Patents

Literature

141results about How to "Stable stirring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

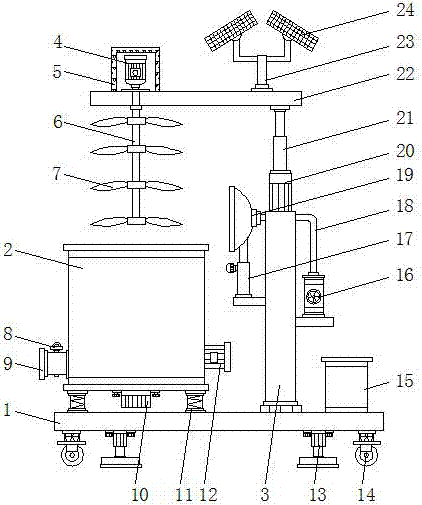

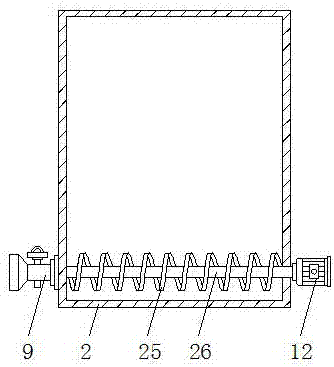

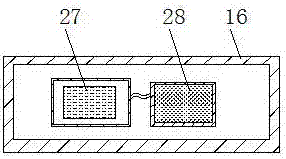

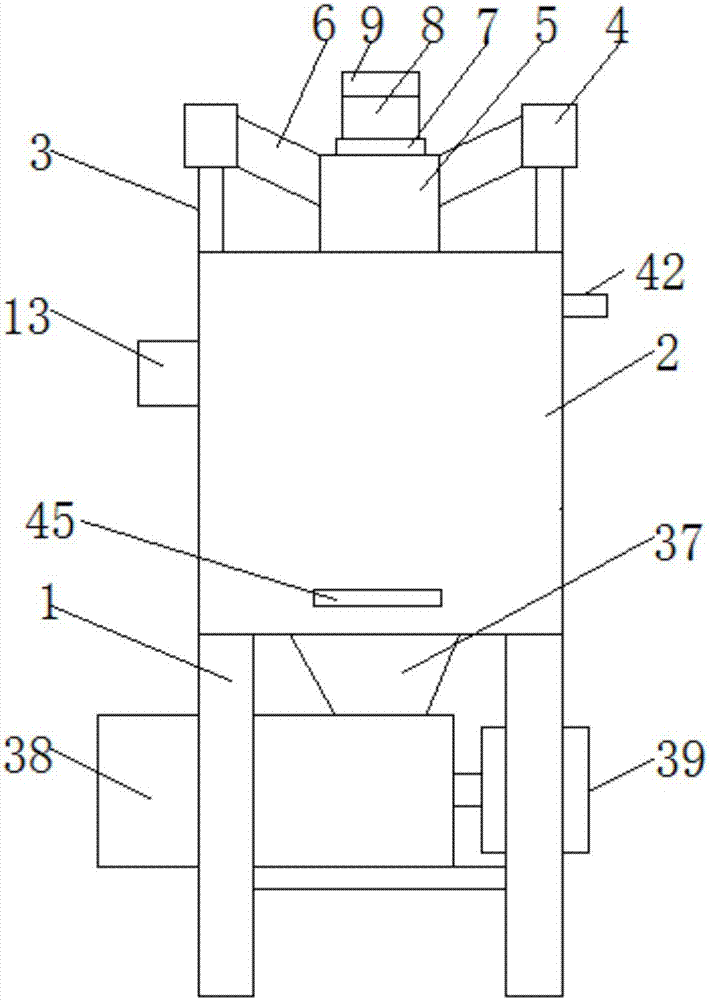

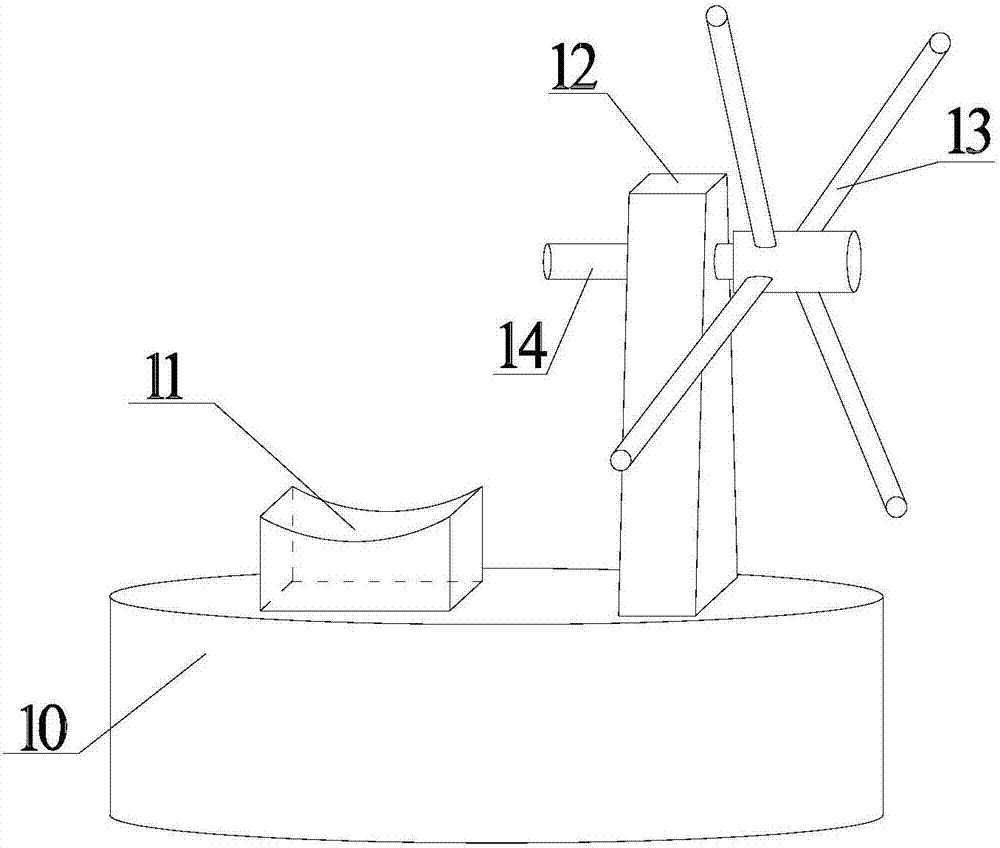

Concrete stirring device for building construction

InactiveCN107379256AEffective absorption and removalAvoid pollutionDischarging apparatusMixing operation control apparatusArchitectural engineeringSolar cell

The invention discloses a concrete stirring device for building construction. The concrete stirring device comprises a base, a stirring barrel and a supporting cross beam; rolling wheels are installed at the four corners of the bottom of the base, the stirring barrel and a supporting column are arranged on the top of the base, a dust collector is installed on the side wall of the supporting column, and a dust collection hood is connected to the dust collector through a dust collection pipe; an electric cylinder is installed at the top end of the supporting column and connected with the supporting cross beam through a ball screw, the supporting cross beam is provided with a stirring motor and a support frame, and solar cell panels are installed at the top end of the support frame. According to the concrete stirring device for building construction, flying dust generated in the stirring process can be effectively sucked and removed, and the condition that the flying dust floats around to pollute the environment is avoided; solar energy in the environment can be utilized to provide electric energy for running of the whole device through the solar cell panels installed on the support frame, and energy conservation and environment protection are achieved; in addition, materials can be automatically conveyed out when discharging is conducted, manual operation is not needed, and therefore the labor intensity is greatly reduced.

Owner:唐云龙

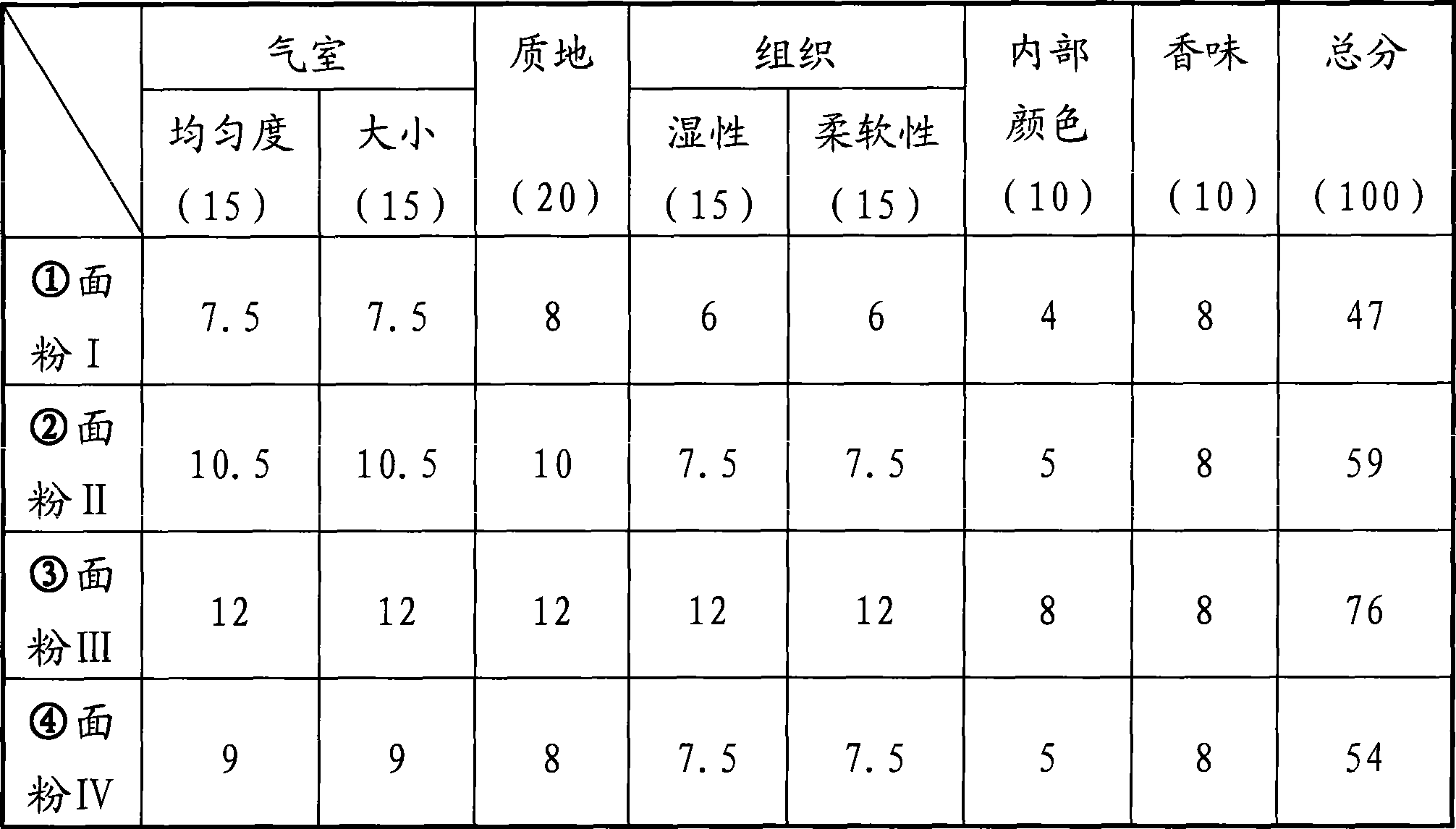

Cake powder quality improver and preparation method thereof

ActiveCN101485346AResistance useIncrease health functionDough treatmentBaking processesAmylaseCellulose

The invention relates to an agent for improving the quality of cake mix and a preparation method thereof. The agent for improving the quality of the cake mix comprises the following compositions in portion by weight: 0.6 to 5.5 portions of stearic propylene glycol ester, 1.5 to 6 portions of CSL / SSL, 0.02 to 0.6 portion of L-cysteine hydrochloride, 0.13 to 0.25 portion of lipase, 0.02 to 0.15 portion of alpha-amylase, 0.005 to 0.025 portion of neutral protease, 14.4 to 29 portions of mono / di-glyceride, 2.6 to 6 portions of gelatin, 6 to 30 portions of insoluble cellulose (CMC) and 37 to 56.3 portions of anticaking agent. The preparation method is to mix various raw materials in a cone-type mixer for 20 to 30 minutes according to proportion, and obtain finished products of the agent for improving the quality of the cake mix. The invention makes an emulsifier have better complementary relation with sensitive enzyme in the aspect of stabilizing the quality of flour, and fully reveals the synergistic reaction of the emulsifier and enzyme preparation.

Owner:中山市南方新元食品生物工程有限公司

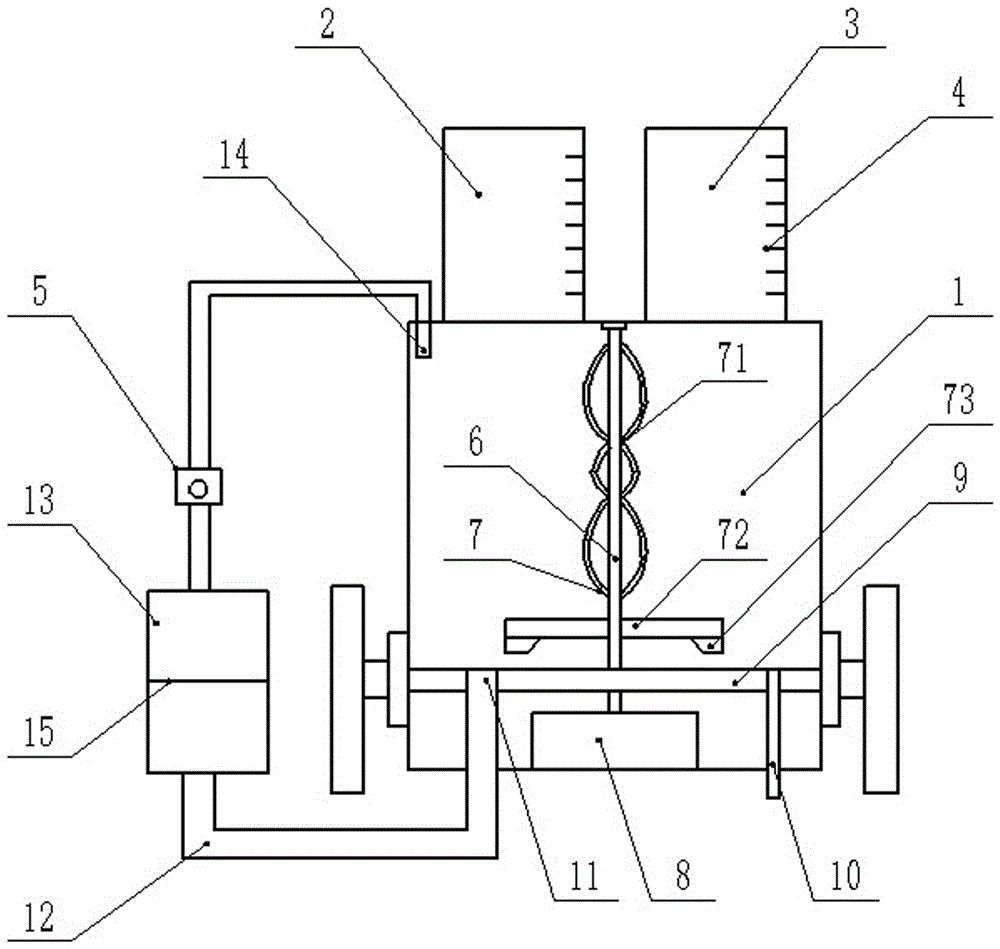

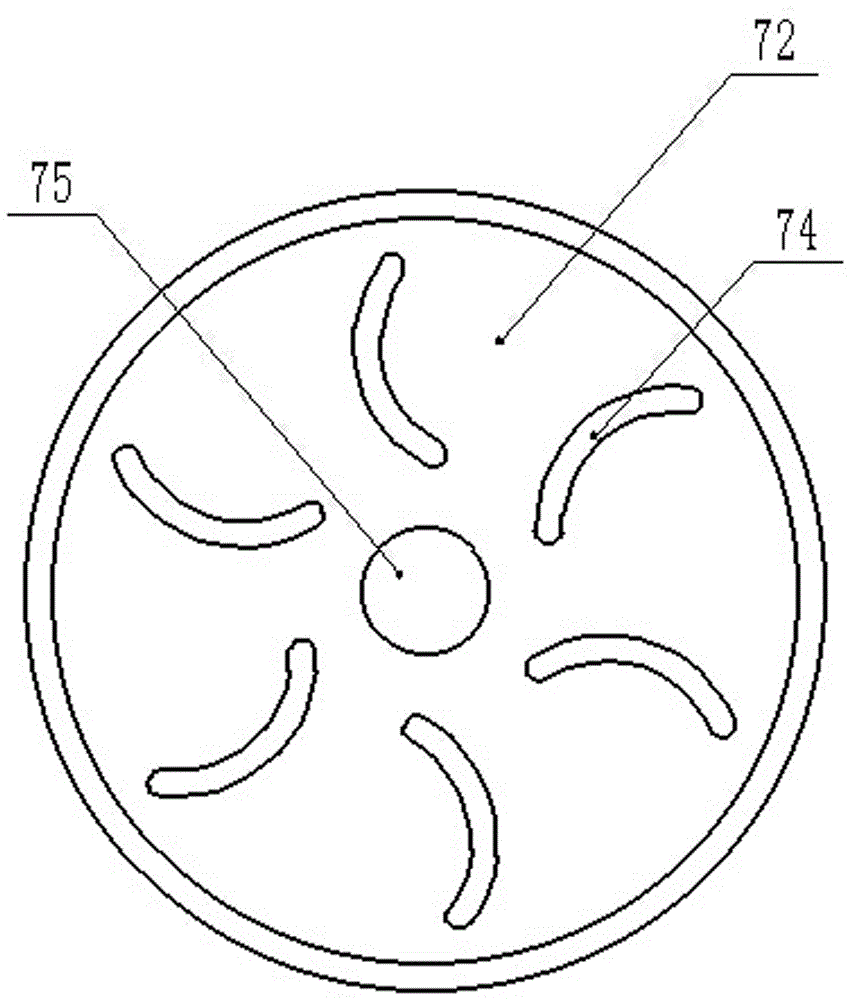

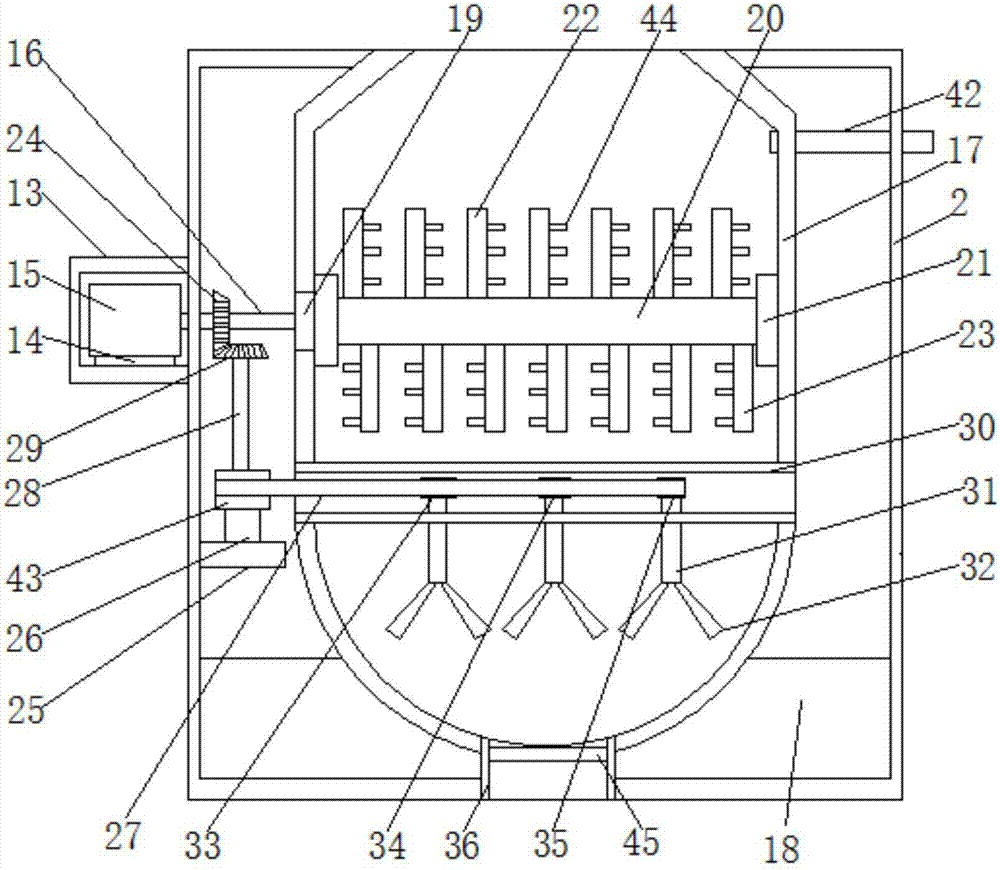

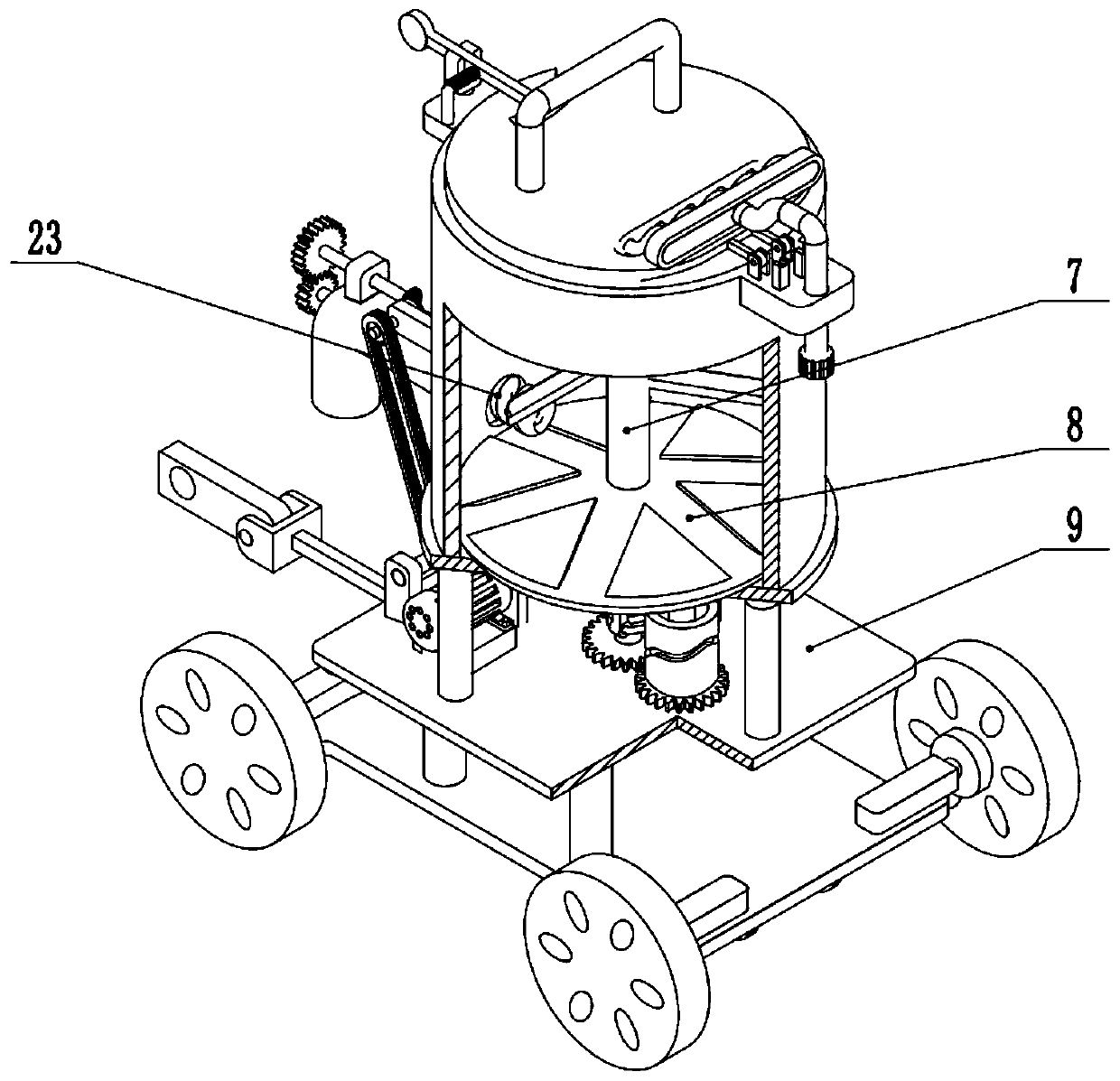

Constructional engineering concrete mixer

InactiveCN106346606AImprove product qualityAccurately grasp the feed ratioCement mixing apparatusSold ingredients supply apparatusElectric machineryArchitectural engineering

The invention discloses a concrete mixer for construction engineering, which comprises a mixing box, a mixing shaft, a mixing assembly, an isolation plate and a water outlet pipe; a feeding box and a water inlet box are respectively arranged on both sides of the upper part of the mixing box, wherein the feeding Both the feeding box and the water inlet box are made of transparent materials; the surfaces of the feeding box and the water inlet box are all provided with scale lines; inside the mixing box, a stirring shaft and a stirring assembly are arranged, and the stirring shaft is located in the mixing box center, wherein the top of the stirring shaft is provided with a bearing assembly, and the bottom of the stirring shaft is driven and connected to a motor; the stirring assembly includes an annular stirring plate and a stirring paddle; an isolation plate is provided between the agitator and the motor; There is a water outlet, and the right side of the isolation class is provided with a material outlet, wherein the water outlet is connected to the water outlet pipe, and the water outlet pipe is connected to the purified water tank; the water outlet pipe of the purified water tank is provided with a water pump; the invention improves product quality, has high stirring efficiency and Low energy consumption is conducive to saving resources and reducing production costs of enterprises.

Owner:GUANGXI UNIV

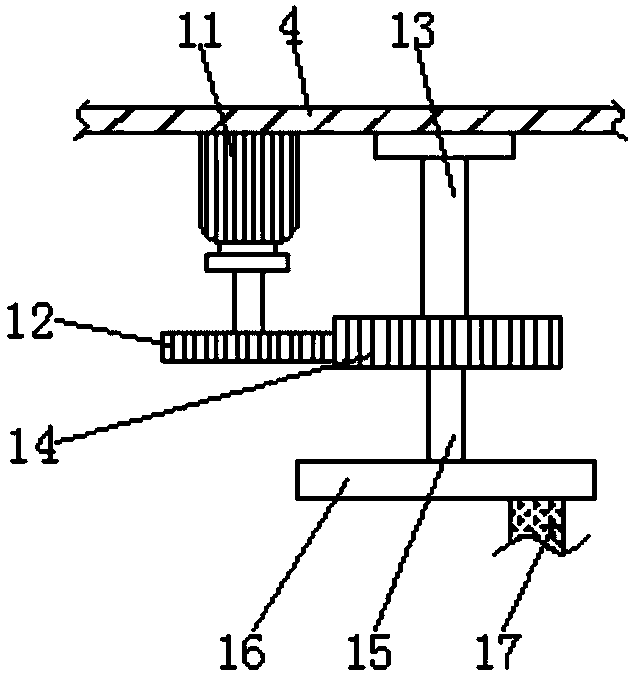

Mixing device for spraying plastic UV light oil on notebook computer

InactiveCN106975393AStir evenly and comprehensivelyStable stirringTransportation and packagingRotary stirring mixersMixing effectPetroleum engineering

The invention belongs to the technical field of notebook computer spraying, particularly relates to a mixing device for spraying plastic UV light oil on a notebook computer and aims at solving the technical problem of providing a mixing device for spraying plastic UV light oil on a notebook computer, which is capable of saving manpower and saving time, and is good in mixing effect and high in work efficiency. In order to solve the technical problems, the invention provides the mixing device for spraying the plastic UV light oil on the notebook computer. The mixing device comprises a bottom plate, a lifting device, a movable plate, a first motor, a bearing block, a rotating shaft, a cover plate and the like, wherein the lifting device is arranged at the left side of the top of the bottom plate; a mobile component of the lifting device is connected with the movable plate; and the bearing block is arranged at the left side of the movable plate in an embedded manner. The plastic UV light oil in a mixing barrel can be comprehensively stirred by a stirring rod through cooperation of a second slide block and an annular sliding chute, and the mixing area can be increased through a hollow sleeve, a scraper blade and mixing blades.

