Reaction kettle convenient for layered disassembling of filter screens

A technology for reactors and filter screens, which is applied in the field of reactors that facilitate layered removal of filter screens, can solve problems such as gas leakage, hazards, and unfavorable production of polymer polyols, and achieve increased sealing effects, easy stirring structure, and prevention of gas The effect of the leak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

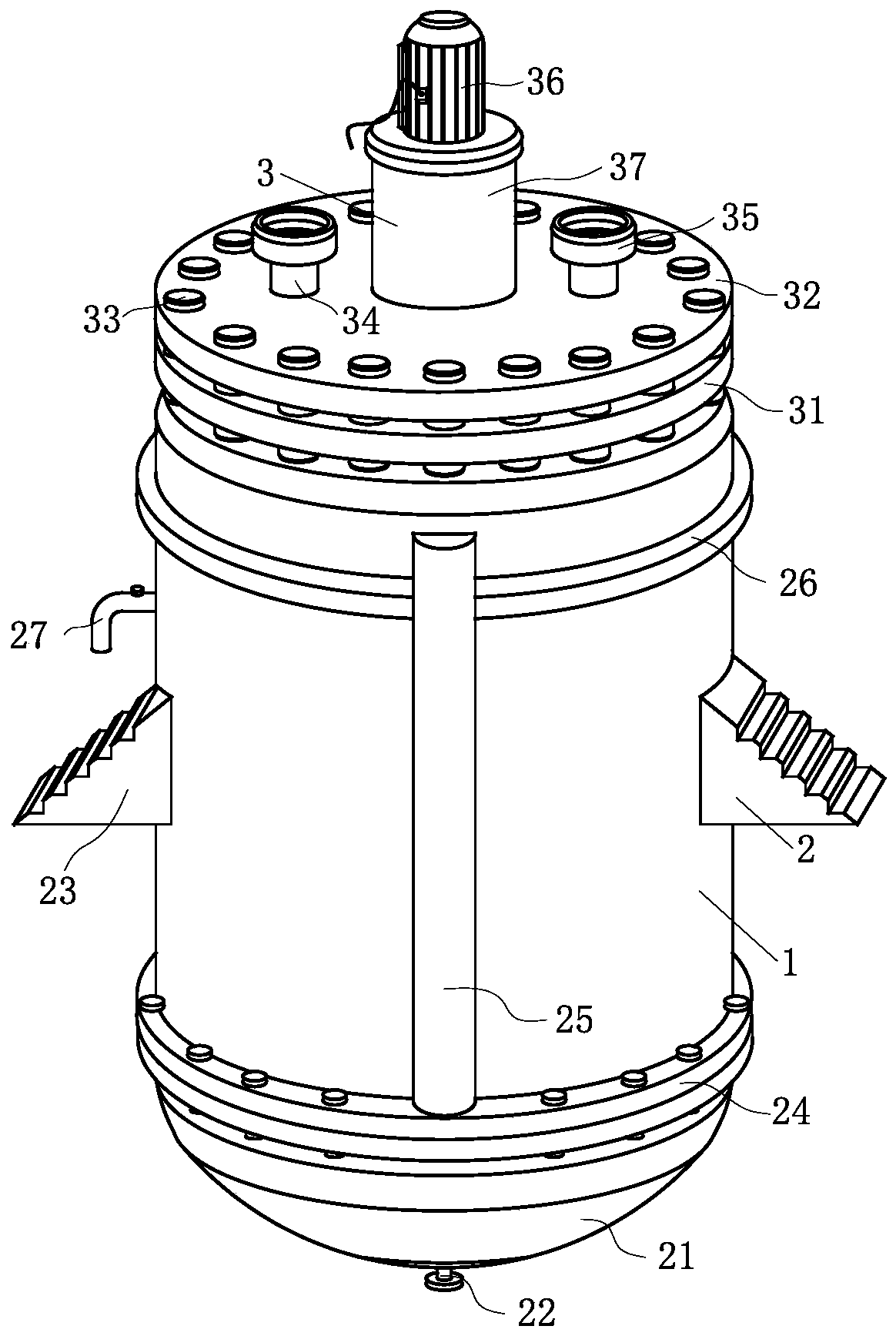

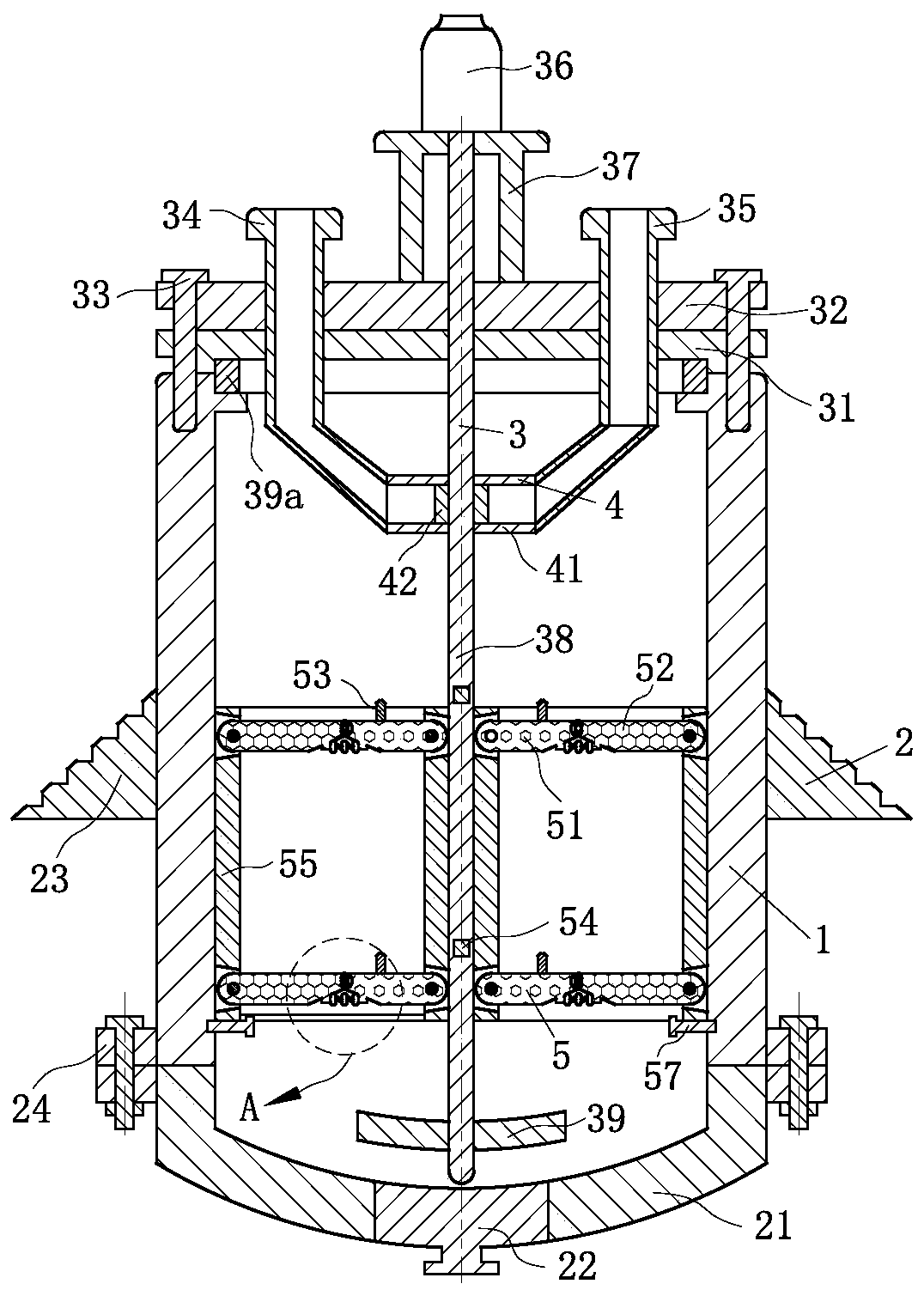

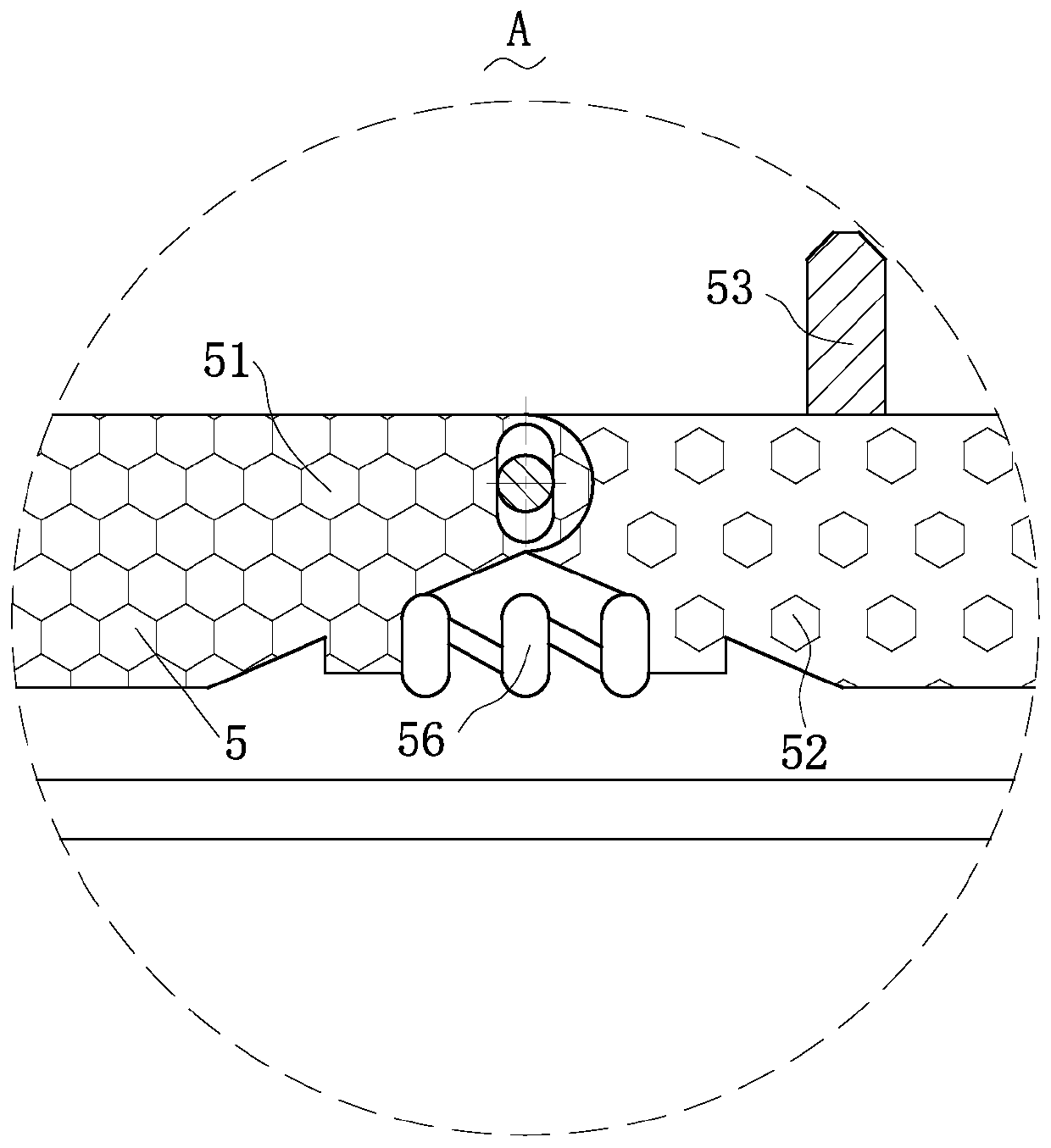

[0022] like Figure 1-Figure 6 Shown, a kind of reactor of the present invention is convenient to layered removal filter screen, comprises reactor body 1, auxiliary structure 2, stirring structure 3, mixing structure 4 and filtering structure 5; The reactor body 1 is connected with the auxiliary structure 2 for feeding, assisting, and strengthening, and the reactor body 1 is connected with the stirring structure 3 for keeping away from the mixed reaction with the catalyst. The inside of the reactor body 1 It is connected with the mixing structure 4 used to increase the relaxation of the catalyst and the raw material, which is beneficial to the discharge. The mixing structure 4 is connected to the stirring structure 3. The interior of the reactor b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com