw materials is facilitated.

Owner:刘茂林

Chemical reaction kettle

PendingCN112915948AReduce precipitationReduce resistanceHollow article cleaningChemical/physical/physico-chemical stationary reactorsEngineeringChemical reaction

The invention discloses a chemical reaction kettle which comprises a kettle body, a driving rotating shaft is rotatably connected to the center of the top of the inner wall of the kettle body, a spiral blade is fixed to the bottom end of the driving rotating shaft and close to the bottom of the inner wall of the kettle body, and a stirrer is fixed to the surface of the driving rotating shaft and located in the kettle body. A scraper device is fixed at the bottom of the stirrer and is close to the bottom of the inner wall of the kettle body, a first magnetic block is fixed at the bottom of the inner wall of the kettle body and is close to the spiral blade, and a second magnetic block is fixed at the bottom of the inner wall of the kettle body and is far away from the first magnetic block. The invention relates to the technical field of reaction kettles. According to the chemical reaction kettle, the purpose of preventing precipitation is achieved, precipitates can be scraped in time, self-cleaning can be achieved during scraping, the adhesion condition is avoided, the mixing reaction quality is high, long-time recycling is facilitated, and the mixing reaction efficiency and the use performance are improved.

Owner:陈世君

Efficient vehicle interior decoration member extrusion equipment

InactiveCN109263007AImprove toughnessMaintain production environmentDirt cleaningDomestic articlesEngineeringMaterial supply

Owner:QUANJIAO XIANGRUI PLASTIC

Polylactic acid polycondensation synthesis equipment and method

PendingCN113181866AReduce concentrationReduce retentionProcess control/regulationProductsPolymer scienceWater collection

The invention discloses polylactic acid polycondensation synthesis equipment and method. The equipment comprises a reaction kettle, the bottom of the reaction kettle is connected with three sets of supporting legs, the top of the reaction kettle is connected with a sealing cover, the sealing cover is provided with a detection piece and a feeding piece, and the reaction kettle is provided with a discharging piece; a steam exhaust pipe is mounted on the sealing cover, and the steam outlet end of the steam exhaust pipe is connected with a condensation assembly for collecting and condensing steam in the reaction kettle; and according to the present invention, the design is performed according to the existing requirements, the circular truncated cone can reduce the concentration of the material in the middle of the reaction kettle inner cavity, the material is well contacted and heated with the reaction kettle side wall, the shearing effect of the stirring assembly is small, the fluidity and the mixing degree of the material can be increased, and the disassembly and the assembly are easy, and the water collection assembly can prevent the condensed water on the inner wall of the steam exhaust pipe from dropping in the inner cavity of the reaction kettle. Water is prevented from dropping into the inner cavity of the reaction kettle to influence the condensation polymerization of materials, and effective condensation polymerization synthesis of polylactic acid is facilitated.

Owner:峰特(浙江)新材料有限公司

Treatment device for dust and waste gas in building material industry

ActiveCN113457289AReduce damage rateReduce impact forceDispersed particle filtrationDust controlProcess engineering

The invention discloses a treatment device for dust and waste gas in the building material industry. The treatment device comprises a box body, a particle filtering mechanism, an air duct adjusting mechanism, a cloth bag dust removal mechanism, a speed reduction mechanism and an acid-alkali washing mechanism; the particle filtering mechanism, the air duct adjusting mechanism, the cloth bag dust removal mechanism, the speed reduction mechanism and the acid-alkali washing mechanism are arranged in the box body; the particle filtering mechanism is arranged at one end of the box; the acid-alkali washing mechanism is arranged at the other end of the box body; the speed reducing mechanism is positioned between the particle filtering mechanism and the cloth bag dust removing mechanism; the cloth bag dust removal mechanism is positioned between the speed reduction mechanism and the acid-alkali washing mechanism; and the particle filtering mechanism comprises a filtering plate, a control plate, a buffering mechanism, a material guiding mechanism, a material guiding plate and a discharging mechanism. Large particles can be independently filtered, and the damage rate of a cloth bag in cloth bag dust removal is reduced; meanwhile, in the cloth bag dust removal mechanism, sticking substances attached to the surfaces of the cloth bags can be loosened through vibration, so that the cleaning effect of back flushing of the cloth bags is improved.

Owner:深圳博奥环境技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com