Owner:湖州浩森科技股份有限公司

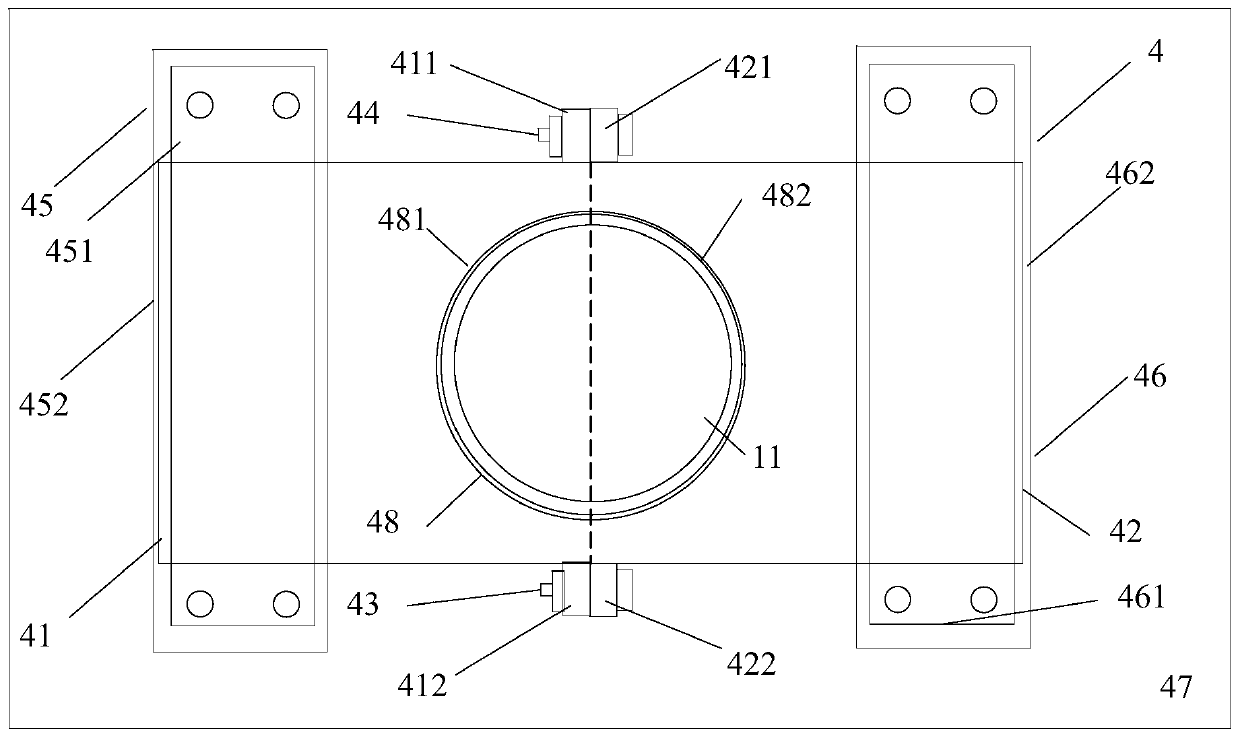

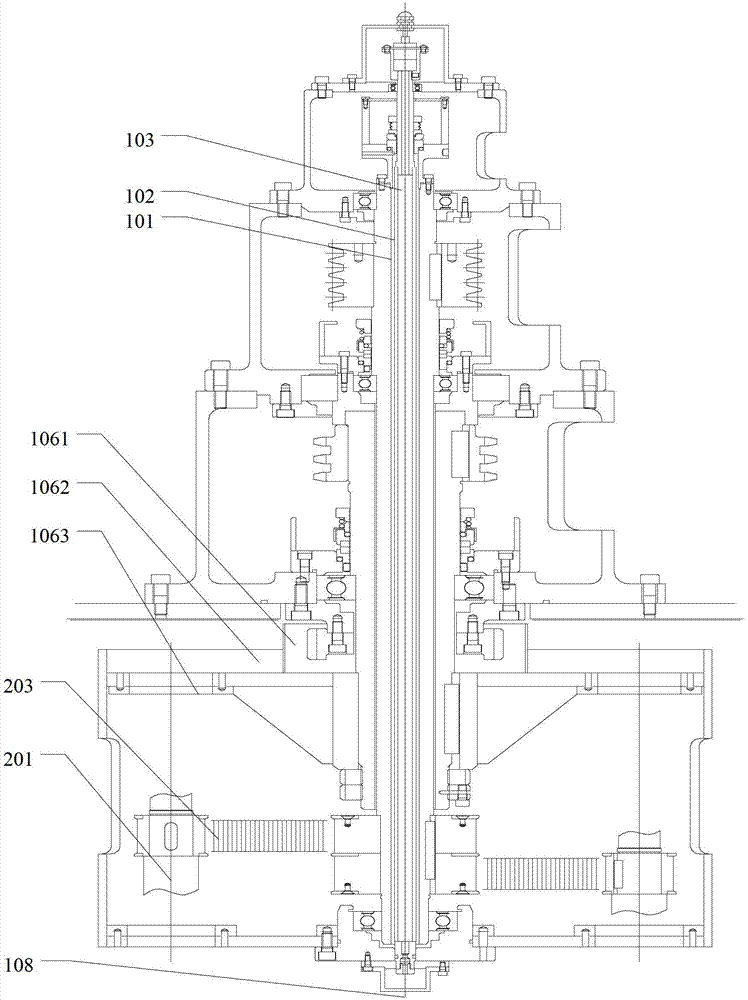

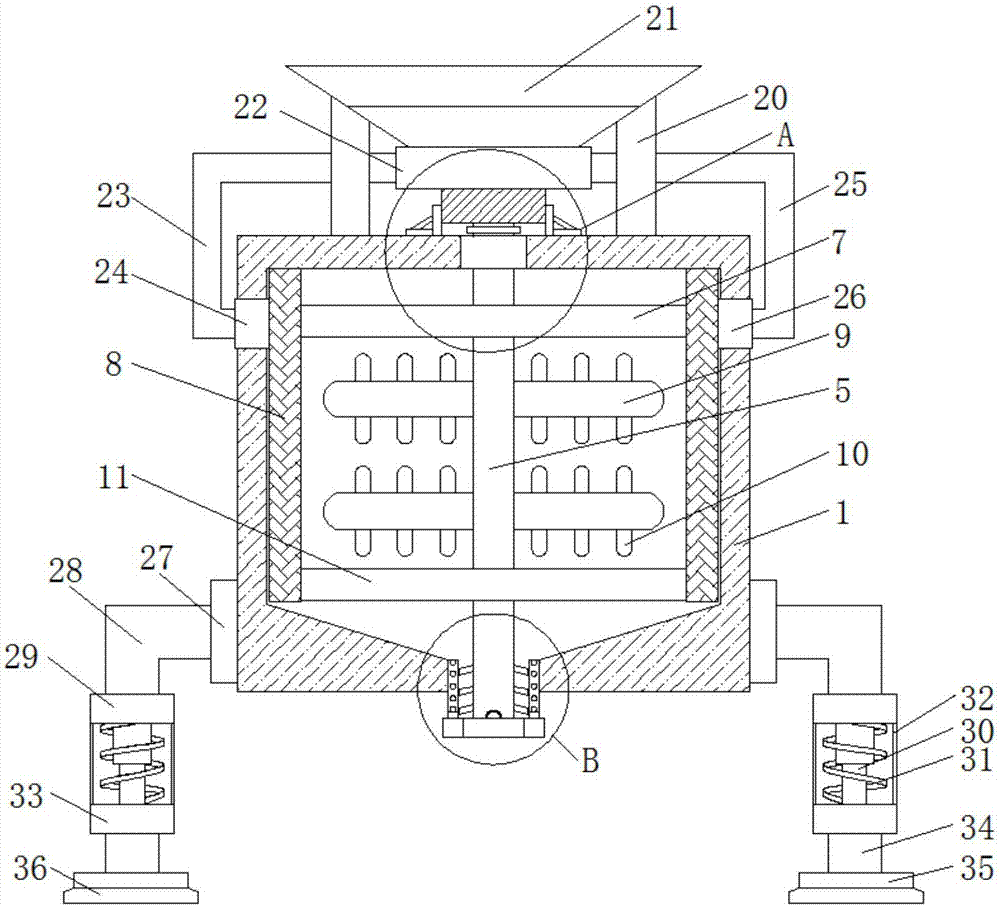

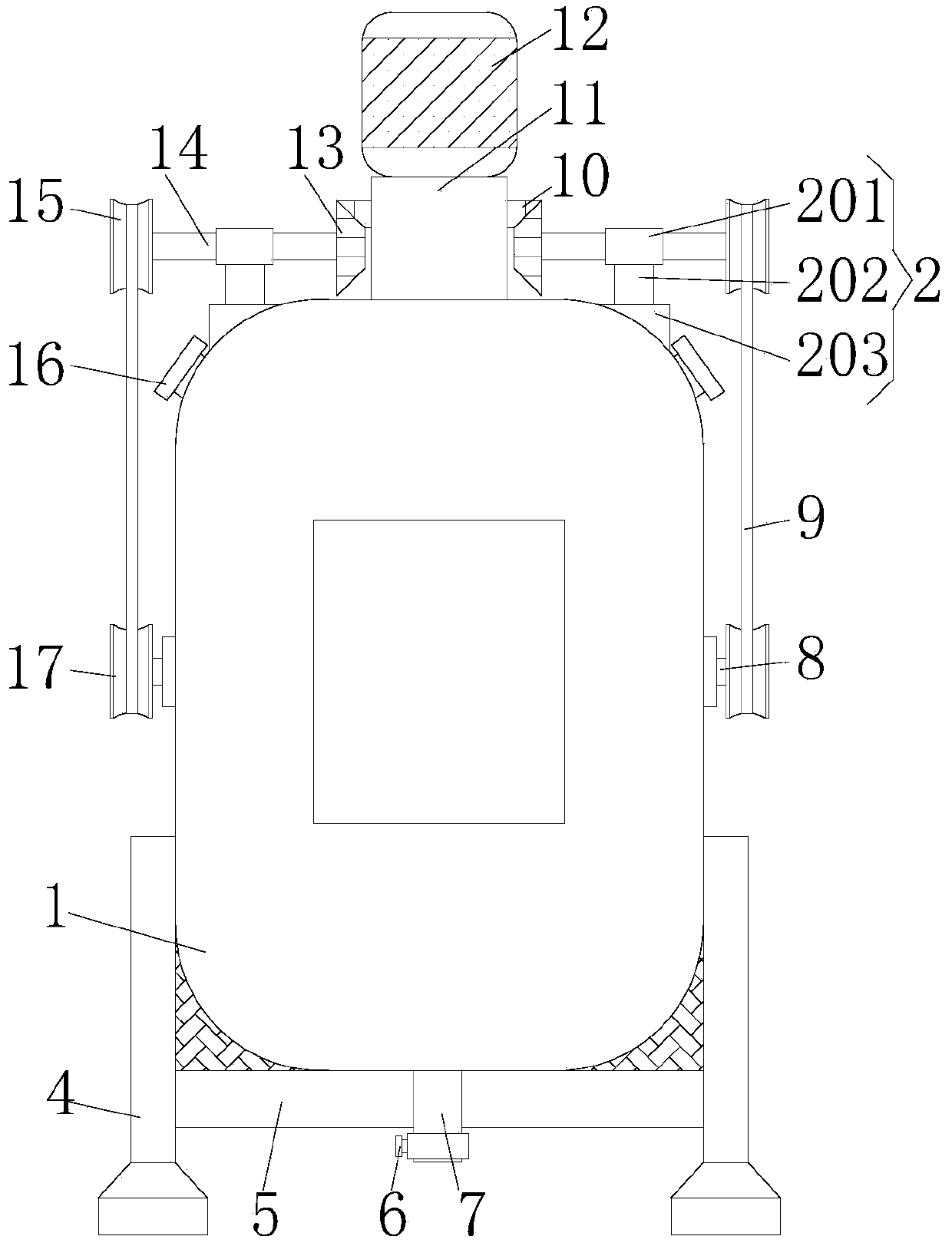

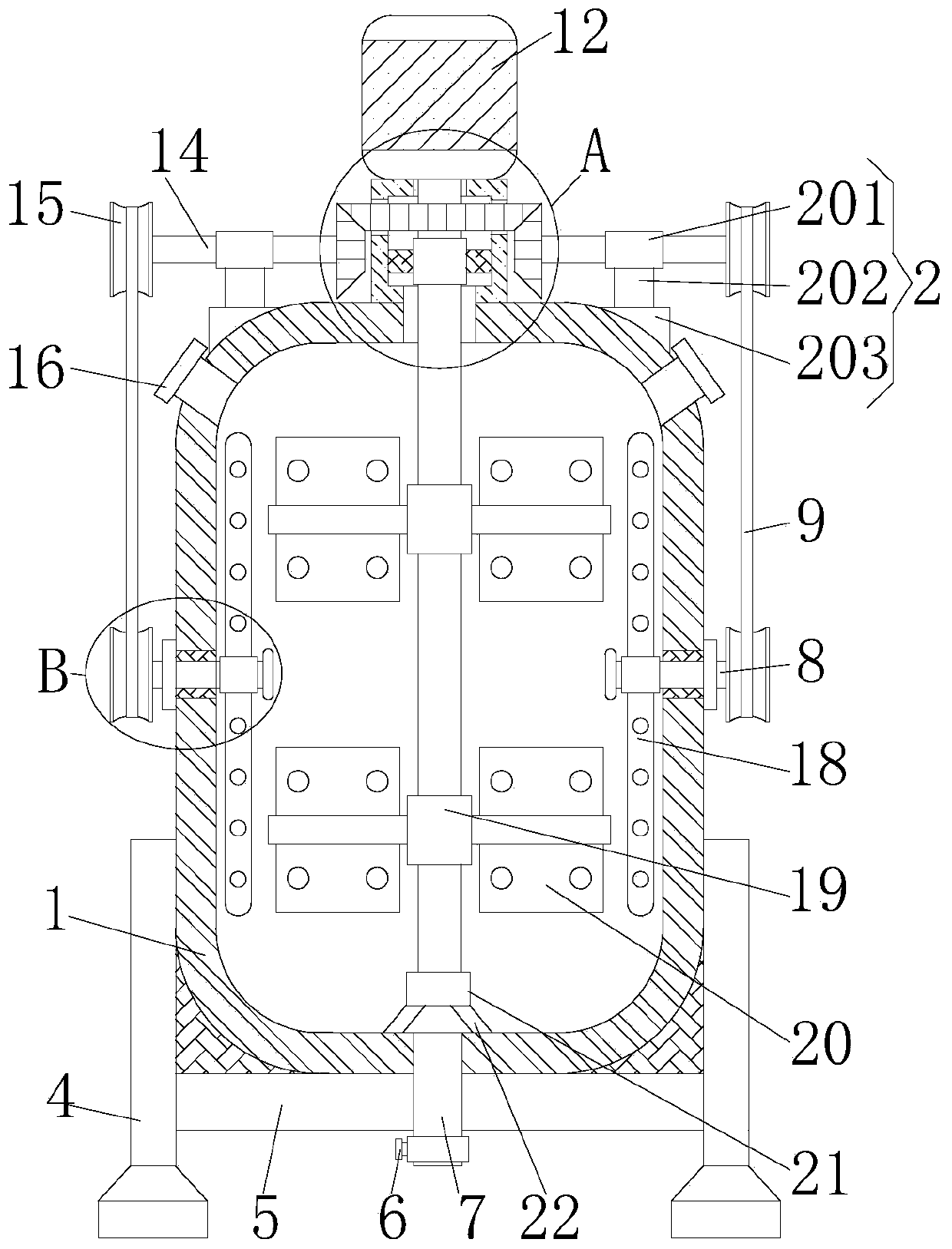

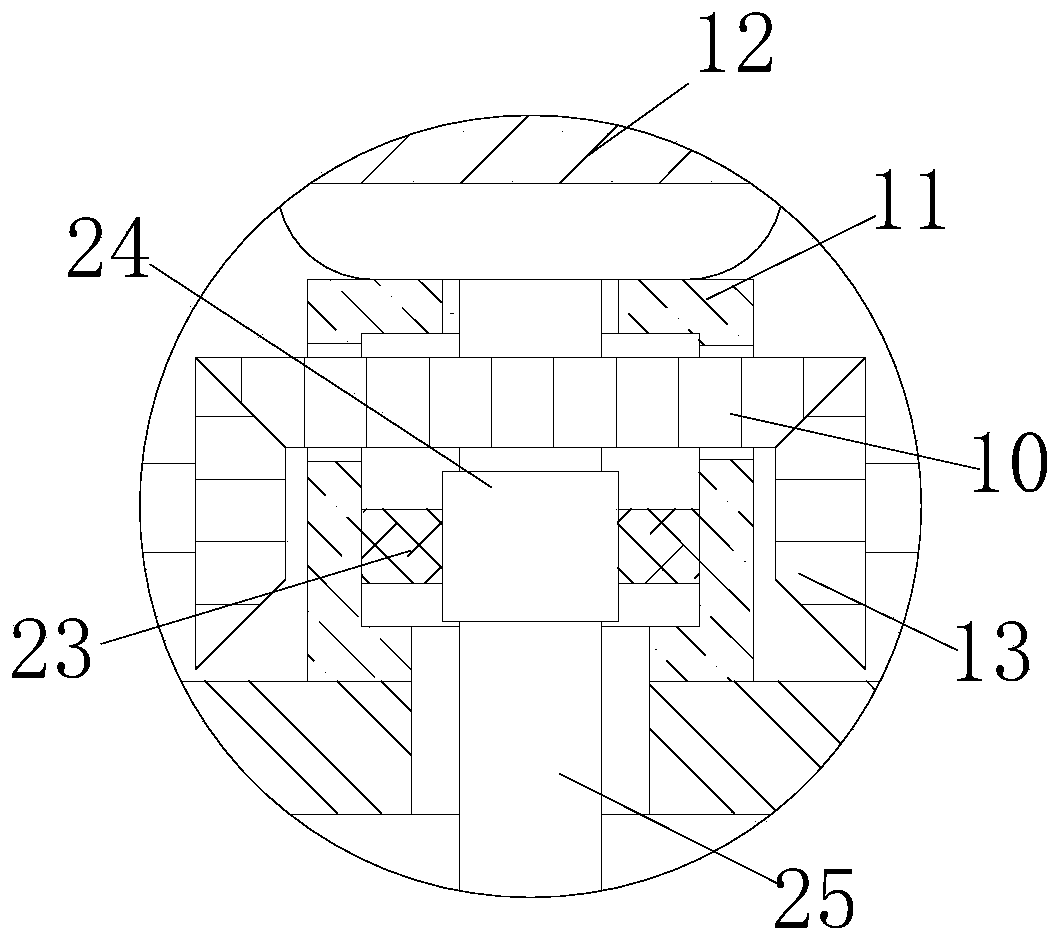

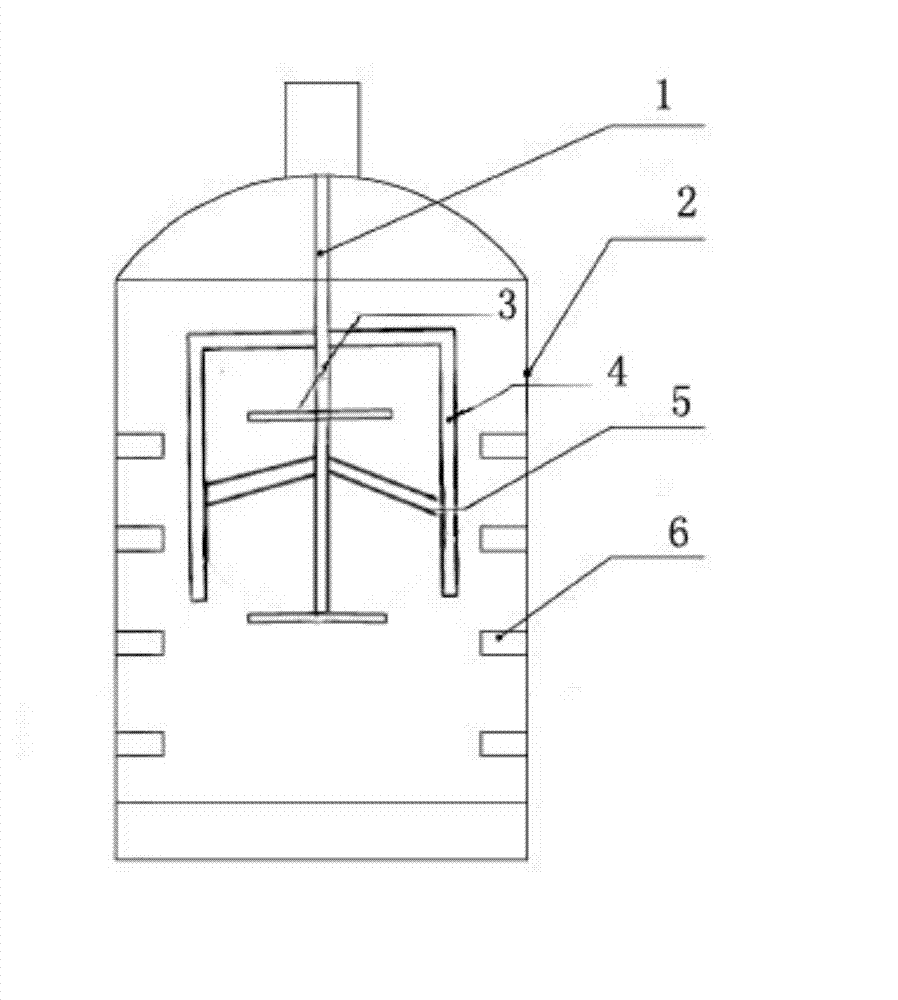

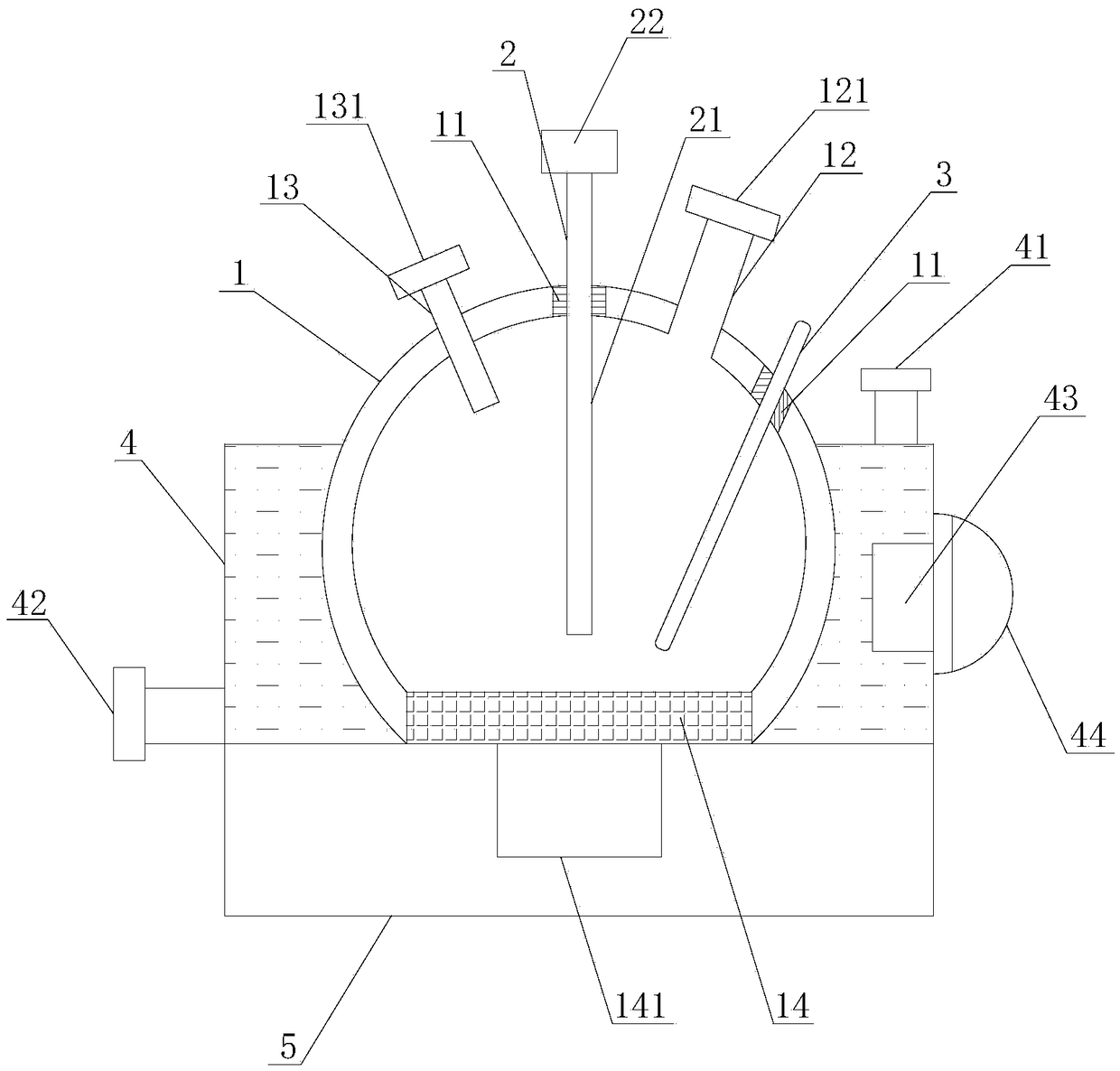

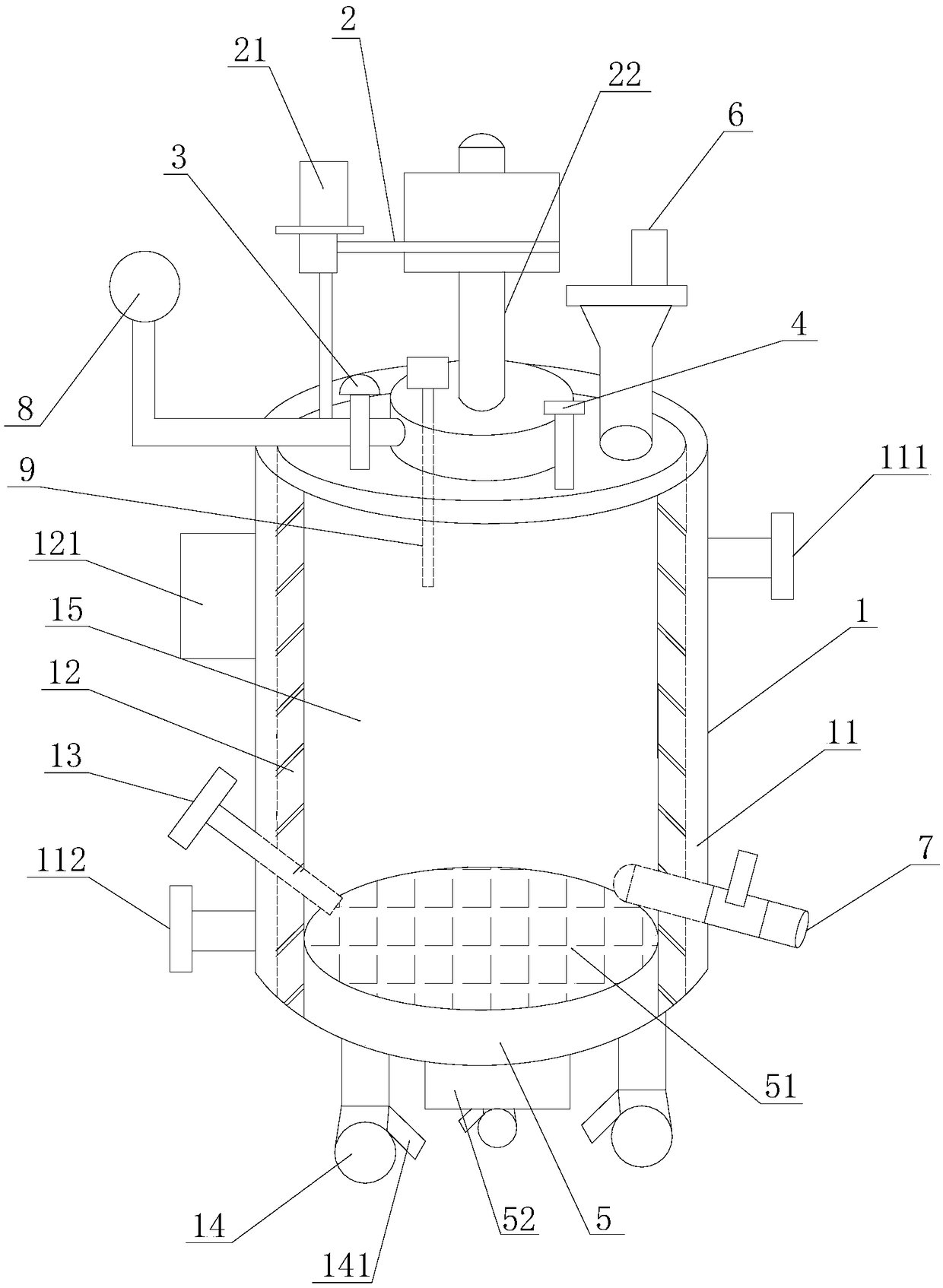

Preparation method of difluoromethoxy polysubstituted nitrogen-containing heterocyclic compound

ActiveCN110385096AImprove performanceImprove protectionOrganic chemistryChemical/physical/physico-chemical stationary reactorsNitrogenous heterocyclic compoundBoronic acid

