Concrete gel for enhancing hardness and processing method thereof

A processing method and technology for concrete, applied in the field of concrete gelling agent, can solve the problems of limited hardness of reinforced concrete, complicated processing method, etc., and achieve the effects of low cost, simple preparation method, and improved strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A concrete gel agent for enhancing hardness, the formula includes: A component: sulfoaluminate, sulfonate and water-retaining tackifier; B component: ammonium sulfate, sodium sulfate, magnesium chloride, potassium sulfate, sodium silicate, Polyferric sulfate, calcium sulfate, sodium gluconate and water, the parts by weight of each component are: A component: 50% sulfoaluminate, 30% sulfonate and 20% water-retaining tackifier; B component : 3.5% Ammonium Sulfate, 2% Sodium Sulfate, 0.5% Magnesium Chloride, 0.5% Potassium Sulfate, 0.2% Sodium Silicate, 1% Polyferric Sulfate, 20% Calcium Sulfate, 0.15% Sodium Gluconate, 70% Water and 2.15% A Component mixture.

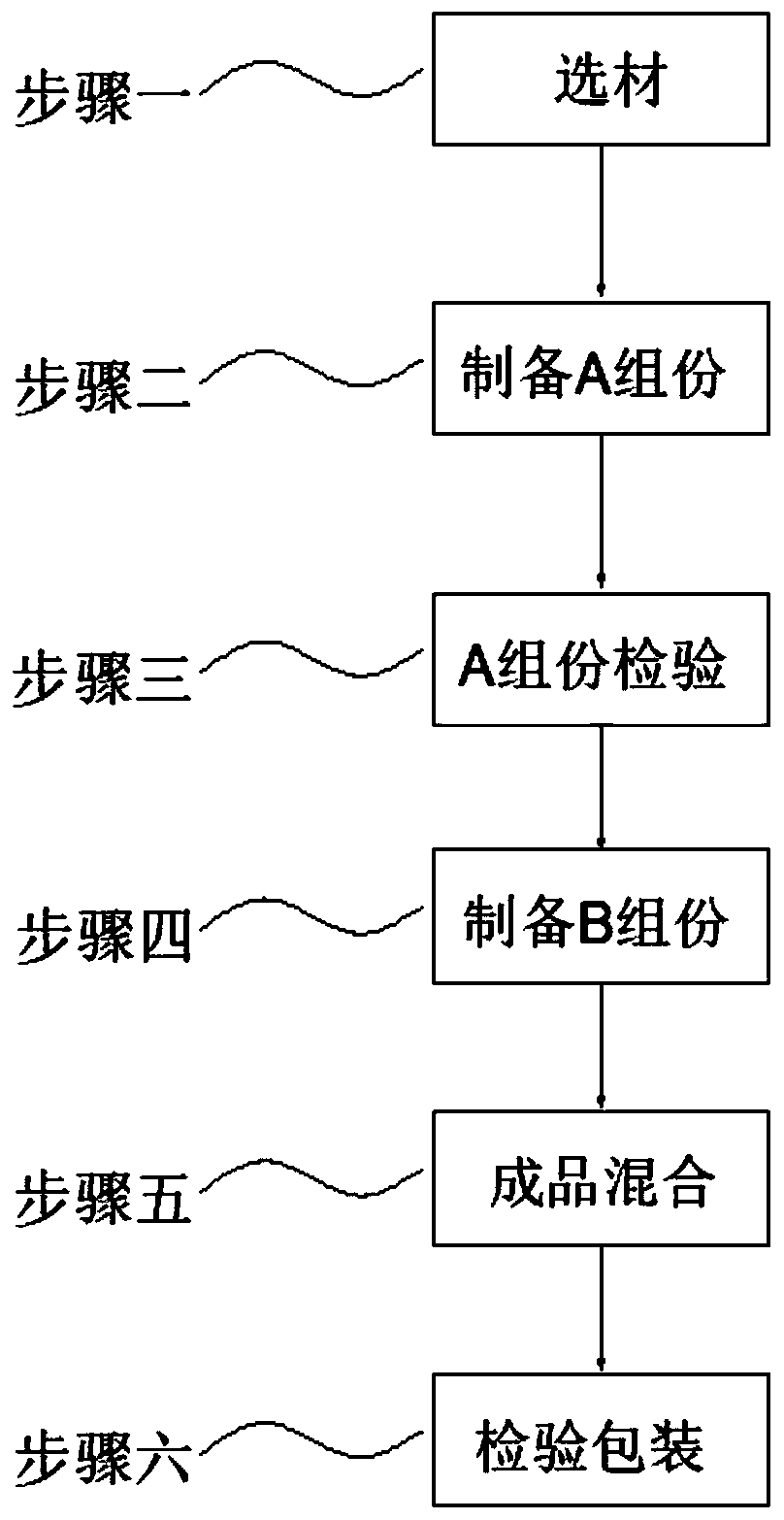

[0027] A processing method of a concrete gel agent for enhancing hardness, comprising the following steps: step 1, material selection; step 2, preparing component A; step 3, testing component A; step 4, preparing component B; step 5, finished product Mixing; Step 6, inspection and packaging;

[0028] Wherein the ...

Embodiment 2

[0043] A concrete gel agent for enhancing hardness, the formula includes: A component: sulfoaluminate, sulfonate and water-retaining tackifier; B component: ammonium sulfate, sodium sulfate, magnesium chloride, potassium sulfate, sodium silicate, Polyferric sulfate, calcium sulfate, sodium gluconate and water, the parts by weight of each component are: A component: 50% sulfoaluminate, 30% sulfonate and 20% water-retaining tackifier; B component : 3.5% Ammonium Sulfate, 2% Sodium Sulfate, 0.5% Magnesium Chloride, 0.5% Potassium Sulfate, 0.5% Sodium Silicate, 1% Polyferric Sulfate, 20% Calcium Sulfate, 0.15% Sodium Gluconate, 70% Water and 1.85% A Component mixture.

[0044]A processing method of a concrete gel agent for enhancing hardness, comprising the following steps: step 1, material selection; step 2, preparing component A; step 3, testing component A; step 4, preparing component B; step 5, finished product Mixing; Step 6, inspection and packaging;

[0045] Wherein the a...

Embodiment 3

[0060] A concrete gel agent for enhancing hardness, the formula includes: A component: sulfoaluminate, sulfonate and water-retaining tackifier; B component: ammonium sulfate, sodium sulfate, magnesium chloride, potassium sulfate, sodium silicate, Polyferric sulfate, calcium sulfate, sodium gluconate and water, the parts by weight of each component are: A component: 50% sulfoaluminate, 30% sulfonate and 40% water-retaining tackifier; B component : 3.5% Ammonium Sulfate, 2% Sodium Sulfate, 0.5% Magnesium Chloride, 0.5% Potassium Sulfate, 0.8% Sodium Silicate, 1% Polyferric Sulfate, 20% Calcium Sulfate, 0.15% Sodium Gluconate, 70% Water and 1.55% A Component mixture.

[0061] A processing method of a concrete gel agent for enhancing hardness, comprising the following steps: step 1, material selection; step 2, preparing component A; step 3, testing component A; step 4, preparing component B; step 5, finished product Mixing; Step 6, inspection and packaging;

[0062] Wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com