Intelligent lubricating oil blending system

A lubricating oil and blending technology, which is applied in the direction of mixer accessories, chemical instruments and methods, mixers, etc., can solve the problems of manpower consumption and lower production efficiency, and achieve the effects of improving efficiency, improving lubricating oil quality, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

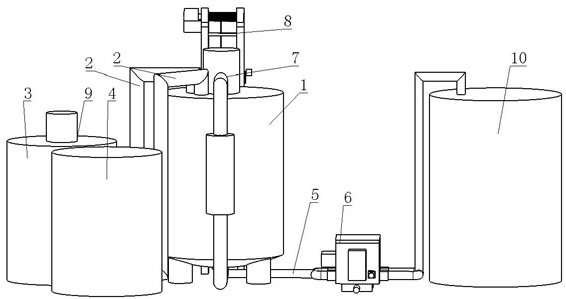

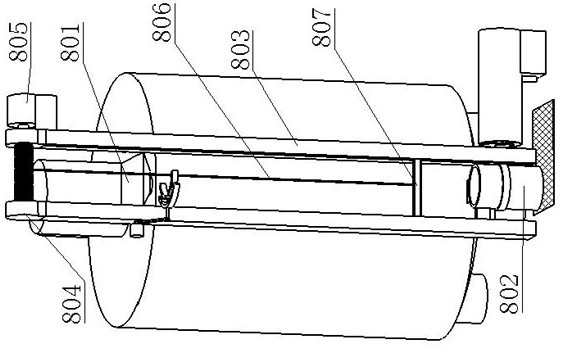

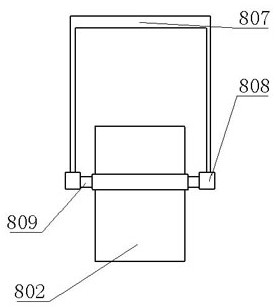

[0062] An intelligent lubricating oil blending system includes a blending system and a control system matched with the blending system; such as Figure 1-21 As shown, the blending system includes a blending device, the blending device is connected with a feed device and a discharge device; the blending device includes a blending kettle 1, and the blending kettle 1 is provided with a mixing device 7 and an adding device 8; the feeding device includes a blending kettle 1 The connected feed pipe 2 also includes a base oil tank 3 and an additive tank 4 connected with the feed pipe 2, and the base oil tank 3 is provided with a cleaning device 9; the discharge device includes a discharge pipe 5, and also includes a The finished product tank 10 connected by the feed pipe 5 is provided with a filter device 6 on the discharge pipe 5; the control system includes a control module, and a pump connected to the control module is provided on the feed pipe 2 and the discharge pipe 5; A heatin...

Embodiment 2

[0073] This embodiment is an intelligent lubricating oil blending system adopting the following method, including the following steps:

[0074] Step 1, add base oil and a large amount of commonly used additives to the blending kettle 1, set parameters such as the temperature, the amount of base oil and additives added; start the blending system, and the control module controls the heating mechanism on the blending kettle 1 to heat to the set temperature , the control module controls the pump on the feed pipe 2 to pump the base oil and additives in the base oil tank 3 and additive tank 4 into the blending tank 1 .

[0075] Step 2: Mix base oil and additives. After the base oil and additives are added to the blending kettle 1, the control module controls the rotation of the third motor 703, and the rotation of the third motor 703 drives the rotation of the main stirring shaft 704 and the first bevel gear 713. The first bevel gear 713 drives the second bevel gear 714 and the auxi...

Embodiment 3

[0081] Compared with Embodiment 1, the first scraping strip 903 of this embodiment is different, such as Figure 22 As shown, the rotation angle of the first scraper 903 is 900°, and the oil adhered to the side wall of the base oil tank 3 can be quickly scraped off by reducing the inclination angle of the first scraper 903; the working process of this embodiment is the same as that of Embodiment 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com