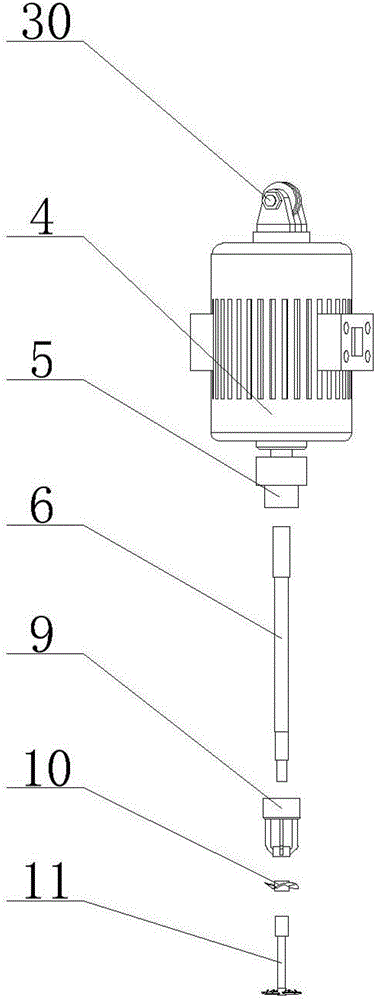

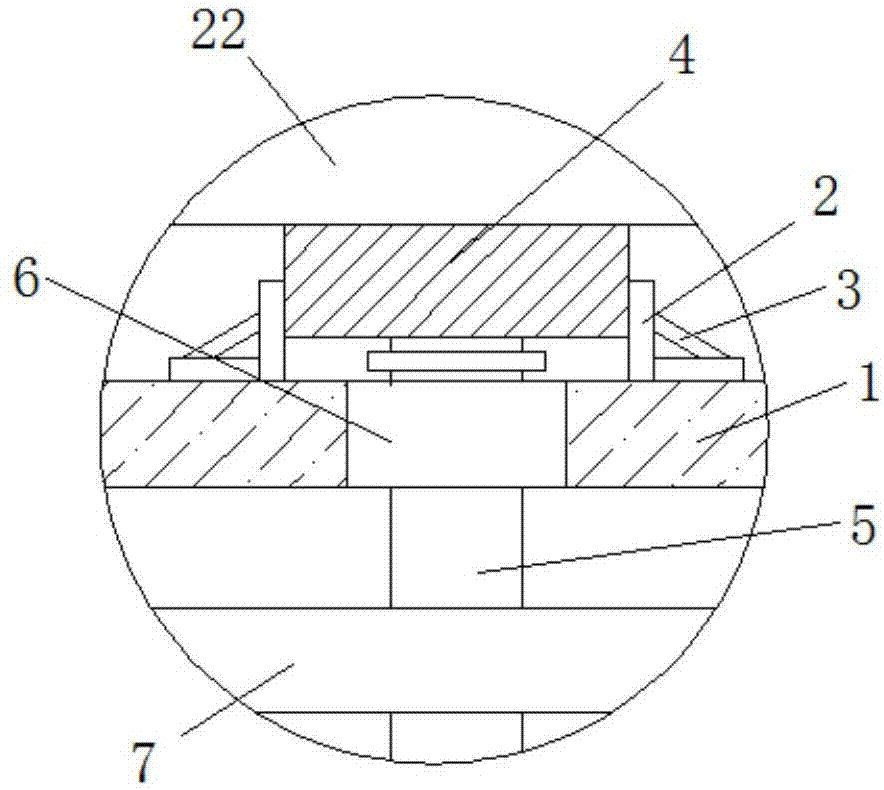

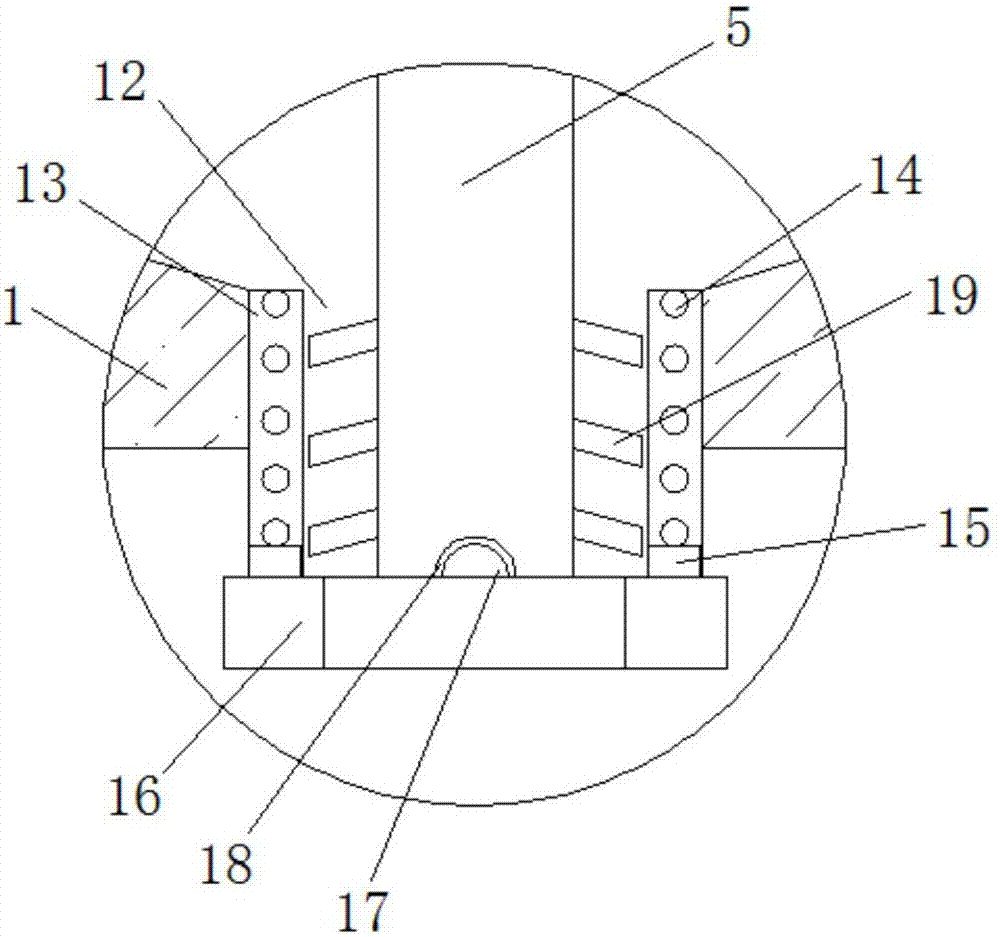

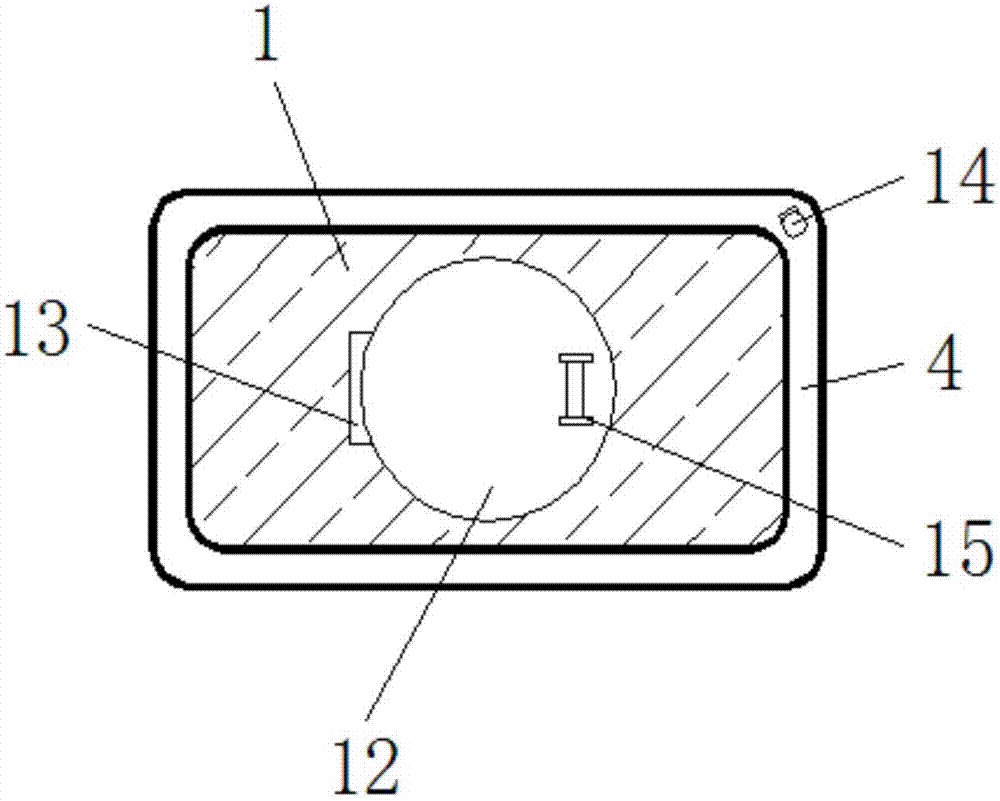

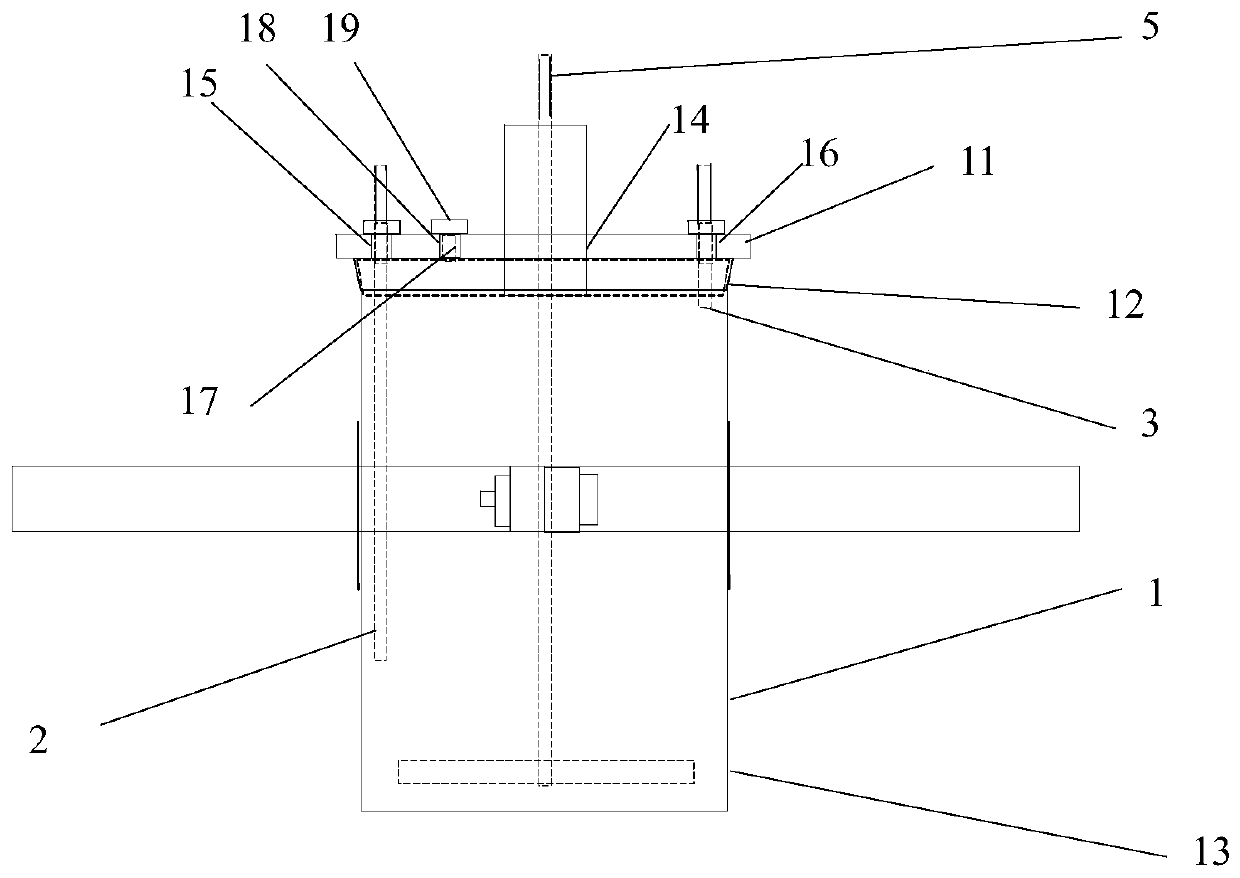

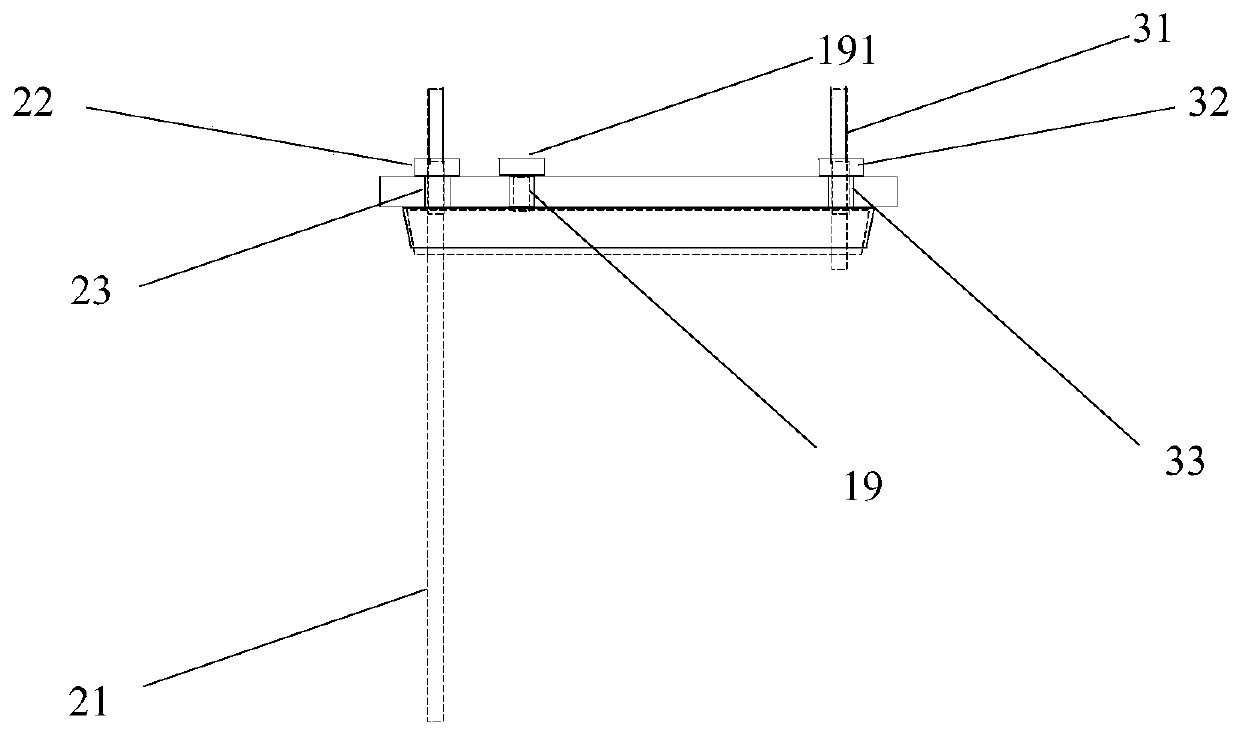

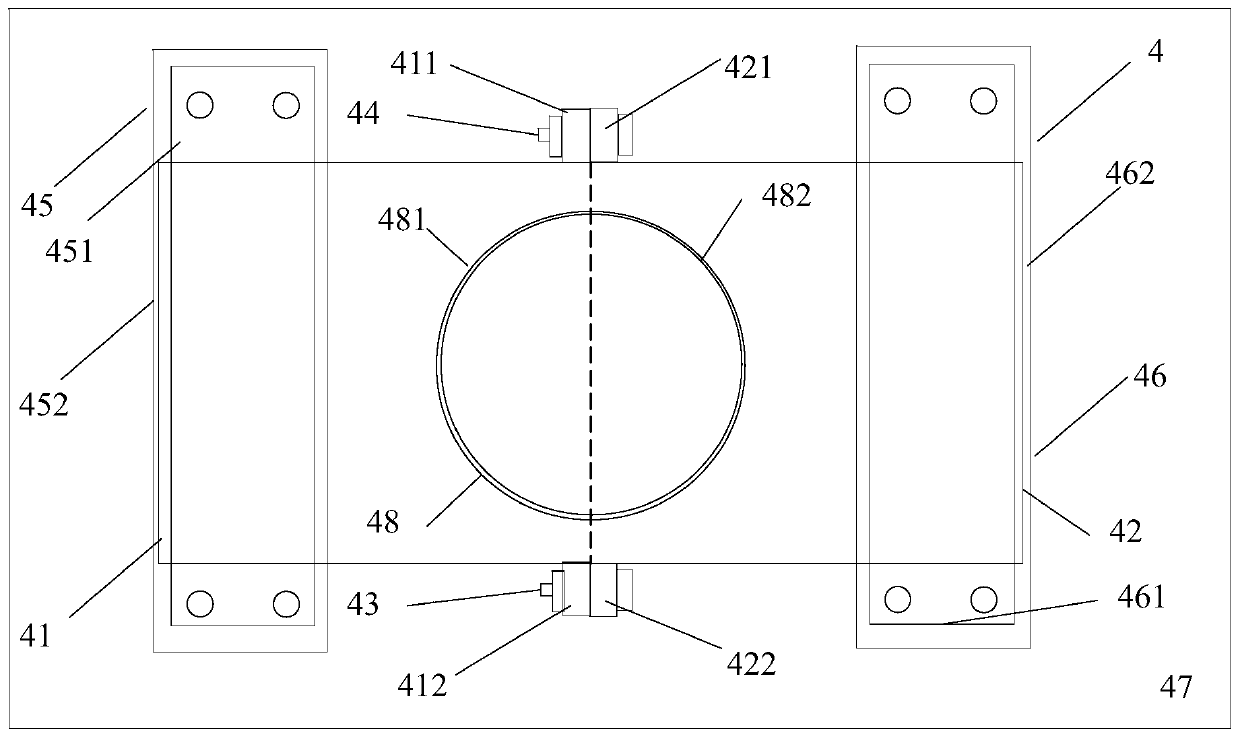

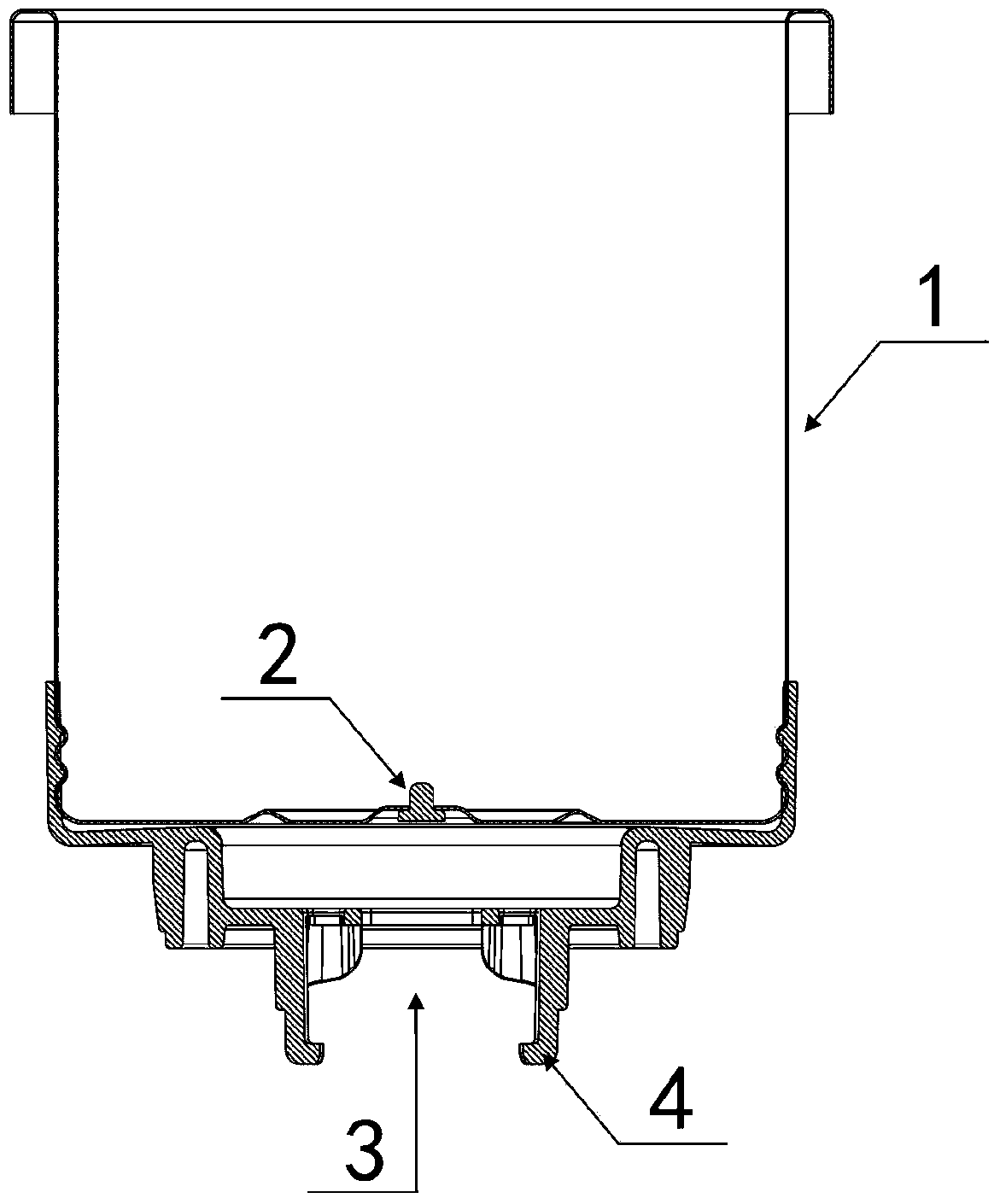

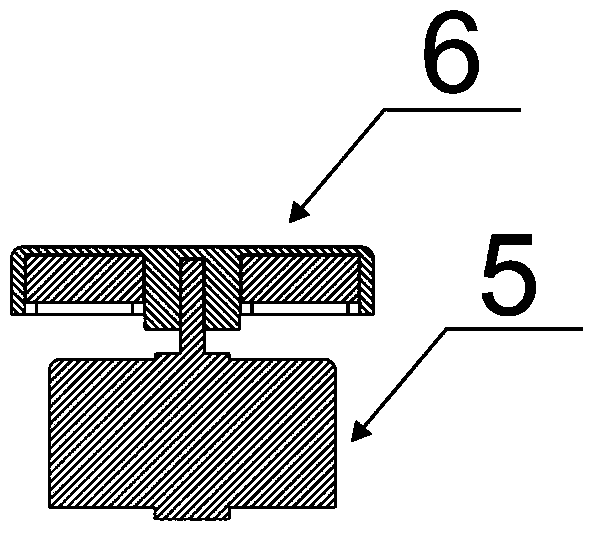

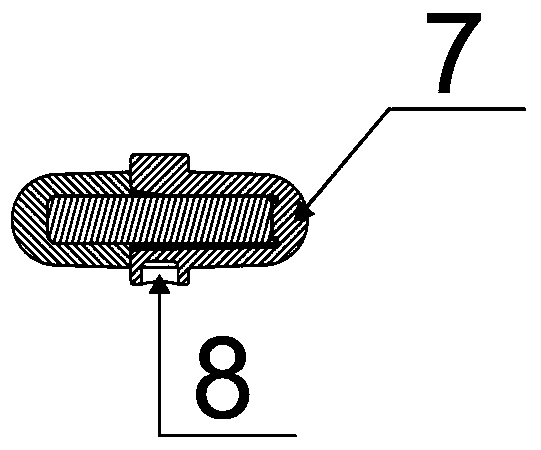

The invention discloses a preparation method of a difluoromethoxy polysubstituted nitrogen-containing heterocyclic compound. The difluoromethoxy polysubstituted nitrogen-containing heterocyclic compound is prepared by using a special reaction kettle, the reaction kettle is provided with a glass body (1), the body is provided with a kettle cover (11), a lower flange (12) and a cylinder body (13) and further comprises an air intake assembly (2), an air outlet assembly (3), a fixing device (4), a stirring part (5) and a cooling pump tank (6); 2-bromo-3-fluoropyridine is used as a starting point to obtain 2-bromo-3-fluoropyridine-4-boronic acid, and 2-bromo-3-fluoropyridine-4-boronic acid is used for preparing 2-bromo-3-fluoro-4-hydroxypyridine; transition of 2-bromo-3-fluoro-4-difluoromethoxypyridine is performed; 3-fluoro-4-difluoromethoxypyridine-2-ethyl formate is prepared; a low temperature reaction under nitrogen protection is performed under protection of nitrogen to obtain 3-fluoro-4-di Fluoromethoxypyridine-2-methanol, a reaction is performed at a room temperature to obtain a final product of 3-fluoro-4-difluoromethoxypyridine-2-formaldehyde.

Owner:北京六合宁远医药科技股份有限公司

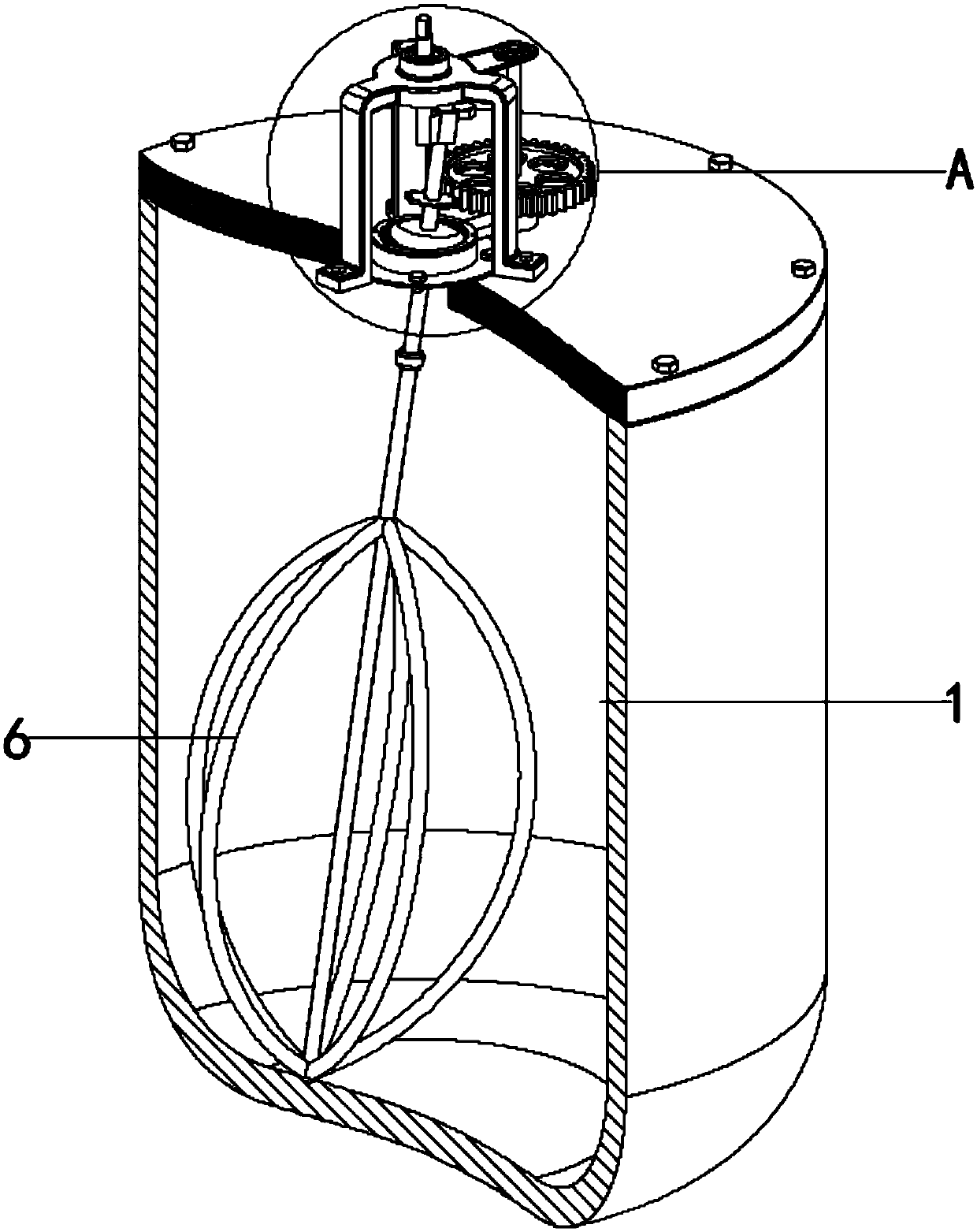

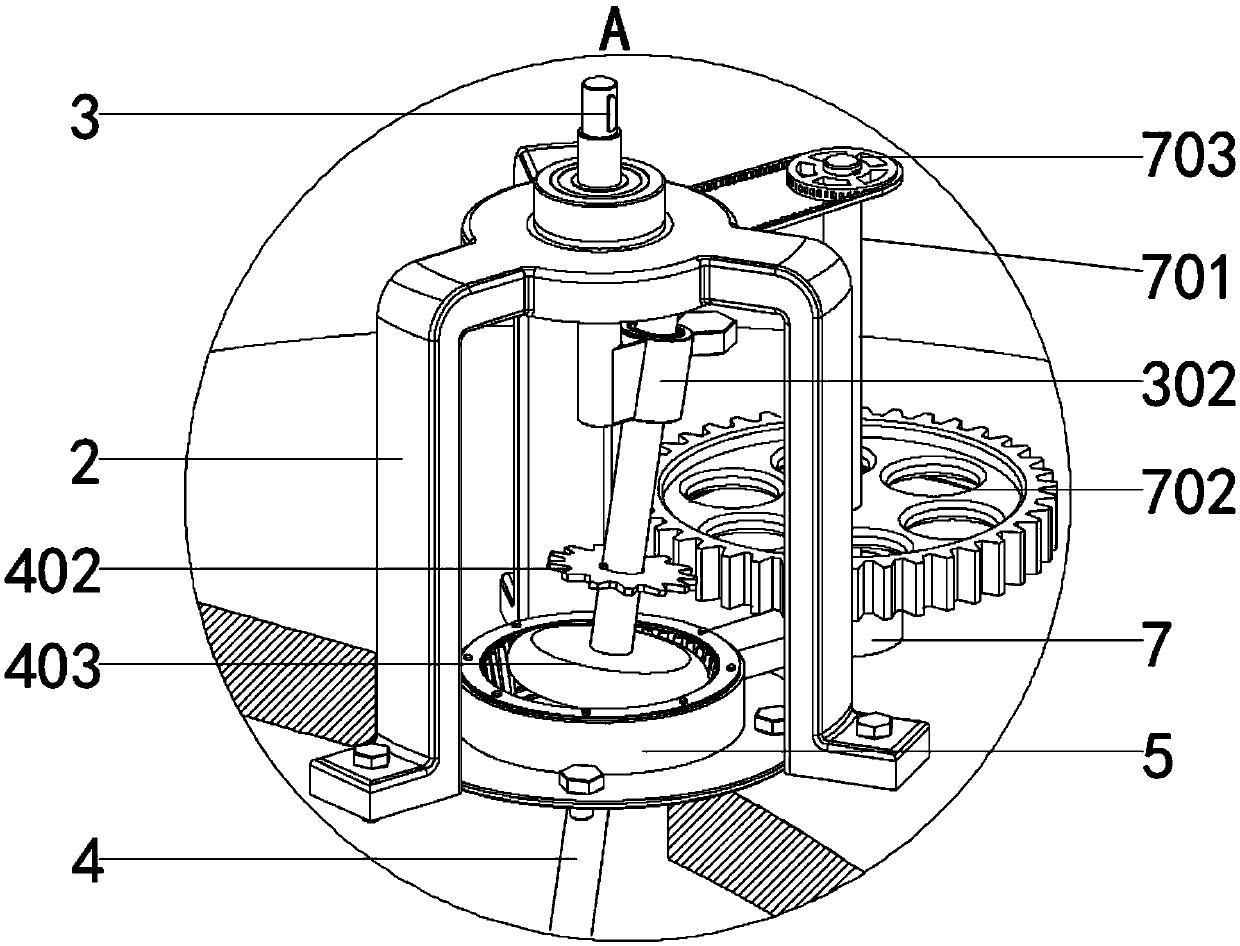

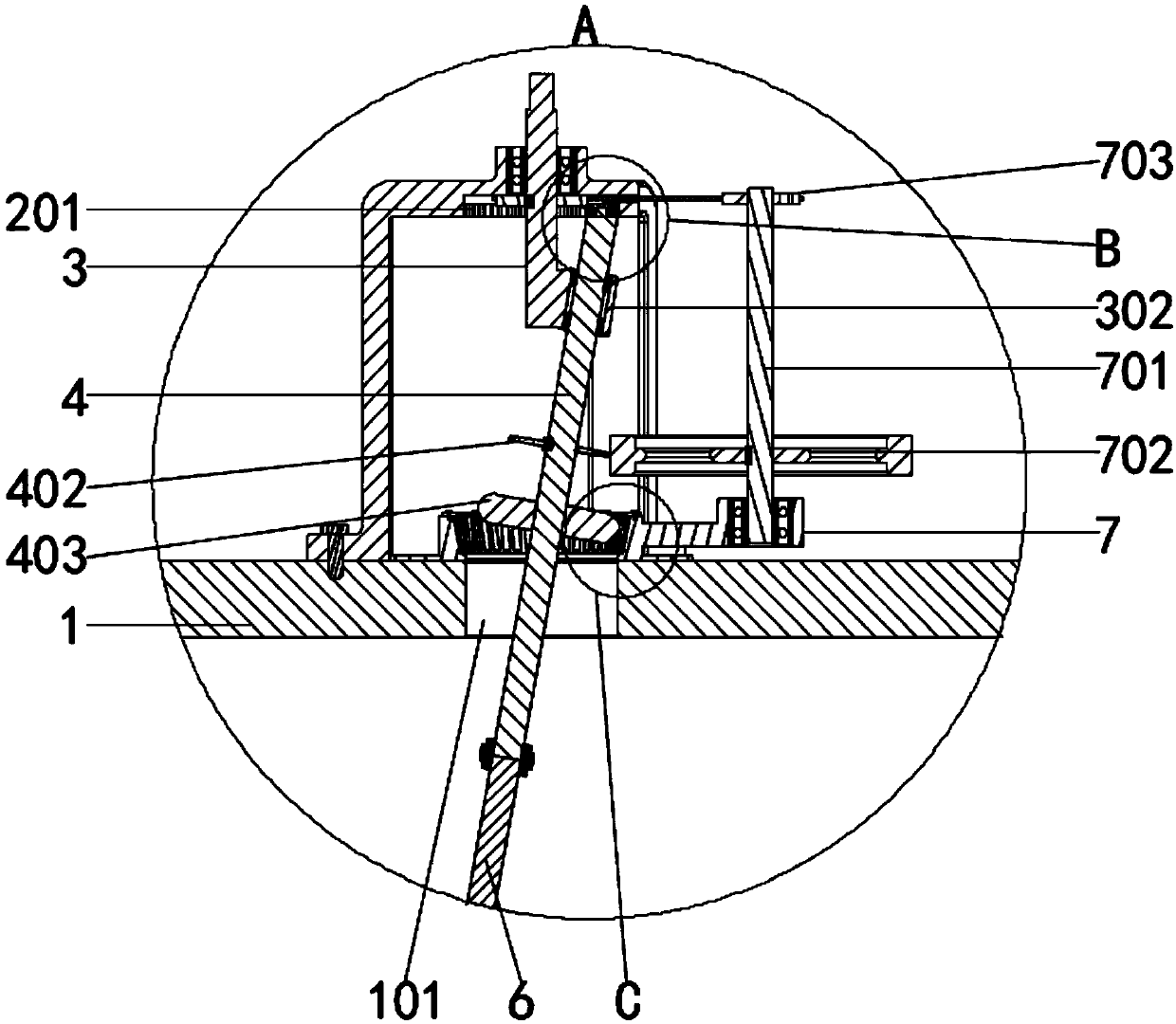

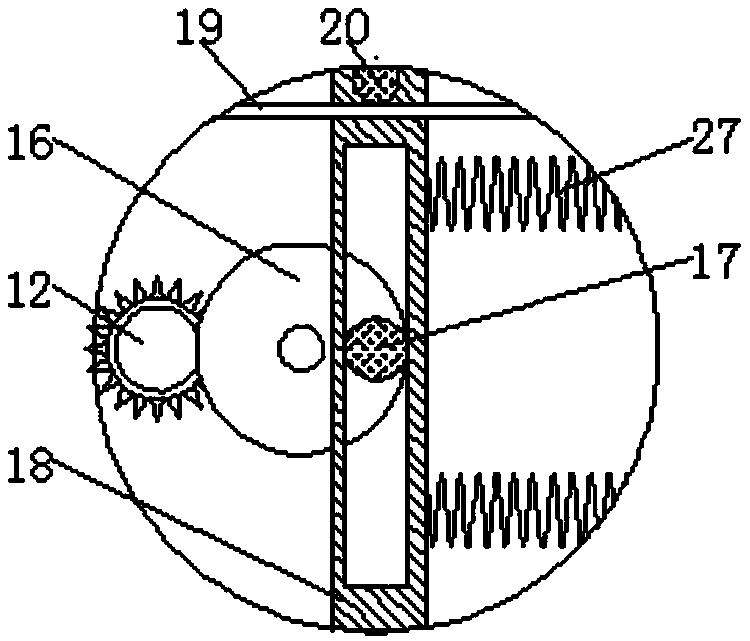

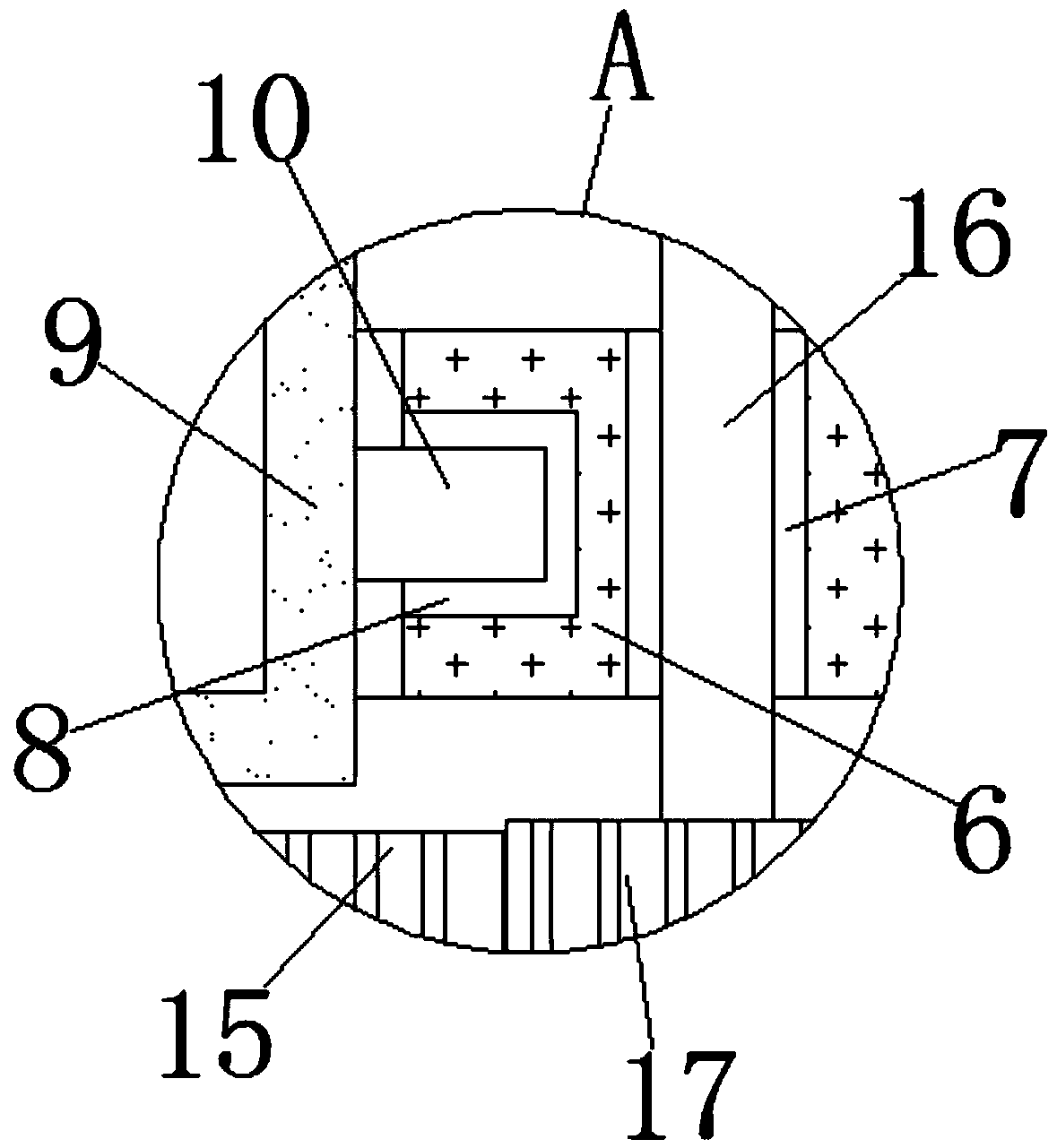

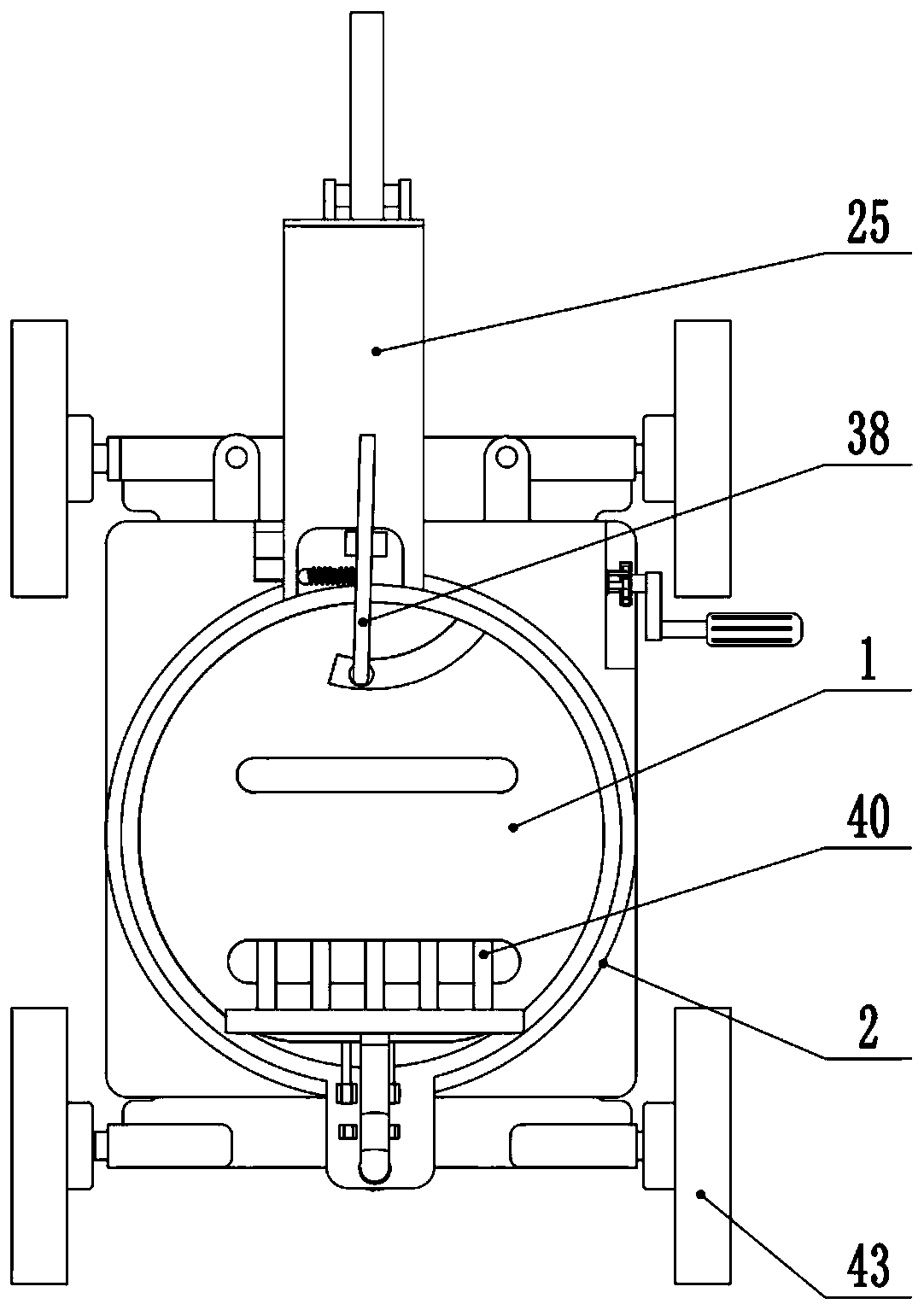

Chemical tank gyro wheel axle stirring device

InactiveCN108671823AImprove the mixing effectStir wellShaking/oscillating/vibrating mixersTransportation and packagingGear wheelCircular cone

The invention provides a chemical tank gyro wheel axle stirring device which comprises: a tank body, a through hole, a mounting frame, an inner gear ring, a mounting seat, a bulge, a bearing embeddinghole, a sleeving slot, a power shaft, a main synchronous belt wheel, an eccentric sleeve, a wheel shaft, a planet gear, a pinion, a gyro wheel, a rotary shaft, a gyro wheel seat, an upper cover, a roller slot, a roller wheel, a mounting flange, a through hole, a stirrer, a connecting seat, a driving rod, a main gear and a secondary synchronous belt wheel, wherein a cylindrical gyro wheel seat isarranged above the through hole; an integrated mounting flange is arranged at the bottom of the gyro wheel seat; the gyro wheel seat is fixed at the top of the tank body through the mounting flange and a bolt. According to the device provided by the invention, through improvement of a chemical tank gyro wheel axle stirring device, the device realizes the functions of cone swing type stirring and reverse autorotation stirring, and has the advantages of good stirring effect, long service life, stable stirring and the like, and thus effectively solves the problems and shortcomings in the prior art.

Owner:HUIZHOU WULING KANGTAI HEALTH TECH CO LTD

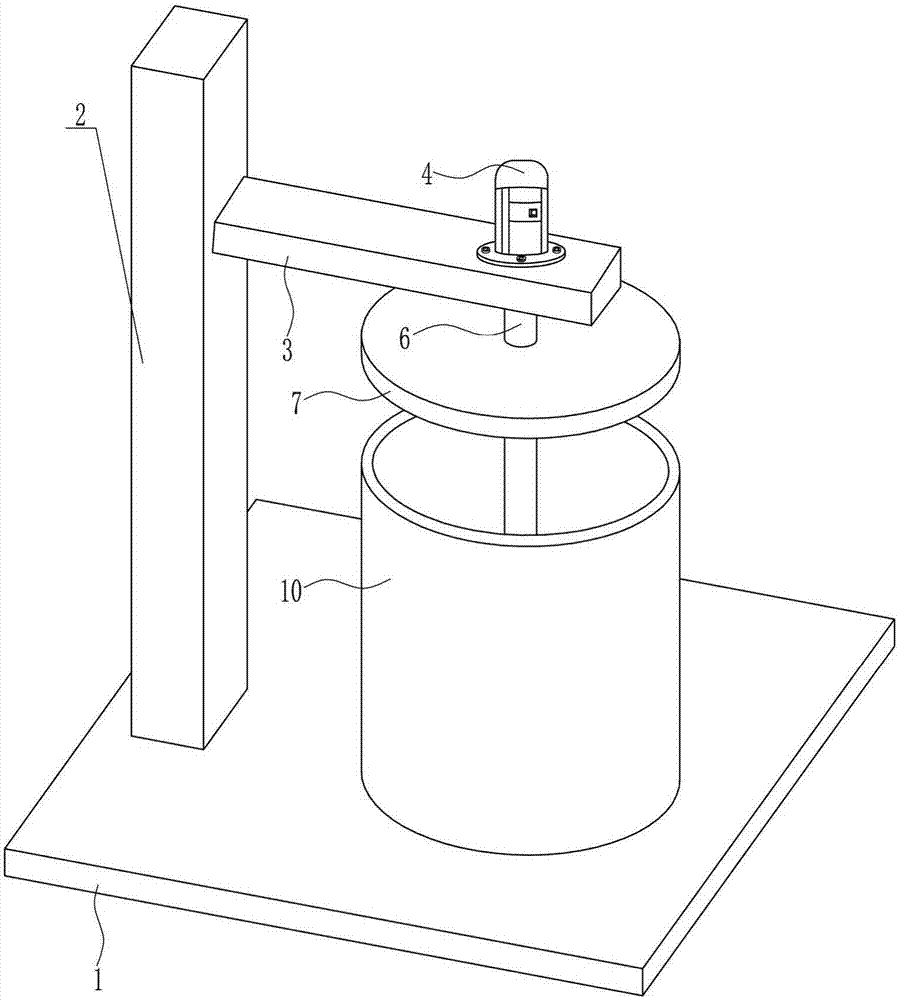

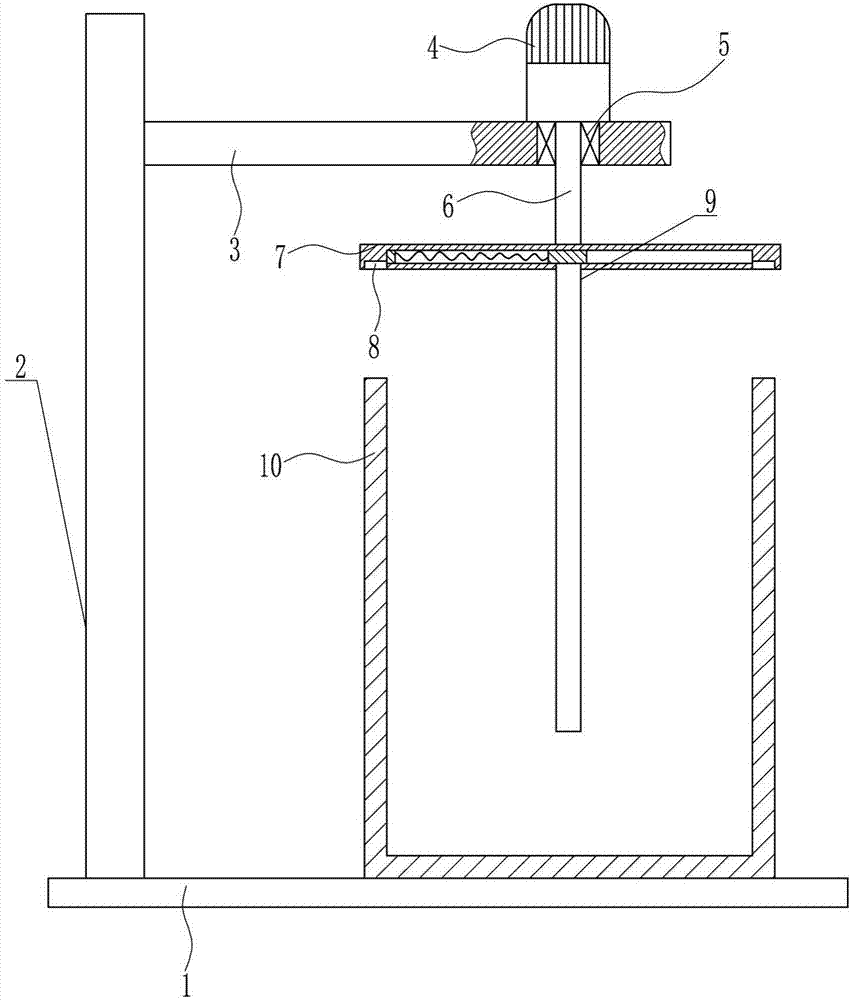

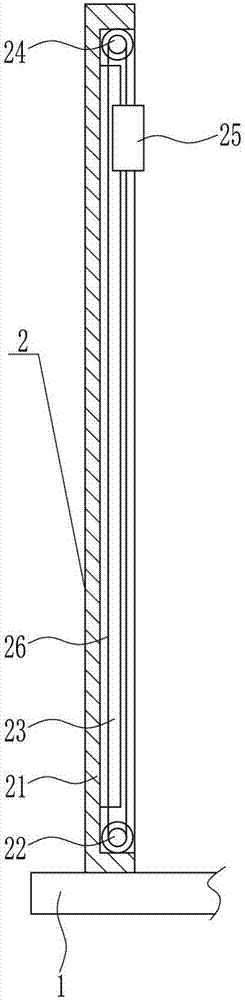

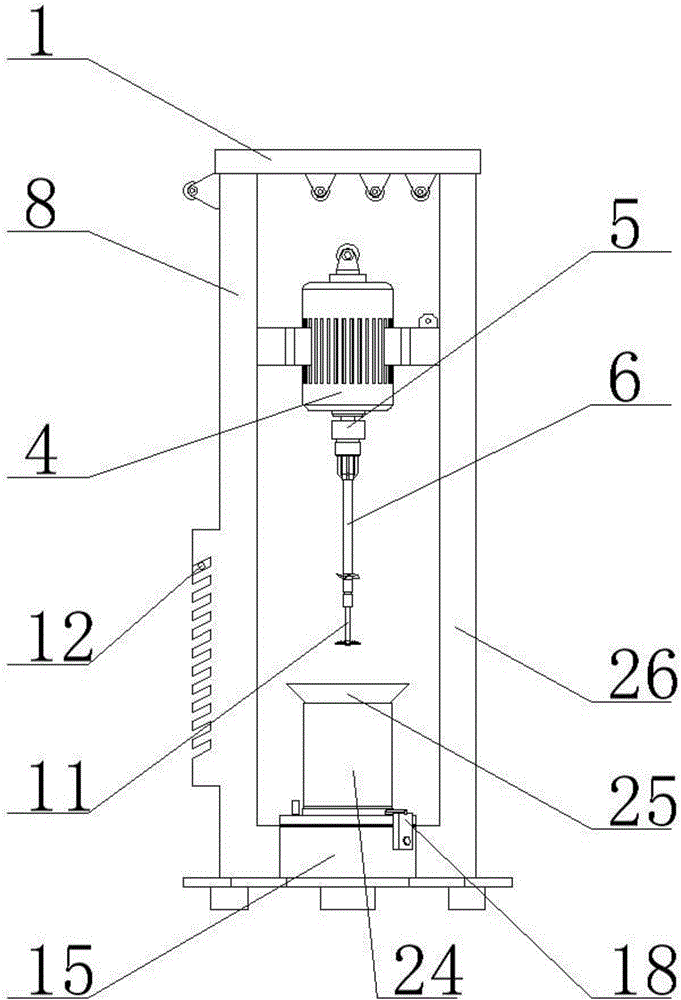

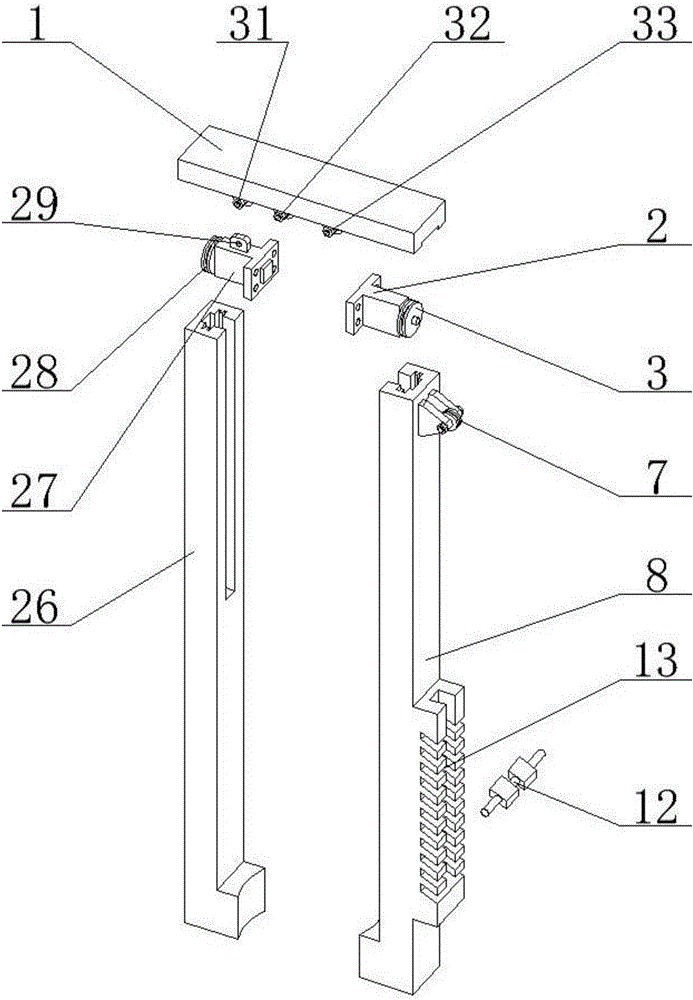

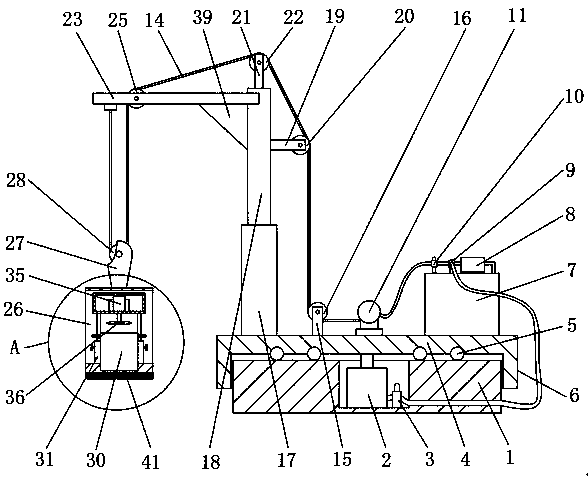

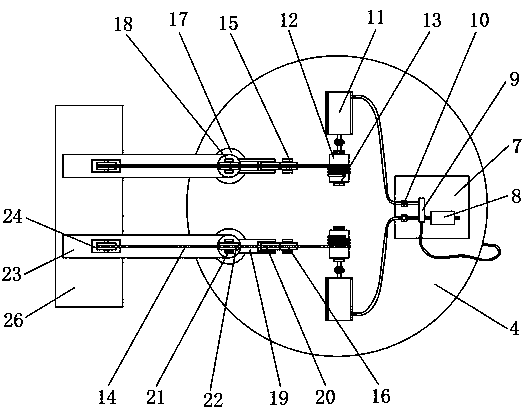

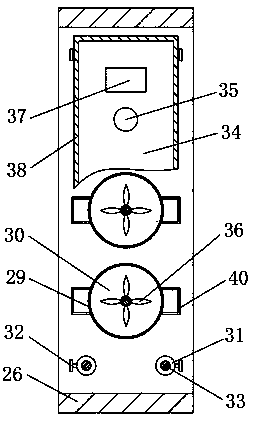

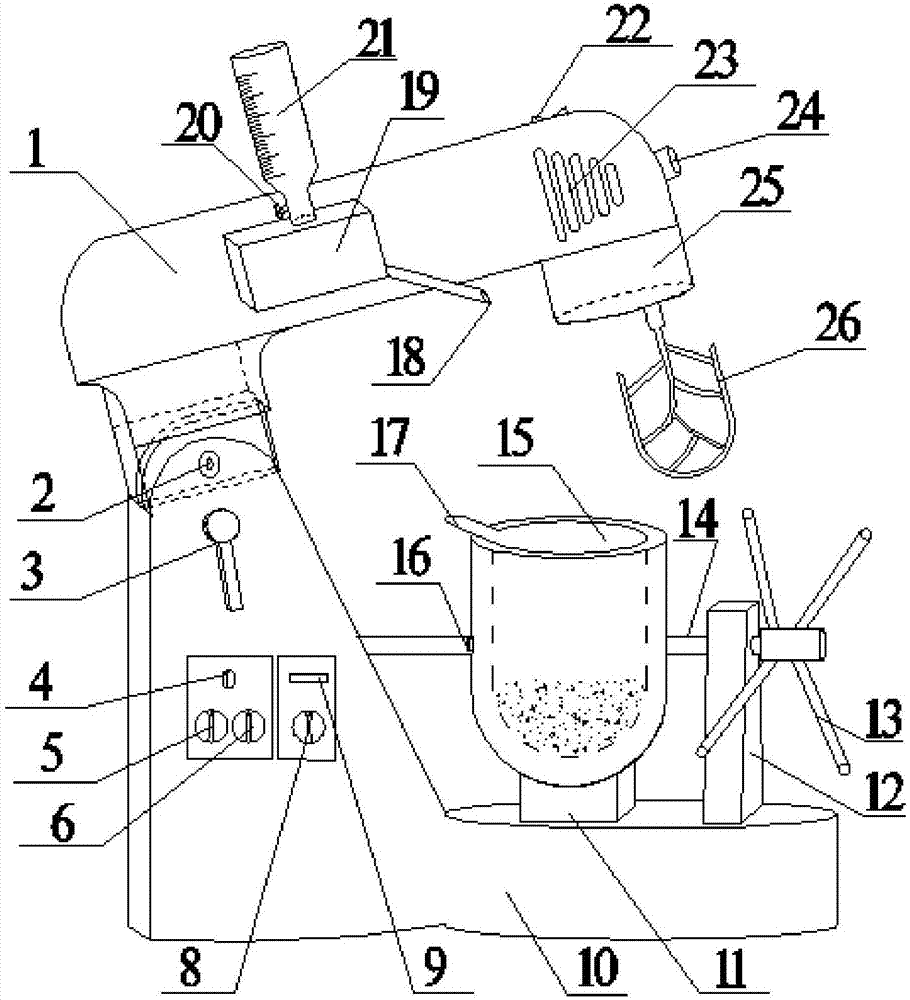

Sliding rail type mechanical stirrer

InactiveCN105709668AEasy to liftImprove stabilityTransportation and packagingRotary stirring mixersImpellerGas liquid reaction

The invention discloses a sliding rail type mechanical stirrer which comprises a motor adjustment component, a stirring component, a base component and a stirring container component, wherein the motor adjustment component is fixed on the base component; the stirring container component is adsorbed on the base component; and the upper end of the motor adjustment component is connected with the stirring component through a steel wire rope, and two ends are matched with the stirring component in a separate tightening manner. According to the sliding rail type mechanical stirrer, by the adoption of symmetric sliding rail motor adjustment, the problems of inconvenience in motor adjustment and working vibration are solved; by the adoption of a shaft reinforcement piece, the problems of shaft vibration, noise, and deflection are solved; by the adoption of a magnet adsorption type base, the problem that a stirring trough clamps a bracket is solved; by the adoption of a lifting type base, the problem of poor stirring due to a fixed position of a stirring impeller is solved; by the adoption of the stirring impeller, the problems of poor stirring and small circulating amount are solved; by the additional arrangement of a fan wheel, the problem of long stirring time in gas-liquid reaction is solved; and by the adoption of a simple anti-splashing cover, the problem that a stirred liquid is splashed to a user in a liquid stirring process is solved.

Owner:JILIN UNIV

High-stirring-uniformity stirring device for animal feed production

InactiveCN107570035AStir wellStable fast entryFeeding-stuffRotary stirring mixersEngineeringRaw material

The invention discloses a high-stirring-uniformity stirring device for animal feed production. The stirring device comprises a fixing base, the top of the fixing base is fixedly connected with the bottom of an outer tank, upper supporting blocks are fixedly connected to left and right sides of the top of the outer tank, and tops of the supporting blocks are fixedly connected with bottoms of feeding sleeves. The top, between the two supporting blocks, of the outer tank is fixedly connected with the bottom of an inlet sleeve, a fixing sleeve internally sleeves an opening in the top of the inletsleeve, an air collection hood sleeves the fixing sleeve, and the top of the air collection hood is fixedly connected with the bottom of a fan cover. By use of the two feeding sleeves, feeding of different types of powder materials can be realized, the materials can be stably and quickly fed into the inlet sleeve by use of a transmission box, and a fan body rotates to mix the different types of powder materials in wind, so that a mixed state is achieved before stirring, and high stirring uniformity is guaranteed.

Owner:郑艳峰

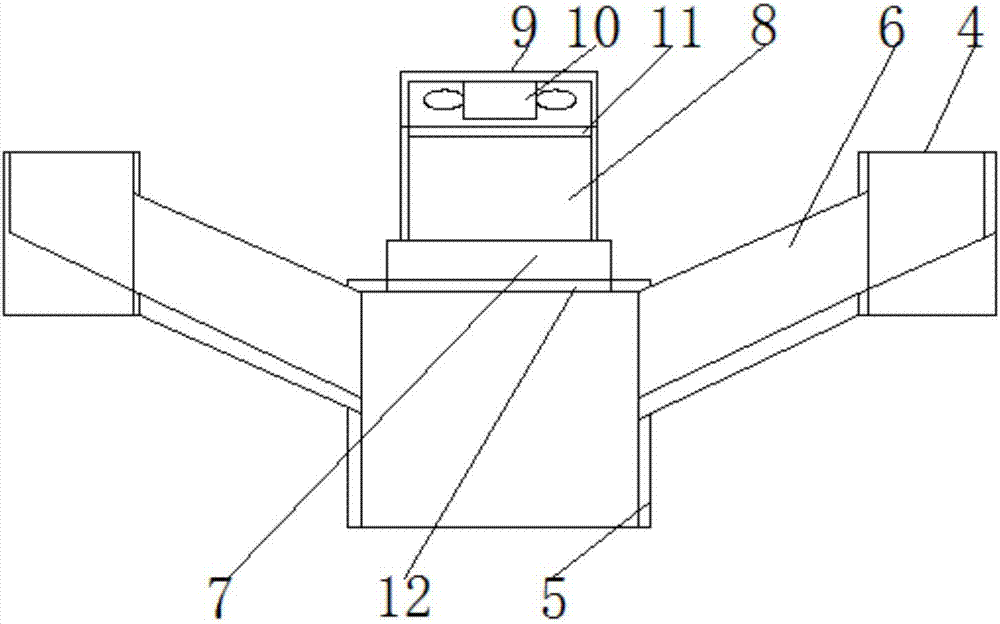

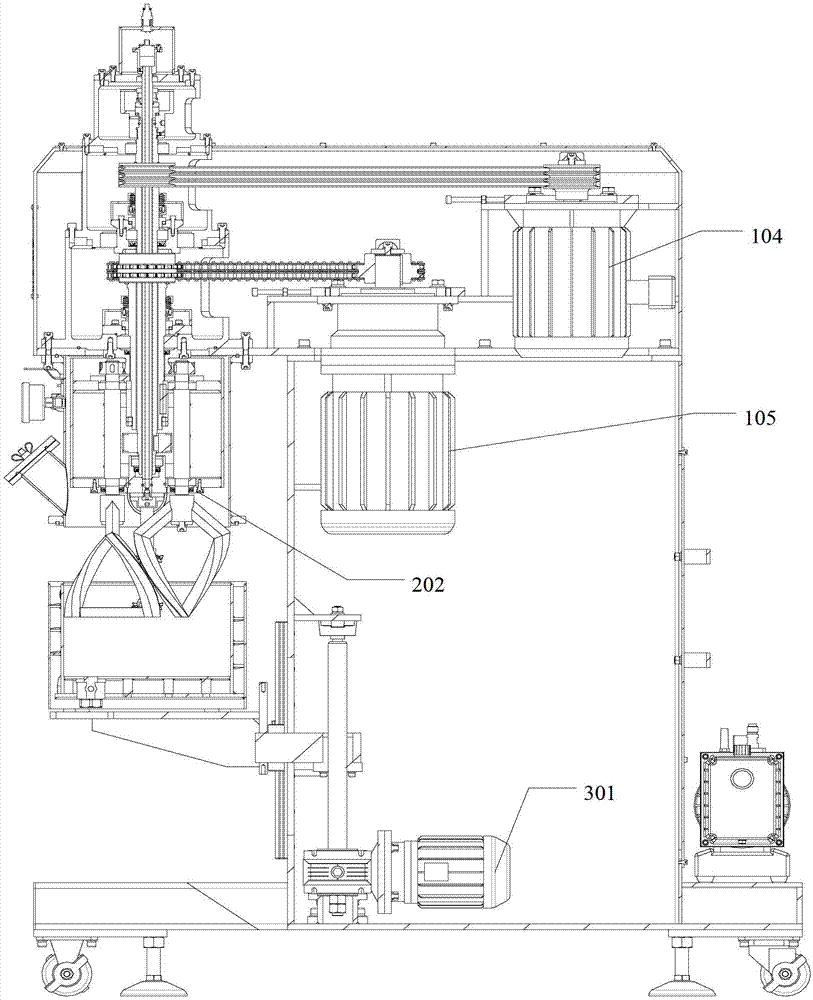

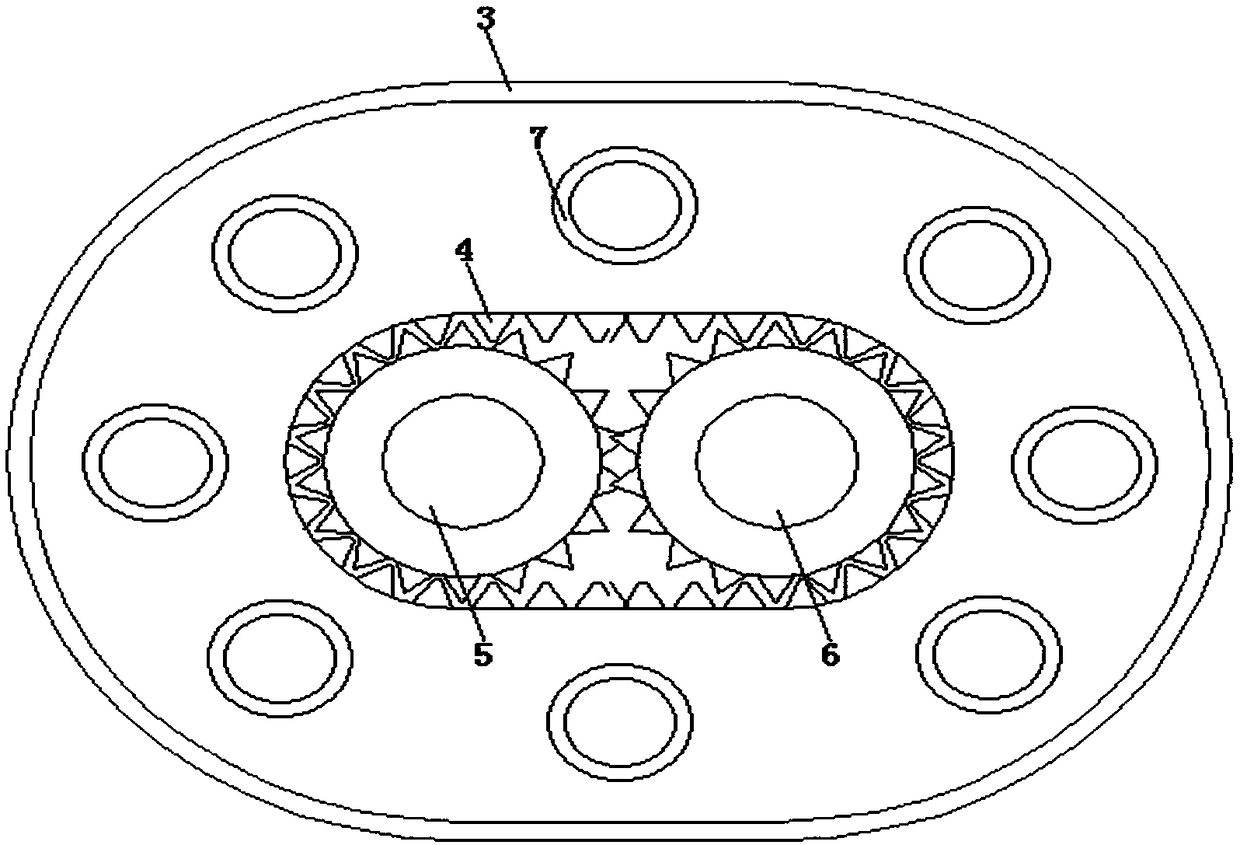

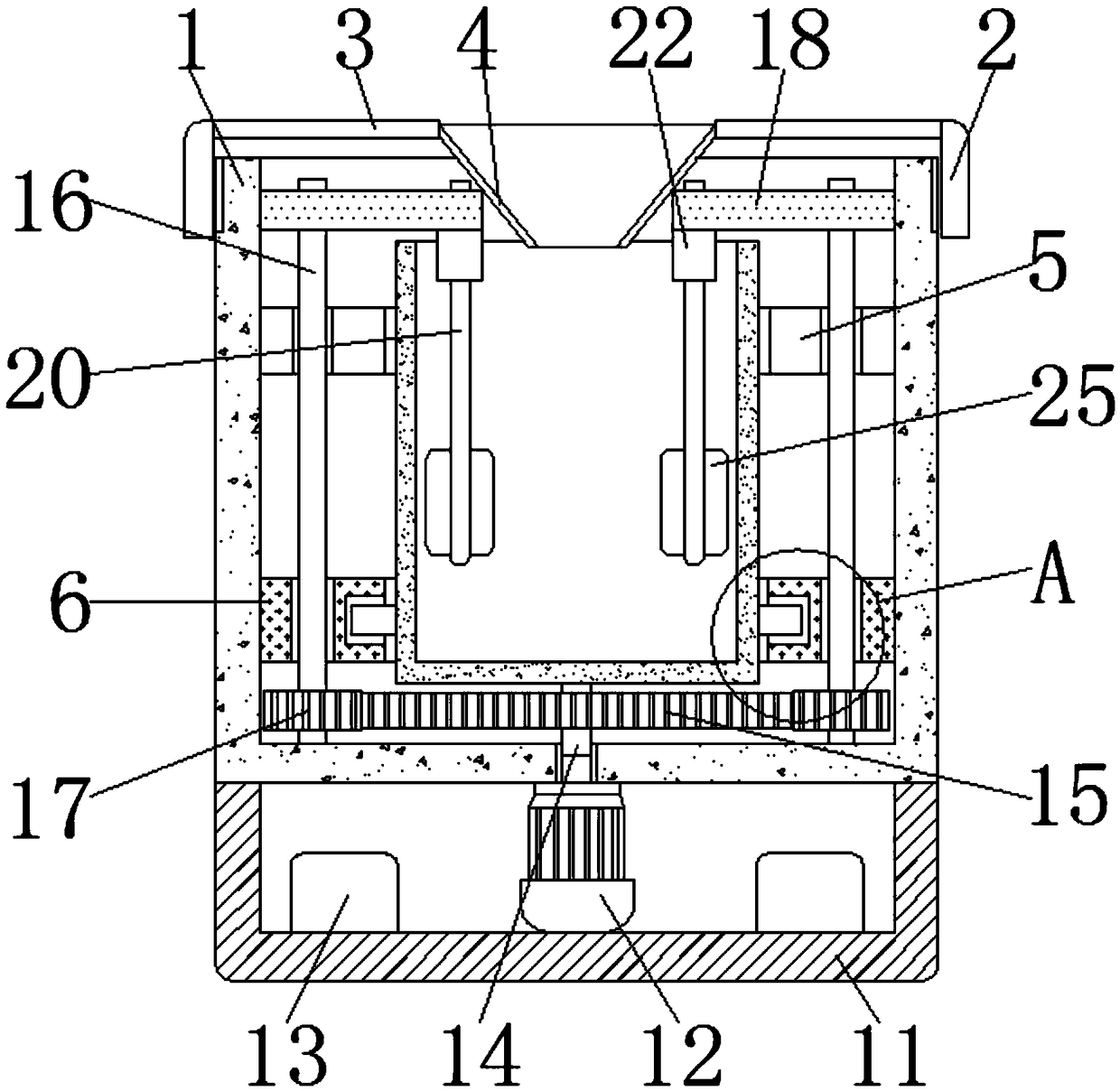

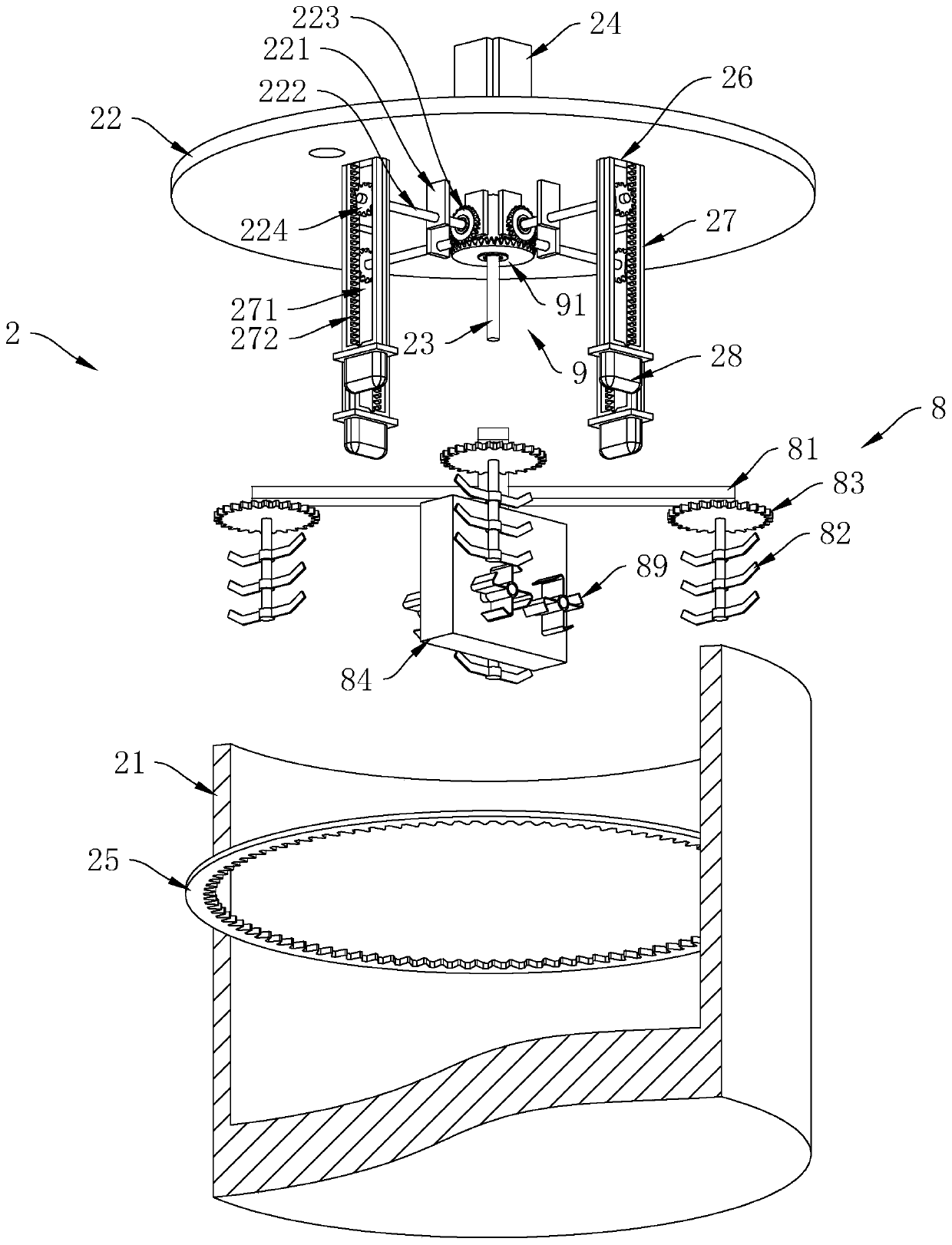

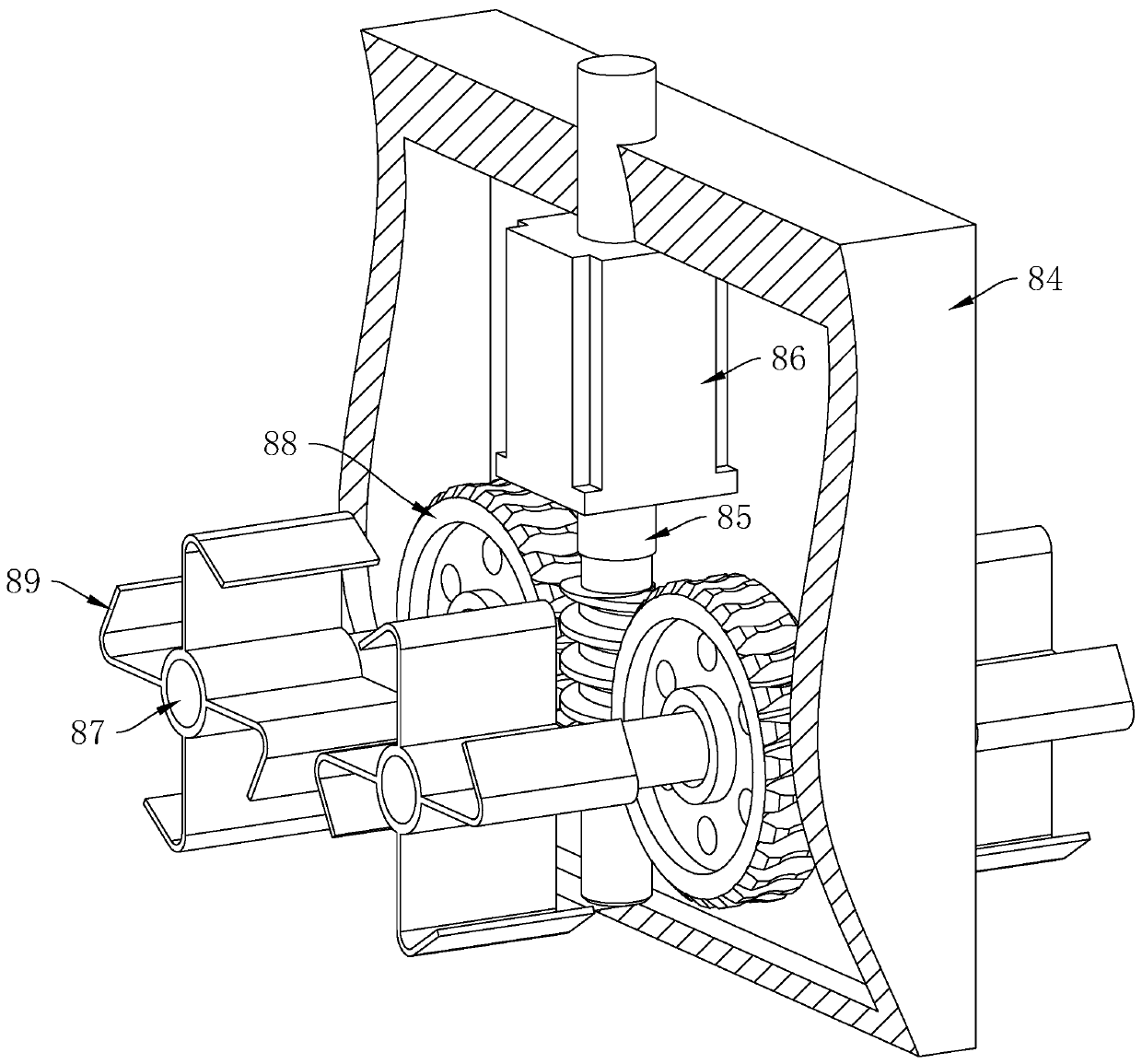

Dual-planetary wheel mixing machine

The invention discloses a dual-planetary wheel mixing machine. The dual-planetary wheel mixing machine comprises a material pot container, a power mixing structure and a high-speed dispersion structure, wherein the power mixing structure is provided with a mixing main shaft, a dispersion main shaft and a temperature measuring rod shaft; the power mixing structure is also provided with a stirring motor, a dispersion motor, a stirring mechanism and a planetary wheel mechanism, and the planetary wheel mechanism is connected to the mixing main shaft; the high speed dispersion structure is provided with a dispersion rod shaft and an emulsifying rod shaft, the dispersion rod shaft and the emulsifying rod shaft are connected with the dispersion main shaft, and the dispersion main shaft can provide power and is used for control; the material pot container is provided with a coil for cooling and a guide plate. The dual-planetary wheel mixing machine is suitable for preparing a lithium iron phosphate storage battery which takes an acetone substance as a solvent, and the corrosivity of an acetone substance is effectively resisted.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

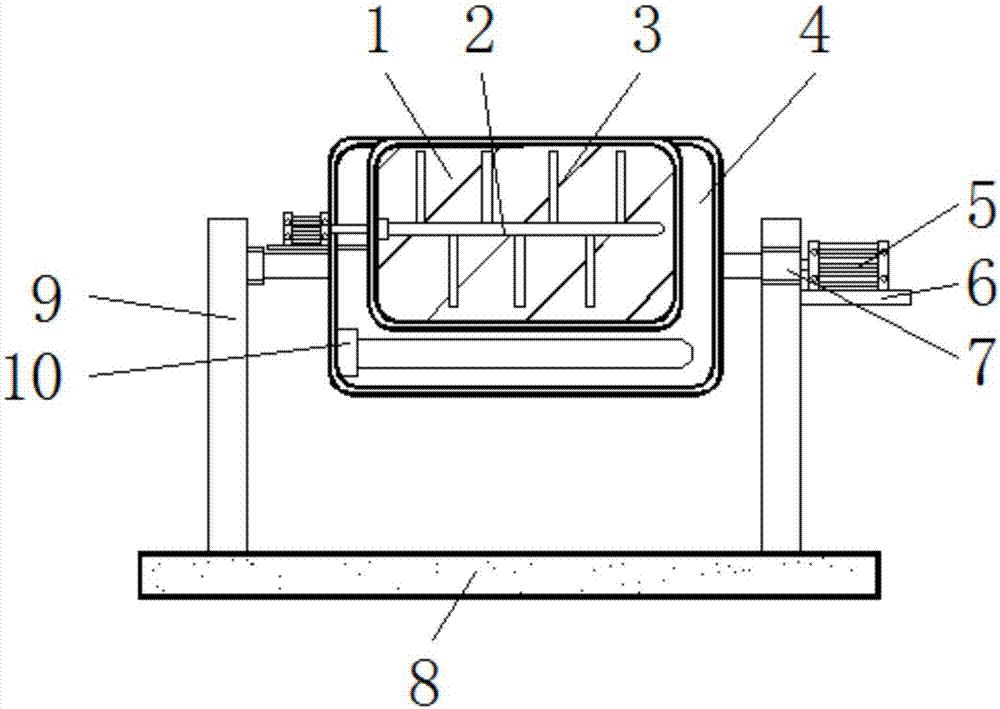

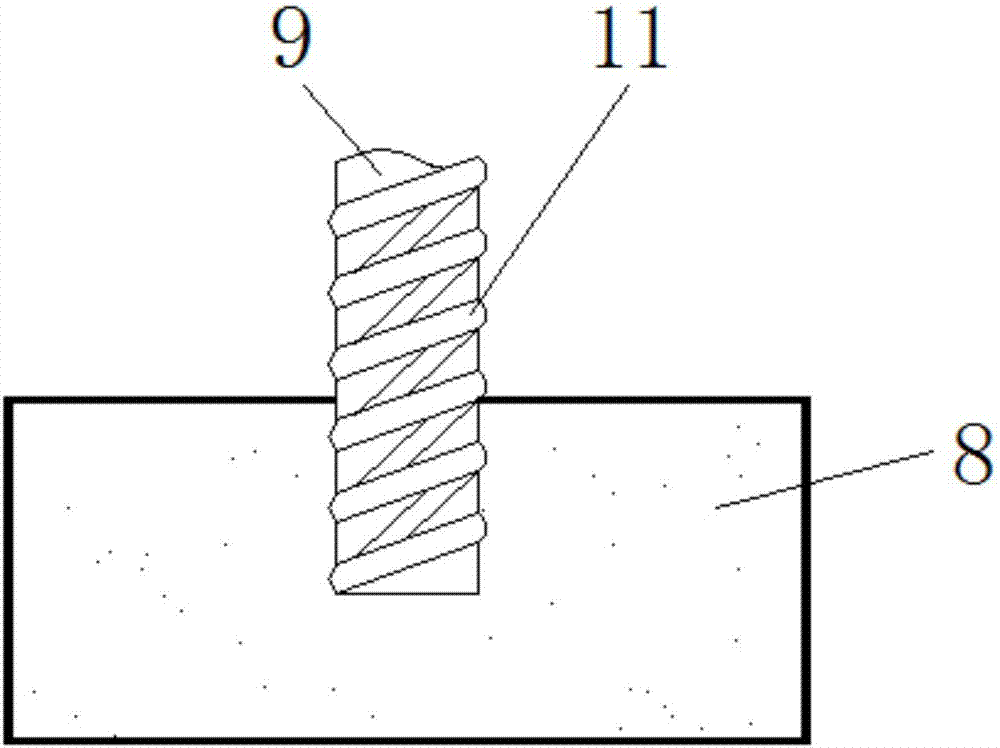

High-efficiency drying device for organic fertilizer production

InactiveCN109114919AEvenly heatedSolve the problem of incomplete dryingDrying gas arrangementsDrying machines with non-progressive movementsAgricultural engineeringOrganic fertilizer

The invention discloses a high-efficiency drying device for organic fertilizer production. The high-efficiency drying device for organic fertilizer production comprises a bottom plate, supporting columns are fixedly connected to the two sides of the top of the bottom plate, the top of the bottom plate is provided with a stirring box, the stirring box is positioned between the two supporting columns, and a transmission box is fixedly connected to the right side of the top of the bottom plate. According to the high-efficiency drying device for organic fertilizer production, the transmission box,a heater, a fan, a heating column, a first motor, a driving gear, a first transmission column, a driven gear, a second transmission column, a transmission disc, a first transmission pin, a first transmission frame, a second transmission frame, a second transmission pin and a third transmission column are used in a cooperated mode, and the drying effect is achieved through the fan and the heatingcolumn, the third transmission column is pushed to move left and right through the second transmission frame, so that the effect that the organic fertilizer is uniformly heated is achieved. Accordingto the high-efficiency drying device for organic fertilizer production, the problem that an existing drying device is not thorough in drying effect of the organic fertilizer is solved, the practicability of the drying device is enhanced, and the production efficiency of the organic fertilizer is improved.

Owner:湖州怡辉生态农业有限公司

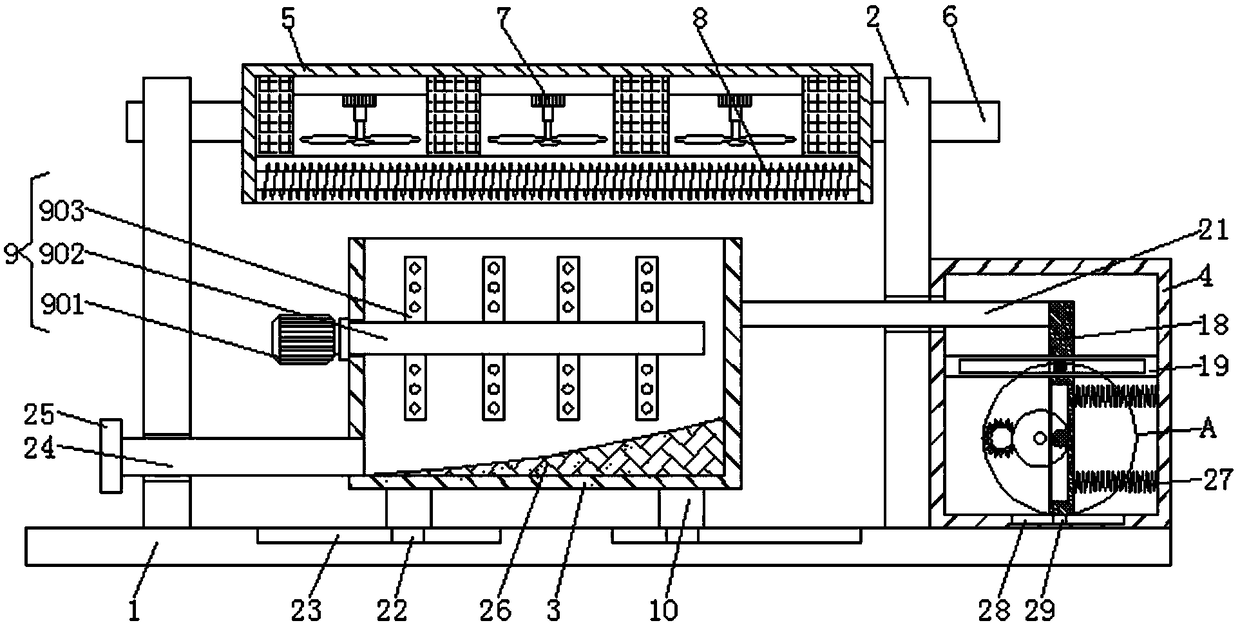

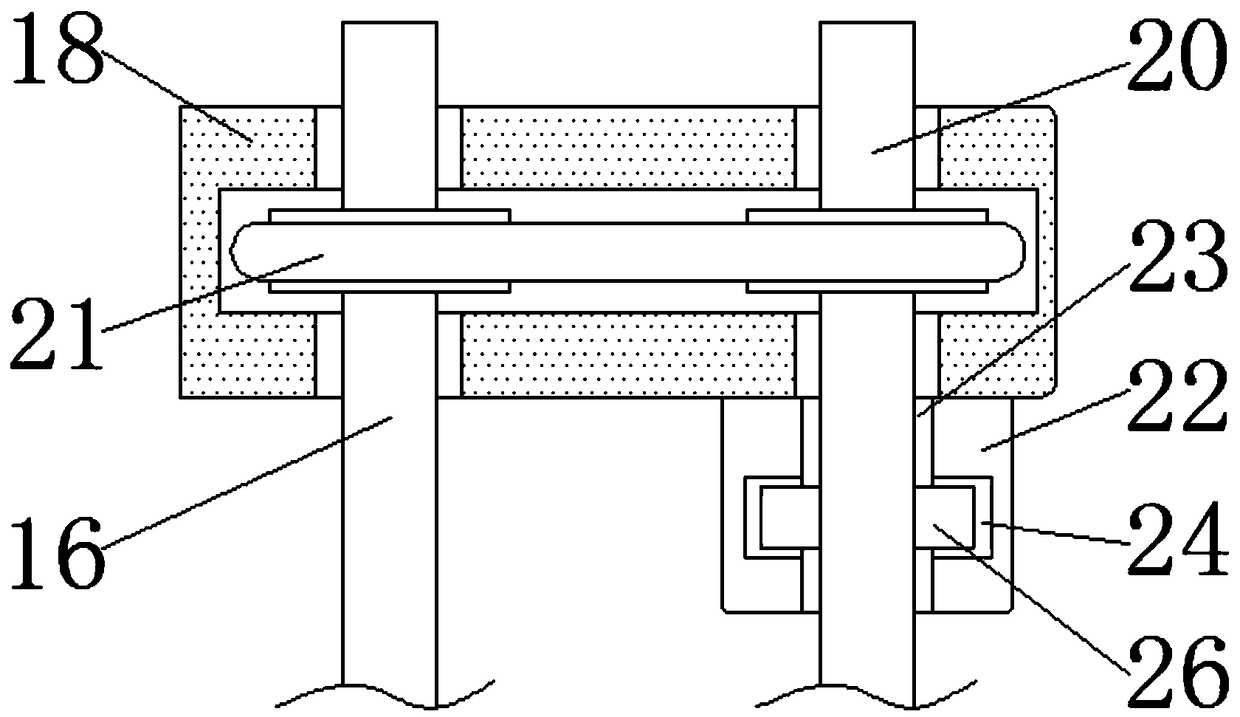

Tumor cell culture apparatus for anti-tumor experiment

InactiveCN108753614AShake evenlySteady shakingBioreactor/fermenter combinationsBiological substance pretreatmentsGear driveCulture fluid

The invention discloses a tumor cell culture apparatus for anti-tumor experiment. The tumor cell culture apparatus is characterized in that driving gears are driven to rotate through a first motor, the driving gears drive driven gears to rotate to drive placement discs to rotate, culture solutions in culture bottles can be shaken evenly and stably, mixing blades in the culture bottles are startedto have the culture solutions evenly mixed, labor intensity of medical staff is reduced, test result errors caused by uneven shaking are avoided, and temperature and humidity in an incubator can be accurately and automatically regulated. An air bacteria detector is arranged at the upper end of the biochemical incubator, bacteria in the air can be detected through the air bacteria detector, power of an ultraviolet sterilization lamp is controlled, and when the bacteria in the air in the biochemical incubator is in good condition, the working power of the ultraviolet sterilization lamp can be reduced, and energy consumption of the biochemical incubator can be effectively reduced.

Owner:TAIYUAN NORMAL UNIV

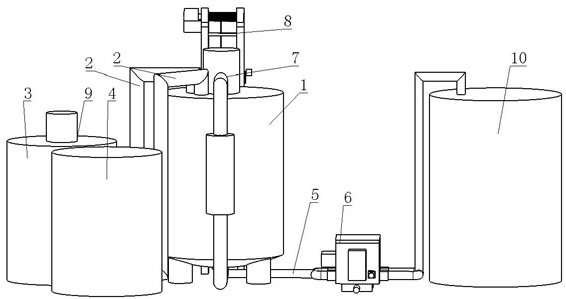

Intelligent lubricating oil blending system

ActiveCN113546558AImprove qualityMix well and evenlyRotary stirring mixersMixer accessoriesControl systemProcess engineering

The invention belongs to the technical field of intelligent manufacturing, and relates to the technical field of industrial production process control systems, in particular to the technical field of chemical product manufacturing in the manufacturing execution system technology, and particularly discloses an intelligent lubricating oil blending system which comprises a blending system and a control system matched with the blending system. The blending system comprises a blending device, and the blending device is connected with a feeding device and a discharging device; the blending device comprises a blending kettle, and a mixing device and an adding device are arranged on the blending kettle; the feeding device comprises a feeding pipe connected with the blending kettle, and further comprises a base oil tank and an additive tank which are connected with the feeding pipe, and a cleaning device is arranged on the base oil tank; and the discharging device comprises a discharging pipe and further comprises a finished product tank connected with the discharging pipe, and a filtering device is arranged on the discharging pipe. The invention provides the intelligent lubricating oil blending system which is convenient to add additives, good in blending effect and high in production efficiency.

Owner:梧州科润润滑科技有限公司

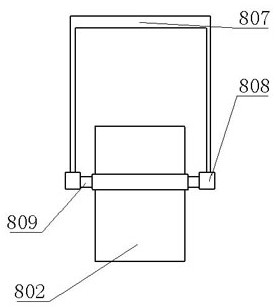

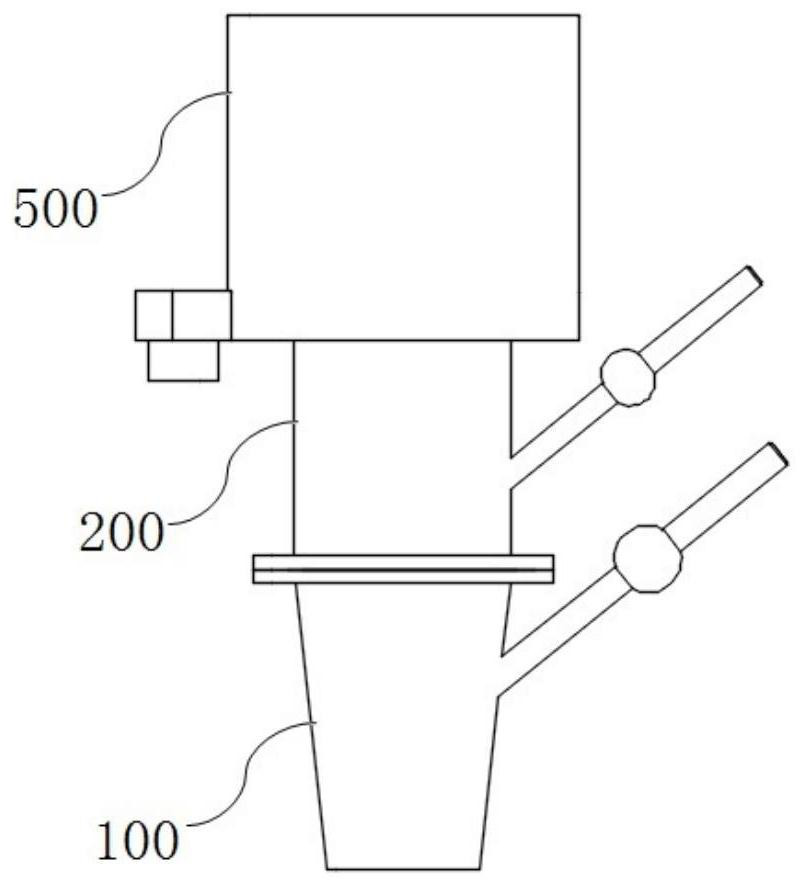

Cement lifting equipment for industrial production

InactiveCN107902565ASmooth liftImprove carrying capacityPortable liftingCement mixing apparatusHydraulic motorImpeller

The invention discloses cement lifting equipment for industrial production. Through cooperation arrangement of a rotating oil cylinder, a turntable, a ball and a flange, the turntable can be rotated to an appointed position stably; through cooperation arrangement of a hydraulic motor, a wire winding roller, a steel cable, a first guide wheel, a second guide wheel, a third guide wheel, a fourth guide wheel, a movable pulley, a movable pulley connecting frame and a box, the box can be stably lifted to achieve higher bearing capacity; through cooperation arrangement of a clamping groove and a mounting plate, a cement holding barrel can be stably fixed in the box for lifting; and through cooperation arrangement of the mounting plate, a support sleeve, a support rod, a fastening screw, an accumulator, a stirring motor and a stirring impeller, cement in the cement holding barrel can be stirred to prevent solidification of the cement in the transportation process. The cement lifting equipmentfor industrial production can stably transport the cement to a high place, can prevent scattering or solidification of the cement in the transportation process, prevents wastes of cement resources, is high in transportation efficiency, and relieves the burdens of workers.

Owner:长兴曼尔申机械科技有限公司

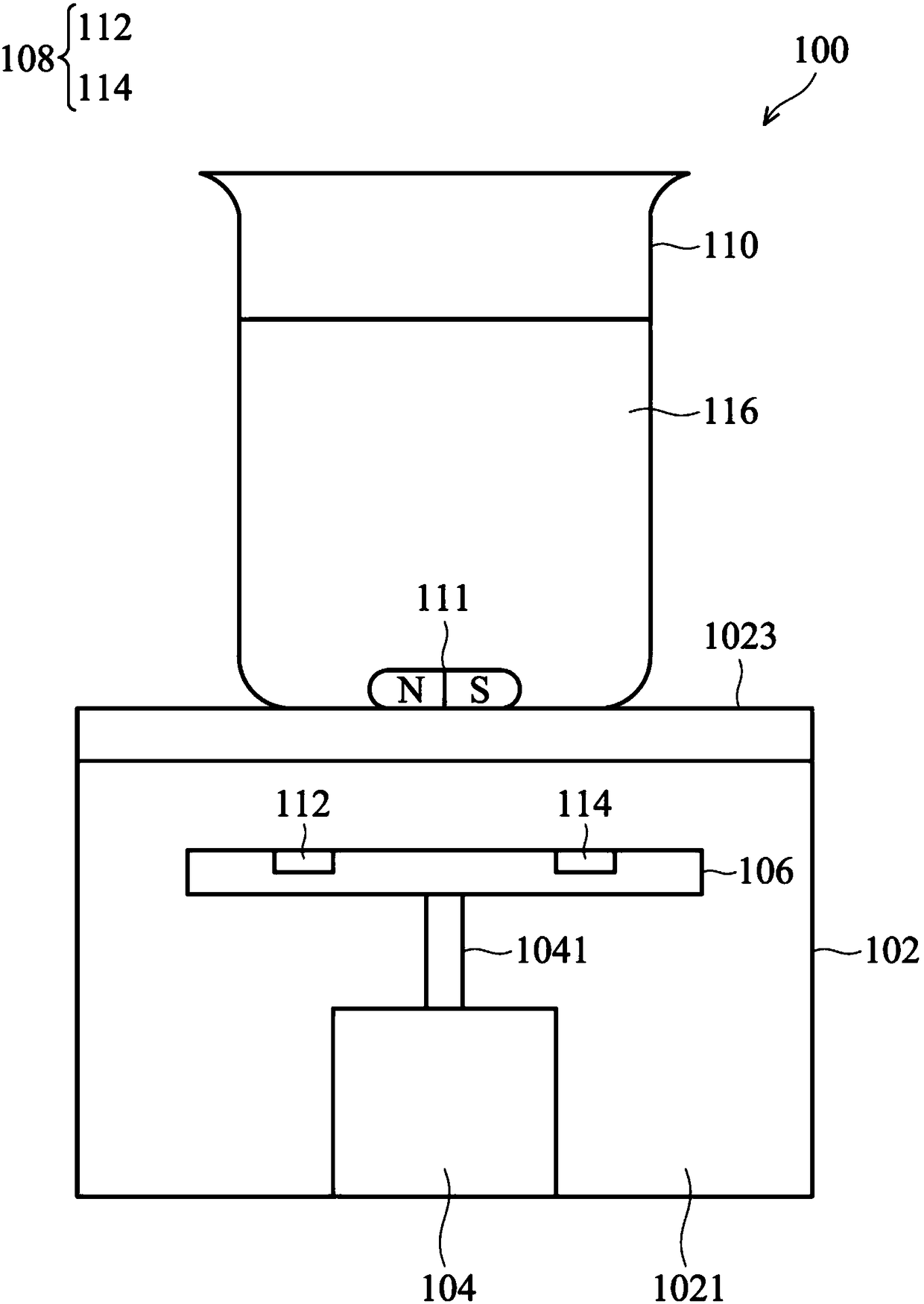

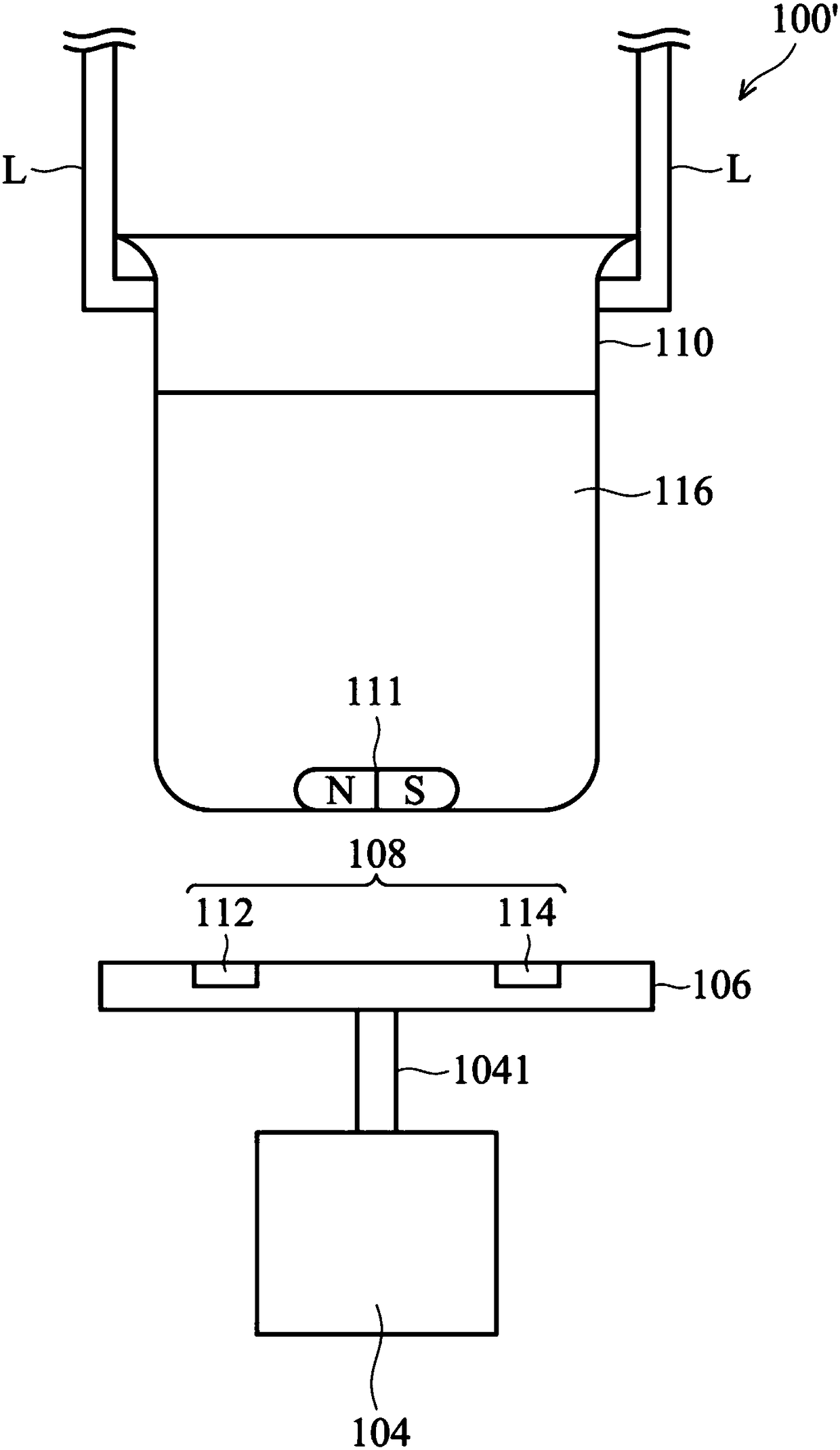

Photocatalytic hydrogen production system and hydrogen production method

ActiveCN104226224AThe detection method is simpleReduce the difficulty of operationHydrogen productionEnergy based chemical/physical/physico-chemical processesHydrogen fuelProcess engineering

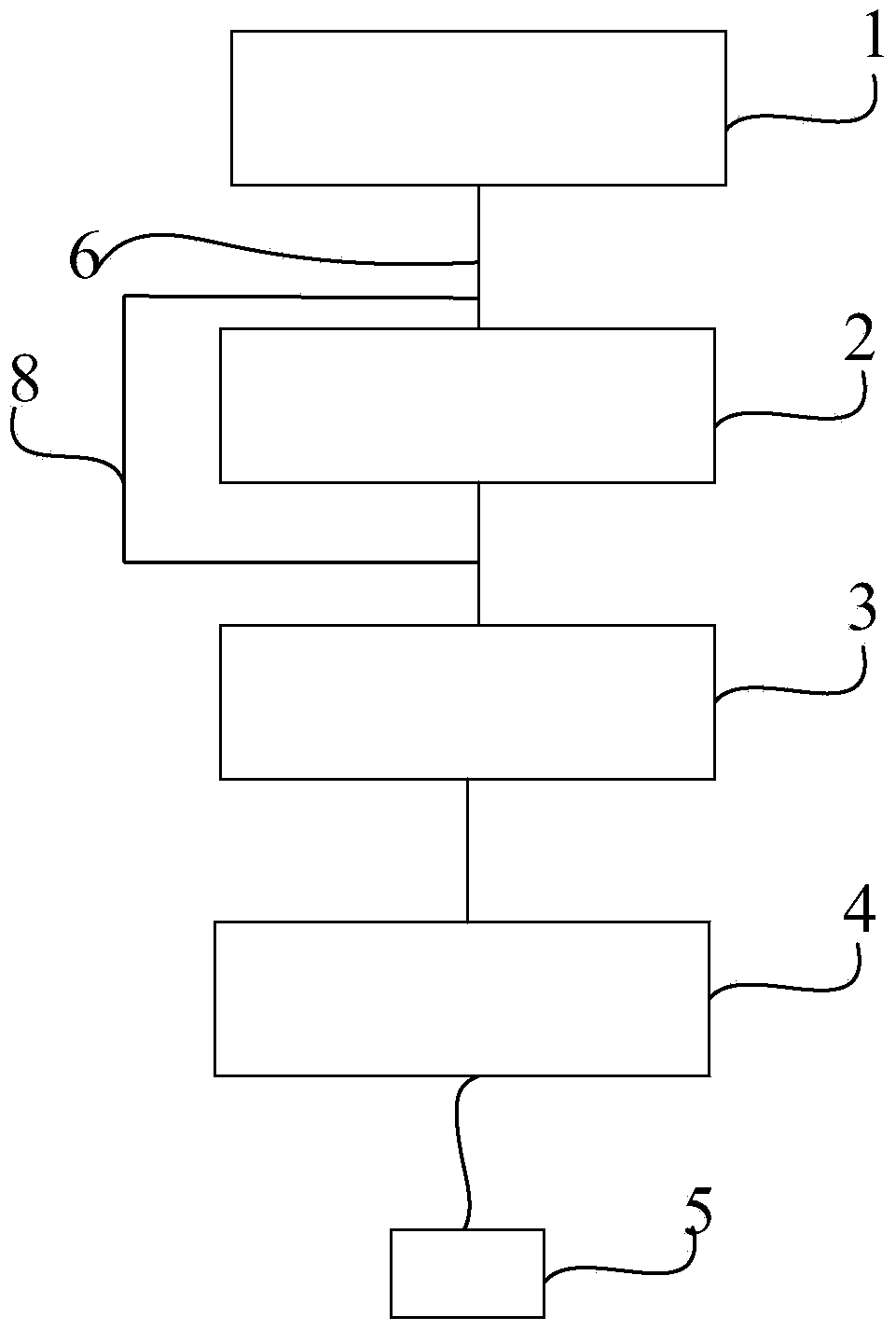

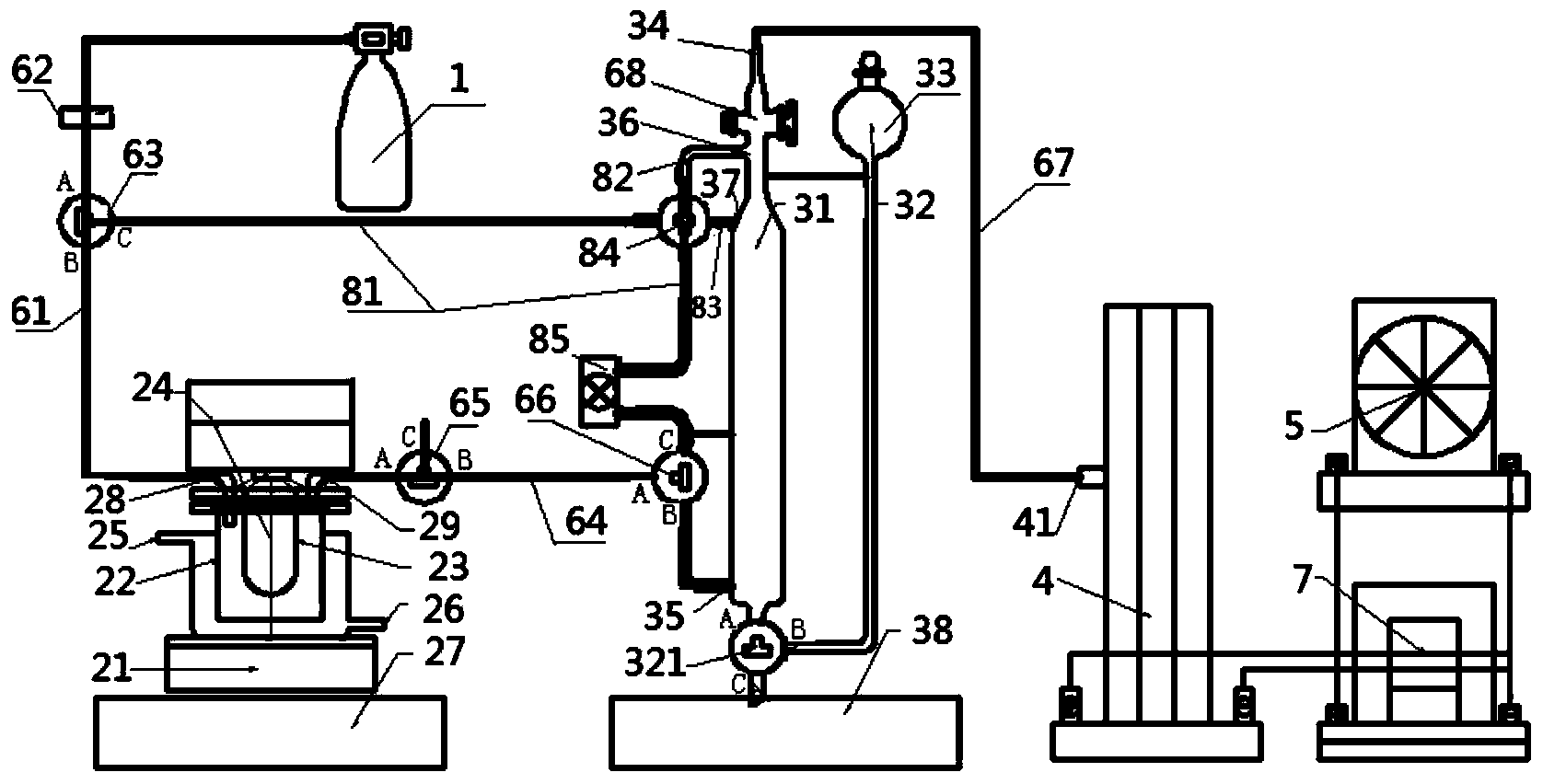

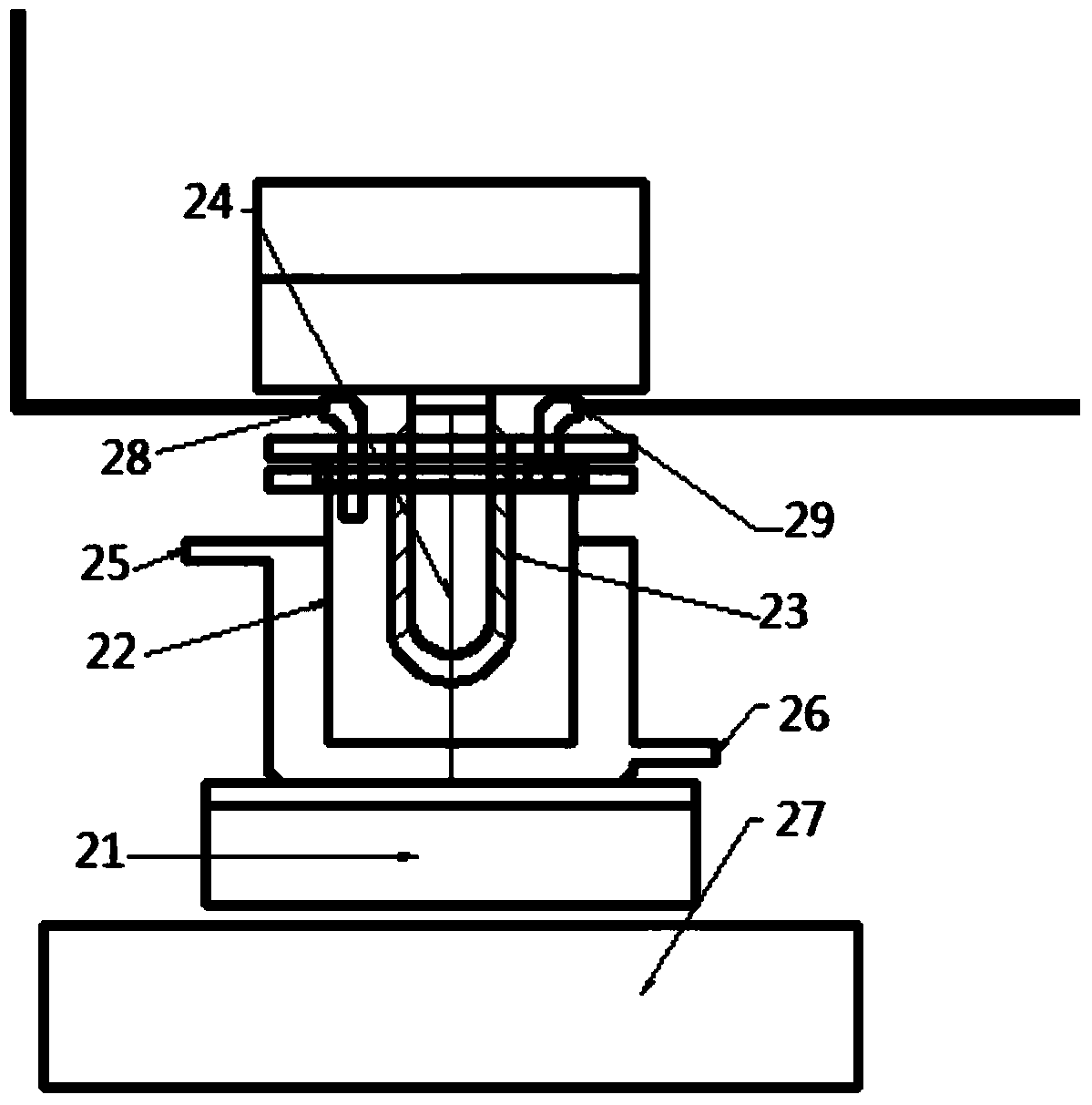

The invention relates to a photocatalytic hydrogen production system and a gas production measuring method. The photocatalytic hydrogen production system comprises an inert gas source, a photocatalytic reaction device, a gas collecting, discharging and measuring device, a gas detection and verification device and a main valve control pipeline, wherein the main valve control pipeline is connected with the inert gas source, the photocatalytic reaction device, the gas collecting, discharging and measuring device and the gas detection and verification device sequentially, a hydrogen fuel cell is arranged in the gas detection and verification device, and the hydrogen fuel cell is electrically connected with a load. Two ends of the hydrogen fuel cell are also respectively connected with a voltage display gauge. By adopting the photocatalytic hydrogen production system, the integration of the photocatalytic reaction, the gas production measurement and gas detection and verification can be realized; the gas measuring and detection method is simple, visual and effective; the operation difficulty is lowered, and the maintainability is improved; the product cost, the maintenance cost and the running environment cost can be greatly reduced.

Owner:BEIJING PERFECTLIGHT SCI & TECH

Cloth dye stirring device with convenient usage

InactiveCN107376708AEasy to useAvoid different shades of colorRotary stirring mixersTransportation and packagingCouplingPulp and paper industry

The invention relates to the technical field of printing and dyeing, and discloses a cloth dye stirring device with convenient usage. The cloth dye stirring device comprises a machine body, a bracing frame is fixedly connected with the top of the machine body, a motor is fixedly connected with the inner side of the bracing frame, an output shaft of the motor is fixedly connected with a rotating shaft through a shaft coupling, the bottom of the rotating shaft passes through and extends to the internal part of the machine body, a first cross bar positioned in the machine body is fixedly connected with two sides of the surface of the rotating shaft, and a scraper plate is fixedly connected with the first cross bar far from the rotating shaft. The cloth dye stirring device with convenient usage is characterized in that when the motor works, the rotating shaft is rotated, so that an agitator arm can be continuously rotated, the stirring blades on the surface of the agitator arm continuously stir a dye in the machine body, the stirring is more uniform, different cloth colors and uneven color after printing and dyeing due to non-uniform stirring can be prevented, and the cloth dye stirring device has the advantages of labor saving and time saving, and more convenient usage.

Owner:梅明会

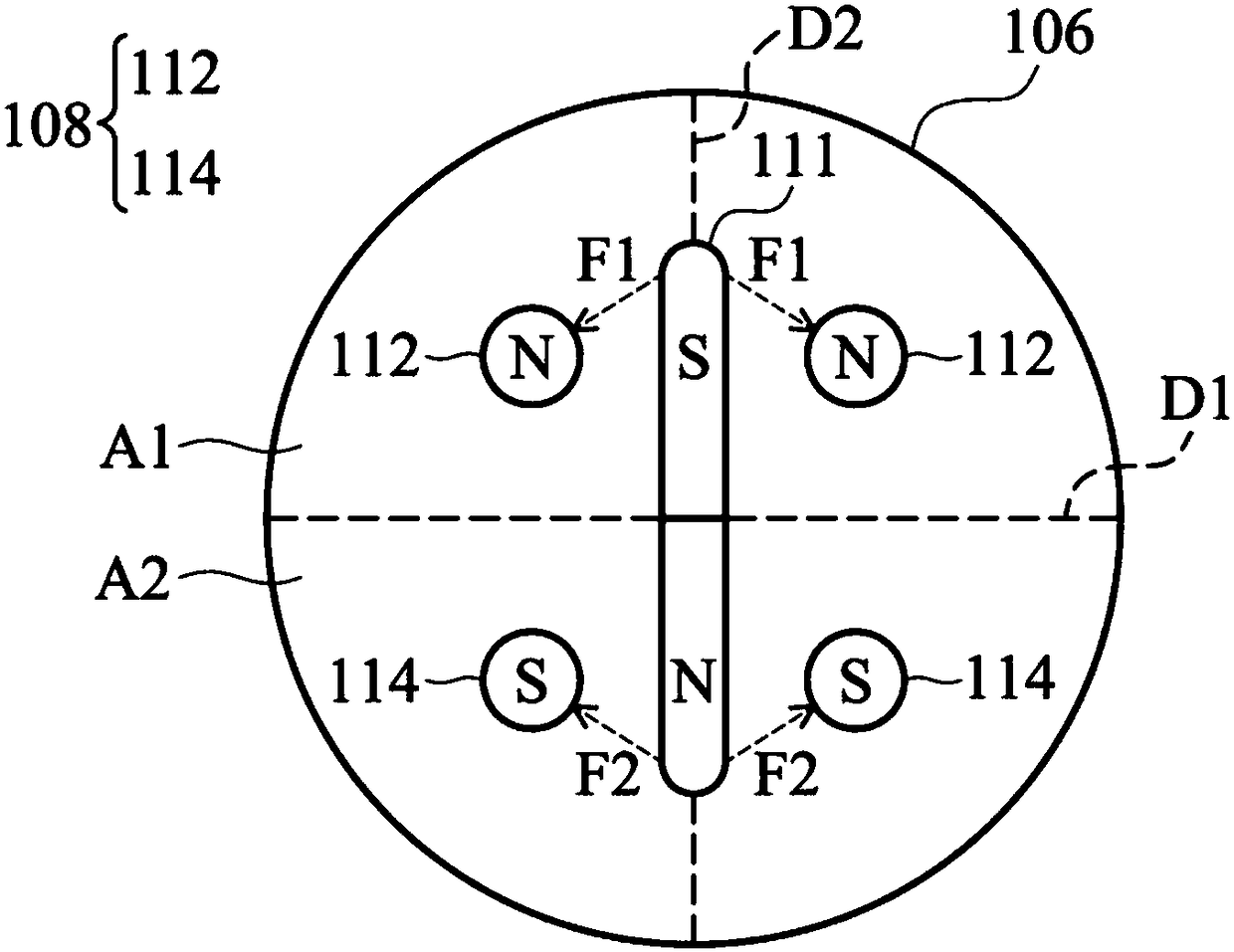

Magnetic coupling assembly and magnetic coupling stirrer mixer

ActiveCN108092486AStrong couplingCoupling Space ConstraintsTransportation and packagingRotary stirring mixersCircular discSuction force

Owner:牟敦刚

Stirring device for material production

InactiveCN109908782AEasy to useImprove mix qualityRotary stirring mixersMixer accessoriesEngineeringControl valves

The invention discloses a stirring device for material production. The stirring device for the material production comprises a stirring box, wherein a bottom plate is fixedly connected to the bottom of the stirring box, supporting legs are fixedly connected to both sides of the bottom plate, one side, close to the supporting legs, of the stirring box is fixedly connected with the supporting legs,feeding pipes communicate with the both sides of the top of the stirring box, and discharging pipes communicate with the bottom of the stirring box. According to the stirring device, the stirring box,a supporting mechanism, a second rotating sleeve, the supporting legs, the bottom plate, a control valve, the discharging pipes, a rotating shaft, a belt, a first bevel gear, a fixed shell, a motor,a second bevel gear, a movable rod, a transmission wheel, the feeding pipes, a second transmission wheel, a second stirring blade, a first rotating sleeve, a first stirring blade, a second bearing seat, a support rod, a connecting plate, a first bearing seat and a rotating rod are used cooperatively to solve the problem of low material stirring quality caused by uneven stirring and incomplete stirring of the existing stirring device for material production.

Owner:JIANSU JINSHAN BEER RAW MATERIAL CO LTD

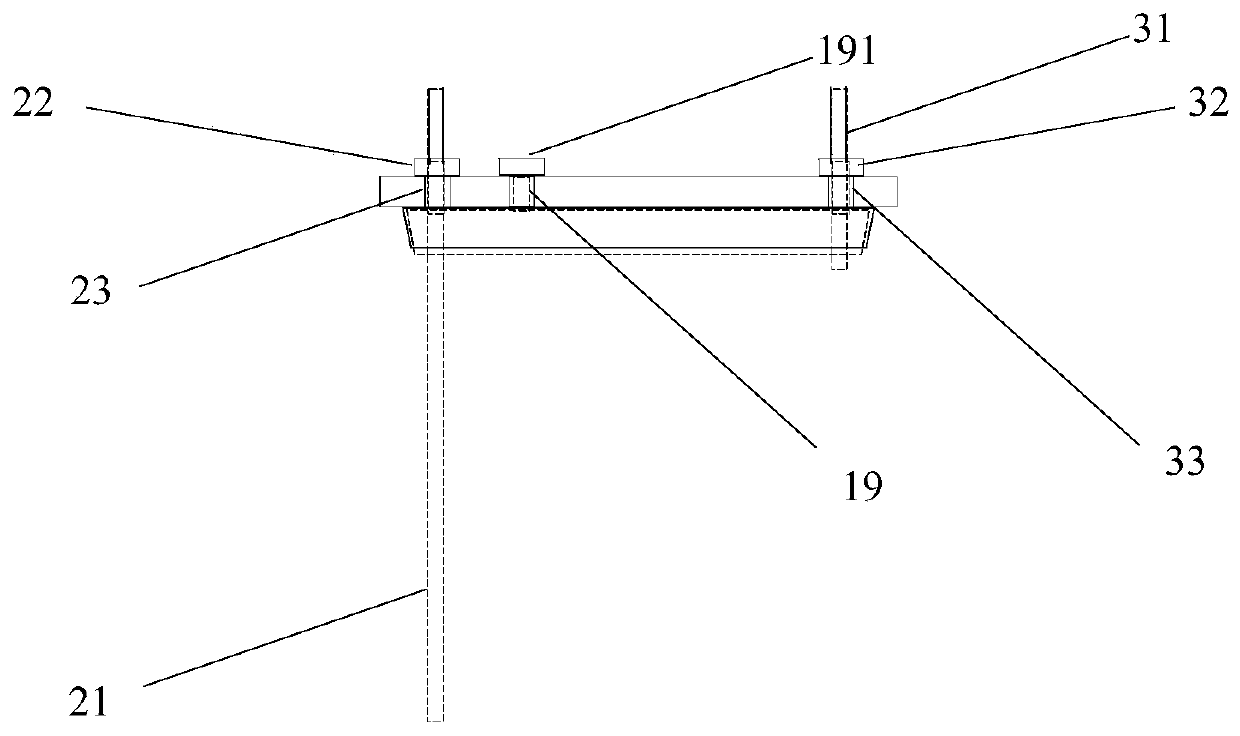

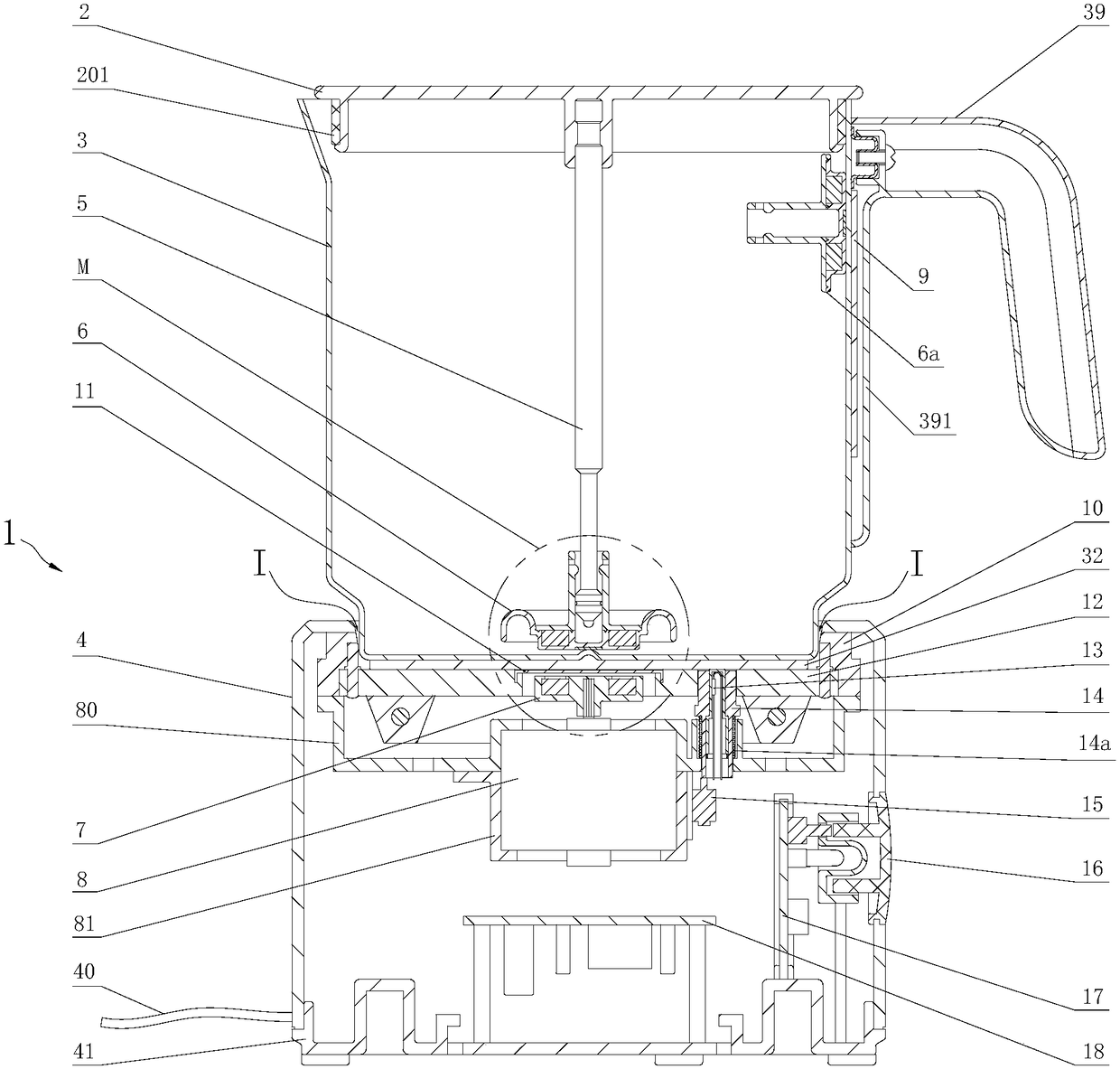

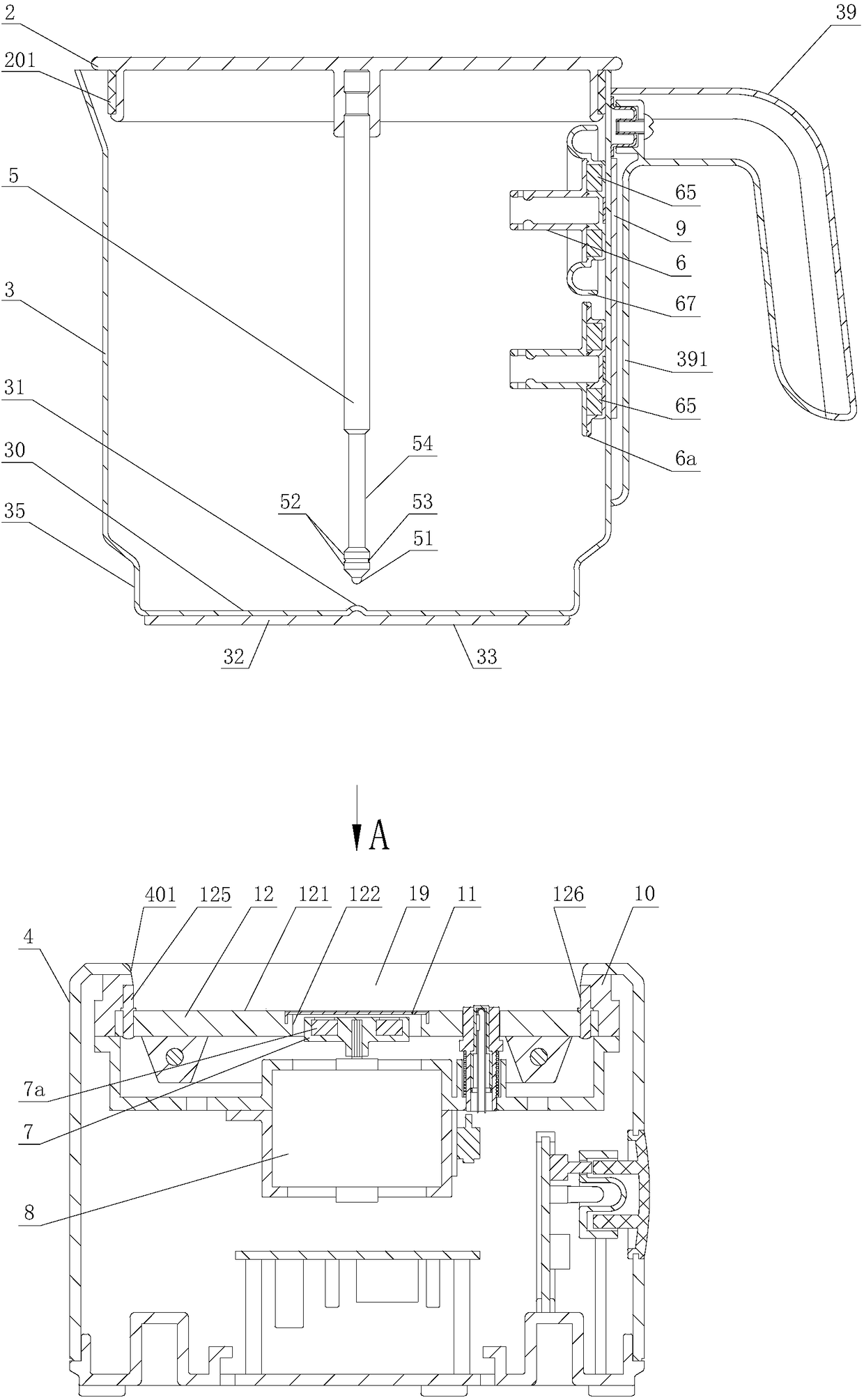

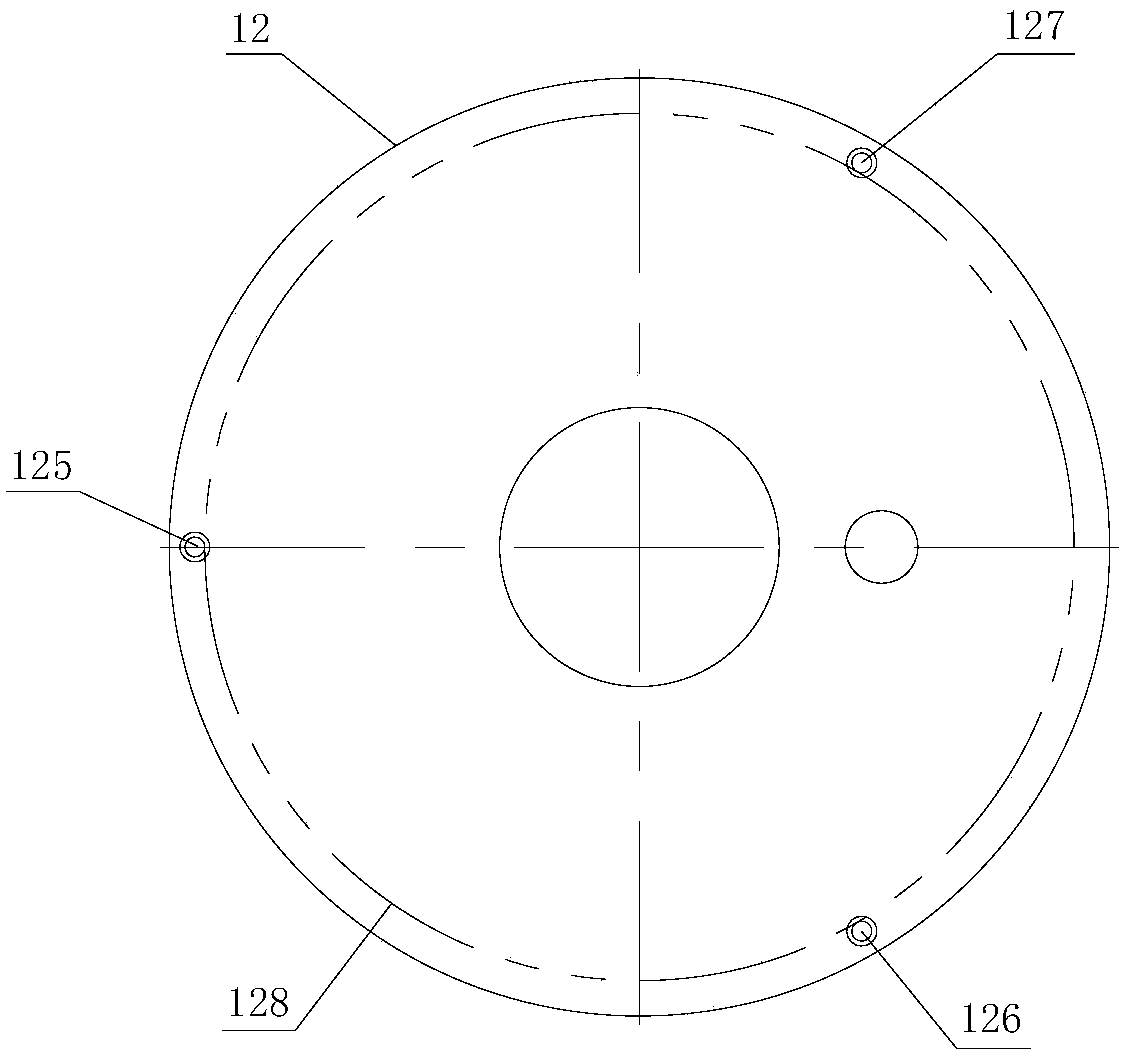

Milk foaming machine

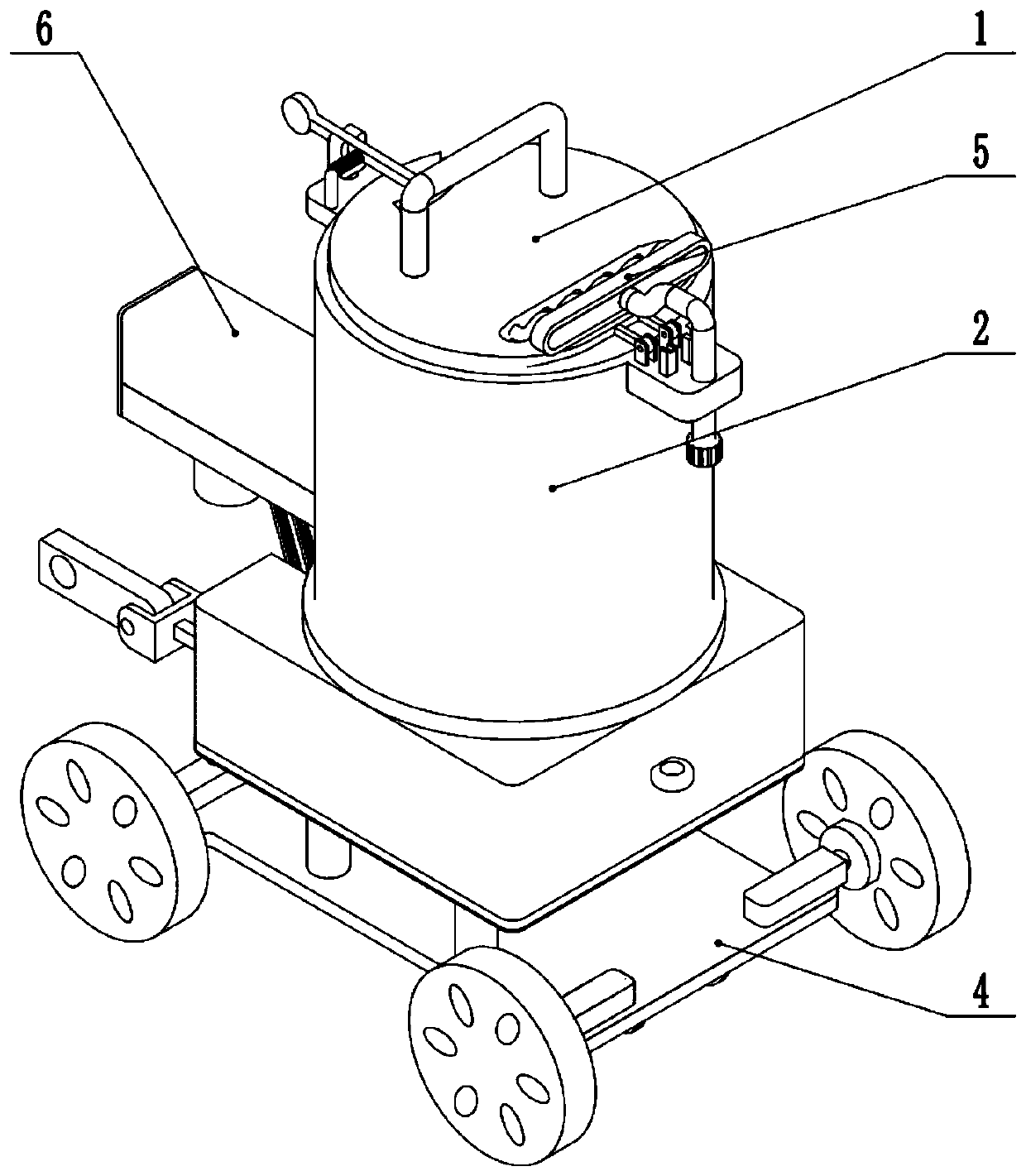

The invention discloses a milk foaming machine (1) which comprises a container cover (2), a container cup (3), a seat (4), a center shaft (5), a stirrer (6), a heat-resistant ring (10), a heating plate (12), a driving device (8) and a driving magnet plate (7). The driving device (8) is used for driving the stirrer (6), upper end of the center shaft (5) is fixed to the container cover (2), the lower end of the center shaft (5) is rotationally connected with the stirrer (6), a positioning device is arranged on a heating surface (121) of the heating plate (12), a groove (19) for accommodating thelower portion of the container cup (3) is formed by the positioning device and the heating surface (121), a protrusion (31) is arranged on an inner bottom surface (30) of the container cup (3), the stirrer (6) is provided with a bottom plane (66), and the height location of the stirrer (6) can be axially adjusted at the lower end of the center shaft (5) in the up-down directions, so that the bottom plane (66) can be butted onto the protrusion (31).

Owner:熊兴剑

Device for preparing powder coating for paint spraying

The invention relates to the technical field of powder coating preparation and discloses a device for preparing powder coating for paint spraying. The device comprises a tank, a first fixing ring is in threaded connection with the top of the outer side wall of the tank, a second fixing ring is fixedly connected to the top of the inner side wall of the first fixing ring, and the inner side wall ofthe second fixing ring is fixedly connected with a feeding hopper. The device for preparing the powder coating for paint spraying has advantages that by meshing of a first gear and a second gear, limiting rods and a connection strap enable stirring rods to rotate conveniently to realize stirring of powder coating in the preparation tank, manpower resource waste is reduced, and labor intensity of workers is relieved. A motor enables the preparation tank to rotate through a rotating rod to accelerate stirring, stirring efficiency is improved, and convenience in use is achieved. By the conical feeding hopper, raw materials can be added into the preparation tank conveniently. By counterweights at the bottom of the tank, the gravity center of the tank is lowered, and stability of the preparation tank in stirring is improved.

Owner:蒙城县虹升塑粉有限公司

Raw material mechanized stirring device for food production

PendingCN106902681AStir wellImprove qualityRotating receptacle mixersTransportation and packagingEngineeringIngested food

The invention discloses a raw material mechanized stirring device for food production. The device includes a stirring barrel, a water tank, an electric motor, a heating pipe and a handle. The stirring barrel is internally provided with a rotating shaft, and a sealing cover is mounted at the surface of the stirring barrel and under the handle. The stirring barrel is fixed in the water tank, and the heating pipe is externally provided with the water tank. Columns are arranged at right and left ends of the water tank, and a bearing is fixed at upper ends of the columns. The columns are mounted at the left end of the electric motor, a fixing board is fixed under the electric motor, and a pedestal is mounted at the bottom ends of the columns. Springs are installed at the lower ends of the columns. The raw material mechanized stirring device constantly vibrates during working, and the springs are arranged to minimize the vibration of the device, so that the device is stable.

Owner:康东星

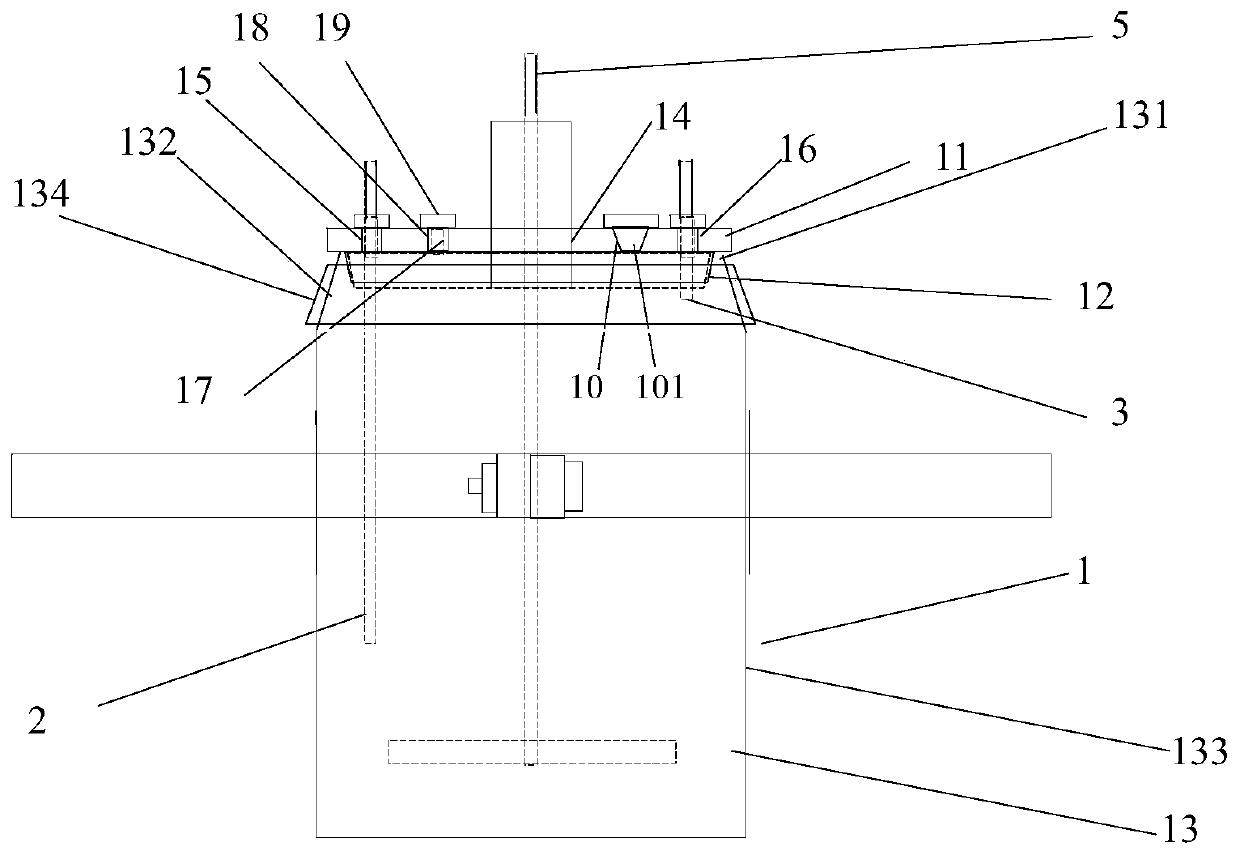

Method for preparing novel spiro compound through amino substituting

ActiveCN110368887AImprove performanceImprove protectionProcess control/regulationCarbamic acid derivatives preparationEngineeringMethyl group

The invention discloses a method for preparing novel spiro compound through amino substituting. Preparation is conducted by using a special reactor, the reactor is provided with a reactor body (1) made of a glass material, the reactor body is provided with a reactor cover (11), a lower flange (12) and a cylinder body (13), and the reactor further includes an air inlet combination (2), an air outlet combination (3), a fixing device (4), and a stirring part (5). The preparation method comprises the following steps that 4-((((benzyloxy)carbonyl)amino)methyl)bicyclo[2.2.2]decyl-1-formic acid is dissolved in THF, Net3 and isobutyl chloroformate are added to obtain ((4-carboxamido bicyclo[2.2.2]decyl-1-yl)methyl)benzyl carbonate, and thus ((4-cyano bicyclo[2.2.2]decyl-1-yl)methyl)benzyl carbonate is prepared; absolute methanol, nickel chloride hexahydrate and BOC anhydride are added, and ((4-((((benzyloxy)carbonyl)amino)methyl)bicyclo[2.2.2]decyl-1-yl)methyl)benzyl carbonate is prepared; andthe ((4-((((benzyloxy)carbonyl)amino)methyl)bicyclo[2.2.2]decyl-1-yl)methyl)benzyl carbonate is added into a 1,4-dioxane solution and a dioxane hydrochloride solution are added, and MTBE is added toprepare ((4-(aminomethyl)bicyclo[2.2.2]decyl-1-yl) methyl)benzyl carbonate.

Owner:北京六合宁远医药科技股份有限公司

Novel magnetic stirring cup

PendingCN110537814AReduce frictionStirring power is strongDrinking vesselsPower parameterEngineering

The invention discloses a novel magnetic stirring cup comprising a cup body, a motor, a magnetic driver and a magnetic rod; a positioning pin is arranged on the inner bottom surface of the cup body, amounting hole matched with the positioning pin is formed in the middle of the magnetic rod, the magnetic rod is rotationally connected with the positioning pin, the outer bottom end of the cup body is detachably connected with a driving connecting sleeve, the motor and the magnetic driver are arranged in the driving connecting sleeve; and the magnetic driver drives the magnetic rod to rotate through attractive force of a magnetic field with the positioning pin as the center so as to realize a stirring function. According to the novel magnetic stirring up in the invention, the magnetic rod issleeved with the positioning pin on the inner bottom surface of the cup body through the mounting hole, that the kinetic parameter of the motor is too large or the power parameter for powering the motor is excessively sufficient does not cause the magnetic rod to deviate from the center and fall off, and the contact surface is small when rotating with the positioning pin as the center, so that thefrictional force is reduced, and the stirring power is stronger; and when the magnetic rod rotates, the inner bottom surface of the cup body is not contacted, so that the inner bottom surface of thecup body is not scratched to influence the beauty.

Owner:HUBEI SPORT MAN CUP POT MFG CO LTD

Stirring device for grouting

InactiveCN111330496AWell mixedPrevent precipitationRotary stirring mixersTransportation and packagingDrive shaftGear wheel

A stirring device for grouting comprises a supporting plate, a hollow discharging pipe is arranged on the front side of the top of the supporting plate, and a conveying worm is arranged in the discharging pipe; the top of the supporting plate is rotationally connected with a driving shaft, the driving shaft is connected with a connecting shaft through a gear set, the lower side of the connecting shaft is fixedly connected with a first gear, the first gear is in engaged connection with a second gear, and the second gear is fixedly connected with a cylindrical cam. According to the invention, the problem of lack of dustproof measures in the stirring process of most existing stirring barrels is effectively solved; enabling stirring, dust fog overflows to pollute the environment; before and after the stirring device is used, an internal cavity, stirring blades and a stirring rod need to be cleaned, so that the cleaning process is time-consuming and labor-consuming, and the problems that the existing stirring device rotates by virtue of the stirring blades, the stirring efficiency is relatively low and the working time is prolonged are solved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Novel stirring kettle

InactiveCN104722224APrevent overflowReasonable designRotary stirring mixersRaw materialChemical engineering

The invention relates to a novel stirring kettle. The novel stirring kettle comprises a kettle body, and is characterized in that a stirring shaft is arranged in the kettle body; a foaming rod is reserved at the middle part of the stirring shaft; a paddle is reserved at the bottom end of the stirring shaft; an outer frame is arranged on the stirring shaft; a crossbeam of the outer frame is welded and fixed with the stirring shaft; two supports are arranged on the stirring shaft and fixed with the outer frame at a 45-degree angle with a horizontal line; bulges are arranged on the sidewall of the kettle body. The novel stirring kettle disclosed by the invention is reasonable in design and stable in stirring; the outer frame also rotates during stirring, and is stable due to the action of the supports; materials are adequately mixed, the stirring effect is good, and the materials in stirring collide with the bulges on the sidewall to be further adequately stirred; due to the design of the foaming rod, the overflow of the raw materials due to too much foam in the stirring kettle is prevented.

Owner:TIANJIN HUAJINPU CHEM

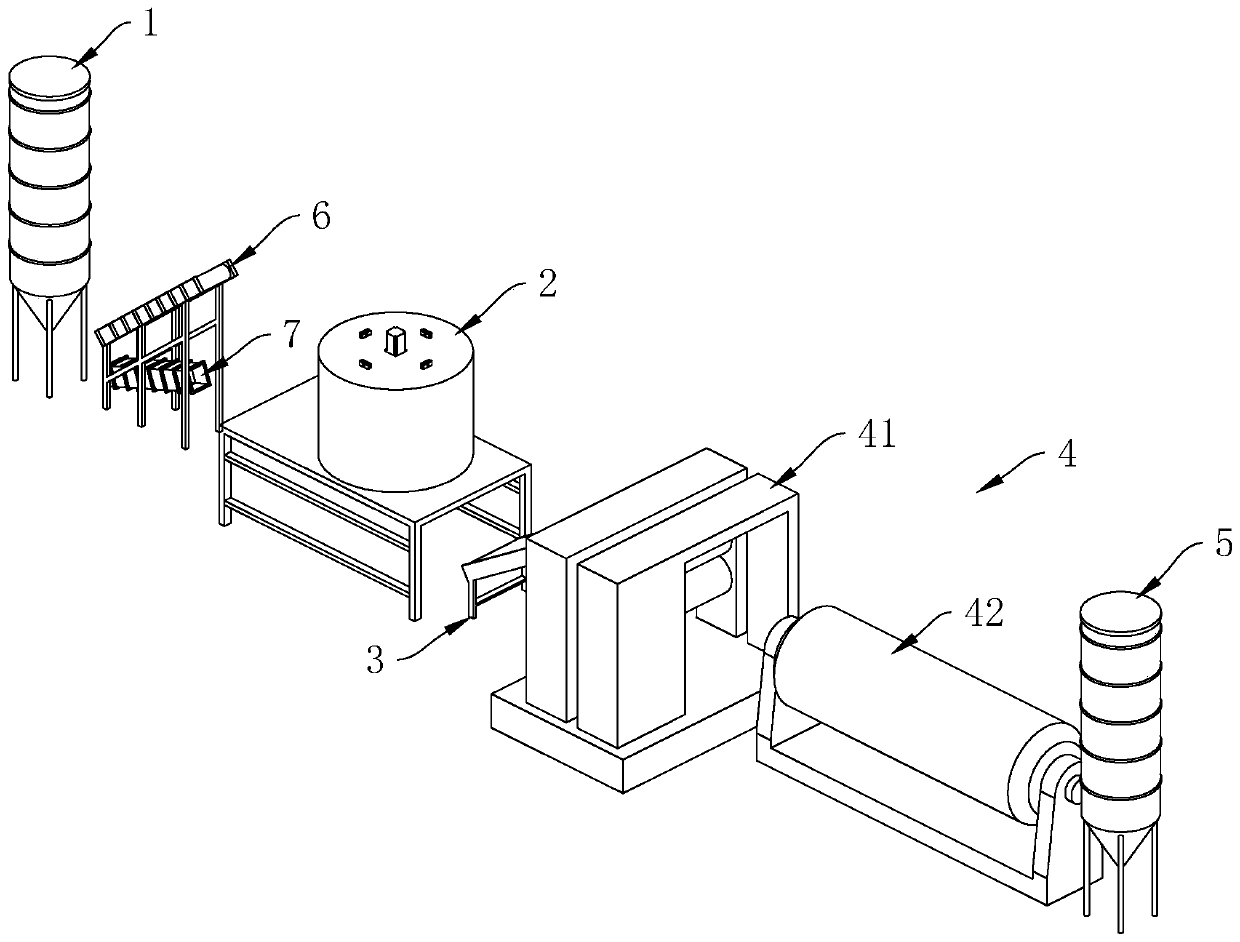

Portland cement production line

The invention discloses a Portland cement production line, and relates to the field of cement production. The Portland cement production line comprises a storage tower, a stirring device, a powder conveyor, a grinding device and a cement bin; the stirring device comprises a stirring box and a box cover, and a rotating shaft is rotatably connected to the middle of the lower end face of the box cover; a plurality of sliding holes are formed in the box cover in a penetrating mode, the sliding holes surround the rotating shaft, wherein sliding rods are vertically connected into the sliding holes in a sliding mode; an impact rod used for abutting against the bottom wall of the stirring box is vertically arranged on the lower end face of the sliding rod, and a driving mechanism used for drivingthe sliding rod to reciprocate up and down is arranged on the rotating shaft. The cement stirring device has the following advantages and effects that raw materials in the stirring box are stirred byarranging the efficient stirring paddle, meanwhile, the sliding rod is controlled to drive the impacting rod to reciprocate up and down, the impacting rod is used for mashing the raw materials, thorough mixing and uniform mixing of the raw materials are achieved, and then the product quality of cement is improved.

Owner:HANGZHOU NANSHAN CEMENT

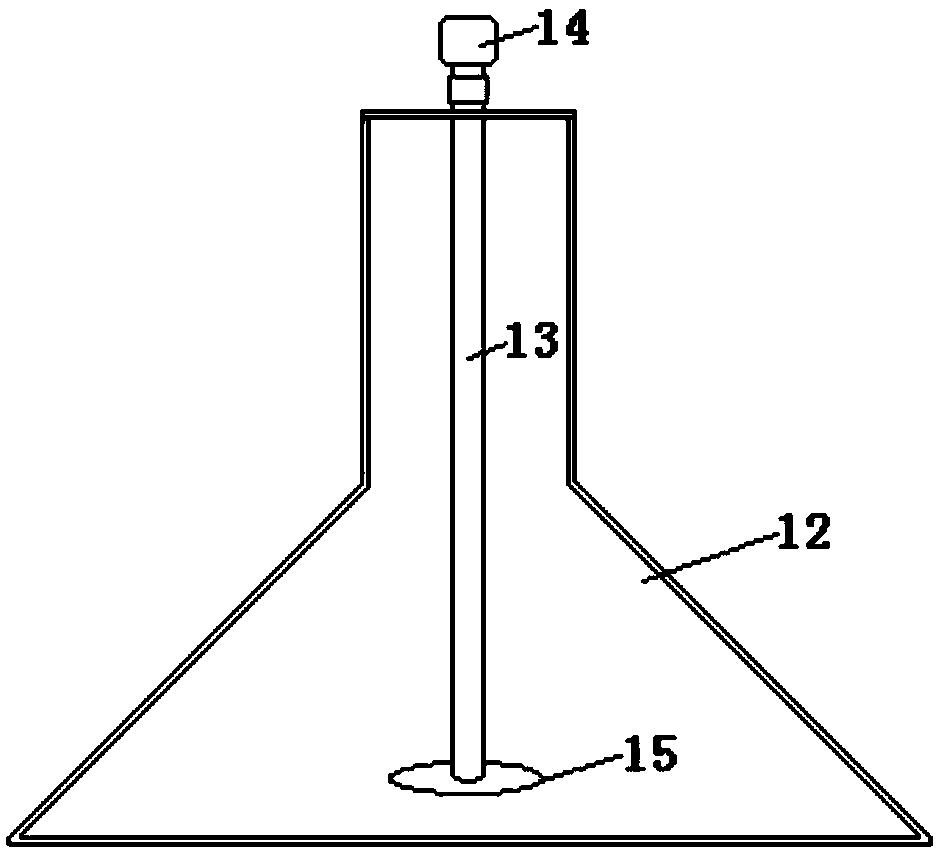

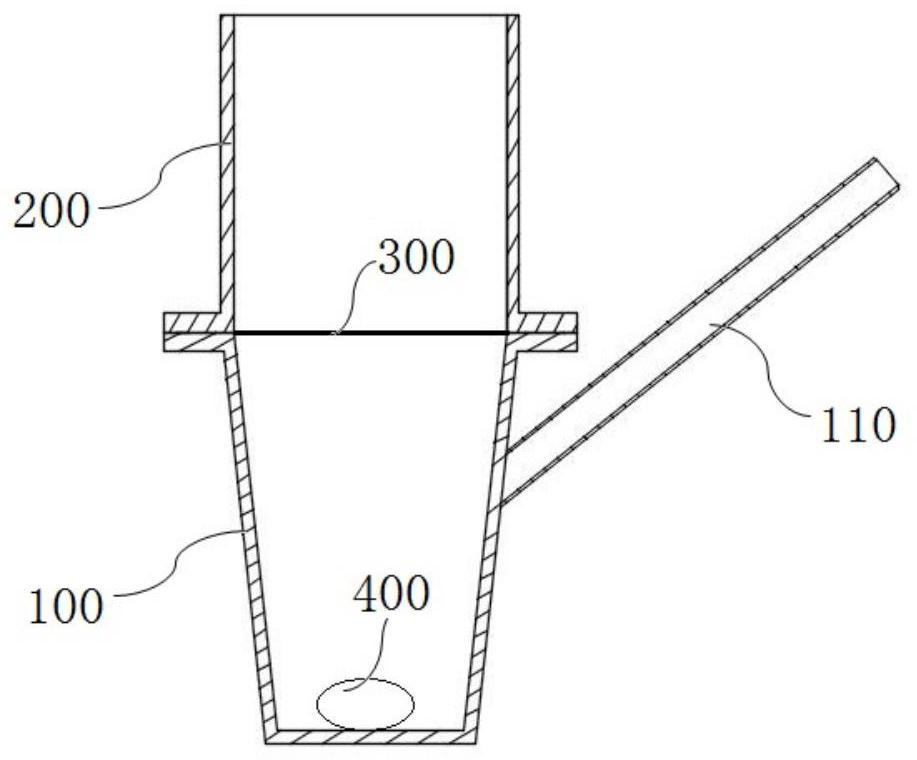

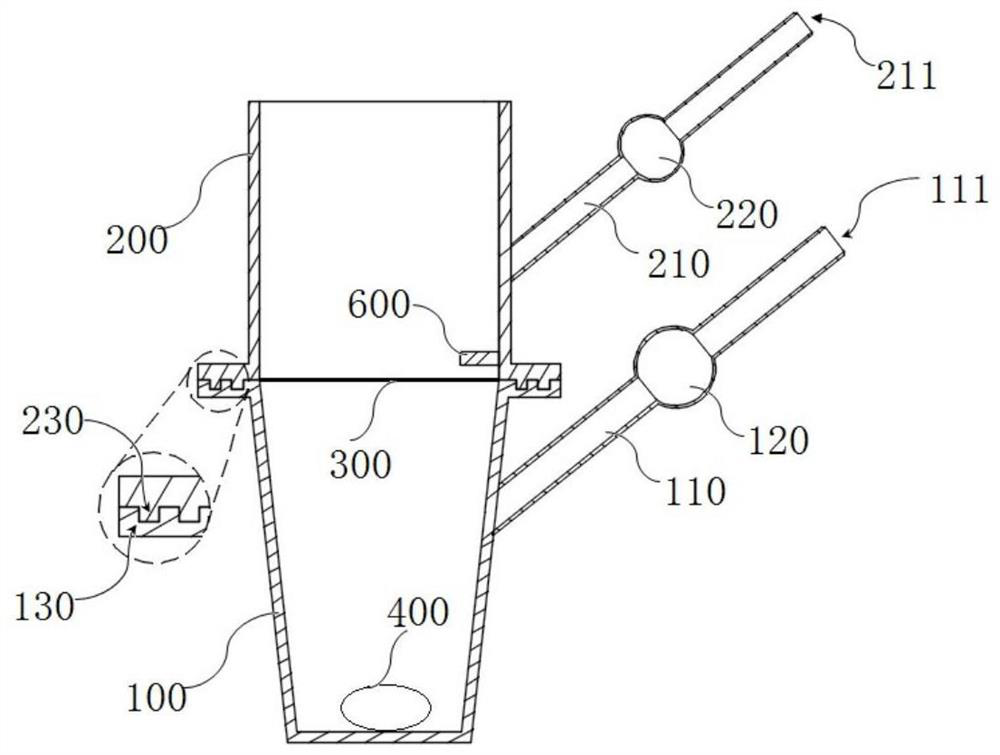

Transdermal diffusion cell, transdermal diffusion instrument and oral mucosa transdermal diffusion experiment method

ActiveCN112945806AStable stirringThe results of the transdermal diffusion test are accurateDiffusion analysisMouth mucosaBiomedical engineering

The invention discloses a transdermal diffusion cell, a transdermal diffusion instrument and an oral mucosa transdermal diffusion experiment method, and belongs to the technical field of transdermal experiments. A stirring device is arranged at the upper end of a dosing cell of the diffusion cell and comprises a base, a first power source, a first transmission unit, a second transmission unit, a lifting table, a stirring unit and a control module. The second transmission unit comprises a driving gear and at least two driven gears which are arranged on the periphery of the driving gear in a surrounding mode and engaged with the driving gear, and lead screws are arranged on the driven gears and can drive the lifting table to move up and down; the stirring unit comprises a second power source and a stirring rod, and a stirring paddle located in the dosing pool is arranged at one end of the stirring rod. According to the invention, the environment in the diffusion cell is close to the environment in the oral cavity during gargling through stirring, so that the oral mucosa transdermal diffusion experiment is effectively carried out, the experiment result is more accurate, and the invention further provides a transdermal diffusion instrument and an oral mucosa transdermal diffusion experiment method.

Owner:南京海关工业产品检测中心

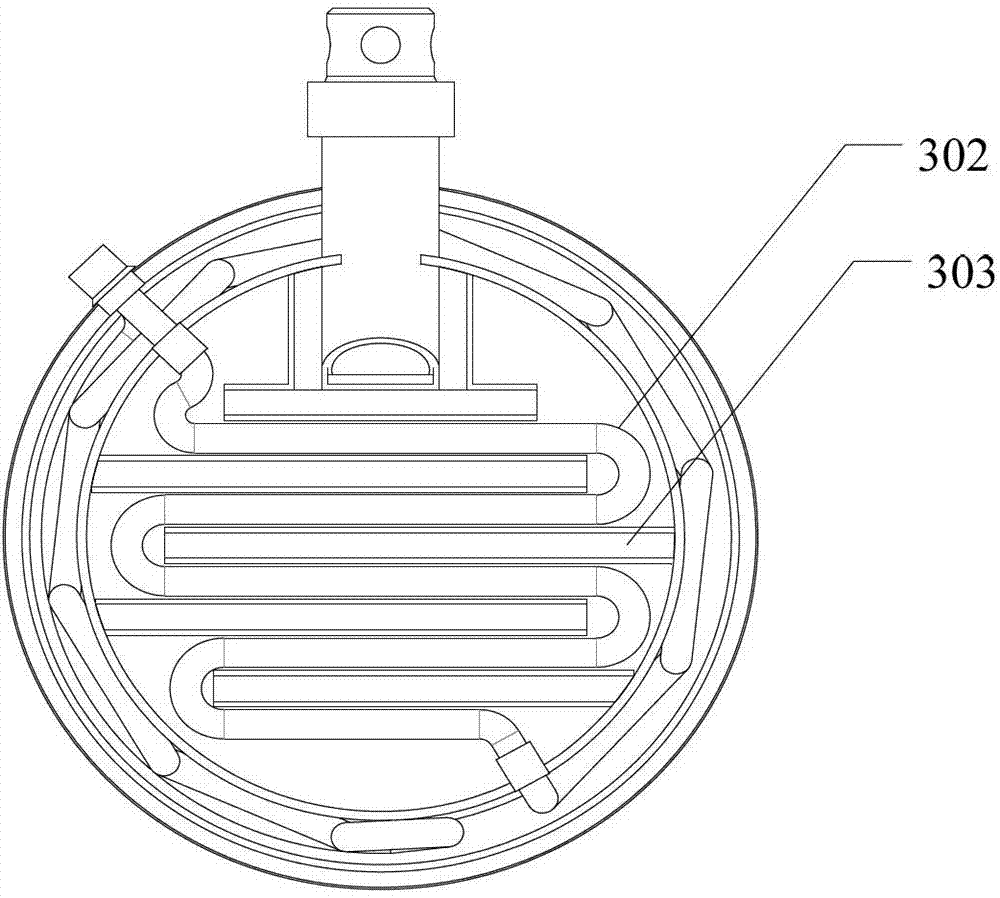

Preparation method for efficiently synthesizing palladium-carbon catalyst for biotins

InactiveCN108620065AFlexible handlingFlexible adjustment performanceSugar derivativesSugar derivatives preparationOrganic acidActivated carbon

The invention discloses a preparation method for efficiently synthesizing a palladium-carbon catalyst for biotins. The preparation method comprises the following steps: adding water into a flask, adding a palladium precursor into water, stirring and dissolving, adding an organic acid to continuously stir and dissolve, raising the temperature, and regulating the pH value of the solution system withaqueous alkali; adding activated carbon into the solution for impregnating; and adding a reducing agent into the solution for rapid reduction after impregnation completion, filtering and washing, thereby obtaining the palladium-carbon catalyst. According to the preparation method disclosed by the invention, the palladium salt and the organic acid are coordinated to form a stable macromolecular complex in the aqueous solution, and the activated carbon is added into the solution for impregnation. The complex strength of the organic acid and palladium and distribution thereof in the activated carbon pore channel can be controlled by controlling the pH value of the aqueous solution and a molar ratio of the organic acid to the palladium, and then rapid reduction is performed, so that the palladium is precipitated in medium and large pores of the activated carbon and the surface in a nano state as small as possible. The palladium-carbon catalyst has excellent catalytic performance while catalyzing biotin intermediate hydrogenation.

Owner:徐学军

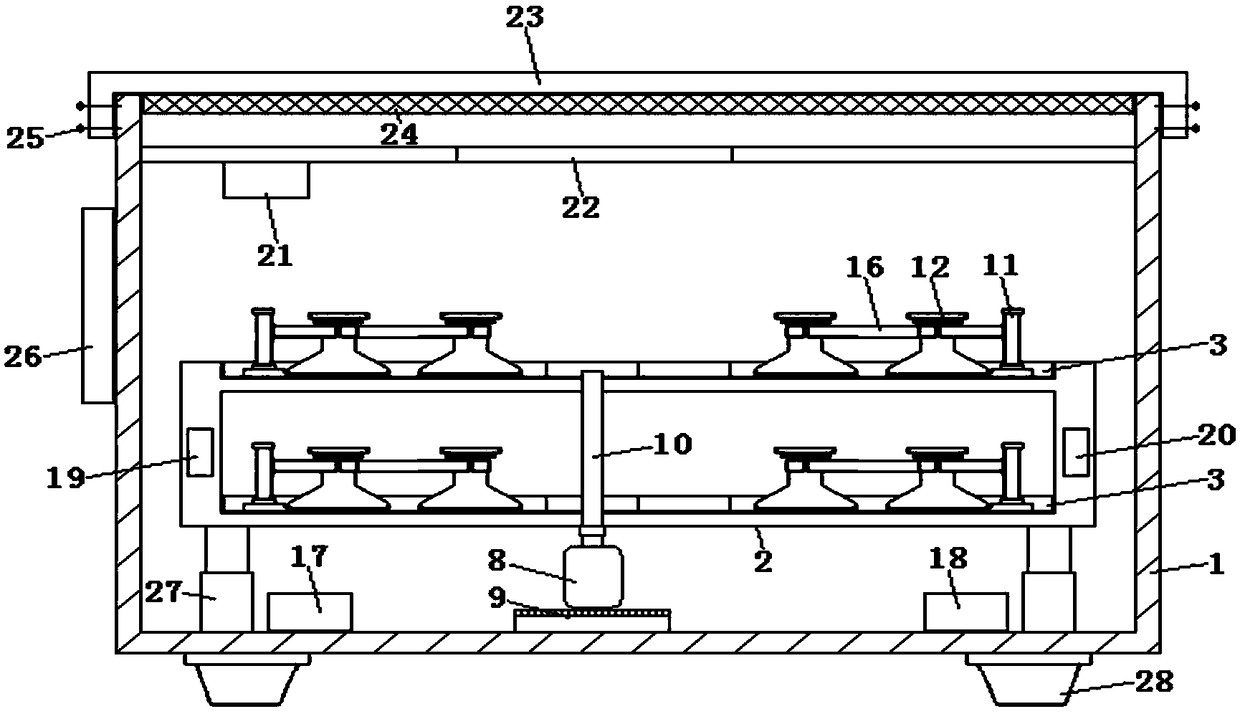

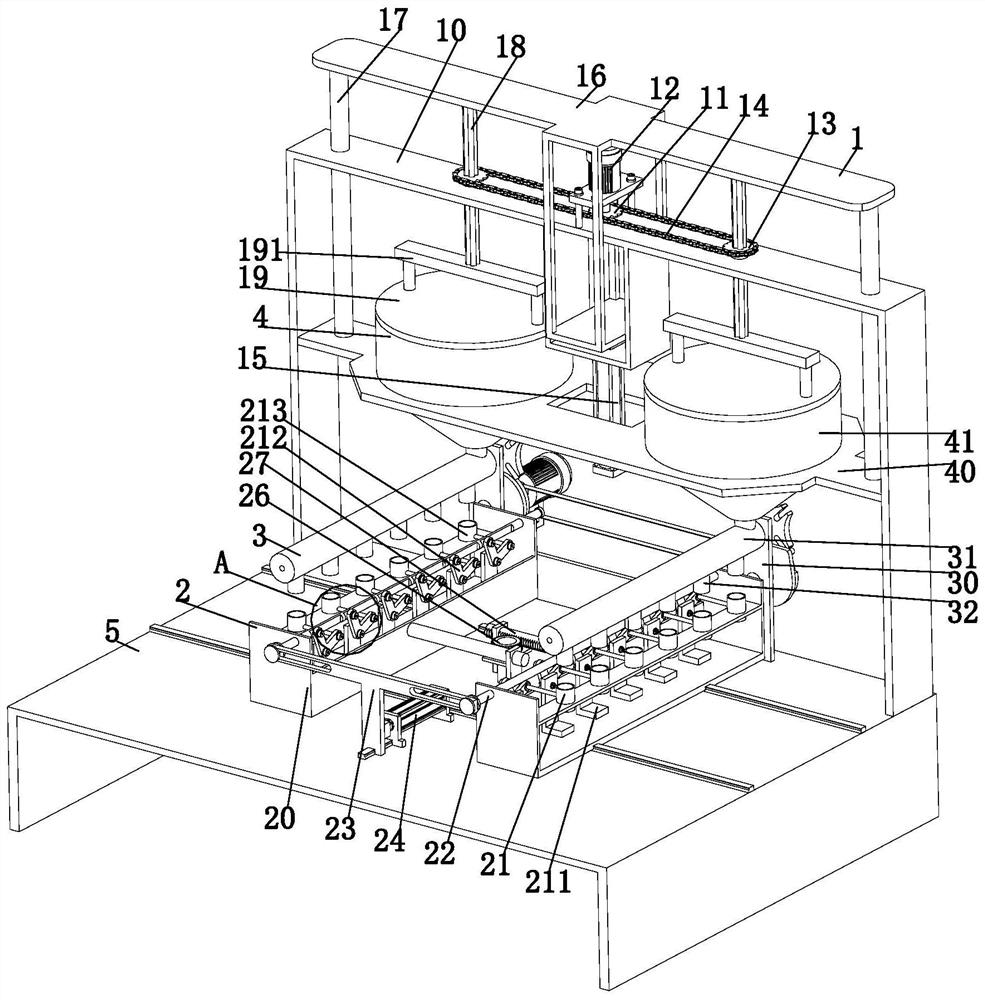

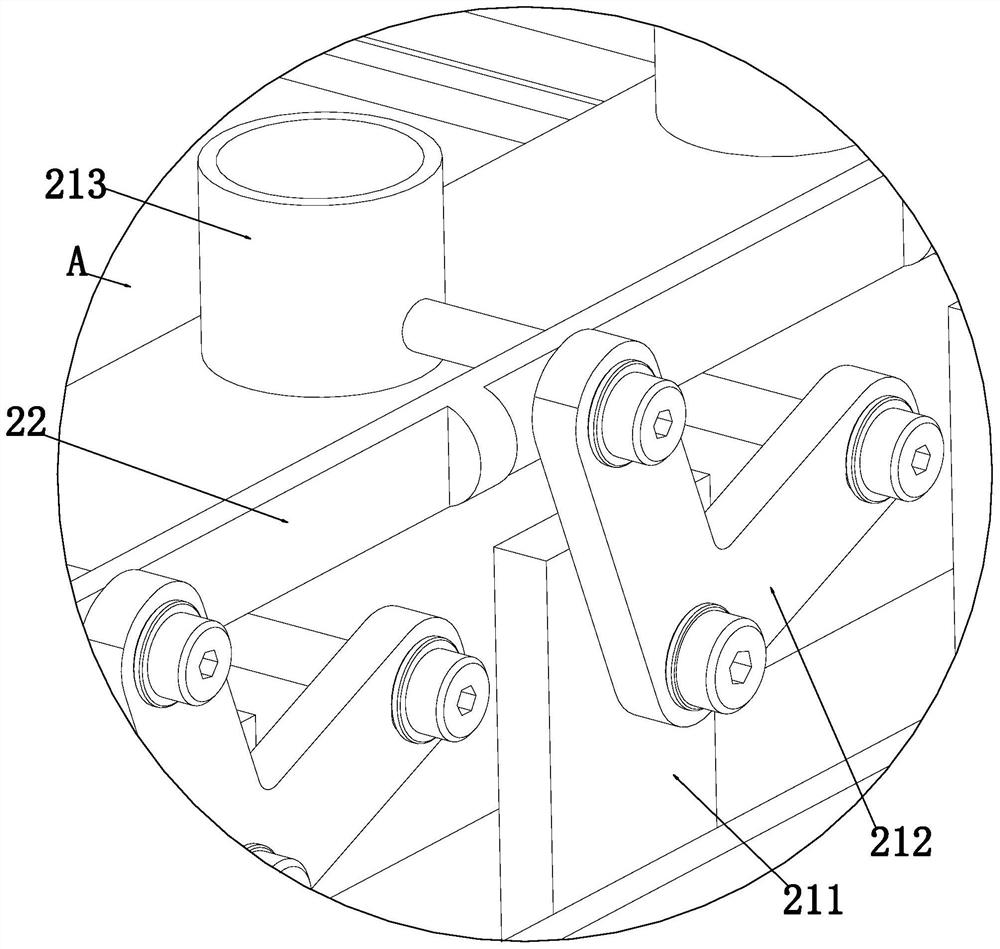

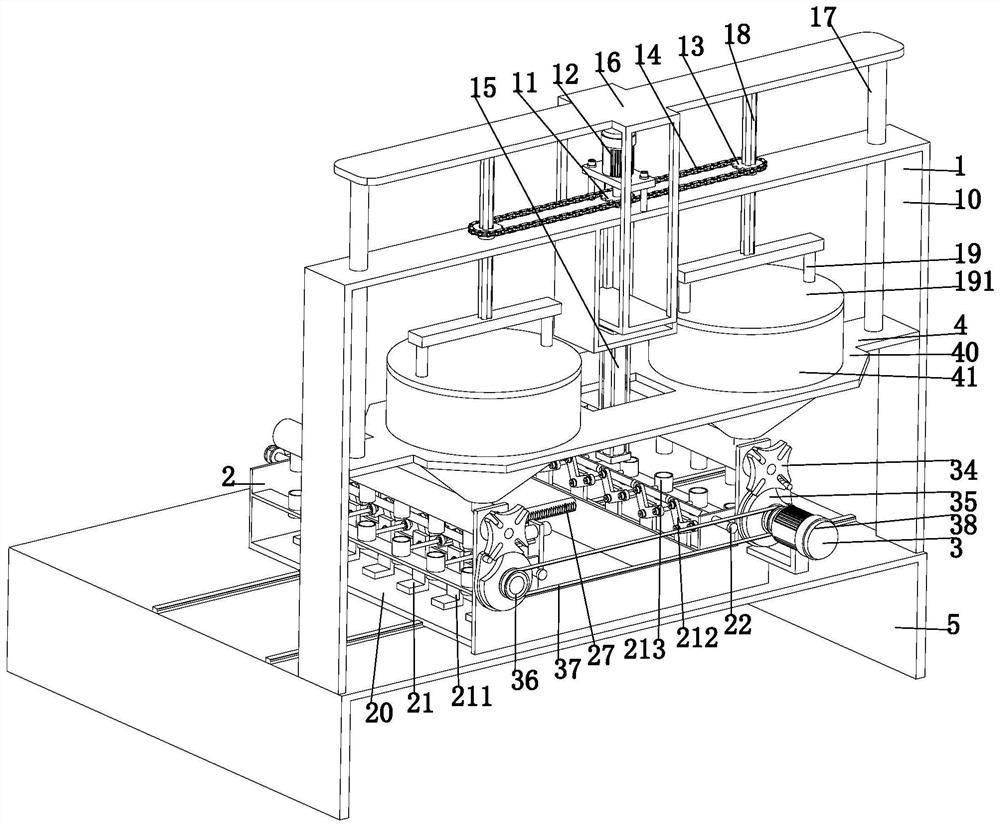

Automatic filling machine for preparing whitening toothpaste and filling method

The invention provides an automatic filling machine for preparing whitening toothpaste and a filling method. The automatic filling machine comprises a falling and mixing mechanism, a top loading mechanism, a row loading mechanism, a material containing mechanism and a main beam support. The top loading mechanism is installed on the main beam support, and the row loading mechanism is arranged above the top loading mechanism and further installed on the main beam support. The material containing mechanism is arranged over the row loading mechanism, the material containing mechanism is installed on the falling and mixing mechanism, the falling and mixing mechanism is installed on the main beam support, and the falling and mixing mechanism is located over the material containing mechanism. The problems that when an existing toothpaste filling machine is used for filling toothpaste, when the toothpaste is stored in a discharging hopper for too long time, the toothpaste is likely to deposit, the uniformity can be affected, and the toothpaste is likely to adhere to the discharging hopper are solved. The problems that paste in the discharging hopper can be solidified easily, the paste cannot be uniformly mixed in the discharging hopper, the discharging is not convenient and fast, and the filling efficiency is influenced are also solved.

Owner:凌小辉

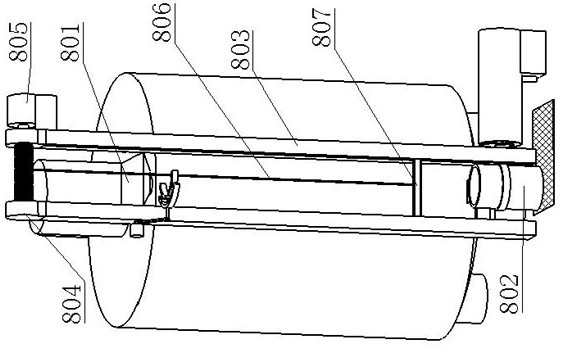

Preparation method of platinum-carbon catalyst for efficient azithromycin synthesis

InactiveCN108704639AStable stirringEasy maintenanceSugar derivativesSugar derivatives preparationActivated carbonOrganic acid

The invention discloses a preparation method of a platinum-carbon catalyst for efficient azithromycin synthesis. The method comprises the steps that organic acid is added to the aqueous solution of aplatinum precursor to be stirred and dissolved, and the PH value is adjusted by using an alkali solution; activated carbon is put into the solution to be soaked; after soaking is completed, the solution is transferred to a high-pressure hydrogenated kettle, air in the hydrogenated kettle is displaced by nitrogen, hydrogen is added rapidly after the temperature is increased, and heat preservation,cooling, and pressure leakage are conducted; after filtering and washing are conducted, the platinum-carbon catalyst is obtained. According to the method, a stable macro complex is formed after the coordination of platinum salt and organic acid is conducted in the solution, the activated carbon is put into the solution to be soaked, the coordination strength of the organic acid and platinum is controlled by adjusting the PH of the solution to further control the size of the platinum complex and the distribution of the platinum complex in activated carbon pores, rapid reduction is conducted, and the platinum is condensed in medium and large pores in the activated carbon; the prepared platinum-carbon catalyst can rapidly catalyze the hydrogenation reduction of 6,9-imino ether, and the catalyst can be used for consecutive 30 times without being processed.

Owner:徐学军

Multifunctional mixture blending device

InactiveCN106984226AMix fully and evenlySolve the problem of complex unloadingRotary stirring mixersTransportation and packagingDrive motorEngineering

The invention discloses a multifunctional mixture blending device. The top end of a main shaft is equipped with a driving motor through a rotating shaft, and the end part of the driving motor is equipped with a stirring vane through an eccentric base, thus the revolution stirring when the stirring vane is stirred in a rotation manner can be realized effectively, thus the stirring is more sufficient and uniform; the right end of the rotating rod is provided with a rotating handle through a stirring bucket, and the driving motor is rotated to the horizontal position through a motor lifting handle; a telescopic stirring vane is extended to the stirring bucket, and the side face of the driving motor is provided with a water tank, and the water tank is connected to an arc water inlet tank through a water outlet pipe, thus the mixture enters the stirring bucket. The problem of complex unloading of mixture after blending can be well solved, the purpose of adding water in the process of blending the inorganic combined material mixture is completed, and the purpose of high-efficient and uniform blending of the mixture is reached. The device is simple in structure, convenient to operate, and high in automation degree; the purpose of operation of stirring the asphalt mixture and inorganic combined material mixture can be realized, and the accuracy of the experimental result is guaranteed.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com